| Author | Message | ||

Hoser |

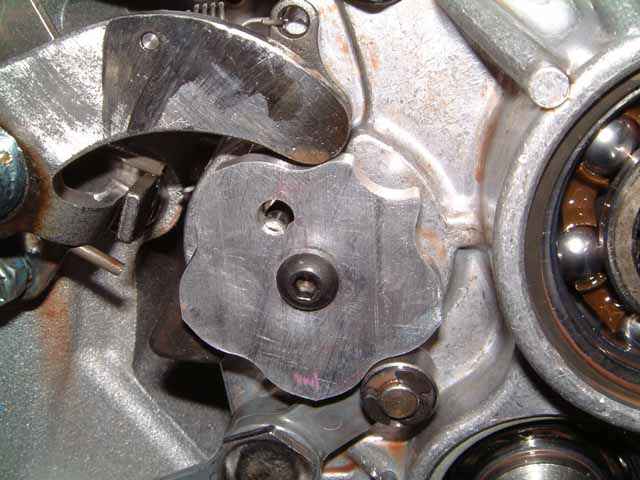

Anyone: A flaw exists in our transmisions that has been bothering me for some time now but I have been too busy to do anything about it until today. The shifter drum has four pins pressed into it that index with the detent plate , the detent plate is retained with a cheesy little clip , allowing the detent plate to "float". What can happen due to this "floating" condition is the pins which are pressed in can walk axialy out of position , this then causes the detent plate to become cocked at an angle , it will then make contact with the back side of the clutch hub. Usually its only one or two pins which do this , but I have seen this happen on six different bikes , now my S1 is afflicted with this problem. I first noticed it as noise , meaning the transmission was starting to make more noise than it should when shifting into gear from neutral , on upshift and downshift , shifting started to require a bit more effort. I have a fix in mind and will provide more details as I proceed , it has to do with how the detent plate is retained on its tiny little pin and retaining clip , I have a better idea that involves machining and substituting the pins for crankpin rollers pressed in to replace the pins. I will report back in the next few days to provide an update , luckily I have a few shift drums to play with. Jeff | ||

Sportyeric |

They've both got to come off. Front drive sprocket, clutch basket, and chain have to come off as a unit. My mechnaic says replace the sprocket nut whenever you remove it but nobody here seems to agree, or even have an opinion. Use an impact driver and a stouter screwdriver! A block of wood would probably be better than another screwdriver. I think the thing to avoid is getting little bits breaking offf and hiding in the chain. That's why I like aluminum. | ||

Sportyeric |

One nut or the other has reverse threads. Make sure you're turning it the right way. Aaron I think posted which is which earlier. | ||

Roc |

Thanks Sporty, its the clutch that has the reverse threads - the one that comes off easy. | ||

Jmartz |

Hoser: I observed the condition you describe when I replaced the detent plate for the newer pointier end one. The other problem in there is the nylon shoe whose metal support breaks. This situation has been corrected in the design of the part but many bikes such as mine still have the weak one installed. Finally there is the "jerk after release" tug that AAron has mentioned when the "shifting dog" (our trans doesn't really have these anymore but are part of the gear itself)beocmes rough near the tips preventing full engagement until a load is applied. | ||

Cesler |

Folks, I just adjusted the clutch and the primary. My 99 M2 shifts fine cold, but then shifts hard when it heats up. It's ridable, but is certainly not making the 'snick, snick' sounds it made when new. Any suggestions? Would the clutch adjustment do this.. other problems... I am sure the primary is adjusted properly. | ||

Hoser |

Jose: I am working on a fix , I await a new shift drum to get a measurement on pin protrusion and then will proceed with my plan , one thing I am not 100% sure of is wether the detent plate will operate correctly bolted on rather than being retained by a clip , other designs use a solidly bolted style detent plate , the drum itself has very little axial play on our transmissions so I feel it will both work and be an improvement. Anyone else have an opinion on this ???? Jeff | ||

Aaron |

You mean like this? Yeah, it works. | ||

Hoser |

Aaron: Thanks !! we must think alike , that looks like a 1/4" fastener , is it ? , I was planning on using 5/16"-24 ,with an appropriatly size standoff and using crank pin rollers to replace the pins. Jeff | ||

Aaron |

Jeff, I'd love to take credit for that idea, but that's the Baker 5-speed XL shift kit. Comes with a new drum and that bolt-on plate. Yes, if memory serves, it was a 1/4" coarse thread. AW | ||

Al_Lighton |

Hmm, i was about to go in and replace the detent plate and 2nd gears on my s1w... maybe while I'm in there....???? http://www.bakerdrivetrain.com/sportsterfivespeed.asp | ||

Aaron |

Hell, if you're going that far, might as well put in their 6-speed! | ||

Al_Lighton |

I'd LOVE to... but there's too many little green rectangles between me and the Baker 6. HotRod Bikes august issue had an install article on the Baker 6, they liked it. It'd be way cool, you even get a new derby cover proclaiming it's coolness for all to see :-) Al | ||

Al_Lighton |

Hmm, on a re-read..not to confuse anyone with the "they liked it" statement, they didn't really do any performance testing with it. The article was a "How to install" article, and they will have performance testing in upcoming issues. The install was clean enough, gotta love those cassette transmissions. There is some case grinding needed, but Baker provides the grinding template so it seemed not a big deal if you have a die grinder and carbide bit. Wouldn't want to do it with just a dremel, though! It's a good article, just not a performance test one. Al | ||

