| Author |

Message |

Ft_bstrd

| | Posted on Thursday, September 28, 2006 - 03:32 pm: |

|

It's ok Whodom. Very much Treky here! |

Xbimmer

| | Posted on Friday, September 29, 2006 - 11:27 pm: |

|

Fan still rattling and of course running much less now due to cooler weather. Maybe I've become normalized but it doesn't seem to vibrate as much as before.

At 9.5k now but if it fails I have a new one in a box two feet to my right.

Affected of course by the cooling effects of my RSS the fan has to undergo some weird cycles this time of year in CA. Wee morning hours on fwy 85+ and no fan until shutoff (maybe), yet afternoons ambient enviro temps increase significantly enough to kick it on occasionally.

Couple days ago I rode home pretty briskly and it was pretty warm out so when I shut down the fan kicked into highspeed mode.

With wild hair inspiration I grabbed a drugstore receipt from my tankbag and held it in front of each scoop alternately.

Held at the top edge of each scoop, the thin paper pulled equally into each opening. Not a lot, but when it shut off the paper ceased movement. Blocking each scoop in turn produced no appreciable change in paper reaction while the fan was running.

Aside from the implications that the RSS might actually work with and not against the LSS this supra-unscientific experiment indicated to me at least that the fan does pull some serious air and it seems that it ought to be a highest quality long-life part. |

Electraglider_1997

| | Posted on Saturday, September 30, 2006 - 11:13 am: |

|

I hope Buell is taking this fan issue as seriously as Husky. This is good stuff.

My fan takes a long time to come on while riding these days. Most of the time it only comes on when I shut down. Nebraska temp has dropped quite a bit since the terrible heat wave that ended over a month ago. I don't know much about electric motors but maybe Husky can tell us if a brushless motor would be better or even possible for this application??? |

Xbimmer

| | Posted on Saturday, September 30, 2006 - 07:51 pm: |

|

How does a brushless motor work?  |

Lowflyer

| | Posted on Saturday, September 30, 2006 - 09:13 pm: |

|

Brushless motors work by electronically switching the motor current on and off in the different windings. |

Xbimmer

| | Posted on Saturday, September 30, 2006 - 10:05 pm: |

|

Got it. Thanks!

Would I be correct in assuming then that without frictional resistance from brushes against a commutator (?) the armature windings could be smaller/lighter, and/or the motor could turn faster with less power?

Electrics ignorant here... |

Jlnance

| | Posted on Saturday, September 30, 2006 - 10:24 pm: |

|

Xbimmer - no, the advantage of the brushless design is an increase in reliability due to not having brushes. Another is not having losses associated with the arcing that happens with brushes. But the windings are the same size. |

Xbimmer

| | Posted on Saturday, September 30, 2006 - 10:46 pm: |

|

Thanks!  |

Electraglider_1997

| | Posted on Sunday, October 01, 2006 - 12:22 pm: |

|

Probably Buell went with a brush motor to save on cost but those savings have certainly vanished. Just my guess. |

Ft_bstrd

| | Posted on Sunday, October 01, 2006 - 09:45 pm: |

|

I would say that there is a degree of simplicity in the motors with brushes vs. the brushless design. Cost probably factored into it as well.

It's a manufacturing gamble folks. This is the benefit of owning the first year's run of a new model. The good news is that Buell, for the most part, has been interested in identifying and dealing with widespread issues. I'm still trying to decide if the fan issue is widespread. I can't tell if there are only 15 Ulys owned and all the fans are bad or we only have 15 bad fans in all of BadWeb. |

Husky

| | Posted on Monday, October 02, 2006 - 07:13 pm: |

|

I have completed my analysis of the Ebay Fan I talked about in an earlier post on this thread.

For recap, here is my original post:

............................

Archive through September 28, 2006

The Bad Weather Bikers' Buell Motorcycle Enthusiasts' Discussion Forum: Big, Bad & Dirty (BadWeB Adventure Board): Fan Failure Thread: Archive through September 28, 2006

Posted by Husky on Sunday, September 17, 2006 - 04:38 pm:

I received the Ebay fan Saturday and started to check it out. It runs with lots of fan blade whine but no noticeable bearing noise. The fan is supposed to be salvaged out of a bike with 260 miles on it.

I wish I had measured the fan speed before I disassembled it. I need the info to calculate the expected fan life. I had to drill out part of the fan hub to get the propeller off.

