| Author | Message | ||

Kenm123t |

Its most likely you too much oil in the crankcase . This is problem for some Carrier O6D recip hvac compressors. They used several casting vendors over time and the internal volume could be 1.5 quarts off and there was no way to tell which you had due to large number of rebuilds in the replacement parts system. The reduced hp is most likely from drag on the rod ends as the splash through oil The way we could find the over filled O6Ds was by checking the amps when it was running it run 30% higher @ 40degree coil temp 105 condenser on R 22 with all other factors being equal the extra power comsumption went into moving oil with the crank and rods The 1125 has had difficult time with fill levels and oil management the reason for the alternator wiring harness and reflash. the cooling oil flow is too low under 5000 rpm and high elctrical loads. stop and go traffic fans on lights etc. The harness and reflash are to addres stator heat small alternator has to be cooled or the load reduced. | ||

Bigschwerm |

i just ordered 3 quarts of Motul...figured id try it out got a decent deal so why not. | ||

Stormy |

I have reported on this power change before during all the discussions of the reflashes causing great changes in dyno output. The great change in hp output is caused by incorrect dyno setup, not oil or the position of the IAT. The 1125 will, when sitting still, injest air heated by the exhaust header. It will not, when moving on a road. If the dyno operator does not get sufficient cool airflow to the intake duct to displace the hot air that exists naturally here when sitting still two things will happen that will lower hp readings. First, hot air is less dense and makes less hp than cool air, and the dyno correction factor will not take this into account because the dyno air temp sensor is off to the side somewhere in ambient air temps. Second, the ECM will react to this hot (but correct) temp. The injection pulse width will change to compensate for the less dense air, however the ECM will also perhaps richen the mixture to cool the engine and protect it so if the IAT is hot enough the mixture may get richer. More importantly, to protect the engine from very harmful detonation caused by hot intake air the ECM will change the timing value. So the engine will be running less dense air, at a less than power optimized A/F while removing timing. This is what causes the observed 12-20hp drops. Do not move the IAT sensor to trick the motor into not reacting to the hot air, it happens for a reason. Also my testing has found that casual attempts to direct air at the intake are often insufficient, very deliberate ducting is often required. | ||

Joshinga |

Stormy... Being that I am a buell tech I did have my concerns about the move and what you say does make perfect sense I kinda wanned to do it just to see what would happen I did and now I think I will leave it alone and look at a different avenue to try like wrapping the pipes. | ||

Joshinga |

ok got the pipes wrapped and the results really surprised me. Air temp at idle with engine up to temp was around 87-90 degrees before. Now with the wrap on they are down to 76-78 degrees. I believe that a 10 degree drop is really good and its still in its stock location. | ||

Joshinga |

bump | ||

Captain_america |

Rule is: 10 degrees in (intake) air temp drop is equal to 1% power gain, If I remember correctly... (Message edited by Captain_america on March 26, 2010) | ||

