| Author | Message | ||

Greg_e |

I really need to get myself a TIG that can weld aluminum, not finding too many choices in the under $1000 realm. Even the Harbor Freight AC TIG is up at $1000 now and that is just plain more than I can spend. Nothing popping up on craigslist... So I am looking at the HYL TIG-200P on Amazon with free shipping (because it weighs a ton) at $430 plus tax. It suggests that it comes with flow meter or pressure gauge, TIG torch, cables, etc. My only wish would be to have it run on 110v because I doubt I'll be welding anything thick enough to need the full power. Not looking for production level tools, looking for hobby level welding that can do more materials than my little fluxcore machine can do. Alternate might be the unit that Eastwood sells, though with freight that might cost almost what the Harbor Freight costs. | ||

Bandm |

I picked up a used Miller from somebody that was upgrading. They're all over Craigslist. https://chicago.craigslist.org/chc/for/d/new-comme rcial-quality-200a/6667158035.html | ||

Sifo |

Kind of hard to find many details on the HYL TIG-200P. What I did see is that it's lacking a foot pedal. They claim it has Hi frequency start, but I'm not sure how it's accomplished without the foot pedal. I don't see anything about amperage control on the torch. I assume the torch has some sort of on/off switch, but hard to say. I picked up a Vulcan ProTIG 200 from HF last winter. Pretty happy with it for the price. Works well, has a decent torch, and a pretty good pedal. I just can't imagine welding aluminum without a pedal or a control on the torch. It doesn't seem to have an upgrade path to adding a torch with amperage control though. I realized how nice that would be when contorted under a car on jack stands, trying to weld up some chassis bracing. There are certainly welders with more features, but I find it to be a pretty usable unit for the price. I think HF has really tried to step up their game with the Vulcan series of welders. One feature I wish it had was adjustable pre and post flow for the argon. For many things you simply don't need the 5 seconds of post flow it's set too, so it wastes some gas, especially when tacking things up. It's pretty simple to tap the pedal to extend the post flow if needed though. I watched for them to go on sale and got it for just under $900. Still need to add argon. It did come with 3 nozzles and 3 different size tungsten, but you will most certainly be buying more tungsten soon. It's just nice to have a hand full of them sharpened and ready to swap in. It would be nice to see better description on the HYL, but I just didn't find much. Kind of makes me wonder about it. A foot pedal would be a must IMO, and I would certainly add that to the price up front when comparing. | ||

Greg_e |

Looks like a pedal is another $43 and I bet a torch with variable control could be adapted fairly easily. https://www.amazon.com/gp/product/B072WJNTT2 The Vulcan computes post flow based on the current you are using, or so says people on one of the welding sites. | ||

Sifo |

The Vulcan computes post flow based on the current you are using, or so says people on one of the welding sites. Mine is simply set for 5 seconds. It's possible it's been updated. It wouldn't make much sense to me basing it on the current though. It's more about the type of material you are welding Ti or stainless steel need much more post flow than steel or aluminum, regardless of current. | ||

Greg_e |

If the Vulcan came back down to $800, I would probably go buy it because I now it is complete and reviews are very favorable. The 1 year return and extended warranties seem to be upheld really well and if something fails I can go into the stores with my receipt and exchange the parts with no questions asked. I'm not really bothered about post flow time, as long as it flows enough at the end, a little more is fine with me. Again this could be an issue in a production environment where nickels matter, but I think I can afford an extra nickel each time I fire off a weld. Note to anyone reading this, make sure to set up your HF account with an email address... Then your receipt will get sent to the address for safe keeping. The thermal paper that is used to print the receipt is junk and will fade or blacken in a short time, rendering it useless in a claim. Apparently the serial number of the welder is also stored in a database which might save you. | ||

Greg_e |

Found the user manual at the USA importer's site https://iwestore.com/pages/manuals If any of you that weld can take a look, I'd appreciate it, only 23 pages. Tig 200P AC/DC Digital in the model needed. | ||

Greg_e |

Not much in the manual, but looks like it should be decent. Just wish it could be run off of 120 volts as well as 240v. | ||

Sifo |

Looks like a lot of features built into that thing! It's just hard to imagine all of that at about half the price of competing welders. I know nothing about the brand, so I would say the quality might be a crap shoot. They do claim to have a 2 year warranty. Almost sounds too good to be true. Tough call. I read some of the reviews from a few places that sell them and some did claim crib deaths. If they will take care of you with the warranty though... | ||

Greg_e |

Yeah, still thinking. Don't want to jump into something that is not going to stay working. The biggest issue seems to be boxes crushed and dropped. It's heavy and the jerks around here really treat heavy stuff badly, and then dump it and run so you can't refuse it. Probably going to buy it though. | ||

