| Author | Message | ||

Skully |

Spiderman - Air box cover stiffness is what drove me to the number and pattern of holes that I used. I can't tell that the cover is any weaker structurally than it was. 03xb9r - I don't know without going back to the dyno where the "tank cover" becomes the limiting factor in air flow to the engine. Good question. What is the real purpose of the velocity stack? Is it supposed to help airflow or is it really an effort to reduce induction noise? It could be the limiting factor now. I rode the bike in this morning and while not quantitative, it feels real strong. I guess I'll just have to take it back to the dyno... Keith | ||

Misato |

did anyone see the new force air box plate? I did and already have one made. no, where did you see that? | ||

Spiderman |

Here are some photo's from ATC (hope ya don't mind Scott)   | ||

Blake |

I'd be skeptical the two fasteners, especially given their locations, would adequately seal the top plate to the filter. Why not show it installed? | ||

Darthane |

Make it out of aluminum that's thick enough (3/16" or so, or just use something stronger than aluminum) and those two fasteners should exert just as much is not more pressure on the top of the filter as the stock airbox. If you're really skeptical, though (and if I do this I think I will follow my own advice), put two more at the fore and aft of the filter, so you have a cinch point at every curve. Bryan | ||

Ar15ls1 |

Very good idea darthane. I though of this after I installed mine. Even though the plate is 3/16" of an inch, the front of the filter does not fit as tight as I would like it to. I will add this to mine this weekend! By the way, I attended a Mobil oil seminar today! Got some good information from the lube engineers! | ||

Captainplanet |

Since I thought the Latus was too loud, I decided to cut open and modify a stock xb pipe. There was a drawing earlier suggesting to cut the entire section of pipe near the rear out. If you did that, it would make the exhaust a straight through pipe, and I expect as loud or louder than the latus. As you can see in the pic, I just cut the end off the exhaust, cut a small section out of the rear of the pipe. What this allows is that some of the air flow will immediately go out the tip after coming in the straight in pipe. It also allows some muffling effect so that the remaining air goes though the center and third pipe and then out. After the cuts, just weld the end back on and your done. Now my bike sounds like I want it to. The sound is not nearly as deep as the latus but it sounds way better than stock. I haven't heard a buell race kit yet, so I can't compare mine with it. Seems to run exactly the same as before. As I just wanted better sound and was not really in need of more power, I like it. | ||

Darthane |

Well, I made mine this weekend. Used Plexiglass 'cause I couldn't find any aluminum...plus being able to look right down the throttle body's kind of cool. Survived it's test ride A-OK. Definitely a noise difference, but now the damned TPS needs to be reset again...I also hacked the velocity stack down, and I'm wondering if it really needs that funnel shape on there. I may epoxy it back on, sans 3/4" or so, and see if it does any better. Suggestions?      Bryan | ||

Skully |

Bryan, What are the symptoms? What would you have affected to make the TPS need to be reset? I too am curious as to why the velocity stack is the height it is. Keith | ||

Darthane |

Keith, Well, apparently the mods I did, creating my 'own' Force intake and hacking off the velocity stack (I simply cut it off about 1/2" above the bottom seal), altered the air intake enough to toss the computer for a bit of a whirl. Immediately after I had finished the mod, I started the bike up, let it warm up a bit, and cracked the throttle a couple of times. Seemed to respond fine. I brought it up to ~4000RPMs and held it there for 30 seconds or so, then let it go, and the bike dropped to 500rpms before dying. Started it back up, tried the exact same sequence, this time it was fine, but it did seem to be idling a bit low. I adjusted the idle via the little screw to about 1050-1100rpms (the recommended setting) and everything seemed fine. However, I went out for a ride and every now and then the bike just did not want to come back down to idle from speed, going real slow down from 4500rpms to about 2000 and sitting there for almost 15 seconds before dropping to idle. The AFV is !#$%ed up. I'm going to take it on the freeway tomorrow afternoon for a bit and see if running at a steady clip for a few minutes will help it readjust itself. Regardless, I was planning on a TPS flash before the NE tour, but I'm trying to decide if I should put the funnel portion of the velocity stack back on first or not. Oh, Ar15ls1, in case you're wondering, there is not enough room to put another stud in the front or rear (inside the filter, anyways). I am toying with the idea of creating a small bracket that utilizes the front bottom air box mounting screws to clamp down on the front of the plate, but it seems to seal fine as it is. For anyone that's interested, I used: 1 - sheet of 18"x24" 1/4" thick Plexiglass 2 - 5/16"x5 1/2" lag bolts 2 - 5/16" bonded seal washers 6 - 5/16" rubber washers 6 - 5/16" cut washers 4 - 5/16" nuts 2 - ~3 1/2"x1/2" steel tube 1 - 1/16"x1 1/4" zinc stock w/1/2" holes 2 small pieces of "200mph duct tape" (GOD I love that suff!) Total cost - ~$17, the majority of that being the Plexiglass sheet. Oh, and I bought a new Dremel with all the fixins. Heehee... Bryan edited by darthane on June 01, 2003 | ||

