| Author | Message | ||

Zroknwn |

Yea the torque wrench is in inch/lbs, I'll see if the bolt stops at any point. For me just to check if it stops would it be a bad thing to just leave to bike off, or should I always do the adjustments while the bike is on? Ordered a new boot from the local HD dealer $17 I didn't mind the price so I went ahead and ordered it, it'll take a week to come in so no riding until then.  Thank you so much again Gearhead | ||

Ezblast |

If you do it the inch pound method - then go 25 flats out instead of 5 flats out. EZ | ||

Gearheaderiko |

The torque wrench adjustment is done with the bike off. You only turn the bike on when doing it "by ear". I think 25 flats is a bit excessive. | ||

Zroknwn |

Ok so about looking further into the bike i found out some interesting things.  This is the Spark Plug that I found installed, I see that the plug should have been an RA8HC if the used the proper plug from Champion. I have ordered an NGK Iridium plug part number DCPR8EIX (6546) from my work.  I am also wondering if this part could be another problem with the bike running correctly, I have seen several videos and have seen this part at the top of the fuel door.  This is how my fuel door is as of right now. Is there an issue with the other part not being a part of this? | ||

Kenny_gilgore |

The fuel tank vent is missing. Looks to be broken off and stuffed under the tank. You will have to correct this. It is dangerous and the bike will not run properly if the tank is not vented. Your second picture shows the vent and the vent hose sitting on the frame. Kenny G (Message edited by Kenny Gilgore on March 12, 2016) | ||

Ezblast |

Concur!!! You can use a dirt bike vent, but it needs to be vented. EZ | ||

Gearheaderiko |

The vent could be the problem alone. It doesn't need to be anything special, it just needs a vent hole (Though stock it has the vent running to the ground and a rollover valve to close the vent if you lay the bike over). It appears you have a problem child :-( Over fixed or just plain abused. It's a clear reminder that people can really f'up a bike, even one as simple as a Blast. At 4100 miles (if that's true), they spent more time "fixing" it than riding it. Provided the compression is good, you'll have a good bike once you fix all the "mistakes". the fact that they pushed the tank vent under the cover is a clear indication they had no idea what they were doing. At this point that vent and hose aren't doing anything except add weight to the bike | ||

Zroknwn |

So I should be able to just reuse the tank vent that is on the bike now I just need to mount it where it is supposed to go at the top of the fuel door correct? Would it be better to replace the vent that was on there before with a stock part to ensure correct fitment? You guys have helped me out tremendously, thank you so much. | ||

Kenny_gilgore |

I suspect the threads were stripped on the vent or the tank as to why it was disconnected. Before you attempt to reconnect the vent make sure that the vent hose is not clogged or melted shut. Possibly you can epoxy the vent back onto the ring on top of the tank where the PO filled the hole with a sheet metal screw. Kenny G | ||

Gearheaderiko |

Make sure you check to see if either actually vents. The unattached vent and the vent hole. Just blow through them. It might have been taken off for a reason. | ||

Zroknwn |

So I found out that the roll over valve works about 50% of the time. Looks like I am going to go ahead and replace both the valve and the vent. Found the valve for $19.49, vent for $10.80 and the o-ring for $1.31. Overall with everything and shipping online it will be $45.95, seem reasonable or a little overpriced? Anyone know where to possibly get everything cheaper than at HD?  | ||

