| Author | Message | ||

Ezblast |

No need to compress clutch - remove as a unit, etc. EZ | ||

Imblasted |

any opinions?  | ||

Imblasted |

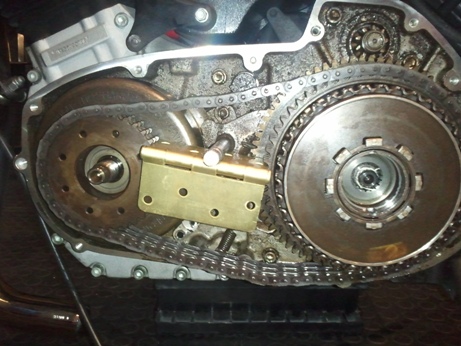

I replaced harley's engine sprocket lock with a 4" door hinge from ace...  | ||

Imblasted |

how should i handle this?  | ||

Ezblast |

They gave you the wrong gasket - sigh EZ | ||

Ezblast |

Rejet to 45 170 for stock, and 45/175 if have exhaust that is not stock. EZ | ||

Gearheaderiko |

Is that the only hole that doesnt line up? If so and the rest of the gasket sealing surface lines up, high tack* the gasket to the cover and cut out a wedge for the bolt. Or take the gasket back. Whichever is most convenient. * silicone, yamabond, 3m yellow, etc just so the gasket doesnt move around on you, but it shouldnt. | ||

Gearheaderiko |

...and thats normal valve colour for stock jetting! | ||

Imblasted |

it is the only place that doesn't align i had to resize the picture so u cant see that. I really want/need to ride tomorrow for 70 miles... is that a bad idea with a new primary chain, chain tensioner, and primary and engine oil fluid changes? I am installing the V&H pipe tonight as well. I am hoping not to get stuck with another saturday off and no riding. I pretty much am screwed with the gasket for the night then, huh? b/c i don't have any "gasket maker" | ||

Gearheaderiko |

If you can get the gasket aligned without and adhesive then use it. It probably wont be that hard, but it is 10:20 pm.... Doing all that work and taking a long ride really isnt a good idea. You should always do a decent, daylight test run or stay reasonably close to home. If everything is good then there isnt any reason you cant ride all day. Did you get new jetting? You could be fine with the stock jetting, but if its really warm out it may knock and ping a bit as gas isnt as good as it used to be  | ||

Imblasted |

im in miami and it has been real hot lately... damn it. ok well i won't be going to my scuba diving in the morning. i am going to photoshop my plans for the gasket and post. | ||

Imblasted |

cut gasket material from the old gasket to fill the void? or is that a bad idea?  | ||

Imblasted |

I do only use 93, does that help? and from shell | ||

Gearheaderiko |

93 is better than 91. Just listen carefully to your engine. If the gasket is making contact, youre okay. Its on the top so its not prone to leak as if it were on the bottom. Some sort of adhesive would really help things. I wouldnt use a part of the gasket to fill the void unless you had some adhesive, but then you wouldnt need to fill the void with the gasket. How do you do engine work and not have any kind of sealer around? | ||

Imblasted |

lol, i actually moved from MI to Miami and i have just started rebuilding my tools. this is actually my first motorcycle work. I had to buy all standard tools too! silly americans why dont we just use metric! its killing me not having this thing done its been since the 6th, the parts came in on the 15th and ive been buying tools since. ive spent the same on tools as parts. im putting it together if it leaks i buy a new one! I actually cut the section i need off of my old gasket, im going to just stick that in there. its not beat up so i think itll be fine. | ||

Imblasted |

so wait did you say you would just cut the part that is in the way out and leave the rest? | ||

Ezblast |

yes. EZ | ||

Gearheaderiko |

Concur!!  Its not really in a high leakage spot. It would only see spray from the sprockets and chain. If it does leak, I'm confident that you could still seal it off with some silicone you can buy later. | ||

