| Author | Message | ||

Barrick09 |

Been a long time since I've posted. Been doing jeep things all winter but it will soon be spring and time to fix my buell!! So a little background on the Problem. 6 months after getting my 99 X1 the rear cylinder gasket blew out. So I had it rebuilt and the gasket replaced. This lasted a week and it blew out again! This time I had the surfaces all done, new cylinders, rings etc etc, the whole 9! This fixed everything and the bike ran great for a season, then half way thru last season about September 2013, the front cylinder blew out exactly like the rear the season before! I always let the bike warm up till the heads are hot to touch, almost never go over 70, never past 4k rpm. I baby this bike, so what the cause of this blowout problem every year?? What can I do to prevent this this year when I have it fixed next month? The first time it blew out when clutching, this time the front was when i went to start the bike, as soon as i hit the button, Bang! and i felt it on my leg. As a note I run Straight pipe exhaust. that's my only confession/idea to the cause> Any advice would be of tremendous help! | ||

Phelan |

Sounds to me like the headbolt breathers are clogged. | ||

Lynrd |

mmmm Lets look at the facts: 1. Straight pipe 2. Won't get it past 4000 rpms. 3. Lets it "warm up" until Heads are hot to the touch 4. Never goes over 70 You don't think the bike is running real lean or fat from the straight pipe and low RPMs, and is overheating? I sure think so. What kind of FI map is going to allow for a damned straight pipe and a 4000 RPM power band with Cams that really work at about 4800?? Deck your heads, deck your cylinders, buy a muffler (OK, you can have a loud one if you must) and start using the Rev limiter as a shift indicator. If you can't get it past 4000 RPMs, you're lugging the engine, if anything, which won't blow head gaskets but will wear your bores faster. Clogged head bolt breathers - I would expect blown rocker box gaskets, not head gaskets. Bad warm up procedure (starting out too cold) I would expect leaking cylinder base. | ||

Barrick09 |

Could be, my X1 has a mikuni carb, and the lines that come off it have a filter on it, I've replaced/changed this a couple times but it always seems messed up/dirty, I think its supposed to be an actual "catch can" but mine is not. here is the only pic i could find that shows it. see the small filter just above the shift lever and below the frame. Get a better photo of the actual set up tomorrow morning.  | ||

Barrick09 |

Bad warm up procedure? (to cold) as opposed to what? This bike almost red lines at 5,500, I generally shift at around 3,500 - 4000 which is well within the norm. | ||

Kalali |

I don't think the warm up procedure and/or keeping the engine speed at 4K has anything to do with this issue. That's how I treat mine with only occasional 5K+ shifts in second or third. In my book using the rev limiter as shift points is same as thrashing the bike. But that's a whole different discussion for another time. | ||

Reepicheep |

Straight pipe exhaust? Your problems are caused by bad karma. You are annoying a lot of people around you. | ||

Rocket_in_uk |

I assume you mean head gasket? I assume you mean you don't ride over 70mph or 4000rpm, not the bike won't go over? First it's basics. Correct temp plugs. Ignition timing correct. Carb jets correct / fueling correct. Head off, check combustion chamber size. Confirm pistons suit head / combustion. Determine compression ratio from chamber capacity and piston type. Check squish band. Measure deck height with current base and head gaskets, make sure replacement gaskets correct thickness for deck height / clearance / compression ratio before rebuild. Replace base and head gaskets. Use Cometic gaskets only. Any of Denish's books on Harley / Buell tuning, or Kip Woodring's book, should give you all the knowledge you require in layman terms. Rocket in England | ||