Fan Components1

Fan Components 02

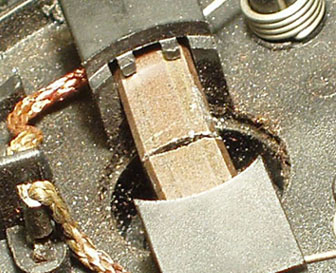

The following picture is of the plastic end cap assembly from the motor. The bearing grease is starting to spread out of the bearing mount hole onto the face of the end cap and onto the brushes and brush holders. You can also see the specs of brush dust clumping on the film of grease.

The brushes, brush holders, and armature commutator had a very light film of grease on them, like from a very fine light spray or mist.

Grease spreading on End Cap and Brush assemblies

Most of the grease was coming from the bearing on the commutator end of the motor. There is a fiber washer on the armature shaft, between the bearing and the commutator. I noticed the outside diameter of this washer and the end of the communicator were wet with grease. The washer was tightly clamped between the bearing seal and the end of the commutator. I pried open a gap between them (I'm afraid the commutator shifted on the shaft toward the windings when I pried) and the washer had been rubbing on the bearing seal. Grease had been flinging out of the bearing past the seal onto the washer and then out onto the areas described above.

Fiber Washer on Armature

The bearing seals do not look like contact seals to me. They are good quality, but do not appear to be contact seals and I am guessing at the seal material (viton). Therefor lubricant and vapor can easily get by the seals. The grease looks like a synthetic.

The bearing on the commutator end was made by NMB, Basic part # R-1350. The bearing on the fan end was made by NTN, basic part # 695LA.

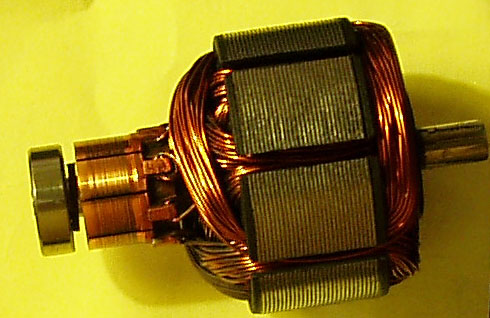

The light scoring you see on the commutator is from the brushes, which are fabricated with scored ends to facilitate the brush break in process. This allows the brushes to quickly wear to the exact radius of the commutator. The brushes still had the break in bars, indicating it was a very low time fan assembly.

So where am I at on this problem?

I don't like the fact lubricant has already exited the bearings and mad its way to the motor brushes and commutator.

I suspect the bearing seals are a main part of the problem.

I don't care for the fiber washer being included in the design because it can be compressed onto the seal surface which is not rotating while the shaft and washer are.

I really don't know what the seals are made from, what the lubricant is, what the fan speed is and what the fan temperature is.

I need some help here to finish up. Does any one have a reliable cylinder head temperature for normal riding or maybe the air temperature coming out of the fan under those conditions (at the exit face of the fan)?

Does any one know the fan speed (rpm)?

I need this data to plug into the bearing life formula.

...........................

Now for the new information.

The fan speed was 6994 rpm at 14.68 volts (terminal voltage auto engine running, and 6176 rpm at 12.8 volts engine off.

Temperatures provided by "Teeps" were 300 to 336 degrees F as measured by an IR sensing thermometer. I chose 300 degrees F as the baseline temperature and assumed that temperature as a worst case for the entrance to the fan.

Fan bearing temperatures typically reach a temperature 54 degrees higher than the ambient air. This added to the fan inlet temperature gives us a bearing temperature of 354 degrees F (179 degrees Centigrade) which I used for my life calculations.

1. The bearing material appears to be 52100 per ASTM A295 which has a maximum operating temperature of 250 degrees F. For our operating temperature we should be using Heat Stabilized 440 C per ASTM 756 or M-50 steel. This is probably the largest contributor to the early bearing failure.

2. The bearing lubricant is probably G2 grease, packed to a 35% fill, so I use it in my "as is condition" life calculations. The G2 grease has an upper operating temperature of 250 degrees F, but more importantly, its viscosity at 354 F is only 0.847 Centipoise and this bearing requires 15.1 centipoise at 354 degrees F to achieve maximum bearing life. We should be using a grease like Braycote 601 or Dupont Krytox 240AC per Mil-G-27617 which has a viscosity of 38 centipoise at 354 degrees F. This grease also has the unique properties of excellent oxidative stability, does not creep, is water resistant and chemically inert. Due to the low speed, I would recommend a 50-70% grease fill on the bearing.

