| Author | Message | ||

Greenlanternjeep |

is it a good thing or a bad thing i've read mixed reveiws i really don't see what it would hurt but i would think it would take a lot of pressure off the rear wheel bearings | ||

Johnboy777 |

""is it a good thing or a bad thing i've read mixed reveiws i really don't see what it would hurt but i would think it would take a lot of pressure off the rear wheel bearings"" This reminds me of the right side air scoop - mixed reviews. Lots of pros and cons. And some (Buell employees no less) even said it hurts the engine somehow. Then the factory came out with one. How can a spring loaded belt tensioner hurt? ... | ||

Froggy |

The thing about the FS tensioner is that all it has been proven to do is make your wallet lighter. Your bearings will still fail, your belt will still snap. Will they last longer with that tensioner? Possibly.

There have been reports of the tensioner breaking, but I believe that was a defective batch.

The difference is, Buell had the resources and did the testing on the scoops, and found that in some conditions the right side scoop will cause vapor lock. The OEM scoop is not even close in design to the popular after market ones, and if you look closely it has a scoop to direct airflow over the fuel rails. Buell revisited the scoop situation many years later as computers and software got better and allowed them to look deeper into the issue and develop the comfort kit scoop. I don't know what data Erik and the gang has regarding the tensioner, but when I do get around to buying the tensioner, it will be for the bling factor. | ||

Pdento |

Froggy it's funny that you mentioned the vapor lock thing . Because after I have been riding for along time mine will go into a vapor lock . But only after I shut it off for just a few minutes like when I'm refueling and take off again . I don't think it started doing that until I installed the comfort kit. | ||

Deltablue |

I have said before that in my opinion the Ulysses is the perfect platform for the belt tensioner. The Spring loaded tensioner allows some give to the belt. if you happen to pick up small stones or twigs while off road the spring will allow it to pass around the final drive gear and come out the other side without perforating the belt. That is the theory any way. I put it on my Uly, with the tensioner installed I have had no belt issues with either of the 03's I had, or the Uly. Could also be luck, but I believe in the theory behind the tensioner. It will not prevent belt failure or extend life, but does in my mind add a little give to the situation. | ||

Andymnelson |

Me thinks so. My Buells: '04 Blast, 18,000 miles '99 X1, 21,000 miles '03 XB9S, 25,000 miles '06 XB12X, 26,000 miles All stock belt setups, all still on the original belt with no issues. | ||

Trojan |

The thing about the FS tensioner is that all it has been proven to do is make your wallet lighter. Your bearings will still fail, your belt will still snap. Will they last longer with that tensioner? Possibly. We have sold literally hundreds of FS belt tensioners (Sprung) and from the feedback we have and our own experience we KNOW that wheel and gearbox bearings last longer, belts don't break so easily through 'shock' loadings and the suspension movement is much smoother as it isn't having to fight the belt tension in order to move. In fact these tensioners are now considered here in the UK by most experts to be the first thing you should fit to a Buell XB model, period. The factory didn't get everthing right first time you know  Likewise the right side air scoops. I have fitted aftermarket right side scoops to all of my own XB's (XB9R, XB12R, XB9S, XB12X + race bikes) and have never suffered from any vapour lock or other heat related issues. In fact on one race ike I even removed the fan and still had no vapour lock issues. The factory were always very quick to denigrate a lot of aftermarket parts but a lot of them ended up being incorporated into models later on, such as this right side scoop, modified airbox etc. I think the major reason that the sprung tensioner didn't end up on production bikes was production cost related rather than anything to do with efficiency. | ||