Dannybuell |

Rocket_in_uk ~ excellent thoughtful response. | ||

Lynrd |

By bad warm up procedure, I mean - starting it with the choke on, and leaving it that way after it's running. If it was still Fuel Injected, it wouldn't be a problem, but the enricher circuit delivers a very rich mixture. If you let the engine sit there and idle that way, it is going to get very hot. With no air traveling over it because sit isn't moving... The opposite it to hit the button and just take off cold.- doing that is worse. The engine needs to get to operating temperature gently Best advice is start with the choke, as soon it's running take it to half choke or less immediately, or just turn the choke off and keep it running with the throttle. Let it come up to temperature and go, The idea is just to get the aluminum to all expand with heat evenly. I think Rocket gave good advice. The fact is, if you changed from FI, you also had to install aftermarket ignition. If you're blowing head gaskets, you *could* be pressurizing the breather port - sure - either that, or you either have a top end that was not torqued correctly, or it's getting too hot and warping. Rocket gave a good list of things that can cause the engine to be running too hot - Assuming that the top end was done correctly, all surfaces decked and manual followed with regards to torque values. As far as "Babying the bike" or "Thrashing the bike" by actually using the power band - the red line and rev limiter is there for a reason. If you are short shifting, you are *under* the power band for the bike - shift recovery point for a 4000 rpm shift is going to be about 2200. Don't kid yourself that lugging the engine is somehow better for it than staying on top of the power band, or that riding on top of the power band is equivalent to abusing the engine. As I said before, lugging it won't blow head gaskets - it WILL put wear on your bores and your bottom end. But I agree - that is a bit off topic of this discussion. If it's blowing gaskets from heat I would a long look at your tuning after you get it back together. Straight pipes only work right at a specific RPM, which you normally tune for the shift recovery point. Above or below that RPM they will tend towards lean or very lean. If your timing is off at all, or the carb is not well dialed in for it, you could be detonating - and with the straight pipe, you may not be hearing it. That makes a LOT of heat - if it doesn't just take the top end out on it's own. Wait - did your ignition module call for a VOES switch when you changed ignition? Did you install it? No VOES means it's going to run full advance all the time - which again, will lead to detonation and excess heat. The way this new failure happened - right at startup - sounds like the engine was too hot when shut down last ride and didn't cool evenly. So when you hit the starter, the gasket was ready to go. | ||

Barrick09 |

Thanks for all the info. I have already Purchased a new pipe for the bike. which actually isn't nearly as loud as a lot of the jap sport bikes around where I live (downtown Pittsburgh). Anyways, when it was rebuilt the guy who did it did an amazing job and is very reputable. I know he followed the torque specs etc. cause I remember him having to find the numbers when he did the rebuild. Not sure on the gasket but i vaguely remember the cosmetic on being the only one he could find available at the time. I'm really not that concern with the rebuild as much as I am with what i can do to prevent this in the future. How often should I check head bolts? Or what should I check often that is known to come loose? how often should I Have the carb re-tuned/checked? I'll post some really detailed pics of the carb "catch can/breather" set up and hopefully someone can recommend better setup than is currently on there. IS there something i can do after a ride to help it cool down better? I've never had an over heating issue before, even in stop and go traffic it runs amazing and not really that hot. Again any preventative things I can do after a ride, once a week etc? to prevent this? Also regarding my start up procedure, 90% of the time i start with the choke them almost immediately turn it off and use the throttle to keep it from stalling, the other 10% i just push the button and it starts and runs without ever needing anything but maybe a little gas. Thanks again for the feedback. | ||

Hootowl |

When you say cylinder gasket, do you mean the base gasket, or the head gasket? Or the rocker box gasket? Base gasket blowing may be breather related. Make sure the breather lines do not run up hill anywhere along their path to the catch can. If it's the rocker gasket, you simply need to use the new metal gaskets. I rarely rev past 4K either. No need to on the street. I'm not having issues like these. Have you tried aftermarket gaskets? The metal cometic ones are pretty stout. | ||

Firemanjim |

Several things will lead to head gasket failing, esp on the early tubers---- improper torque, not cleaning threads and oiling as per manual, the early HD gaskets sucked, use Cometic gaskets, and the stock cylinders are known to separate and the inner liner will raise causing gasket to fail there, you can see if this has happened, running your finger nail across will catch on raised section. Cylinder needs to be tossed. | ||