Hoser |

All: My plan to "bolt the detent plate" to the shift drum is on the back burner , here's why. I chucked the shift drum in the lathe to drill the neccessary hole , I was able to complete that part but it was reeeaaaally tough to do , the drum is powdered metal and is heat treated , to be able to tap a thread would be beyond my capabilities at this time. I do have several "used" shift drums , but for now I have replaced my "defective" part with a new one and did the chain tensioner as well. I have mentioned this problem to our Warranty rep on several occasions , hoping HD would then upgrade this part and offer a retrofit but the factory seems more interested in development of new product and big twins than improving existing XL product. Big twins have received shifting upgrades three times in the last three years !!!! Jeff thinkingaboutbecomingashitdisturberbecausewearenotallowedtocallthefactoryfromcanada | ||

Hoser |

Anybody know anything about the "upgraded shifting" on the XB9R ??. Jeff | ||

Schemky |

Aaron, Any comments on the shift quality with the Baker XL shift kit? I am seriously considering a 6-speed by the spring of 2002, however, with just over 10,000 miles on my 99M2, the shifting has gone from acceptable when new, to "like butter" now. I have never experienced a transmission improvement of such magnitude, and assume this to be normal for the XL tranny. But if an even greater improvement can be gained from the shift kit, I would install it. I firmly believe the Red Line Shock Proof Heavy contributes to the quality of my M2's tranny characteristics. | ||

Bull |

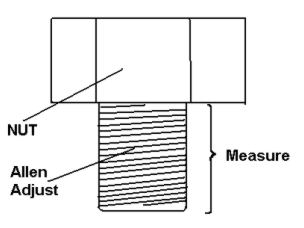

Hi Guys, Can someone please give me a reference measure on the chain tensioner?? I'm looking for a measure on how much the allen adjuster bolt protrudes...  Crappy picture, but I hope you get the idea... Please, metrics, I havent figured out the " yet :-) Thanks/ Jojje | ||

Hans |

Jojje, Yesterday just adjusted my (old model) chain tensioner (2000 M2, 3000 Mls) and still 12 mm protruding. Wondering why you want to know. Hans. | ||

Bull |

Hans, Just wanted a couple of reference values to see if the measure is valid to determine chain and tensioner wear. Thanks/ Jojje | ||

Jeffsd |

I just made the switch to redline heavy shock proof oil for the trans on my 2000 X1 at 4k miles. The Banks shifter is mounted using two allen head bolts on the very bottom of the primary cover. After filling the trans last night, I did not notice any leakage. TOnight, however, I did notice some redline in one of the bolt holes. ( I have not yet reinstalled the shifter). What are these bolt holes for and why is there trans fluid leaking from them? And, most importantly, how do I stop it? THanks, Jeff | ||

Blake |

Jeff: Before the installation of your Banke shifter, those bolts were the same as all the others that bolt the primary cover to the left-side crankcase. The Banke shifter kit provides the necessary longer version of those same bolts so they can also be used to support the shifter. If you are lucky, when you retorque the two bolts, your leak will stop. If you are very unlucky, you may need to install a new gasket and retorque all the bolts in an expanding star type pattern as per the manual. | ||

Jeffsd |

Blake, thanks for the heads up. Have I mentioned lately how much I love this Gosh Darn bike? It is like a motorcycle, an erector set and a garage project all rolled into one. Since I am usually never lucky, it looks like I will have another project on my hands. Guess I'll get to replace that chain tensioner after all. Jeff | ||

Sem1 |

Blake, About the primary cover torquing pattern; which section of the manual is it in? I remember looking for it in my S1W shop manual, but could not find it, so ended up improvising a pattern. So far no leaks except for the occasional dripping from the clutch cable hole. Cheers, Semi | ||

Blake |

Semi: I mispoke saying the pattern was per the manual. Seems strange that a pattern isn't specified. That suggests that it isn't critical to the integrity of the seal. If you number the bolts from 1 thru 13 starting with the forwardmost bolt and going counterclockwise (ccw) as you face the cover, my tightening sequence is 4-11-3-12-5-10-2-13-6-9-8-1-7. I'd first go through the sequence making all bolts just snug tight (~20 in-lbs) then repeating twice again, first to 50 in-lbs then to 90 in-lbs. Then (after adding tranny lube) I'd take a good long test drive or two; after she'd cooled down to room temp (the next day pehaps) I'd retorque to near the high end of the specified torque range (80 to 110 in-lbs). Call me anal, but that dang seal likes to leak if it isn't just right (meaning clean and bone dry with the gasket properly seated and the cover properly torqued). The real experts on this though are the technicians/mechanics and those like Aaron, who's had the primary covers off all his bikes at one time or another. They may have a better and/or less rigorous method that is just as leak resistant. | ||

Wruffus |

Anyone seen a gear indicator/sensor for the sportster trans or know of one that might be modified to fit? I'm not concerned about the display, just getting an electrical indication of the gear I'm in. | ||

Sem1 |

Blake: Thanks for the info. I will jot down your bolt tightening sequence in my manual. I did the retorque-after-cooldown also back when I replaced the primary chain tensioner. | ||

Bomber |

WARNING!!!!! I was just installing the new '01 style factory shifter on my Y2K M2, and the shift lever mounting bolt snapped WELL short of the 25-29 ft lb listed in the instructions . . . . . . .I realize I may have gotten a bad bolt, but I'd like to help others avoid my mistake . . .. now, out to pull the primary case and see if I can get the vice grips on what's left of the bolt . . . . sheesh | ||

Henrik |

That sounds like a lot of torque on that bolt. It's up there with the front brake caliper mounting bolts. Could it be a misprint? Henrik | ||

Nemo |

Has anyone come up with a shorter bolt for the primary drain? Loosening the exhaust is getting old. Could I just remove and cut that bolt, rethread the end. Comment or ideas. Thanks |