| Author | Message | ||

Rocket_in_uk |

Hmm... Definitely something to think about, anyone have suggestions for an engine enamel that will hold up and not look like crap after one season? Two pack paint worked well on my heads! Rocket in England | ||

Puls4521 |

Hey everyone, I have a question about bleeding the lifters. I followed the manual step by step slowly tightening the bolts in cross pattern and waited over an hour for the lifters to bleed to the point where I would be able to spin the pushrod with my fingers. That point never came. So I took it all back down to make sure I had done it properly. Same thing. Any advice? I really want to make sure I do this right. Thanks everyone! | ||

Puls4521 |

Hey everyone, I have a question about bleeding the lifters. I followed the manual step by step slowly tightening the bolts in cross pattern and waited over an hour for the lifters to bleed to the point where I would be able to spin the pushrod with my fingers. That point never came. So I took it all back down to make sure I had done it properly. Same thing. Any advice? I really want to make sure I do this right. Thanks everyone! | ||

Ocbueller |

A little history may help. What work was just done on the engine? How cold was it where you are working? With recent temps maybe the oil thickness was preventing the lifters from bleeding down in a reasonable time. SteveH | ||

Ocbueller |

sorry just found the rest of this thread. SteveH | ||

Puls4521 |

Thanks for the thoughts! I had the valve train out to take off the cam cover to have it powder coated. I had the same thoughts on the temperature. It's been in the single digits so that could be part of it. So warming the lifters up might be a good start. | ||

Puls4521 |

I had just given up on it for the night and went out for dinner, when I got back the lifters had bled down and I could spin the push rods smoothly. Looks like you were right ocbueller, Must have just been cold oil. | ||

Littlebuggles |

Nice looking bike. Sharp paint, I'd think very carefully about stripping it down and repainting if the current paint is intact. My racing stripes and lettering are vinyl and they have bubbled though, where my paint has remained in good shape since the bike was painted in '06. If you do end up doing paint be sure to give it plenty of cure time before putting fuel in the tank. After a few days of drying I put my plastics out on my deck for a few days until I couldn't smell new paint anymore (as suggested by the painter) then set it in the garage for a few more weeks while I got some other projects on my bike done. Since you've got the X1 mounting block you won't need to mod anything for the swingarm, just swap out to the newer block and swingarm. | ||

Puls4521 |

Thanks for the tips Littlebuggles, I may actually end up painting everything. Before I do anything I want to talk to a few paint shops and get a few tips on how to keep the tank from bubbling. I have read good things about epoxy primer. But it will be a couple months before I have to worry about that! For now, does anyone know what the right upper most hole is for on the motor mount? I dont remember taking anything off of that. Is that a tie bar mount for a different model?  | ||

Littlebuggles |

That is for an additional tie bar originally just on the S3 | ||

Ocbueller |

Glad it was that simple. This cold has been doing some strange things to all items mechanical. SteveH | ||

Puls4521 |

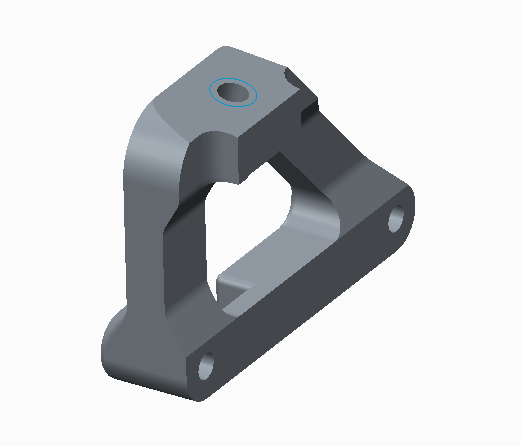

So here is my first shot at a 3D model of what would be a billet aluminum motor mount. I worked with my university machine shop to get all the critical dimensions off the stock mount. From those dimensions I remodeled the part, the general shape resembling the billet mounts that are currently sold. So here is the first rendition, does anyone have any tips or advice to improve?   | ||