Rocket_in_uk |

I'm really not that concern with the rebuild as much as I am with what i can do to prevent this in the future. Fatal mistake. This is the first thing you should check. Without knowing what is in that engine you have no idea what you're up against. You say your builder is reputable and you think they used Cometic gaskets as they're the only ones available. They're also available in different thicknesses, of which the wrong thickness of base gasket and head gasket could have you quite easily running a compression in excess of 11 - 1. If so and you're running on low octane, your problem could be right there. At the very least you should be going to your builder and finding out exactly what he did. Without this knowledge you really need to be pulling the cylinders off and finding out what I mentioned above. Think of it this way. You have to pull the head to repair it anyway, so it's dumb not to pull the cylinder and measure to determine where this engine is at. Rocket in England | ||

Ratbuell |

+1,000 - WHAT gasket is blowing? Base gasket - bottom of cylinder, where it attaches to the engine cases. Head gasket - top of cylinder, where the head and cylinder meet. Rockerbox gasket - three levels, actually, if you're using the stock rockerbox setup. Think of a valve cover on a car - they sit on top of the cylinder heads, and on an X1 there is an upper, a lower, and a cap, with gaskets between each layer. If you tell us WHICH gasket(s) is/are blowing, it would help figure out a solution. | ||

Screamer |

If the engine is still assembled, you may want to check the cranking compression on the rear cylinder (or whichever one is not leaking). That might give you a rough idea on how the engine has been set up - or at least a pall park read on cylinder chamber pressures. Less likely, but still worth checking is to make sure that the cylinder studs aren't pulling from the cases. | ||

Kalali |

"If you tell us WHICH gasket(s) is/are blowing, it would help figure out a solution." I was assuming head gasket going by the clue of "felt it on my leg"... | ||

Lynrd |

That was what I figured too - Head gasket it the only one that you could feel if it blew. Screamer - actually a good call - the only time I have had to deal with blown head gaskets it was a bad cylinder stud hole at the root cause - that was a 1993 80" FXR (Cheryl). Didn't figure it out until I was reassembling it and one of the head bolts did not act like it was torqing correctly per the manual. It turns out, one of the studs was "pulled" one was about 80% as bad. I redid all 8 holes with timeserts and she's still on the road 10 years later. Barrick - Carbs do not go out of adjustment - once they are set, they work a certain way - so no need to re-tune EXCEPT if you change anything in the intake-exhaust chain - different air cleaner, a different exhaust, different cams all should come with a re-tune. Technically a large altitude change may cause a different running condition, but that is not something you deal with in normal riding. The only exception I can think of to that statement is that intake seals have been known to fail - that is a known trouble point and a bad seal will make the bike go lean. That can be checked by squirting fluid at the head/manifold joint with the bike idling - a change in idle speed or cadence indicates a leak. Head bolts - ditto - there is actually no way to retorque all of the bolts without popping off the rocker boxes, so it definitely is not routine maintenance. Fireman Jim nailed it: there is a very specific process sot installing the head bolts on an Evo, the manual should be followed exactly. Once they are on right, you should not touch them or have to touch them. My statement about cooling down unevenly has a lot more to do with it being too hot in the first place - Like most everybody, when I am done riding, I park it - no post ride ritual. I do remember to shut off the gas every time, though. Whatever is going on with your engine is NOT normal so I don't think you are going to find a routine maintenance item that would prevent it. It sounds like your warm up procedure is fine. As far as your breather set up - you could change out for the XB top rocker box/ PCV valve units, which is going to make routing lines to a catch can much easier and keep the oily mess in the catch can. Since you see oily mess from them now, I would think that they are functioning normally, but it would be worth verifying. If your system called for threading solid (not hollow) bolts into the heads into the two holes near the air cleaner, you did stop up the breathers. That would be bad. Once the heads are off it will be very obvious if you are dealing with an overheat or detonation issue just from the color and condition of the combustion chamber and piston tops. I don't know if you are mechanically reclined and have the time to spin your own wrenches, but if you have the factory manual, none of the top end stuff is hard - you can just farm out the machine shop stuff out to a good place, either locally or send it off. Dealing with this thing that way would give you an opportunity to inspect the stuff Rocket mentioned and also ensure that YOU can be sure that the manual was followed exactly for the re-assembly. | ||