Joshinga |

so thats like 1.48hp gain hell ya now all I need is some flames | ||

Captain_america |

Yeah Buddy! | ||

Highscore |

I opened this thread to show up how difficult it is to measure and test the 1125 accurately on a dyno. 12 HP difference for an all stock bike with just 1000 miles between the different runs is an enormous variance. Engine-break-in? The Helicon engine has hard-plated cylinder liners. The only parts, waiting for some break in and bedding, are the piston rings. This procedure is done after 2 hours of engine operation. The early state of my "acquaintance" with the 1125 on the dyno was characterized continuously by "happy" runs with "lucky" HP-numbers. I have seen this healthy 137 WHP during this first test session, but I was unable to reproduce this number. For this reason I have rebuilt my 1125 during the r&d-process more often than I do it with other bikes. Simply to be sure, where the base line is, the engine performance, a tuning-modification like an exhaust system may be compared with. All dyno runs have been recorded on my own dyno. There are 7kw fans moving 3000 m3 per hour fresh air by a speed of 30-35 mph around the bike. 60 mph air speed would need 28 kw electric power and we start talking about a wind tunnel. I do not want to work in a wind tunnel. Working at a chassis dyno is always a delicate thing. At a pure engine dyno all engine fluid are tempered externally, but at a work shop dyno things have the tendency to run hot. Every experienced dyno operator develops therefore a sense for engine temperature, which enables him nevertheless to operate and test the bike in a pretty constant manner. Take it for sure that I make dyno runs with the care necessary. The surprising fact is now, that the 1125 has lost all of these bad habits and excitement. It runs now not only strong but stable showing reproducible performance figures. It is not my intention to start a new oil discussion. But the effect of my oil change was so surprising for me, that I have reported here about. New oil is always better than worn one. We shall see how this new fill will perform over the period. But regarding the air intake of the 1125 I really do not believe this design is a master piece of engineering: The position of the air box intake duct below the steering rack is sub-optimal: 1. At this point the ram air effect is limited. The perfect position would be the faring noise in the front of the bike with an intake at the air´s stagnation point - common feature of most other "ram air bikes". 2. At 1000 rpm and the 1125 is pumping approx, 300 m3 air per hour. This number is pretty close to the capacity of these two radiator fans, which blow their heated air side by side directly onto the engine´s air intake duct. No good idea. 3. The IAT sensor is located directly in the down stream of the left radiator fan. So its housing is artificially heated by this arrangement. As long as the sensor housing is warm, this increases reasonable the respond time of the sensor to read accurate ambient temperature. Here is the explanation why the IAT reading need so long to fall back to normal ambient numbers although riding faster. I guess a relocation of the IAT sensor out of this zone of heat excess should help a lot. Additionally it is worthwhile to think about to change the engine air intake duct completely. The genuine 1125 ram air with this small and angled intake duct looks not like a real efficient one. But even if there is a large and straight duct to the engine´s intake bells, the charge effect is rather limited, only 30mbar pressurization at 160 mph, equal to a gain of 3% of engine performance compared to a no-ram-air-intake. The question is, if this 3% of gain at 160 mph are worthwhile the trouble,the stock 1125 intake is causing the rest of the time. An free flowing airbox lid, perforated in the XB-style, could solve all of this heat issues instantly. (Message edited by Highscore on March 28, 2010) | ||

Joshinga |

HIGHSCORE So would you venture to guess from what you said is that loosing top of the air box and relocating the IAT into the air box baseplate would be optimal. I fully understand your "Ram-air" argument I have done the math to figure the required airspeed to achieve a good forced induction (that would make a real HP difference) and it is well beyond any safe street speed and closer to motogp speed or higher. Which leads me to believe that was the whole "Ram-air" aspect in the marketing of the 1125 was just a bunch of HD hype. | ||

Highscore |

Joshinga,you understood me right. I am aware, it is a "Venture" to criticize the ram air effect here, since I have read somewhere else, somebody has lost 20 mph top speed just by removing the inner air box cover but remaining the "cosmetic" cover above. It is an easy thing to monitor the effect of a forced induction by "ram air", it is only necessary to locate a pressure sensor within the airbox. Up to 60 - 80 mph this sensor reads close to nothing compared to the ambient atmosphere around. In deed usually there is a slight relative depression caused by the "aerodynamic" imperfection of the air ducting and the filter (if there is any). "Forced induction" by air flow in front of the motorcycle starts up with a speed of 110 - 120 mph. Here a (absolute) pressure sensor reads some positive pressure in relation to the ambient. But sadly this readings remain within the range of normal weather changes: 30 mbar at 160 mph is the difference of "High" to "Low" in weather, between "Rain" and "Sun" fronts. "Ram-Air" is a benefit for pure race bikes and air planes, since from 200 mph air speed upwards there is 10% charge-benefit with an increase by a square further on with raising speed. But for "normal" motorcycles there is no need for it in my opinion. From my point of view the crucial "design-parameter" of the genuine 1125 air ducting is not the benefit of potential forced induction, but to calm down and damp the intake roar, the noise of the engine. This idea explains further this curious "lip" at the end of the even small air duct into to air box in front of the filter, reducing this limited streaming area without any need. To bring my thesis to a point: Yes, I would remove the air box lid to release the full potential of the engine Furthermore I would relocate the IAT sensor from its heat-exposed position. I would not choose the air box base-plate as a preferred, alternative location,because here the sensor is still heated "artificially" by the engine. I would prefer a position away from this influence. This sensor should read "ambient" and nothing else. (Message edited by Highscore on March 28, 2010) (Message edited by Highscore on March 28, 2010) (Message edited by Highscore on March 28, 2010) | ||