Imblasted |

ok deal i like that idea better. im putting oil in. what a pain, guess i shoulda known i need a funnel... when i put the fluid in the primary i read something about filling from the trans breather?? seems very difficult and slow. cant i just pour it into the inspection whole? | ||

Gearheaderiko |

Yes. The inspection hole is the preferred filling location. But that means pulling the Y-frame and cover (which you've done). Pouring it through the trans vent line takes almost as much time as pulling the y-frame and cover, but its a whole lot easier!!! | ||

Imblasted |

alright so the new chain is very tight and well i just tightened the primary cover on hoping it has pushed the chain tensioner into place along with the tensioner spring and pin. i want to take the primary cover back off to check that it has done such. please advise. thank you | ||

Ezblast |

Take off - you have to put the tension-er together half way, and then finagle it the rest of the way on, till it is on and under the chain totally, the spring fully inserted both ways. Then button up carefully, do the clutch adjustment, soft - very soft bottom then 1/4 out. Then fill to bottom of gear teeth. button up. Adjust primary by book, but 14 flats out instead of 4, then after 1/2 riding adjust by sound. If no sound, then go back to the 14 flats out method and be happy. It is successfully adjusted if you can easily shift, and reach 95 mph. Do a few heat cycles (1/2 hr or more of riding) and then re-torque your primary bolts in the correct pattern. | ||

Ezblast |

PS - don't forget to check your oil at least once a week! EZ | ||

Imblasted |

done. goodnight. Thanks you ez and erik | ||

Imblasted |

ok, im fairly stumped. my current plan is to pull the primary, then open the transmission and clean everything out that i can find, then readjust the clutch (obvly), i skipped the shift pawl adjustment which i will do this time, rejet, readjust air/fuel mix, and if nothing then i have no idea what could possibly be going on. Here is the problem: Sometimes it refuses to shift from 1st or neutral, and it will not start now. it smells like gas, it blows back into the airbox like a back fire but with no flame. IF it starts it idles like poo and if i try to pull the throttle she dies. IF i can get it to go down the street sometimes it feels like it misses a few times and then goes back to running... what the "H"??? | ||

Imblasted |

ok i may be an idiot... i still think i should pull the trans open and check if there is anything in there. but i got it to start by starting to remove the carb and realizing that the superboot was barely conected at all. so i reseated both sides and tightened it down and it starts and idles and revs normal again. now just to fix the trans problem... i am buying new jets tomorrow... | ||

Swampy |

Ok; The shifting problems you are experiencing are possibly related to the following: Too tight primary chain adjustment. Incorrect clutch adjustment. Shift pawl adjustment. I would make those adjustments in that order and check the shifting results, if it gets better you are done, if not, go to the next stage. If you get to the shift pawl adjustment, glue the shift drum pins in place with a JB weld, make the shift pawl adjustment, chamfer the plate the holds the stator wires inplace and spooge some RTV silicone under the plate to keep the wires from vibrating through the insulation and shorting out. Red loctite the shift drum retaining bolt in place. readjust the primary chain, readjust the clutch, and run the pi$$ out of her! | ||

Imblasted |

i know i should have done the pawl adjustment when i was in there... but i didnt have the drill bit... so i didnt do it. the primary chain makes a little slap noise so im going to tighten it by the sound method. the clutch i have felt getting looser since the repairs. but you didn't see the piece of the tensioner that i pulled out of the gear box. it was the whole side but it was about 3mm thick and about 3" long.i pulled it out through the little whole under the clutch basket. but i have a feeling the pawl adjustment is my solution. on another note, since i can't do the pawl adjustment tonight, any thoughts on drilling the hole next to the jet needle in the piece that holds the diaphragm and putting a thin spacer in under the jet needle? | ||

Imblasted |

ok, i guess since i am rejetting tomorrow i don't need to space the needle. and i probably do not need to drill the slide either. i was just getting excited b.c i have it all apart for the first time. | ||

Ezblast |

Do not drill the slide! EZ |