Zac4mac |

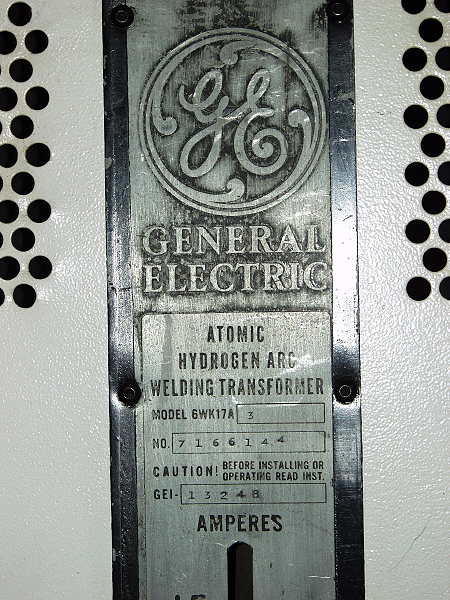

Two tungsten electrodes both with a hydrogen(H2) shroud. A 7500 degree torch. Built by GE in 1947. Sounds like a dozen banshees when set up right. Z | ||

Greg_e |

I don't have room for a large welder, tons of those on craigslist, but most won't have higher than line frequency which seems to be important (what I read). Would be nice to be able to afford a made in the USA welder (or really a made in Germany Fronius), but the price leaves me out of that market. When even the domestic companies are having product built overseas, there isn't much choice. Buy a welder from China with a USA name on the side, buy a welder from China with a Chinese name on the side. Still buying a welder made in China and depending on the company, the work is probably just as good either way. Wish the HYL was a little lighter and could run on 120v for lighter welding. Going to have to build up an adapter for a drier plug or install a new plug off an old garage door opener circuit (yes there was a 220v door open in one place). | ||

Screamer |

I bought an Eastwood (my first "non-Miller") a few years ago. Works fine - but I may still buy a Miller. | ||

Sifo |

So here's where it gets kind of weird... Discussing some of the cheapest welders available, and the guy who bought from HF is about to suggest "cry once", "one and done", what every you wan to call it. It would be great if you bought this welder and it met all of your expectations. If it fails, it's a pretty pricey fail. I get that you are not starting a welding business, but you probably don't need a $400 boat anchor either. I might consider, if you can budget for an AHP, it's a name that has some history behind it. https://www.ahpwelds.com/product/ahp-alphatig-201d x It seems to have pretty similar features to what you are looking for (at less than double the price! Still considered a cheap welder!), with more stuff included. Includes the foot pedal, and also a stick holder for when you want to try stick welding. Supports your desire for dual power sources. On sale at 10% off right now. I will say, I wish my HF unit supported the 2T/4T function. 3 year warranty. It's probably what I would buy if I were to do it now, knowing what I now know. One other thing. I had a cheap auto darkening helmet that I was using with no problem stick welding. It absolutely sucked with TIG! Really sucked with AC TIG!!! I was constantly getting flashed, which left me wandering around partially blind for the next 20 minutes. Forget being able to see a weld puddle anytime soon. I picked up a Striker helmet, with 4 arc sensors (Really cheap helmets tend to only have 2), with many more features, and is far more comfortable, and will hold a cheater lens to help with my aging eyesight. Great helmet for the price IMO. http://www.usaweld.com/Striker-Supreme-XL-Welding- Helmet-p/supremexl.htm | ||

Greg_e |

I thought the HF welders had 2t/4t modes built in, I have a feeling I might use that a lot. Still haven't ordered, the black hole of info suggests nothing good. Should have bought an Eastwood last month when it was $680, but the shipping would bring it up to around $850 so where is the bargain? Still thinking about the HYL, the few reviews of systems that didn't get damaged in shipping are pretty good. There other welders get pretty decent reviews, but again not many of them. Good info on the helmet, something else I might have to upgrade. I have a cheapo Kobalt with 2 sensors, also have an adjustable cheapo HF with 2 sensors. Bought the HF so that I could pull the shade unit and put it in front of a camera lens... Needs some refinement but it worked OK, had the shade a touch too dark for what I was doing. And I'd still need to get a bottle of Argon. All this other stuff pushes up to close to $1000, if I started at $1000 for the welder it's not going to happen. Not sure, don't want to get bitten but can't really justify the expense right now for a known welder. | ||

Greg_e |

For good or for bad, decided to buy one. They dropped it to $400 even and still with free shipping. Says it will arrive Thursday or Friday. Two things I want to build with it (in due time): Human powered Tadpole recumbent trike (when I find a decent design). 125cc miniGP track bike with real person sized frame. Reading a good book on the subject right now https://motochassis.com/product/book-motorcycle-ha ndling-chassis-design/ Wanting to make the racer out of aluminum tubing (or welded plates to form a box like structure). Fuel in the tubes because I only need like 1 gallon and it should be easy to fit that little in a twin spar design. Immediate build: New "clip on" adapter for my Z125, similar to the Chimera U bomb thing https://www.steadygarage.com/store/chimera-u-bomb- handlebar-clipon-adapter-grom-zuma-ruckus I built one out of steel and it functions like I want after I moved the tubes from center to edge. https://www.z125owners.com/forum/what-did-you-do-y our-kawasaki-z125-today/15379-clip-mounts.html | ||

Greg_e |

What electrodes should I buy for Aluminum? Something that will make the learning process easy? Also what should I use for steel? I've read a few things and it looks like Thoriated is good for aluminum, but want to make an order up today to get some of the consumables on the way. Also need good filler for 6061/6063, should I buy 4xxx or 5xxx filler rods. | ||