Joshinga |

So in your opinion what would be a good location for the IAT that would give a more accurate reading of the air in the air-box? | ||

Pwillikers |

Regarding oil viscosity Motul 300v 15W-50 is a very good choice. From the manual: Buell recommends using Screamin' EagleŽ SYN3 Synthetic Motorcycle Lubricant when adding or changing oil. If SYN3 is not available and addition of motor oil is required, H-D 360 SAE 20W50 may be used. Although H-D 360 is compatible with SYN3, we suggest the mixture of the fluids be changed as soon as possible. If SYN3 or H-D 360 are not available, the final option would be to add a synthetic 15W-50 oil that meets SG and JASO MA specifications. We again suggest the mixture of the fluids be changed as soon as possible. At the first opportunity, see an authorized dealer to change back to 100 percent Harley-Davidson oil. | ||

Kc10_fe |

All that means to me is H-D making $$$$$ at 75 bucks an hour labor. (Message edited by kc10_fe on March 28, 2010) | ||

Captain_america |

I love reading your posts Highscore... they are so informative! I wish I had the time to do the testing you do. I also love the fact that you think the "ram air" and inner box are ineffective, unless I read incorrectly. Me too. Although the IAT sensor wire is very short, I'd like to put the sensor inside the air box, maybe on top of the filter or something. I have no problem extending the wire as I build EFI harnesses all the time. Just don't want to void the warranty... Small cap GM HEI computer controlled distributor harness  | ||

Captain_america |

Joshinga and Highscore, What do you guys think about my below IAT relocation idea? I think it would be a good spot, and be very accurate. I do not use the inner air box cover as is, because I love the sound of the 1125 gulping in air with the throttle open.    | ||

Dannybuell |

what is the red spot? | ||

Joshinga |

well that looks like thats about as close as you can get to ground zero, As for temp I believe that would give the most accurate reading do to the proximity to the intake runners and the injectors. as for the outer air-box cover I find it a bit terrifying it sounds like if I get to close its gonna suck me in. Not the mention all the squirrels, birds and small children.  Danny... Its a paint pen mark. | ||

Captain_america |

Josh, You win!  haha haha The red is just a paint mark to show where the sensor will go. You can see my fancy new charging system harness in yellow in the first pic... It works niceeeeee I will be working on this in the next day or so and will post up when done. Do you see all the dirt that is getting past the filter! WTF! | ||

Ezblast |

Future mounting point? EZ | ||

Captain_america |

Yes, I will be installing the IAT sensor where the red dot is... | ||

Joshinga |

you know in my time working the Flight deck of an aircraft carrier I have heard my share of jet intakes and let me tell you there is a slight similarity.  | ||

Captain_america |

Don't you love it Josh? Man She sounds so mean and angry when you crack the throttle! I heard it and I was addicted, I couldn't keep the throttle closed for long. Its a shame the rider is the only one that can hear it.  | ||

Highscore |

@ Captain_America: I am sure this new position of the IAT-sensor ensures much more accurate readings as its stock location at the "hot spot" behind the outlet of the cooling fan. But unless the air supply into the air box is unchanged, the sensor even at this new position is still effected by the hot air, coming up into the air box thru the stock take funnel below the steering rack. I for myself really think about to plug the stock intake duct totally and open the air box cover above the filter element sufficiently. The following dyno runs show the effect, when the engine breathes freely thru the filter without any lid above:    I have promised you in this thread above "inflationary" dyno-numbers. Here are some: Note - exhaust system all stock. This runs show solely the effect of more air to breathe for the engine. The base run below is "all stock", the run in the middle shows the effect by removing the air box cover, but stock fueling, the "red" run above the result of applying some additional fuel. Indeed the stock fueling, the stock A/F-ratio is yet a little bit on the lean side, but not as dramatically as reported in some other dyno-threads at this board. I have measured an "all stock" Lambda 0,87 or 12,8:1. This value is close to preferred (Dynojet" 13:1 - A/F-calibration, but in fact it is to lean for a large-bore and high-compression engine like this Helicon-engine. Without air box cover and more air thereby flowing thru the engine the A/F-ratio raises up to Lambda 0,93 or 13,6. This value is still not so far away from the Dynojet-ideal 13:1, but for this type of engine it is definitely to lean. You see this leanness clearly by the erratic and fluctuating shape of the dyno graph. Adding now some additional fuel smooths the graph significantly. There is also an effect on pure peak power at the very end of the engine´s operation range, but more evident is the increase in torque in the middle of the range. The A/F-ratio is set to Lambda 0,83 or 12,2:1. I guess 143 WHP and 80 ft-lbs torque I may call "inflationary". O.k. there is no ram air effect when the air for the engine comes from above. But I guess this figures,especially for torque,are so promising, that nobody should miss any "high speed super charge" (if there is any). The exhaust is still the stock one. A well designed pipe should therefore push the 1125 beyond the 150 WHP - barrier. Would be crazy, isn´t it? | ||