Use of the G2 grease at the 354 F temperature reduces the bearing life by 90 % (assuming the basic bearing material is suitable for the temperature).

3. I have no doubt that the bearing in the fan had a standard Class 2 internal clearance. For this application where the temperatures are so very high we should use C3 or maybe even C4 internal clearance in the bearing. This could extend the bearing life significantly at the load and temperature levels we are using.

4. We are not sure of the bearing seal materials. We should be using metal reinforced Viton contact seals to retain the grease and prevent grease contamination by debris from the brushes.

Calculation results:

I used data and the online Calculations feature in the engineering section of the SKF web site http://www.skf.com/

I used data from the NMB web site http://www.nmbtech.com/miniature_precision_ball_bearings_assemblies.htm

I used data from a Barden Corp. Precision Bearing Catalog.

The baseline life calculation assumed the following factors:

Bearing ring and ball material was STD 52100 steel.

The lubricant was G2 grease at a 35% fill.

The seals were contact seals.

The internal clearance was std at C2.

The bearing fits to the motor interfaces were not affecting the internal clearance.

The motor speed was 6994 rpm.

The bearing loads were 2 Newton radial and 5 Newton axial (1 newton is 0.2248 lb).

The bearing temperature was 179 Degrees C (354 degrees F). This could be debated by thermal guys, but if some one would put a thermometer right at the exit face of the fan exhaust we could refine the calculations

The baseline calculation indicated the bearing was 90 percent likely to have a useful life of 87300 hours.

Since the fans were lasting about 3000 to 6000 miles, I assumed an average driving speed of 45 miles per hour to get a demonstrated life of 66 hours as the time they started to get noisy to 132 hours when they actually stopped running, which is quite different from the 87300 hours the life calculations gave.

In my opinion, the reason is the wrong materials and internal bearing clearances are being used in the bearings.

Just for kicks, I changed the loads on the bearings to 100 Newton radial and 22 Newton axial and ran the calculations again. I got a life of 1650 hours for the basic bearing and only 170 hours when including the lubrication factor (G2grease).

So there it is!

The brushes in the motor are quite short, and I could not tell from the pictures "Chief" posted how long they were, so I do not want to predict how long the fan would last if not for bearing problems.

But, the 89 Astro Van I drive has over 246,000 miles on it. The cabin air circulation fan is run 100% of the time, usually at mid to full speed here in California's furnace like weather, and it still has the original fan in it.

In summary, I recommend the following changes be made to the fan.

1. Change the bearing ball and ring material to Heat Stabilized 440 C per ASTM 756 or M-50 steel.

2. Change the grease to Braycote 601 or Dupont Krytox 240AC per Mil-G-27617. I would recommend a 50-70% grease fill on the bearing.

3. Change the bearing internal clearance to C3 or maybe even C4.

4. Change the bearing seals to metal reinforced Viton contact seals.

5. The Fan company (SPAL) should review their fan motor assembly procedures to make sure they are not distorting the inner race on the commutator end and the outer race on the fan end of the motor with their staking procedures.

Regards,

Joe |

Lorazepam

| | Posted on Monday, October 02, 2006 - 09:39 pm: |

|

Wow, thanks for the report. Badweb certainly has an incredible group of folks.

So, how many fans do we have to order to get one with that spec? |

Brad1445

| | Posted on Monday, October 02, 2006 - 11:20 pm: |

|

great report Husky,

Now for improving the sound?

|

Blake

| | Posted on Monday, October 02, 2006 - 11:48 pm: |

|

Would be interesting to hear some feedback from some anony on your analysis Husky. Great stuff! |

Whodom

| | Posted on Tuesday, October 03, 2006 - 06:23 am: |

|

Husky,

It sounds as if it would be possible (although probably relatively expensive) to retrofit a stock fan with these modifications? |

Aeholton

| | Posted on Tuesday, October 03, 2006 - 07:41 am: |

|

Thanks for your time and effort, Husky! Great report. As Blake said, it would be nice to see some sort of Anonny feedback on your analysis.

As an aside, I am constantly amazed by the abilities of the folks here on BadWeb. You guys are awesome!

(Message edited by aeholton on October 03, 2006) |

Jlnance

| | Posted on Tuesday, October 03, 2006 - 08:23 am: |

|

Now for improving the sound?