Skully |

Darthane, When I first cranked my XB up after modifying the air box (see above), mine idled slow and rough. I rode it to work and it seemed to be a little flat in the midrange. By the third day, though, the ECM had learned the new AFV and the bike kicked butt! I'm sure the TPS is fine and after a few miles it will run just fine. BTW, I did not reset the idle. After running for a few minutes the ECM reset the idle back to the correct RPM as well. Keith PS Plexiglass is an interesting idea... | ||

Ar15ls1 |

Darthane, very well made! I like the plexiglass idea. And yes I did find that there was no room for a third hold down bolt. I did make another one out of 1/4" aluminum and it seems to be a little more sturdy. I have not had any problems as of yet with the tps sensor needing to be reset. I also put my original plate on my buddies stock bike and it seems to run pretty good. He only has about 30 miles on it since I installed it. I do need to check my plugs to see if its running leaner now, but as far as get up and go I am still impressed. | ||

Darthane |

Guys, Well, like I said, I was planning on a TPS reset anyways...my bike still has the annoying stutter every once in a while that seems to plague some XBs no matter what, but at the earliest the reset would be done Friday morning. Since the weather is supposed to be nice all week here (HALLELUJAH!) I'll get a couple days of riding in for it to hit the books and relearn the proper AFV. I did notice that it started to idle higher and higher as the day went on, so I'll probably end up pulling it down a bit within a day or two. Bryan | ||

Darthane |

Ar15ls1, What exactly did you use to glue your velocity stack back together? I got a 2 part epoxy here that will bond flexible rubber, but it says it is not recommended for temps above 200F and I believe that the intake at the throttle body will get hotter than that. Bryan | ||

Ar15ls1 |

I used a blue lawson high temp rtv(silicon)You just have to let it dry for a couple of hours. Granted its not the prettiest finish but I was not to worried because nobody will see it anyway. I fit the wide end back over the end tube and then siliconed it. I smoothed the rtv out with some rubbing alcohol and my finger. Wish that I could just show you but I still have not gotten access to a digital camera. | ||

Darthane |

Well, I decided to just give this epoxy a shot. I hacked about 1/2" - 5/8" out of the tube itself, beveled the inside edge, and slid the funnel over the smaller tube that leads into the throttle body. It came out really well, and the top of the funnel is now well over an inch lower than before, which personally I think will help. The bike seemed flat without the funnel on it, so hopefully this will cure it (will know tomorrow morning when I ride into work). They don't call it a velocity stack for nothing. My brain was elsewhere and decided to forget fluid flow dynamcs when I hacked it off... I'm hoping to get it on the dyno Friday morning before I head off for the NE adventure. Will post the sheet if I get the chance.   Bryan | ||

Ar15ls1 |

Bryan, your velocity stack came out really well.That is almost exactly how mine looks except for my blue rtv. Hurry up and get those dyno numbers. I am anxious to see the improvement with the stack and the airbox. | ||

Blake |

Ar15, As the O2 sensor can be extremely sensitive to components in some RTV silicons, if the RTV used on your velocity stack was not labeled as safe to use with O2 sensors, you might take note of any detrimental effects and be prepared to replace the sensor with a new one. Darthane, Constituents of epoxy may have similar effects, I'm not sure. Just something you might want to be aware of in case the engine starts acting up in the near future. | ||

Darthane |

Blake, Noted...this is a trial run (albeit a 3000+ mile one). I will be taking the airbox cover off several times to inspect everything in there along the way. I am also bringing an extra plexiglass cover plate and a razor - if I note the epoxy doing anything funky - -=shnick!=- - off it comes and I'll live with a slightly flat bike for a while until I get my hands on a new stack. Not overly worried about it. The bike was very happy last night, but obviously it needs to be run up to temp and a longer duration to be sure. Bryan | ||

