| Author | Message | ||

Gentleman_jon |

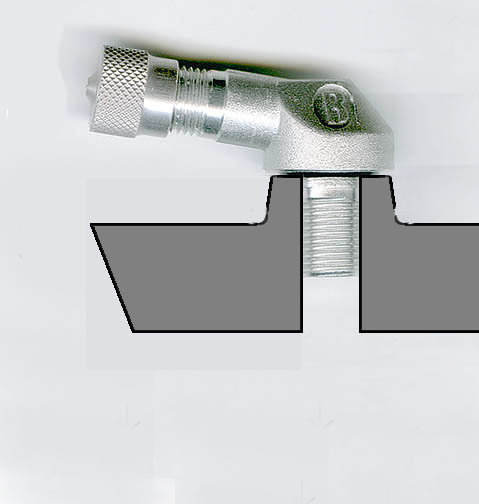

Here is the good news and the bad news: The good news is that PJ Parts went to considerable trouble to find and to order 8.3 mm right angle valve stems from an Italian source. That is the correct diameter of the stem that goes through the rim. The bad news: this stem is about an inch too short, as shown in this diagram. This is because not only is the Buell rim thicker than most, but it also is unique in having a raised shoulder, which I don't believe is necessary, and which makes finding ANY valve stem for these wheels almost impossible. These stems do fit on most high performance Italian wheels that come on Ducati, Aprilia etc.  This is really a shame, as these valve stems are very light, and they make checking air pressure much easier. In addition, because the schraeder valves are at almost a right angle to the rotation of the wheel, centrifugal force does not reduce valve closure pressure. It might be possible to machine the Buell wheels to accept these, but it would require either removing the shoulder and recessing the inner face of the wheel, or perhaps making an extension for the stem of some sort. Any ideas?  | ||

Beachbuell |

Check Triumph 90 degree valve stems. They MIGHT be a little different and work for ya. They are pricey, I can tell you that. A bunch of friends on imports just did a big group buy on some. | ||

Reepicheep |

What about pulling the valve core from the stock valve stem (left in place) and making a simple coupling collar to attach this right angle valve stem to the stock valve stem? It is an extra couple of parts, but won't add that much weight, and will make the stems easier to access. | ||

Gentleman_jon |

Beach, The only thing I could google up on Triumph 90º valve stems was an adapter:  Is that what you meant? Not a bad idea, but a bit of an inconvenience to put it on and off. They don't recommend riding with it attached, as it is a bit on the heavy side. Cheep, Funny that you mention that. I took the bike down to Andy, my machinist-magician, and we came up with a couple of similar ideas, but having it all inside the wheel, which we have yet to inspect. Going to change tires next week, so we shall see what we come up with. Current thinking is sort of like the lower illustration above. Stay tuned, sports fans, we haven't completely given up yet!  | ||

Djkaplan |

Are the stems actually mating with any threads in the wheels, or are they just not using all the threads available? All you need is a quarter inch of engagement and thread sealer if that's the case. If your tires go flat in the future because all you had was a quarter inch of engagment and thread sealer holding it on... disregard what I said. | ||

Djkaplan |

| ||

Motornoggin |

I donnut unnerstand what's wrong with the factory issue stems to go to all the trouble to swap them with 90 deg. stems. I've never had an issue with checking or inflating the tires on my Uly. | ||

Roadrailer |

I donnut unnerstand what's wrong with the factory issue stems to go to all the trouble to swap them with 90 deg. stems. I've never had an issue with checking or inflating the tires on my Uly. +100. Seems like a problem that just doesn't need to be solved. I've never had an issue either. | ||

Roadrage |

Many of the bulky digital tire pressure gauges won't work on a XB. | ||

Sloppy |

Buy a new tire gauge that fits or modify a valve stem and rim? It's questions like these that make me reach for more beer... And yes, there's hardly any question that hasn't had me reach for a beer. | ||

Djkaplan |

"I donnut unnerstand..." If you met Jon... you'd understand. | ||

Gentleman_jon |

Why, thank you Danny! You are entirely too kind. As always.  PS: Fresh tires have a arrived, so we may have a solution before too long. Or maybe we won't. Stay tuned to this station............ | ||

Spiderman |

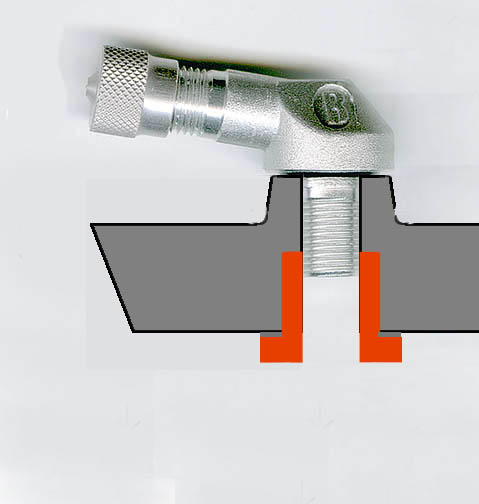

GJ, Counter bore the hole from the tire side to accept the nut... | ||

Gentleman_jon |

Good idea Spider. Going to give a try today, I hope. Gotta get Gerry to let me use his tire changer, and Andy to do the machine work. Could happen.  | ||

Spiderman |

yep i'm smrt S-M-R-T smrt  | ||

Gentleman_jon |

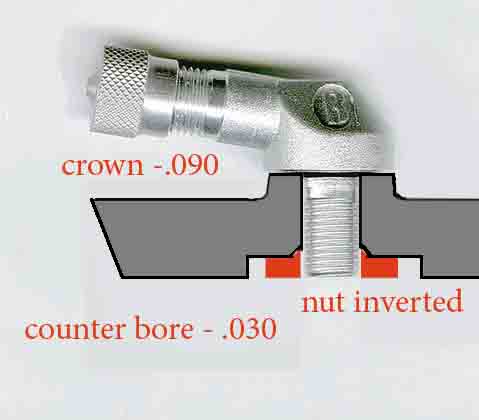

DON’T TRY THIS AT HOME. Actually, there was nothing to it. That’s because Andy the magician machinist did all the work. He milled 90 thousands off the land on the outside of the wheel with a vertical mill.  Then he counterbored the inner bolt land 30 thou. and milled a taper on the nut and the inside of the bore to make an tighter fit when the nut was installed inverted.  In section, the install looks like this:  A little Buell Graphite paint on the wheel land, and a bit of sealant on the inner nut, and badabing it's done. | ||

Firebolteric_ma |

Very nice install there jon. Your Always Thinking!...  | ||

Lugnut |

I don't know why you really had to do that, but wow that was nice machine work. And I really like nice machine work. | ||

Gentleman_jon |

The bike is handling much, much better with these new lightweight Italian valve stems. They only weigh .3 oz . The steel stockers weigh in at .7 oz. This has the related advantage of requiring half the lead to balance the wheels, so we are talking a weight saving of one entire oz. on the front wheel alone!! Of course, one doesn't want to entirely overlook the handling benefits that might derive from fitting a brand new set of Dunlop Qualifiers at the same time.  | ||

Metalstorm |

Of course, one doesn't want to entirely overlook the handling benefits that might derive from fitting a brand new set of Dunlop Qualifiers at the same time.  Jon, your posts are definitely one of the main contributing factors of me surfing the BadWeb so much. Thank you  |