Blake |

Most folks don't realize that their Buell XB already includes a spring tensioner. It's just a stiffer spring. I'm sorry Matt, I've not seen the evidence to support your assertions that "we KNOW that wheel and gearbox bearings last longer, belts don't break so easily through 'shock' loadings and the suspension movement is much smoother as it isn't having to fight the belt tension in order to move." Can you please share? Would be nice to see a video of both OEM and a spring tensioned system on a dyno and with strobe light to identify harmonic behavior. Another valid concern is to consider how many of the tensioners have broken? I've heard of two. So they are obviously not a foolproof solution to reliability for the final drive system. I do like the idea of a not so tight belt. If I recall correctly, it was the belt folks who sold Buell on the idea that a constant tension belt would last longer. That was the folks at GoodYear, the original belt manufacturer for the first XBikes. I wonder if they really took into account the vast differences between a motorcycle final drive versus other more steady state applications. It's a very interesting subject. I'm not at all sure of the accuracy of the above. Someone please correct as needed. | ||

Arcticktm |

Trojan, Not doubting your experience in any way, but just because your bikes did not see any heat issues with RSS (vapor lock), it does not mean the issue does not exist. Anyone in the southern US is going to see much hotter temps than your bikes will see in the UK (especially this year). Has been in the 90'sF here since spring, and I am in the "mountains" of North Carolina! No vapor lock issues with my 2 year old comfort kit/OE RSS to date, but I am just one bike, of course. The logic of the spring tensioner seems sound, but I am one who will wait until I see a problem before I fix it. We'll see if I regret that. My rear bearings went, but it was from water intrusion, not any kind of loading. I keep my original belt as a spare, just in case. I do wonder about the extreme tension the belt seems to be under, especially when new and going through the suspension travel. Spring loaded tensioners never caught on with chain drives (old ATK's), but most long travel bikes run the chains pretty loose, and they can certainly handle more abuse than our belts. | ||

Wesman |

Most folks don't realize that their Buell XB already includes a spring tensioner. It's just a stiffer spring. Can someone elaborate? | ||

Arcticktm |

I believe they were referring to the belt itself, and/or the rear shock. The belt can be considered a very stiff rubber band, and the shock obviously has its own spring. The issue is that you ideally don't want the belt tension fighting your shock, and you don't want to tension the belt beyond what it can handle without damage. | ||

Ratbuell |

...do people forget, the belt gets LOOSER as you compress the suspension (i.e. put a rider and/or passenger and/or luggage on the bike)? | ||

Blake |

>>> Can someone elaborate? The bracket and bolted connections that support the tensioner pulley are in effect a spring, albeit a pretty stiff one, relatively speaking. When you chop the throttle or are coasting or downshifting and engage the clutch to where the rear tire chirps from engine braking action, the lower run of the drive belt see increased tension as it is back-driving the engine. When that happens that bracket, believe it or not, will deflect, not a lot, but it will move. Likewise when hard on the throttle in lower gears, the lower run of the drive belt loses some tension, and the bracket holding the tensioner pulley will deflect upwards accordingly. I've thought about taking a look at the loads and displacements and maybe fashioning a custom bracket that offers a bit more compliance, something like a cantilever leaf spring, but much, much more stiff. I'd want to limit flex to something like around a quarter inch total (up-down) at the pulley axle for the full range of lower belt run loading. More just for fun than anything. I'll most likely leave it stock. The engineers at Buell were pretty sharp and the pulley scheme received a LOT of attention. It would be very interesting to learn the technical details behind the design. | ||

Prowler |

"When you chop the throttle or are coasting or downshifting and engage the clutch to where the rear tire chirps from engine braking action, the lower run of the drive belt see increased tension as it is back-driving the engine. When that happens that bracket, believe it or not, will deflect, not a lot, but it will move. Likewise when hard on the throttle in lower gears, the lower run of the drive belt loses some tension, and the bracket holding the tensioner pulley will deflect upwards accordingly." I'll have some of whatever Blake is smoking.........seriously, take a look at the patent that buell has on this design. It's pretty straight forward, and if you're at all technically minded, you'll understand it.......and it doesn't involve any "deflecting" (you're kidding, right?) of the tensioner bracket. | ||