Littlebuggles |

They seem really overbuilt to me, considering the cut from billet is so much stronger than the porous cast unit that came from the factory... I wonder if it would be worth the weight savings to make it more of an outline rather than the large solid bulk on the left of the upper image? | ||

Puls4521 |

I know what you mean. So anyone is favor of Version 2?  | ||

Littlebuggles |

Yup, I like that one, lets more airflow through for the front head too. Wonder why no one sells them like that, or haven't I been paying attention? | ||

Littlebuggles |

(Found this, but at 120 pounds, plus shipping and possible import fees and taxes it fairly pricey compared to making your own for school credit, or at least, while you're at school...) http://www.billetbikebits.com/shop/index.php?main_ page=product_info&products_id=70 | ||

Jolly |

Option 2!! How much? I need 2 I think.... Maybe just one..... | ||

Phelan |

I prefer the billet ones here http://www.nrhsperformance.com/partsbillet.shtml They fit all XL/Buell heads, not either/or.  If somehow you manage to break one, they'll replace it free of charge. (Message edited by phelan on February 14, 2014) | ||

Puls4521 |

Thanks for the tips guys! As long as things continue to go well though, I do think I'm going to try and machine my design, nothing against anything out there, they all look like great parts, but I'm hoping I can cut my own for a fraction of the cost! | ||

Jayvee |

Version 2 ! Could the bottom bar be thinner between the head bolts? That bar doesn't even exist on the factory ones. It shouldn't need to be as thick as the top two bars. | ||

Puls4521 |

Ok, so I'm fairly certain this is the final version of the motor mount unless there are any other ground breaking ideas! Let me know what everyone thinks. I'm also currently talking to a CNC machinist, I just sent him this file for a quote. That should help ensure that the part comes out as expected, not that my homemade G-Code crashes the end mill through the vice haha. Here she is:   Multiple things added for V3. The back of the part got cut up to allow for valve cover clearance, also the front lip got a angled slot cut in it to allow the front isolator bolt to be installed from the bottom. As many radii as possible to reduce stress concentrations. | ||

