| Author | Message | ||

V74 |

This might not be relevant but the first time I pulled the rocker covers I couldn't believe the amount and size of the flash along the casting lines on the inside.i could pull some away easily and bits where say 5×3 mm in size.i removed all of it with a dremal but had nightmares about any already detached and floating around the engine. | ||

Kalali |

Isn't it why there is an oil filter? | ||

Shupe |

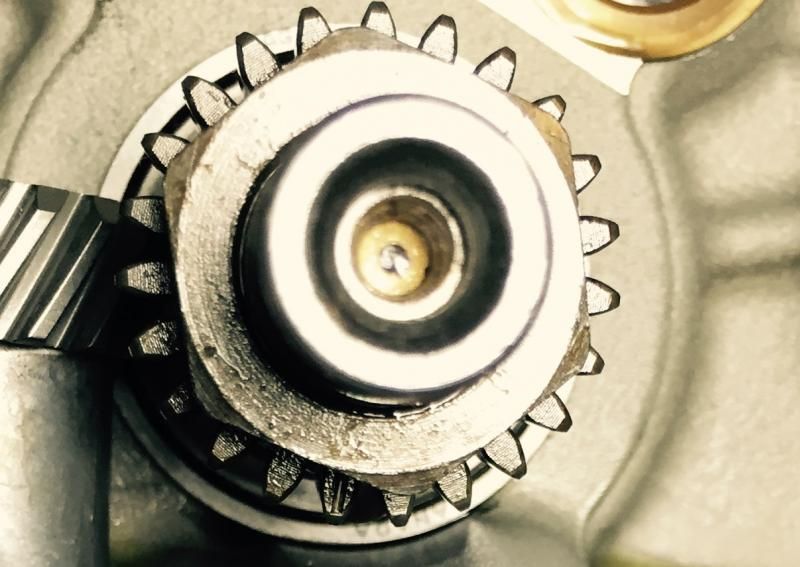

Here's a shot of the end of the pinion gear. It's hard to get it to focus, but you can see a piece of junk in there. I tried sucking it out with a shop vac sealed to the end of the pinion, no luck.  | ||

Reepicheep |

Dumb question, but is that even an oil galley? Or is it just a divot for machining the cranks originally, and a divot for a gear puller? I have many Buell parts here on my desk to look at, but not a crank. Yet.  | ||

Natexlh1000 |

If that's the oil passage that leads to the lube holes in the crankpin, there would have to be "plumbing" in the pinion side wheel. Is this the case? | ||

Odd |

Yes that is a oil passage, you have to get that piece out of there. Oil goes through the flywheel starting there. | ||

Reepicheep |

Is it a pressed in brass jet of some kind? Looks like it. If so, could you drill it out and clean the whole mess then just press in another one? Looks like something you could do without removing the crank. | ||

Oldog |

that oil feed goes straight to the crank big end bearings not good. I would try to pick that out I have had that area appart and do not remember a jet of any kind | ||

Kalali |

Is that supposed to be through hole? Looks blocked by that brass color plug.... | ||

Kalali |

Is that supposed to be through hole? Looks blocked by that brass color plug.... | ||

Odd |

Brass plug is pressed in at the factory, the size hole in the plug determines the oil pressure | ||

Shupe |

Is it a pressed in brass jet of some kind? Looks like it. If so, could you drill it out and clean the whole mess then just press in another one? Looks like something you could do without removing the crank. I'm considering that. If any chips get further in, I'm no better off. Plus I'm wondering if any of the junk already got in there and to the crank/rod bearings. | ||

Odd |

did you try duct taping a 1/4 inch hose to your shop vac and then sealing it to the flywheel end for more suction? | ||

Natexlh1000 |

Can the brass plug thing be removed and replaced with the engine still together? If so, you would perhaps have a better view inside the shaft for other surprises. | ||

Reepicheep |

I would also spend some quality time on the milk crate and figure out if there is another place I could get at "upstream" of there, and put 90 or 120 PSI in that has to come back out through that passage. | ||

Oldog |

I wonder If this is a precursor to big end failure, and as I sit and think on it it might explain what has happened to any number of the cranks that have failed... | ||

Bueller_bueller |

Not wise enough in the ways of Buell motors to comment about the reason for the brass plug, but chip removal looks easy... Go to Harbor Freight- get a set of dental picks. Many have a 30 to 40-degree angle at the tip. Carefully guide it out onto a clean rag, so it doesn't fall someplace you don't intend. The shop vac method will probably fail, because the diameter of the plug orifice isn't sufficient for enough air to flow through. Hope this helps... M | ||

Reepicheep |

A google image search for Buell crank does seem to show that brass jet in a few pictures. I'd start with a dental pick also, and see how far the rabbit hole plug goes. | ||

Oldog |

This sounds nuts and may not work can you put compressed air in to the timing plug hole with all vent and oil lines clamped or blinded off, the thinking is to try to blow the chip out of the orifice | ||

Reepicheep |

I don't understand how the oil gets routed in there in the first place! Its not like there is an oil fitting on the other end of the crank... Google images kinda helps, kinda doesn't. My service manual (at home) might have oil system schematics. Some nice crank pictures here from EricZ's turbo adventures. http://badweatherbikers.com/buell/messages/32777/6 53230.html?1317385800 (Message edited by reepicheep on November 12, 2014) | ||

Screamer |

Oil is fed to the end of the pinion shaft through a passageway in the cam cover. | ||

Reepicheep |

That's good news then, in that the clog you see should come out from the direction you see it. Hopefully it was all big stuff and it jammed in there right away. | ||

Shupe |

I already tried the dental pick - that's how I got the small piece out already. Tried again this weekend with that and a ground down tweezers. There's no way. I'm going in with a drill next. I'll pick up a very tiny bit. Wish me luck. Shupe | ||

Jayvee |

Did you try a magnet, like those skinny 'pick-up' magnets | ||

Reepicheep |

Its the opposite of what you want, hard metal you want out embedded in soft metal you want in. I think. It looks like a brass jet pressed in there anyway. On the upside, if that is the case, it should be easy to get a replacement jet off the shelf or machined to fit, and then you can just drive it or epoxy it in. | ||

Firstbuell |

why is there so much guessing & so little "do EXACTLY this" XL-informed direction here? I sux at BadWeb search - is there a similar issue archived or current in the Tech section? | ||

Alfau |

A 4mm Cobalt drill would be my choice.(very hard, almost unbreakable) I had a look at my stuffed set of x1 flywheels. Using venire callipers, it's a 4mm hole 12mm in to the oil jet from the very end. It might be time to see if you have favour with the big fellah. Pray as you drill. | ||

Reepicheep |

I've been reading threads for a long time, and I don't ever recall the question being asked. Surely it has happened before though, so it might be worth some google searching. | ||

Alfau |

I've been reading threads for a long time hundreds of oil pump failures, far too common and as long as you own a buell you will need to keep reading threads. A bigger piece of shit you'll never find anywhere in the world | ||

Alfau |

I know that seems harsh but reliability is what sells motorcycles , not noise! |