| Author | Message | ||

Ratbuell |

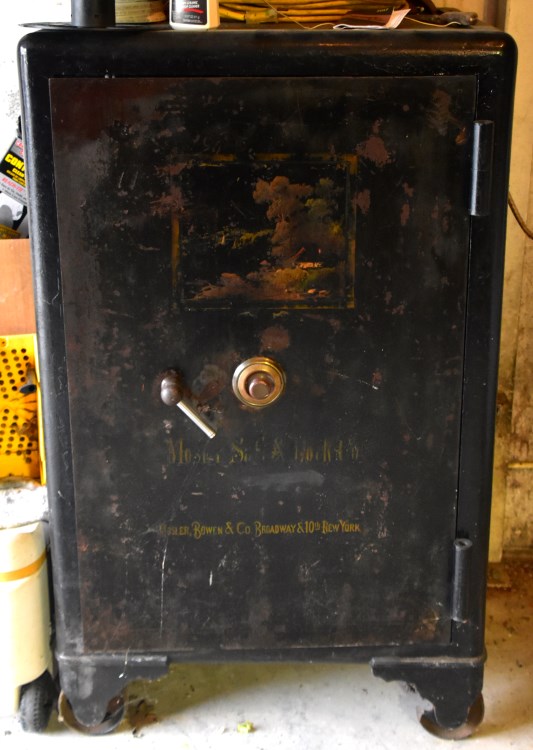

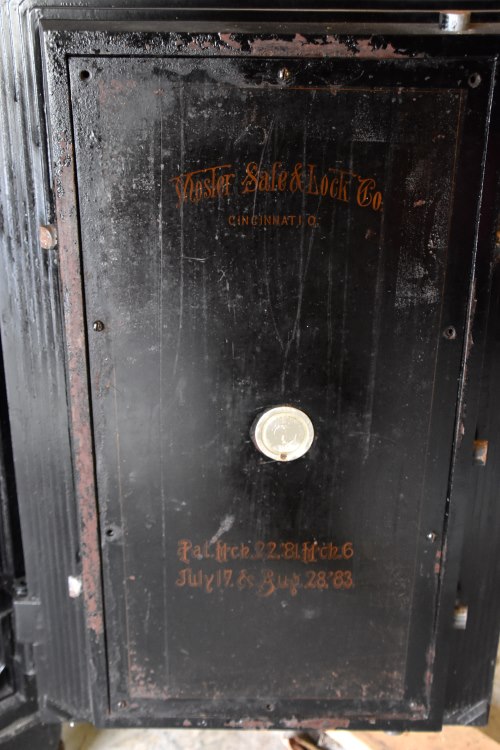

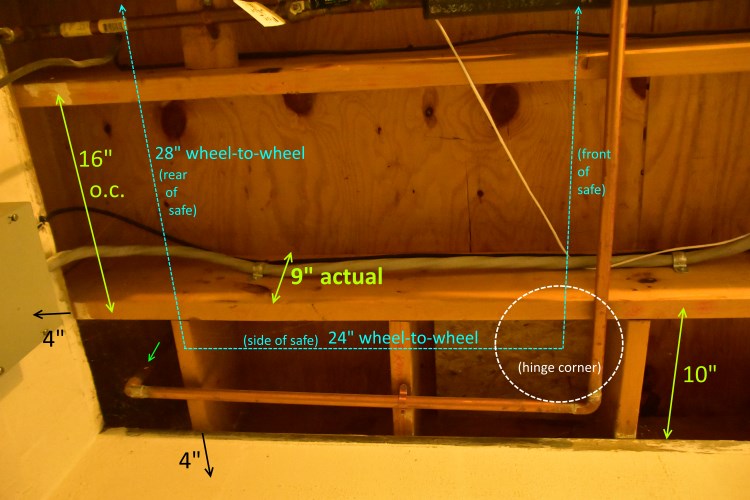

Just to move this out of the "never again" thread... I have a LARGE Mosler fire safe, from late 1800s/early 1900s based on the address of the manufacturer painted inside (different addresses for Mosler indicate different timeframes).  Exterior is 32.5" wide, 26.5" deep, 51" tall (48" tall box; 3" wheel gap).  Sidewall thickness, and top thickness, is 7.5" of steel and, from what I can find online, likely concrete as a fire insulator. Rear panel size is 18.5"x33"; interior depth is 14".  The door is 27.25"x42.25", and 6" thick. All steel, with mech and possibly some concrete in the outer shell. The mech cavity is only about 2" deep (where the locking bolts are); I suspect the accordion-taper section is concrete.  Interior graphics - hand painted lettering. All I did was rat-rod them, and the outer door - clean, and clear-coat. I want to put this in my living room so I can use it, but I'm concerned about weight. It will go in an exterior corner, less than a foot from an entrance so it won't have to roll across much flooring to get in place. Here is a shot of the underside of that corner:  Joists are 2x10" (9" actual height), 16" on center. Flooring is presumably no thinner than 1/2" plywood (I assume 3/4" since the guy overbuilt everything here), with 5" wide, at least 1/2" thick, oak flooring on top. The joists extend 4" over top of the block basement walls, to the outer footer. The copper pipe is for a baseboard heater (green arrow, lower left corner), and it IS the corner in the upper room, less than 1/2" from either wall. I can add bracing. Any suggestions? | ||