Ar15ls1 |

Blake ,I have had this on the velocity stack for about 5 months now. I think if I would have a problem , it would have happened already. This rtv is pretty good stuff too. I dont see it coming off without me peeling it or cutting it with a knife. Darthane, you said that the bike feels flat without the velocity stack? i know I picked up just over 2 hp with the stack off. I did loose 1-2 lbs of torque without it. This may be what you are feeling. Also , you should not see 200 degrees inside of your airbox. You would probably have some detonation problems if you did. Im sure the temp is not much over 130 or so. Air will be passing through there pretty good. | ||

Darthane |

Ar15ls1 (you know, I'm getting really sick of typing that - maind if I call you Joey or some derivative thereof?), Yes, it felt flat, as in it wasn't pulling as hard. Not sure if the SOTP dyno would be able to tell 1-2ft/lbs or not, but I'll take 2.5ft/lbs over 5hp any damned day of the week. As I said earlier, I had a brain fart and forgot my fluid flow dynamics. That funnel is necessary to get the proper airspeed into the combustion chamber (fluids speed up when the diameter of whatever they are flowing through [with a constant pressure] decreases). As far as intake temps go, I know that the airflow will help cool it off, but I bet that the heat conducted through the throttle body to the velocity stack will heat it up pretty good. We'll see. I wasn't referring to the air inside, just the part itself. Bryan edited by darthane on June 04, 2003 | ||

Ar15ls1 |

We think alike! You can call me Joey as long as I can call you Bryan. You could be right about the stack heating up but I still dont think it will get close to 200 degrees. On the ls1 motor that I used to have, the throttle body would get to about 150 degrees but the actual plastic intake manifold(which is closer to the engine) would only get to 110 degrees. Plastic or rubber will dissipate the heat much better. You prefer the bottom end torque where I much prefer the topend hp. I would take 5 hp over a couple of pounds of torque anyday. Torque feels a little better but hp wins races!!! | ||

Darthane |

Joey, Feel free...hell, you can even try to think up a nickname for me, I've never had one that stuck. Spidey's latest one is 'Dreads' shortened from 'Dreadlocks'. Don't ask. Usually he just calls me 'B', but that can get confusing since another in our group is known as ThreeB. LOL Yes, I greatly prefer the torque over top-end HP. I know that sounds kind of odd given my choice of a 'bolt over an older 1200 Tuber, but I fell in love with this bike the moment I saw a picture of it, and every ride just makes it more so. So a tuber can beat me off the line...I walk away from them once past 30mph (over 4500RPMs)...and if a 'bolt can do 0-60 in 3.2 seconds (that was posted here a LONG time ago from one magazine or another), you've gotta figure that they're only beating me for perhaps 2 seconds...hehe...torque's what makes you move, and the only person I'm interested in racing against is myself. Bryan | ||

Skully |

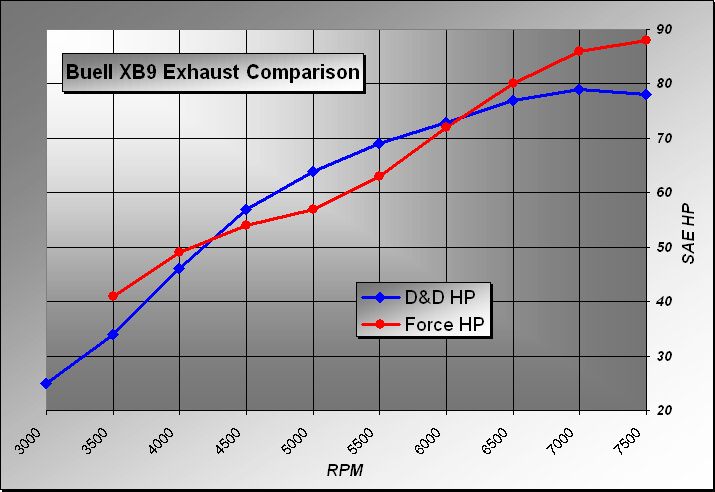

Bryan, I'm very interested in how your dyno run turns out and exactly what modifications you made to the bike that yield those results. Air box, velocity stack, ECM, air filter, exhaust, oil, and anything else that could affect engine performance would be appreciated. I was curious as to how my D&D muffler, K&N filter, Buell Race ECM, and air box modifications stacked up against the Force XB pipe, Power Commander, etc., so I plotted them both in MS Excel and Blake made a .jpg file for me. Check it out:  Buell Exhaust Comparison, D&D vs Force The D&D makes lots of power right where I wanted it for the street. If you are looking for maximum power, the Force is the one. Keith | ||