Schwara |

I don't the design as well as Blake, but I am inclined to agree completely. Patents are a claim to protect intellectual property. They are not infallible by any means. The reality is that anything under load will deflect to some degree ... anything. Designs have to be able to account for this. Did the elves take this into account ... I'm sure they did. Did they do a 110% perfect job ... who knows. I'm sure they did their best within the cost, weight, timeframe, and design space that they were given. Is there a possibility that there is a better solution ... of course there is. There is always a better solution, but sometimes it doesn't make sense because of the $$ or effort involved ... my 2 cents, nothing more. | ||

Trojan |

Another valid concern is to consider how many of the tensioners have broken? I've heard of two. So they are obviously not a foolproof solution to reliability for the final drive system. There was a small batch of 'bad' tensioners that were manufactured incorrectly a couple of years ago. These are the only ones to have suffered any damage as far as I know (and people tend to get in touch pretty quick if stuff fails!). The majority of these were fixed under warranty before any problems arose, but there were a couple that got missed because we were unable to contact the owners. These have since been sorted. Would be nice to see a video of both OEM and a spring tensioned system on a dyno and with strobe light to identify harmonic behavior. This is a strett motorcycle we are talling about here, not space travel! I'm sure the factory never did this either, but I know from years of selling these and comments by owners that they work. simple as that. It is up to individual owners to decide if they want to fit these or not of course, but all the anecdotal evidence over 8 years of supplying these is positive. | ||

Blake |

That's good to know Matt. Prowler, I should have been more clear. The deflection of the bracket as belt load varies is very small, mere thousandths of an inch. I doubt that it's part of the design intent, just the natural behavior of material. The design intent appears to be a rigid bracket. There just is no perfectly rigid material. Anytime a load is applied to anything, it will deform and deflect. Whether you can see it with your eye is another matter. | ||

Andymnelson |

Hey! Stop it! Are you guys actually trying to have a civilized discussion on a topic that you disagree on??? on BadWeb?? Isn't that against the rules?!  lol juuust kidding. Entertaining read for sure. I have never felt the need for the tensioner, as I have not had a belt failure, and only replaced bearings once on all my Buells....and that was done as PM. Fun to see good minds at work here. | ||

Eulysses |

The belt is looser on suspension compression? What, pray tell,causes the groaning vibration during that compression? A loose belt? Sounds and feels awful. | ||

Ratbuell |

weight (curb weight) being transferred from the swingarm, through the swingarm isolators that are mounted to the engine, through the engine, to the frame. to your butt. | ||

Eulysses |

Well, me butt says something is stressin'and it cannot be good for bearings and mounts. Where is the strain coming from whwn bike is two-up and hits dips? | ||

Ratbuell |

weight (curb weight) being transferred from the swingarm, through the swingarm isolators that are mounted to the engine, through the engine, to the frame. read your manual. what's the GVWR (gross vehicle weight rating - bike, fluids, luggage, passenger, rider)? Where does your loaded/2-up weight fall compared to that? Machines are only designed to carry so much weight... don't believe me? 'test-twang' your belt when the bike is empty on its sidestand. then load it. put a passenger on it, and have a buddy pose as the 'rider'. test-twang that belt again. now think. how much weight does that put on the bearings? axle? swingarm? swingarm block and isolators? and the block mounts to...the engine. so you're stressing the engine cases. which hangs from the frame. and the frame holds the seat and the handlebars. I never said weight was good for the bike. i overload mine all the time lol. all i was saying was, compressing the suspension makes the belt looser, not tighter. hell, look at the belt path. suspension extended, there's a 'dent' in the bottom belt path, made by the pulley. compress the rear suspension, it raises the wheel pulley...and the 'dent' goes away. now, swingarm path changes pulley spacing too...but for the most part, the belt has a shorter 'loop' to travel when the suspension is compressed. | ||

Eulysses |

So Rat, you sayin' that groan and vibration hitting a dip is from a looser belt??? | ||