Hootowl |

Re: the factory oil blurb in the manual. It is is talking about MIXING different types of oil together when topping off. Some oils can react chemically with each other. SYN3 and the HD oil do not, and are therefore compatible. Buell can have no assurance that the oil you top off with will not react with the stock SYN3 oil, they therefore recommend that you completely change the oil as soon as possible if you blend oils other than SYN3 and HD oil. Completely changing out your oil with another brand that meets spec is fine, and is not the topic the manual addresses in the quoted section above. | ||

Captain_america |

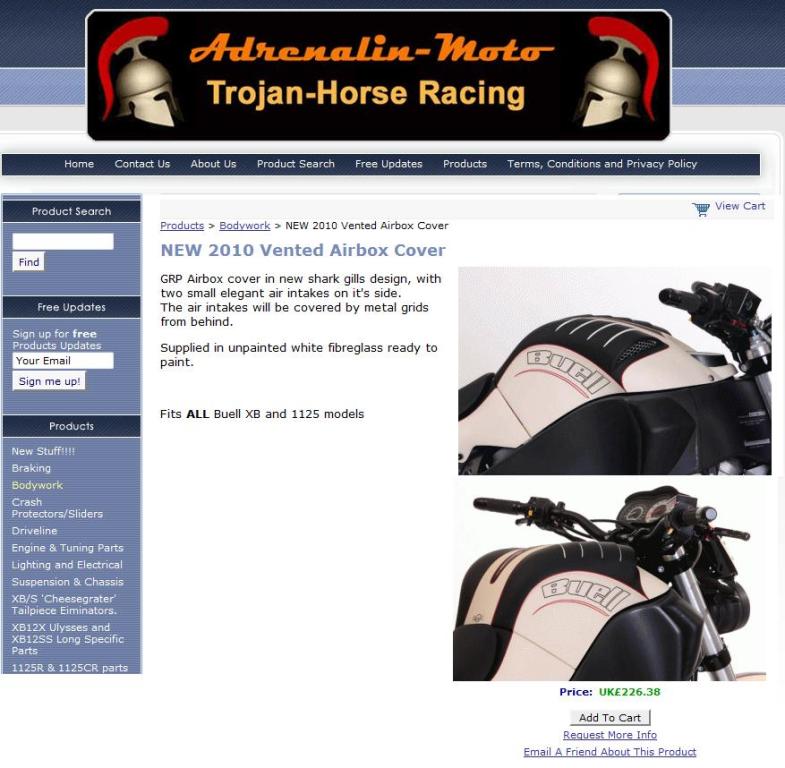

Highscore.... Awesome. I agree 100% with you. great news! I do want to open the top of the air box with the vent behind the gas cap like on the XB12 and possibly one of these air box covers:   I also agree with your air/fuel ratio numbers... while 13.1 and 13.6 won't hurt the engine, down in the low to mid 12's will definitely make more power. How do you go about adding more fuel? what do you use? (Message edited by captain_america on March 31, 2010) | ||

Avc8130 |

Whoa, what airbox cover is that? ac | ||

Captain_america |

MINE! | ||

Joshinga |

340 plus shipping is a littler pricey for a air box don't ya think? don't get me wrong its a bitchin' cover but damn $340!!! |