Darthane |

Keith, Best dyno run to date for my bike was 82.7hp@7500RPMs and 66.2ft/lbs@5400RPMs. Wish I still had that sheet, I gave it to a friend to he it scanned and never saw it again. That was with just a Buell Race Kit and synthetics in the engine/tranny. The worst of three dyno runs that I've had with those mods was 76.4hp and 62.2ft/lbs, and everyone at the dealer that day agreed that the dyno wasn't tuned right and was reporting 4-5hp low. That was also done after the bike had sat all winter on the same fluids (I know, bad Bryan). The other run I had was 81.9hp and 65.7ft/lbs. Since then I have done the following: Homemade 'Force' style intake - see above posts. Velocity stack shortened ~1" - see above posts. Buell Pro-Series Split V sparkplugs. I will be changing the fluids tonight or tomorrow and get the bike dynoed Friday morning and let you guys know what the difference is. Cross your fingers for 85! LOL...one can wish, right? Bryan | ||

Bud |

Hi, I have cut some holes in my airbox ( skully style ), and it has more bottom grunt now. But the thing that worries me is that the airbox cover ( the blue part in my case ) Is vibrating as a paper leave between my legs, when Iím wacking the throttle I think the sucking force is to blame?? Darthane, Dues your modís to the air intake have the same effect ??? And do you have a feeling that the engine is running to lean ?? Or will the race ecm coop with it Gr, martin | ||

Apex1 |

Bryan, The high idle issue you described above is not AFV related, it's simply too high an idle setting. Even though you've adjusted it within the factory settings, if you back it down just a little it will return to idle properly after being rev'd up. I have experienced this condition on both my X1 and the XB. Save yourself the trouble of having the ECM reset. Hope this helps. | ||

Skully |

Bryan, Have you contacted the dealership where your runs were made? More than likely they still have yours on file and would print them out again. What exhaust system did you have on the bike when you got those results? I'm curious to see what it looks like from 4000 to 6000 RPMs. I just spoke to a friend who claims shortening the velocity stack will hurt the performance. This guy has lots of drag racing experience with Harley engines. It will be interesting to see what your results are on Friday. I still have to wonder if the clearance between the inside of the stock air box and the bell of the unmodified velocity stack is now the limiting factor for air flow. BTW, have you ever seen a comparison on a dyno of standard spark plugs to Splitfire or Split V plugs? The results might surprise you. Bud- Go look at Blake's post in this thread on 21 May. It shows the A/F ratio for my bike with the air box cover completely off. The bike is rich through most of the RPM range. It is no where near being lean with the race ECM. I've not yet noticed any of the "tank" cover vibrations you are referring to. BTW, you have a lot of your information "hidden" in your profile so that no one can view it. Did you set your profile variables that way intentionally? Good stuff guys! Keith | ||

Darthane |

Skulley - I have always had them done at the same place, American H-D, where Spidey works. I will ask if they have them on file somewhere when I go in Friday. Every time it was at an open house with free dyno pulls, I don't know if they would have kept those or not. All runs were made with the Pro Series Race Muffler (a.k.a. Fetal Pig). The torque curve path on it is virtually identical to the one on the Buell website. VERY distinctive. We'll see, I suppose. I have to think that having the top of the velocity stack a mere 1/2" from the top of the filter is an impediment to airflow. No, I haven't - can you shed some light on the sparkplug comment? I switched on the recommendation of a fellow 'bolter. Spark plugs are cheap, though, so if there's a better one I've no problem switching. Bud - No, I have not noticed anything other than an increase in valvetrain (top end) noise, but I have no upper airbox cover at all, just a plate to seal off the top of the filter. I am not the right person to ask about rich/lean fuel mixtures. I simply don't have the experience to say one way or the other. I will see if I can get a A/F mixture plot along with the dyno run this Friday. Bryan | ||

Blake |

Dart, There are two "Skull" monikered users one "Skully/Keith" and another "Skulley". Take care with your spelling.  Keith (Skully), I think the guy you are talking to is concerned with top end HP and also may not be considering the other possible reasons (noise reduction, compatibility with stock airbox and intake tract) for the stock velocity stack design. His apparent assumption, that the stock velocity stack is designed for optimum peak HP, may therefore be incorrect. The dyno doesn't lie. We shall soon see eh?  Dart, If you can get copies of your actual dynojet data files (.001, .002, .003... and so on for each successive run) and send them to me, I can post the charts for you. Spidy, a little help (with Dart's permission of course)? There's a more to street engine performance than just the peak torque and HP values. We wanna see the whole plot.  |