Fan noise is mostly the result of turbulance produced by the edges of the blades. It is possible to make quieter fans by changing the blade shape. A lot of effort goes into producing submarine propellers which are quiet. Of course no one is going to share with us the design of a submarine propeller, and it might not work well in air in anyway.

But it should be possible to make the fan quieter and still move the same amount of air. I'm sure aircraft companies have the software to model things like this. Cough Blake cough. |

Whodom

| | Posted on Tuesday, October 03, 2006 - 08:35 am: |

|

Here's the solution to the fan noise problem (if we can just figure out where to put it):

http://www.bigassfans.com/

|

Doncasto

| | Posted on Tuesday, October 03, 2006 - 10:06 am: |

|

Inquiring minds want to know . . .

. . . .Was the stock Uly fan spec'd and ordered by the same person that spec'd and ordered the Showa shocks in 1999?

. . . . . . .Now that a Badwebber (great job Husky!) has done their work for them, will someone at HD/Buell actually open up the corporate coffers wide enough to purchase and supply fans that will actually work in the Buell environment?

. . . . . . .Assuming that my perception that heat dissipation remains a substantial unresolved Uly challenge, can HD/Buell afford NOT TO get very busy on providing a proper solution.

YMMV . . .I continue to have tube frame flashbacks. |

Lowflyer

| | Posted on Tuesday, October 03, 2006 - 11:04 am: |

|

That's weird, I just had yet another flashback to a stupid-ass 80's commercial for a supermarket tabloid.

(Message edited by lowflyer on October 03, 2006) |

Electraglider_1997

| | Posted on Tuesday, October 03, 2006 - 11:21 am: |

|

Whodon,

Sorry but I'm just not a fan of bigasses.

(Message edited by electraglider_1997 on October 03, 2006) |

Thunderbox

| | Posted on Tuesday, October 03, 2006 - 11:32 am: |

|

Hey Husky is the fan assy easy to take apart and would it be easy to put back together again using the bearings you suggest? If that is the case I won't worry about my fan failing again. I'll just do a bearing upgrade when it starts to make some noise. Thanks for the great write up. |

Husky

| | Posted on Tuesday, October 03, 2006 - 08:46 pm: |

|

Thunderbox wrote:

Hey Husky is the fan assy easy to take apart and would it be easy to put back together again using the bearings you suggest? If that is the case I won't worry about my fan failing again. I'll just do a bearing upgrade when it starts to make some noise. Thanks for the great write up.

No its not easy to disassemble.

1. I drilled out the ultrasonic welds on the fan hub to get the fan off the shaft and used ABS water pipe cement to reattach it to the fan shaft. make sure you let it cure for a few days at high temp (200 degrees F) before using the fan.

2. The seal between the plastic end cap and the metal motor housing is a high temperature adhesive which is very hard to breech. I used 2 screw drivers between the plastic end cap (see 2 small openings in the edge of the end cap) and the metal housing to pry and tear the adhesive. You got to be careful going in deeper than 1/4 inch because this is also the area where the brushes reside. It took me about 15 minutes to get it off without damaging anything.

3. The fan end bearing is staked into the metal housing (staked over the outer race).

The only way to remove this bearing is to press the old one out using an arbor press.

Then install the new one and carefully tack stake the outer rack of the bearing in place by using a very sharp small center punch on the metal housing OR just clean the mating metal surfaces real good with brake cleaner or contact cleaner and use Loctite Stud mount to mount the bearing in the housing.

4. The communicator end bearing is staked onto the armature shaft and will have to be remove using a miniature bearing puller. Do not try to pry it off or you will shift the commutator and maybe ruin the motor.

Install the new bearing and stake the end of the shaft in 3 places with a very sharp center punch to secure the bearing.

The other problem may be the availability of the proper bearing with the proper lubricant. I will check and see and let you know.

Joe

(Message edited by Husky on October 04, 2006) |

Ft_bstrd

| | Posted on Thursday, October 05, 2006 - 10:32 pm: |

|

More failed fans? |

Ft_bstrd

| | Posted on Monday, October 16, 2006 - 07:29 pm: |

|

Mine has started "rattling". 4,400 miles. Manufacture date 11/05.

It's only barely audibly perceptible, but I can feel the additional vibration through the seat (Yeah, I know. The Princess and the Pea.).

I called the dealership and told them the fan was rattling. No questions asked, they ordered the fan and will install it at my 5,000 mile service.

(Message edited by ft_bstrd on October 16, 2006) |

|