Zroknwn |

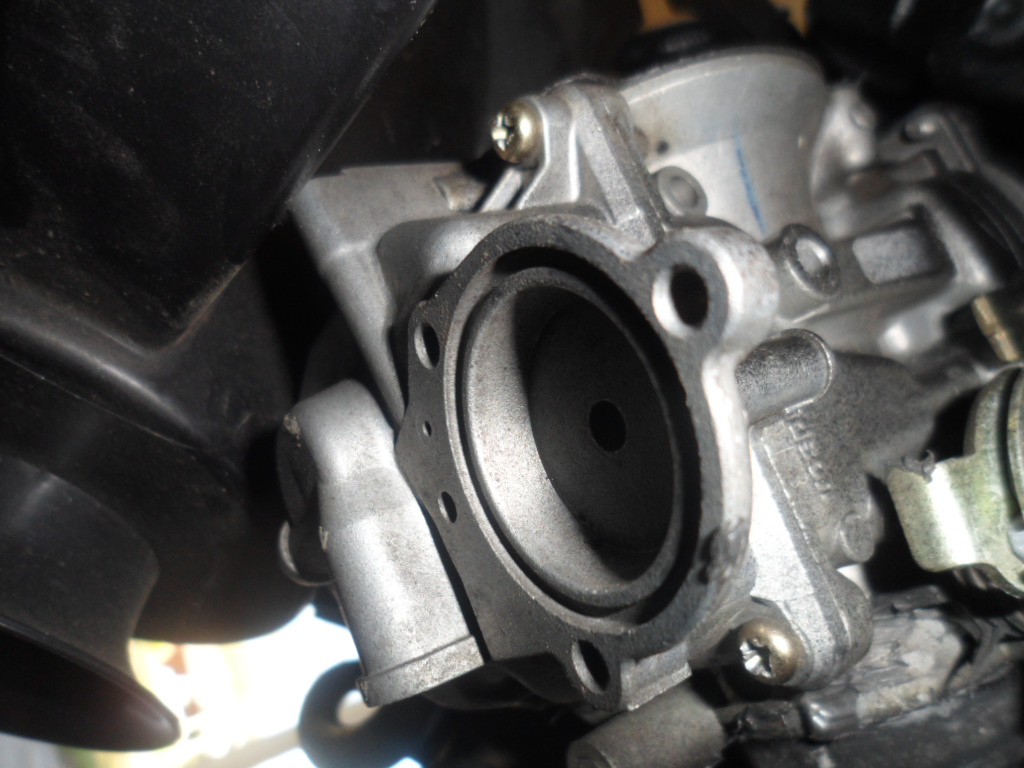

Finally was able to fix the boot issue, although the old boot seemed fine when i took it off and removed the black RTV. I swapped it for a new one anyway, however I did notice this  This is the bottom of the carb and I can't help wondering if there is supposed to be something that is bolted up here that I am missing. I did take it for a ride and didn't really experience any hang up's on idle or anything, but i am still experiencing the low speed on the interstate. I readjusted the limiting screw and tightened to 24 inch/pounds on the nut and backed out the screw on 3 different settings 12,18 and 24 flats. One both 12 and 18 I was able to get her to about 45-50 MPH but nothing more. When checking the first time i had noticed that the limiting screw had jarred itself loose quite a bit, almost to the point that it dropped while riding and was leaking fluid. I torqued everything back up and took it to 18 flats Still getting about the same amount of speed as before. On 24 flats I was able to get her to about the 62 mark again. Here is a picture of how I have the limiting screw as of right now.  I ended up taking off the roll over valve for this ride and plan on replacing it soon but wanted to see if there would be a huge difference between having the roll over valve in the bike and popping the fuel cap to allow for air to seep in or just running with out the roll over valve. | ||

Ezblast |

Keep the primary as loose as you can. Another issue it could be is a improperly sealing/seated diaphragm. Make sure Das boot is new and on correctly as well. EZ | ||

Gearheaderiko |

The carb is missing a part that the Blast does not use. If it was a twin, that's where the accelerator pump goes. The Blast doesn't have or need it. Your description of your primary adjustment seems like you're doing it wrong and I fear you may end up stripping the case. loosen the jam NUT (7/8") so the BOLT (3/4") turns freely. The nut will turn with the bolt, so you will have to hold the nut or back it off considerably. Torque the BOLT to 24 inch lbs (make sure the NUT is not contacting the case and tightening up). Then back the bolt out 18 flats (or 3 full turns) then tighten up the NUT while holding the BOLT at the adjustment. (although the nut is 7/8" it doesn't take much to tighten it down-you will strip the case if you force it) I hope that clears things up or maybe you just conveyed your procedure wrong. | ||

Gearheaderiko |

Let's make sure that's right before you go further. Loosening the gas cap should clear up any tank vent issues (just be careful). Run the bike on the "reserve" petcock setting while diagnosing (just don't run out of gas!!). Please don't take the carb apart. (Yet) But it does not appear that the idle mixture screw has been uncapped (from what I can see in the picture), so we'll need to do that and change your slow/pilot jet to a #45. This won't affect highway running, so leave it alone for now. The main jet will need to be changed to a #170. This will affect highway running especially if your boot is bad. I assume neither jet has been changed because the idle mixture screw is still capped. Let's just get the other issues fixed first. If you've got the money, I would order both jets. $12-$20 for the pair. (Message edited by gearheaderiko on March 20, 2016) | ||

Zroknwn |

Took the bike to work and used our torque wrench to adjust again per your instructions Gearhead. Worked better at 18 flats out but still have issues with getting higher speeds. Had some issues on my way home, about halfway home up a semi steep hill the pitch of the bike's exhaust changed dramatically. Found out when i got home about 2 miles later that this happened.  Looks like it will be parked for a longer time that I thought. Thanks guys for all the help. | ||