Barrick09 |

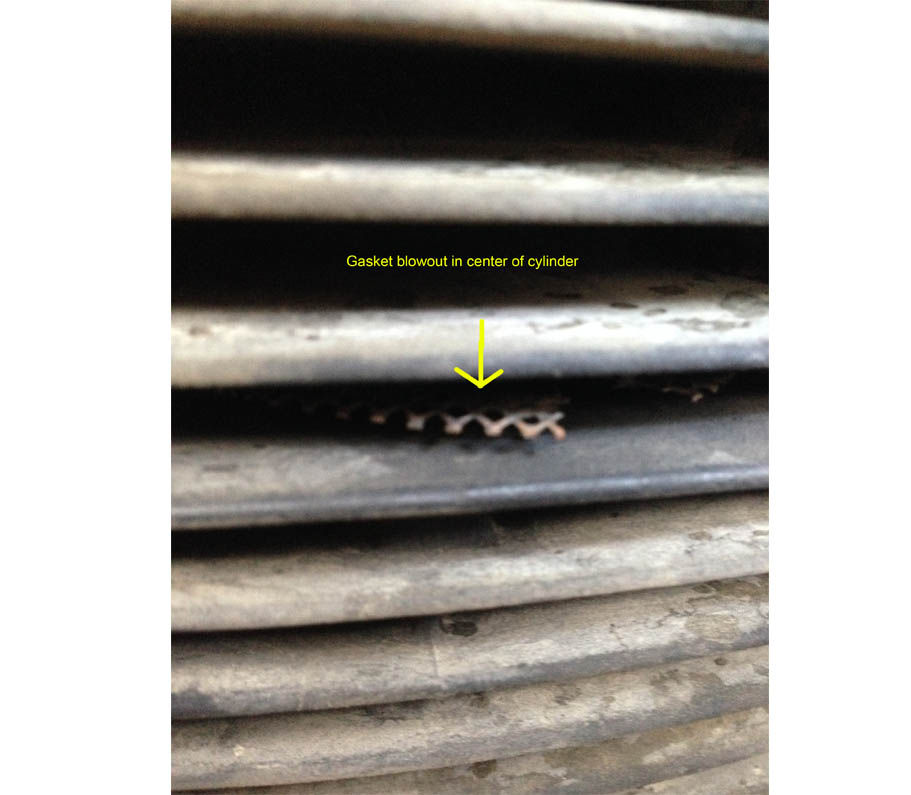

Ok so i took yesterday to take some things off and get some pics. First are pics of the "catch can/filter set up" and finally the last 2 are the pics of the gasket in question. I'll read thru all the post and try to answer any questions the best I can, I appreciate those who are willing to help. If you want to see a specific pic of ANYTHING! just ask and I will get it.      | ||

Firemanjim |

Definitely head gasket. Look for causes listed. | ||

Barrick09 |

Rocket - I understand what you are saying, I wasn't there during the last rebuild (almost 2 years ago), so the details are vague, but I will be there this time so in the future I know how to do it myself. Lynrd - You noted a change in Idle speed. Sometime it will idle kinda high when at a stop and can stay this way for a bit when riding, then other times it's back to the normal idle. This is the only "weird" thing that ever happens when riding. I don't normally shut the gas off, I've heard people say they do but also heard just as many say it doesn't matter etc. sooo ya. Bonus pic of the rear head. Front head is cleaner, no residue around the bolts. And no clue what caused the mark at the rear. Frame?  | ||

Natexlh1000 |

Wow. It actually spat the gasket right out! I hope your head isn't damaged/warped. If you had a muffler, you would have heard the gasket make noise earlier  | ||