Puls4521 |

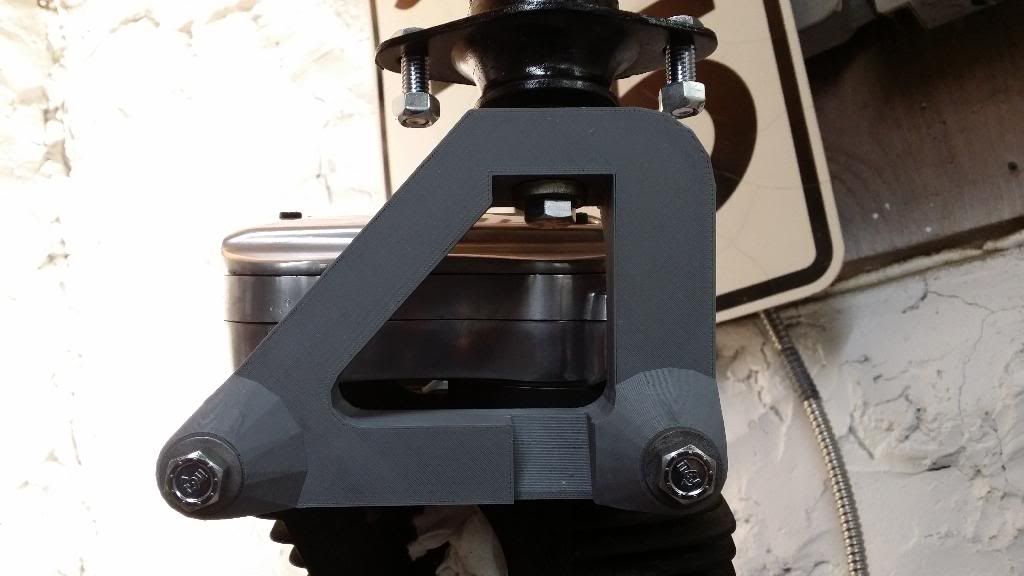

The prototype for my mount just finished being 3D printed! I will post picture of it once I pick it up tomorrow after work, check fitment tomorrow afternoon, if all is good hopefully the chunks of billet I bought will be machined in the next week. On a side note, I bought everything (short of new tires) to make the S1 completely road worthy including: Front LED turn signals, Integrated LED taillight, and CRG Blindsight Mirrors. As well as a pack of resistors to prevent the hyperflash. One final note, I also sent the frame out for powdercoating, and it should be done in about 2 weeks. I was dead set on a matte black frame... until I saw a post from Dutch x1  That was the night before I took it in, I fell in love with that scheme immediately. I definitely dont want to carbon copy (no pun intended) Dutch's bike, as that would defeat what makes Buells so awesome in the first place, their uniqueness. But I love the way the bright white contrasts the dark body work, and really makes the frame pop out and grab your attention. Because if the roar of the v-twin isnt enough to turn heads fast enough to break necks already!  So I went with a bright pearlscent white. and I cant wait to see how it turns out. I also finally got set up to do my own powdercoating, for any parts that will fit in a normal kitchen oven, so I will now be able to do all my own small parts for much less than taking stuff to a shop. (Anyone interested in the southeast WI area interested in having small stuff done feel free to PM me). I cant describe how excited I'm getting to get this thing back together! Its finally feeling like a lot of the pieces are beginning to fall into place! | ||

Jolly |

I agree...the white frame is an incredible contrast and looks great!.. when I am done rescuing this S2 I would like to find a white frame S1 to use all of my spare parts on... OK funny note... I read the last line of your post and keyed in on the following words......powder coating...free...contact me.... had to read it twice to get it straight in my head! post photos of the 3D printed motor mount! | ||

Puls4521 |

Haha! Hey if you pay shipping and material cost, I'll coat anything that will fit into a kitchen oven! www.prismaticpowders.com most powders are less than $15/pound! | ||

Puls4521 |

Well I have the 3D printed prototype in hand. I bolted it up to my motor and it fits just like it should. Unfortunately my frame is at the powdercoaters so I cant fit it up like I want. I'm also working with a machine shop to have it machined. Hopefully I'll have it done around the time my frame comes back. Then the real fun comes, Assembly time! On a side note that ramp at the bottom may turn out to be just a radius cut instead to ease the machining and cut down the cost.    | ||

Jkgonzo |

Who is doing your powder work?? I live close to you and there is a local guy who does great work. My rocker boxes and other misc parts are on the way over to him this weekend......Also, since I live close, I would be happy to help you test the durability of your design  .....if you need me too. But, do keep me in the loop as far as possible production. I could slide one of those right in that X1 that's taking up space in my living room..........jim .....if you need me too. But, do keep me in the loop as far as possible production. I could slide one of those right in that X1 that's taking up space in my living room..........jim | ||

Rocket_in_uk |

That is very impressive to me that 3D printing stuff. I hear through the grapevine Hero EBR are pioneering the use of 3D printing in motorcycle manufacture. Rocket in England | ||

Purpony |

looks like FDM? | ||

Puls4521 |

Jim, I have been using place in waukesha called Hy-Tec coatings. They do amazing work and it is very reasonable. I'm serious about the offer to coat stuff for people. Now that I'm set up to powder coat my own stuff, I'm more than willing to coat stuff that will fit into a normal kitchen oven for others! Just shoot me a PM. Jim, where do you live? If your interested in one of those motor mounts send me a PM for more info. Rocket, 3D printing is an amazing technology, its growing so fast. I really wouldnt be surprised to see it spread to production parts not just prototypes. The materials they are able to print is growing everyday. Its so cool! Purpony, Yup! Its FDM, which is great for this kind of mock up stuff. | ||

Purpony |

I order FDM parts for clients from time to time. I have SLA and SLS in house. There are production SLS parts and probably some FDM in commercial and military planes already and the new Pratt Geared turbo fan will have a DLMS production part in the cold side (still 1200 degrees) of the production engine.... with more to follow if they can figure it out, lol. Ive been in the 3D printing/ Rapid Prototyping business for 10 years now... its always evolving and neeat to see it do so. (Message edited by purpony on March 05, 2014) |