Ezblast |

Weld it and check mount tightness. EZ | ||

Gearheaderiko |

I'm confident your primary is fine now (a picture of the nut and bolt would cinch it!) Did it run any better after the exhaust broke?rodents have been known to nest in exhausts of bikes that have sat. Order those jets and we'll do a minor carb disassembly. Keep us posted on the exhaust. Then we can forge ahead  | ||

Zroknwn |

Big issue with running it just straight dumped without muffler? | ||

Ezblast |

Should be a bit longer to run straight pipe - cold air gets sucked in and things will go bad quick. EZ | ||

Zroknwn |

If I go straight pipe from the crack I would need to definitely reject and shim correct? | ||

Gearheaderiko |

Well, yes. But it won't run very well and certainly not worth the trouble. If you can't weld it you could use exhaust sealer and a tin can with some hose clamps but.......  Your best options are weld it or replace it with a V & H or Jardine exhaust. I don't like to tell people to spend $$ and change things before they fix their current problem, but its not that big a deal. I'm confident we'll get you sorted out. You can run it "as is", but not for long periods- it will do damage eventually. Basically to see if you've found your problem. | ||

Zroknwn |

Ok, I will test tonight when I get off work and see if throttle response is better, if so I guess I should look into either replacing with the V&H or Jardine exhaust. If throttle response is about the same then on with the welding and diagnosis. | ||

Zroknwn |

When getting the exhaust off the Blast I found out that I have no retaining ring in between the gasket and pipe, is this a really big problem and will it cause the bike to have an exhaust leak? I did start the bike up with just the small piece of exhaust that I had, when trying to keep the leak to a minimum I had some burps but was a little more responsive to throttle . I have since had the exhaust welded and will be getting a new gasket and retaining ring from Harley later on today. Is the retaining ring just sandwiched in between gasket and pipe? I saw that the manual states to have it 90 degrees from the collar on the exhaust. I guess it is meaning to have it rotated to where a piece sits in the middle between the 2 exhaust studs? Any help on this would be awesome. Due to them not stocking the roll over valve, vent and o-ring I have to order them. We will see if replacing everything will have an effect on the low top end. | ||

Gearheaderiko |

The retaining ring holds the flange on the pipe. The flange pushes down on the retaining ring holding the pipe in. Make sure you remove the old gasket-it may look like it's part of the head. I don't see the exhaust or rollover valve making any difference if you've already road tested the bike with the broken exhaust and loose gas cap. If the problem wasn't gone then, it won't be gone now. If it says 90 degrees, then that's where you should put it! | ||

Zroknwn |

Well gear the manual isn't really clear on where the retaining ring is supposed to go. The manual states: 1. See the Service Parts illustration. Obtain the exhaust ring clamp saved earlier and the header pipe assembly (2) from the kit. Install the exhaust ring clamp (with the counterbore facing the engine) over the collar onto the header pipe. 2. Install the new retaining ring (6) from the kit onto the header pipe to prevent the pipe from slipping through the exhaust ring clamp. 3. Slip the muffler assembly (1) over the header outlet pipes. 4. Loosely assemble the front bracket (3) and hanger bracket (4) to the header pipe with the hex head bolt (7) and lock nut (9) from the kit. NOTE: The retaining ring may crack if the gap is not positioned at the farthest point from the mounting studs. 5. Position the header pipe on the motorcycle. Rotate the retaining ring at the exhaust ring clamp so the gap is oriented 90° from the exhaust port studs. Does the retaining ring need to have the open portion positioned towards to road or toward the headlight? Since it states to place it on the furthest point away from the studs. I'm just unsure as to where to put it so that I don't end up cracking it and screwing up something. | ||

Gearheaderiko |

It's a low risk. Just midway between the exhaust studs is fine. Unless I'm too late, then don't worry about it! | ||

Zroknwn |

Not to late, didn't want to put it together without direction. Thanks Gear, I'll be putting it together within the next couple of days. If this does nothing for the performance of the bike I guess it's down to opening up the carb and changing out jets. Is there any way to tell what jets are in it? My guess is that they are stamped it labeled in some fashion. | ||

Zroknwn |

Not to late, didn't want to put it together without direction. Thanks Gear, I'll be putting it together within the next couple of days. If this does nothing for the performance of the bike I guess it's down to opening up the carb and changing out jets. Is there any way to tell what jets are in it? My guess is that they are stamped it labeled in some fashion. | ||

Zroknwn |

Not to late, didn't want to put it together without direction. Thanks Gear, I'll be putting it together within the next couple of days. If this does nothing for the performance of the bike I guess it's down to opening up the carb and changing out jets. Is there any way to tell what jets are in it? Are they labeled or stamped? |