Hootowl |

I see your fuel tank and rear rocker cover are intimately acquainted. Mine used to be. I put a rubber spacer under the tank where it mounts in the back. Seat still lines up OK, and it leaves just enough room for the cover not to rub the tank. FYI, the plastic tank is none the worse for wear. If I was a betting man, I'd have gone the other way. | ||

Barrick09 |

ya, spit it right out! When the rear went it was even worse than this, I could actually grab the rear gasket and pull it out almost. I think the head will be fine, unlike last time (when I didn't know what the problem was) I kept trying to start the bike to diagnose the problem also it blew while I was riding and ran for almost 30 secs banging and popping. This time I was much more prepared, as soon as I pushed the start button I heard the bang and knew exactly what it was and didn't try to start it again after that. Can anyone confirm if the set up for this little filter is OK or could be part of the problem? | ||

Hootowl |

Regarding the breather: It looks like there is oil being dumped all over the primary through that filter. I think the idea is that the filter is where it breathes, and the tube with the plug on it is the catch can. That will work, but you've got to orient the filter so that the oil runs into the catch tube instead of out of the filter. Right now, the tube and the filter are both downhill. You need to make the air move uphill a little to the filter, and downhill to the catch tube. A PCV inline with the filter (but not the catch tube) helps. Unless the lines are plugged, and from the oil everywhere it doesn't look like they are, the breather is probably not the cause of the blown head gasket. | ||

Lynrd |

Better yet - get an actual catch can. If you're broke, you can rig up a mountain dew bottle and some duct tape - but a Pegasus can is like $18.00, and other go cart catch cans are right about the same price point. From the picture, it DOES look like it could have burst at the breather riser through the cylinder. You will have to pull the head to be sure of that, I think. That would have not occurred to me as even possible had Phelan not mentioned it, but it makes sense. If that filter is all clogged from that oil blowing everywhere and a plug on the breather hose, that riser would pressurize. The gasket is thinner at that point. There is an aluminum insert and an O-ring that goes there, but that would be a weaker spot in the gasket. Wow. I would not assume the head is fine. A blown head gasket means at a minimum checking BOTH heads on a surface plate. I think I will go hug my XB rocker boxes and catch can now... Oh, and regarding shutting your gas off - it was a bit of a joke on myself - *I* ALWAYS shut my gas off. here's why: http://www.badweatherbikers.com/buell/messages/47623/722687.html (Message edited by LYNRD on March 12, 2014) | ||

Hootowl |

Yeah, catch cans do not have to be elaborate. I'm using a chuck of 1.5" PVC and a couple of end caps with a brass hose nipple and drain threaded on, all nicely tucked under the bike by the rear shock. | ||

Rocket_in_uk |

Contamination of the head or cylinder surface could cause failure of a gasket like that. It only takes a slight scoring of the surface for the combustion gasses to find their way out through such a weakened to sealing area. Of course, a warped head will do similar. I'm still in favour of that engine running too high a compression, too lean a mixture, and maybe too much ignition advance. Rocket in England | ||

Screamer |

The head gasket failure shown in the photo appears to be between the two left cylinder studs (a common location). The drain holes are between left side cylinder studs and the right side cylinder studs - favoring the right side. The gasket does not appear to have failed in that area. The area on either side of a cylinder stud has higher clamp-load and typically will not leak cylinder pressure - most head gasket failures occur (left side) centered between the cylinder studs where the clamp load is lower. Crank case pressures should have little impact on head gasket durability. There are many less durable paths (than the head gasket) for excess crankcase pressure to force it's way out. Plus the head gasket has minimal exposure to crankcase pressure through the drain holes. A head-to-cylinder joint can leak oil at the drain hole area of the gasket but is unlikely to "blow out" leading to a loss of chamber pressure. Although the photos indicate that the breather system could be 'tidied up'', I don't think it's related to head gasket failures. | ||

Lynrd |

I think either is possible, only because I have never seen anyone just plug their breather before. I also agree with the point about clamp load. Any or all of the above could cause this... Well...Only one way to find out... Barrick, please disassemble your engine. We'll wait here...  |