Sifo |

What electrodes should I buy for Aluminum? Something that will make the learning process easy? Also what should I use for steel? I've read a few things and it looks like Thoriated is good for aluminum, but want to make an order up today to get some of the consumables on the way. Also need good filler for 6061/6063, should I buy 4xxx or 5xxx filler rods. I'll tell you what I've been using. I'm strictly an amateur, so take it for what you paid. I've been using 3/32" 1.5% lanthanated electrodes for steel and Aluminum. I wanted 2%, but took what was locally available. I really don't know if it's better or worse than thoriated. Either should be fine I would think. I've been using R 4043 for my aluminum work. Even worked well for welding some unknown aluminum to some cast aluminum. A lot of crap came out of the casting, but it eventually cleaned up pretty well with a second pass over it. I also picked up a dedicated stainless steel wire brush for cleaning aluminum. A tooth brush style brush works well for me, like you can get at Harbor Freight, or many other places. I've been told wire brushing with a power wheel will just embed contaminants into the aluminum. Cleaning aluminum prior to welding helps a lot. Youtube has some pretty good welding videos if you haven't already checked them out. You can certainly learn a lot by watching them. Then nothing beats running beads. I also have a piece of filler rod, about a foot long handy where I watch TV. I can veg out, but still practice feeding filler rod through my fingers until it's a completely natural muscle memory. There's a lot of new things going on running a bead, and anything that can be made fairly automatic helps a lot. Neat project for the clip-on mount. I've never seen that before. | ||

Zac4mac |

When I prep heads to go to the welder, everything gets hit with carbide burrs. Anything else leaves crap and Iíll hear about it. | ||

Greg_e |

I need a good selection of burrs, got a couple that were great but need a few more shapes. My problem is needing 1/8 shafts. | ||

Zac4mac |

Dremel makes a few different burrs, most are HSS but they do have a few carbides. My usual supplier appears to be going out of business... I have a few extras, call me . Use the 635 number in Colorado BRAN Zack | ||

Zac4mac |

Found a place just now - Atlas Cutting tools, butt-load of 1/8 shank carbides. http://www.atlascuttingtools.com/categories/Burs/ Looks promising, I'll be looking closer tonight. Off to the shop. Z | ||

Greg_e |

Supposed to be delivered tomorrow, consumables won't be here 'til next week, and I need to pick up some gas. Trying to decide if I can deal with an 80cf tank, or if I need to use a smaller 40cf tank. | ||

Bandm |

You will want the biggest size tank that the place you get it filled at will sell you. What a straight Argon exchange is listed for at Airgas: 40 59.60 80 89.98 125 103.19 200 107.48 300 148.52 A 125 is 7.3 inches by 48 inches tall. Bigger than 125 gets heavy when full. | ||

Greg_e |

Most places the biggest is an 80cf, anything above that is a rental. Almost $300 for an 80cf at Praxair and refills are like $40. | ||

Sifo |

Have a chance to run some beads yet? Curious how it runs. | ||

Greg_e |

Still gathering pieces. Need to chase down the gas. Got a drier to nema 6-50 adapter and nema 6-50 25foot extension cable Thursday. All the gas places are closed until Tuesday, and hard to get to them, and still have time to get to work. | ||

Greg_e |

Finally got a tank of argon... Did a quick check before I had to leave for work this morning and the flow meter is a real piece of garbage. If I set it for just below 15cfm, and then put my finger over the end to stop the flow, then release my finger, the ball only goes back up to 5cfm. You only get "consistent" stops and starts with it set a little above 15cfm which might be too high for some of the smaller cups and certainly not a good meter to use as a purge only device for stainless tubing. But all told, I'm in for right around $1000.00usd or a little under (including some filler rods, new gloves, tungstens in 2% lanthanated, etc), ready to weld. I'll probably try to run a few beads on plate tonight to see if I can make it work. First real project is to make a cart, didn't find anything I liked or would fit this welder, it's pretty big. Pretty much decided I'm going to make the cart out of aluminum to get the practice, probably 1/8th thick angle and maybe some plate if I can find some cheap. Probably another $60 worth of metal and maybe another $30 to $50 for wheels. Probably should buy a dedicated fire extinguisher for the cart, need to think about that in the design. And yes I bought that cheapo folding welding table from Harbor Freight, it actually seems to be decent and you can use the 20% or 25% coupons for it. Have to see how well it works with aluminum sitting on the galvanized table, might be taking a flap disk to it to remove the zinc. | ||

Ourdee |

Fire extinguisher: Use a rechargeable water extinguisher as your primary. I have powder extinguishers in brackets on my welding tool cart. It is an aluminum side box from under a truck with 2x6s bolted on top and then mounted on Radio Flyer running gear. | ||

Greg_e |

Every thing I think of makes the cart larger... Need a house with a dedicated workshop! (and a pile of money to pay for it) Town won't even let us put up a decent size shed without following a bunch of rules that basically puts it in the middle of the yard. Who puts their shed in the middle of the property? Stupid zoning rules!!! |