| Author | Message | ||

Natexlh1000 |

Just curious about this but is is obvious by looking at the ports if they have been "done"? If so, anyone have pictures of before and after? Also, typically, would a shop do any flow testing or would they just do it by some book? | ||

Endoman33 |

looking at the port (before) should look like regular casting maybe even some texture (after) the in take should look dull polished with swirl markings to increase air lift or flow. some shops bench flow heads some do it by sight and feel, sorry i don't have any pics | ||

Aesquire |

Some shops have spent a lot of time on the flow bench, Some just guess. ( usually wrong. A Buell needs to flow more than a hog since they spin up faster ) In a very few cases a real good head carver played with things until he got it as good as he could, ( and tested his work with a flow bench & then a dyno ) and then put those dimensions into the computer so that a CNC milling machine could then duplicate his hand work on many heads. | ||

Kmbuell |

This should be an interesting thread. Take a look at on old 1200 Sportster port compared to a new XB port. Which one is bigger? Buells need velocity I've been told. Check with Mr. Johnson at JET. As for the original question, porting should smooth out sharp edges and flow/ smooth the areas near the guides. | ||

Thumper74 |

Keep in mind that you can completely re-design a port to address the factory’s short comings. You can really do as little to as much as you want or any place in between. You can do a minimal amount of porting to clean up casting flaws and blending the valve guide to completely re-designing the combustion chamber and ports. It’s really up to the intended use of the vehicle. Vehicle’s that really spin (Honda CBR, Honda S2000, R6, GSXR)and have multiple valves can get away with larger ports because they just need to ingest as much air as possible. The trade-off for crazy power at redline is lethargic throttle response when not in the powerband. On larger engines (Small Block Ford, Chevy, Chrysler, Harley/Buell) with high torque, you can keep the throttle response of the high torque motor by keeping port velocities up as well. You can move the powerband up on a larger engine by increasing port size and decreasing velocity, but you sacrifice some low RPM driveability. On a larger engine, you’re less likely to be bothered by that due to ample torque. | ||

Hexangler |

sorry, couldn't resist.  ) ) | ||

Fast1075 |

I have seen many heads that had killer gorilla flow numbers at high lift that wouldn't make enough power to pull a greasy string out of a cat's butt... If you are interested in porting a set of heads, my strongest advice is to consult a professional with proven results...if all you want to do is clean up the castings, that in itself is doable in a do it yourself situation if you are careful and have the tools, equipment and skills to service the heads...porting goes way beyond hogging the holes out.. One (of several) badweb sponsor shops that not only CAN, but has the records to prove it, and I can speak personally that they are good....is Cycle Rama. Wes and crew are among the "good as it gets" folks. | ||

Mr_grumpy |

Here's one that's done.  And one that isn't.  I realise it's not easy, but I hope this helps.  | ||

Bill0351 |

Hey Grump? Which is the intake and which port is the exhaust? | ||

Wolfridgerider |

I had my Road King heads done by T-Man... people freak when ya pull the front end up on a bagger... I would love to see what he could do with a XB motor... http://www.tmanperformance.com/index.html | ||

Benm2 |

On a non-ported head, there will almost always be a "step" between the valve seat and the ports. The machining done to the head casting to insert the seat into is done from some reference point, and it doesn't always exactly line up with the port core. So, there will be a step in the metal, where the ID of the valve seat will stick our slightly further or slightly inside of the port wall. Even a "stage 1" porting would have those edges blended in, and the transition from valve seat metal to port metal would be smooth. | ||

Mr_grumpy |

Top one's the exhaust, Felixstowe container port, one of the busiest in Europe. The beautiful intake port is a small village in Scotland called Findhorn, it's where my family come from. my sister still has a cottage there with view over the bay. I can just sit for hours watching the boats swing with the tide. Oh & the village has the best chip-shop I've ever eaten from. We apologize for this hijack, & now back to your regular programming. | ||

Pammy |

Just curious about this but is is obvious by looking at the ports if they have been "done"? Yes. If so, anyone have pictures of before and after? probably, but posting is beyond me. Also, typically, would a shop do any flow testing or would they just do it by some book? A proper shop would use a flow bench. Flow as well as velocity needs to be measured(so it can be corrected). Short explaination: the fuel needs to stay suspended and mixed with the air. The air should swirl, but not tumble. Also, the heads need to flow the same. | ||

Rfischer |

Bob Johnson at J.E.T. has forgotten more about flow, velocity, and resulting cylinder fill than most will ever know. If you want H-D/Buell heads done, send them to him. If you want to know HOW and WHAT to do, ask him for a job....  | ||

Dano_12s |

Pammy, I'll try to post some pics. | ||

Dano_12s |

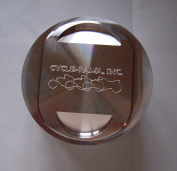

| ||

Dano_12s |

Sorry, I don't have any before pics. Thanks again Wes+Pammy!Great folks to deal with! | ||

Fast1075 |

Them shore is some purdy parts...  | ||

Pammy |

That 3rd photo is very artsy. I like it. I will have to try that myself. As a matter of fact, all those pics are nice. It was very nice working you too, Dan. Keep us posted on your progress. Steve, you know where we are. Come on down... | ||

Blake |

What is that copper looking stuff on the intake valve?  | ||

Toona |

I'm guessing it's just a reflection of something off the face of the valve. | ||

Dano_12s |

Both valves are the same in color.Just a reflection from flash I guess. | ||

Pammy |

I am trying to get a little step by step (pictures)process together so you guys can see what goes into hand-porting a set of heads. |