Strokizator |

Typical design for residential live loads is just 40 lbs/sq.ft. You are going to be way over that especially since the wheels concentrate the loads at 4 points rather than spread it out. Being close to a load bearing wall helps but I'd still look to shore it up from below. Adding anything from above won't increase the strength of the floor but may keep the wheels from damaging the surface. Full depth blocking between joists will help spread the load. It'd be nice to know exactly what the safe and contents weigh so you can get an opinion from a structural engineer. | ||

Ratbuell |

I just don't know how the hell to weigh it...I can jack it up with a car jack but have no idea where to get something that could handle the weight of each wheel... If I could, I'd simply put 6x6 posts under it, but that corner is over my well tank so I don't have clear floor space in the basement. | ||

Ourdee |

Joe, Finnish the Rat Rod treatment. Cut the inner skin open and remove the concrete. If you are really set on having it in the living room. It would also serve as a decoy. Stuff that really needs to be secure could be concealed in a hidden safe in a floor under this safe. Or in a fake outdoor wood boiler. | ||

Chauly |

Joe, to weigh each half, put a jack under one side supported by a 2x10 (or 12) one end on the floor and the other end on a bathroom scale. If the jack is 1 foot away from the end on the floor, and the board is 6' long, what the scale reads will be 1/6 of the weight of 1/2 of the safe weight ('cause the other half is resting on the floor. Then repeat on the opposite side and add together. I can send a sketch if you'd like... | ||

Chauly |

As far as additional support, a Lally column under each joist would be the ticket... | ||

Mnscrounger |

If I did the drawing correctly, based on your dimensions you have about 18.98 cubic feet of safe. An all steel safe this size would weigh about 495 lbs/ cubic foot, or 9300 lbs. My guess is its filled with concrete at around 145 lbs/ cubic foot, so it weighs about 2750. ( more or less) WAY over the live load limit of 40 lbs mentioned earlier, and BEFORE you fill it with all your gold.  | ||

Hootowl |

You’re not going to break a 2x10 with that weight, but it’ll flex. And the floor and subfloor will most certainly flex. So you not only need to support the joist(s) but also the subfloor. As was noted, the load is distributed to four points, likely not directly over the joist. The aformentioned blocking between the joists will help. | ||

Hootowl |

I couldn’t find the failure load amount on a 2x10 but I remember seeing a demonstration a few years ago. It was something l like 5000 pounds. That was to failure. And the wood species makes a difference. And the span. And whether there are defects. If it were me, I would not put it in the house. | ||

Griffmeister |

From the picture, it looks like you could “sister” the two joists with a couple of 2x12’s. Notch one side to fit on top of the foundation wall. On the other side put in a solid brace then support under the joists by bridging with a header and a column to the floor. Hopefully the joists can end beyond your well. You definitely want to distribute the load of the casters. Probably dozens of options, goal would be to transfer load to the joists. Down and dirty would be two steel channels to cradle the wheels. Not very pretty but serves to illustrate. That’s one option anyhow. | ||

Ratbuell |

Not planning to fill it with gold...that would require gold! More likely a lot of little tiny containers with a mixture of lead...copper...maybe some powdery substances... I could easily make the steel-strap look good; this is a very industrial-revolution looking device with cast iron wheels and everything. Something resembling train tracks, on the rustic oak hardwood flooring...hmmm..... Hell. I know scrappers. I could get some I-beam the height of the joists, and insert them between the joists. One end up on the block wall sill; the other end supported by another section of I-beam and a jackpost. With a large foot, so it doesn't simply fracture the basement slab. Regardless of use, it's such a cool piece. I hate to see it languishing in the garage, out of sight...but I really don't know if I should bring it indoors. And, I'd hate to leave it outdoors, even on the covered back patio or front porch. | ||

Crusty |

Big Honkin' Safe?  | ||

Hootowl |

Uh...what are the reservoir ends for? Head? | ||

Pwnzor |

Well, this is taking a strange turn... Back on topic... that's a beautiful safe. I'd just build something to distribute the weight more evenly and put it under the safe. | ||

Court |

>>>>>I just don't know how the hell to weigh it... That's really no problem . . . .I learned a trick with my Labrador Retriever. 1) Step on to a scale and see what you weigh. 2) Step off and allow the scale to return to zero. 3) Pick up the safe and step back on. 4) Subtract the weight of just you . . . from the weight of you holding the safe. 5) Poof . . YOUR ANSWER. Problem solved. | ||

Ratbuell |

Plugging for your new business venture, Canfield Chiropractic?? | ||

Ratbuell |

I wonder if a 1/4" plate the size of the footprint would work? Or would it be a catch-22 from the added weight? | ||