Froggy |

No, it is from turning the bike into a hardtail. Overload your bike, your rear suspension becomes useless. If your belt snapped, you would still feel the vibrations. | ||

Od_cleaver |

I have felt the "dip" vibrations. In my case, the bike did not turn into a hardtail by bottoming out. There is no mistaking a totally compressed suspension. It took a road with a strong dip. In the times I know that I would feel the vibrations, I had the bike loaded for a trip, but less than if I had a passenger. My rear preload was adjusted for the load. I now have the FS tensioner on the bike, but have not been on a long enough loaded trip to say if the tensioner cured my symptoms. However, I have hit plenty of dips with the tensioner installed and have not felt the vibrations. BTW, the vibrations are definitely engine vibrations. Wheel vibrations and drive line vibrations would be a lower frequency. | ||

Ratbuell |

your rear suspension is bolted to your engine. NOT TO THE FRAME. TO THE ENGINE. put more weight on the bike, you're putting more weight on the engine cases. more strain. stress the engine more...you're gonna feel the vibrations more. which is what i've been saying. the groan and vibration is from putting stress on the engine cases. it has NOTHING to do with the belt. you're changing the loads the engine puts on the isolators by changing the load the swingarm puts on the engine. | ||

Eulysses |

So bottoming (actually not "bottomed" to hardtail status but close) drags the engine against mounts "hard" and sends noise/vibrations into frame/ butt/ears? Can this be good for mounts? | ||

Od_cleaver |

Ratbuell, I will give you the fact that I do not know 100% of what I talk about, but what bike are you looking at when you say that my suspension is not bolted to the frame? I removed my rear shock absorber / spring assembly last week. The bottom bolt went to the swing arm and the top bolt went to the frame. I did not touch the engine. I havenít stuck my nose into the swing arm pivot and engine isolator area. Maybe this winter when I rotate the engine to fix my oil leak this will become clear. It looks like the swing arm pivot fastens to the engine and the rear isolator connects the engine to the frame. So if I look at the bike suspension from the right side, counter clock wise you are correct and clock wise YOU ARE WRONG. I was thinking that an increase in belt tension caused by swing arm movement was pulling on the engine isolators thru the front sprocket. The engine should also be moving on the isolators during a dip in the road. Regardless of the cause, I think that these vibrations are felt because one or both of the engine isolators are grounded. By grounded I mean that forces due to dips in the road have compressed the isolators to one side or end coupling engine vibrations into the frame. | ||

Froggy |

Ok neither are the Uly frame, but it is still the same thing. | ||

Ratbuell |

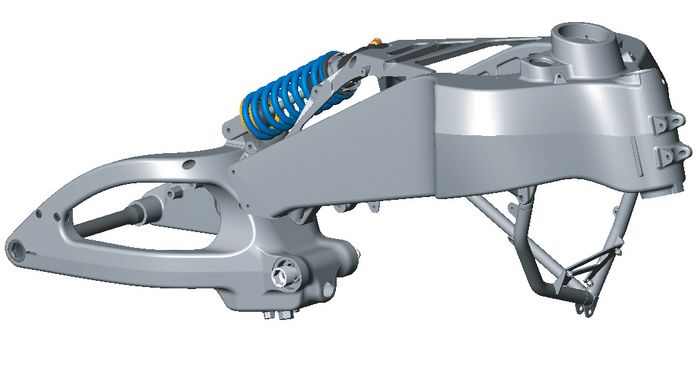

so..if the swingarm is bolted to the frame, why does my fsm show this guy:  lifting a bare frame off an engine...that's still attached to a swingarm and rear wheel? the spring is a link. that's all. and yes, i'm sure it could increase the 'vibration' when you load the bike and 'bottom out'...but the increase would be from the engine. transmitting through the swingarm. into the spring/shock assembly. and from there into the frame, causing the 'buzz'. (not only do i own and work on three generations of my own personal buells...i used to work for a dealership. for six years. i'm familiar with how they're built.) (Message edited by ratbuell on August 14, 2011) |