Hootowl |

Use a pair of chopsticks. Easy peasy.  | ||

Court |

Frankly . . . I'm a fan of the Lolly column. IT is the singular solution that actually transfer the load to the concrete floor below. I'd fabricate some sort of an I-beam arrangement to support the joists below and a lolly column to support the i-beam matrix. I'd also consider something under the wheels to distribute the load. Between Blake and Chauly (I call him Chuck) you have tow of the most talented engineers I know. . . I'd toss a sketch of whatever I did up here . . . | ||

Tootal |

Definitely tie the floor joist together and then run a couple of gussets to your basement wall assuming it's concrete. Using a couple of 2X6's under the wheels that cross the joist would help distribute too. | ||

Sifo |

Just a couple (maybe 4 even) boards on the perimeter would do a lot to distribute the weight on the floor. Just tall enough to get the wheels off the floor. At least that would give a path for the stress to go directly from the safe, through the board and floor directly into the joist. No bending load to speak of on the flooring between the joists. Moving it to that location might be interesting. Might want to check what damage it can do to plywood out in the garage first. Mock it up on 2x to mimic the joists. Better to push the wheels through that out in the garage rather through your actual floor. Cool safe! | ||

Ourdee |

When I moved a safe on carpet. I put 2x6s down like train tracks. To move it, I used large pry-bars an inch at a time. For pianos, I used 1x4s. | ||

Zac4mac |

Too cool Joe. Hope it stays where you put it. Z | ||

86129squids |

Might be hard to find, but surely there is someone out there who could tell you the provenance/make/model beyond those inscriptions, then perhaps also the weight. Great advice, all, BE DANG CAREFUL with that thing!  | ||

Blake |

That awesome piece of old school security looks to be multiple tons heavy. Too cool. But dang! Not knowing the actual weight means erring on the conservative side, which means somewhere between the two values that MN calculated, 3 tons (6,000 LBs) maybe? Court is a wise man. If in doubt, beef it up! Don't make the existing surface and substructure carry all the load. Platform up top, beams and columns underneath. Getting that monster in there while protecting the floor is going to be a challenge. If you can remove the door, that may help with the moving. But the door may be too heavy to allow re-installation by hand inside the house. Once you get the monster in there, you may notice it leaning away from one or both walls, and/or causing the floor to creak and grown when opening and closing the door. Picture a mere 1,300 LB safe supported by rough-cut 4x6's on either side running front to back, all atop a reinforced concrete slab. Picture opening the 400 lb door and seeing the safe visibly lean towards you, away from the wall at its back. It's a neat challenge. | ||

Ratbuell |

Yeah, I tend to over-build. I used to to stage/concert rigging, both live productions and installations. The running joke was always - There's three types of rigging: 1. fast 2. safe 3. cheap. You can pick two. This will definitely be erring on the side of "safe". No pun intended. The door "simply" lifts out of the hinges; the door has the pins, the body has the loops. I'm going to do some weight experimentation. The other hurdle is, even though the proposed location is immediately inside a doorway...the house is one step up from the patio. 8" might as well be a mile. I do know it's heavy. I brought it home on a flat-deck, diamondplate-deck car hauler. The diamondplate had four dimples in it when I unloaded the safe. | ||

Gregtonn |

Ratbuell, Commercial grain elevators have scales that can weigh your tow rig with and without the safe on board. Done. That being said, from what I'm seeing the wheels are likely to concentrate the weight to the point where it would wreck your floor. G | ||

Ratbuell |

and, I no longer have the metal-deck open hauler. Traded it for a steal of an enclosed hauler...but with a wood deck. Fair tradeoff for full cabinetry up front, flourescent lighting tip-to-tail down both sides, and a 15k air conditioner on the roof. | ||

Aesquire |

1917? Good. There's a weird problem with early post WW1 safes from the 1920s, in that some have a glass vial of retch gas liquid in the door where you would drill to pick the lock. A local old factory complex, had to evacuate several businesses when the umpteenth generation business in one section decided to toss an old safe that was in the building, in the way, no combination known. They dropped it off the forklift and the vial broke. Roughly pint sized, and what local fire department spokesman described as unknown, but tested positive for mustard gas chemicals, but not, hastily added, mustard gas, a kind of retch gas far worse than tear gas and outlawed by the Geneva conventions. The news spared the viewer scenes of folk being hosed off as they dry heaved so medics could treat them. No fatalities or known permanent damage, but it took a week to clear the spaces & re occupy the building. The fire chief said the safe company was long out of business and they couldn't find documentation on the chemicals, as they were secret traps thieves weren't supposed to know how to counter. You're probably not going to have that issue, in a safe made before the Armistice. | ||

Aesquire |

We had old safes come up for disposal & sealed auction all the time at work. I just couldn't see how to get one in the house and into the basement without serious professional riggers and structural repair. My porch steps certainty would not take the weight. |