| Author | Message | ||

Radioelasais |

I think I need one but I have really no clue where/what I should look for. Epay is full of offers but ... which one? Ideally a good quality used tool would be OK for me. (something that could work also on metrics would be even better) thanks gianluca | ||

Augustus74 |

Dont buy used just get a Craftsman or the like. | ||

Aesquire |

Buy new. Used torque wrenches may have been used as breaker bars, and re-calibration, or the tools to measure & set calibration may/will cost more than a Sears model. That nice big one on E-bay may be a bargain....or it may snap that bolt that makes you pull the engine, and haul it 50 miles to the closest place that can competently EDM the snapped bolt. ( when the place across town says they can, but wrecks the engine case if you let them ) ( lucky for me Rochester has multiple competent EDM shops, and even some speed shops with a clue. ) It doesn't really matter what system the wrench is marked in. Conversion is simple enough. There are charts online to convert foot/pounds to newton/meters or Gram/parsecs. You need one with a high enough range to do your intended work, It's Nice to have 2, an inch/pound and a foot/pound version for light & heavy application. A smaller wrench in addition to the big one is ideal, but I grew up as a shade tree mechanic installing Heli-coils in Nortons, which used British aluminum alloys whose hardness is measured on a "cold butter" to "frozen butter" scale. Unless they are already "crystalized" and about to snap. YMMV but I usually only use a torque wrench for the heavier needs, and "german torque" for smaller screws. ( gudentite ) This is, naturally heresy, wrong, and errors are sometimes expensive. I'm also used to using a torque wrench with a crowsfoot on an extension, with the calculations magic markered on the wall, to remind you, while working on high pressure flange applications where "tight enough" by feel will lead to high pressure leaks of stuff that dissolves flesh. Sometimes, there are reasons the book says to do something........ (Message edited by aesquire on June 07, 2010) | ||

Maxbuell |

#1 on Aesquire need both ft lbs and inch lbs especially for the Buell.. | ||

Crusty |

In my job, I use torque wrenches constantly. We have torque wrenches by CDI (a Snap On company), Armstrong, a number of specialty (i.e. really expensive) torque wrenches, and one cheap Craftsman clicker. the one that has been the most accurate and needs the least adjustment at calibration time has been the Craftsman. It looks like a cheap POS, but it's better and more consistent than wrenches costing literally five times as much. I have really grown to like it. | ||

Mr_grumpy |

Aesquire, I resemble that remark. Norton alloys were Never on the butter scale. It was the Cheese scale, anywhere from mature cheddar to swiss. When I was but a young muppet & we used to do silly stuff like racing around town for drinks etc, the Britbike boys would always look down their noses at us 2 smokers. But we had a course that was about 2/3 short bursts between roundabouts & city streets, with the last 1/3 being WFO back to the finish. The brit boys never cottonned on to the fact that we'd set it up that way so that they'd have to run maxxed out to catch the light nimble japs before the line. Many a Norton or Trumpet finished the evening sounding like a bag of spanners & puking oil. Back on topic, as previously stated, don't buy used, & if you can, get a big & a little. Also, for the big one try & get one that's reversible, not all are. Very handy for left hand bolts. | ||

Rwven |

And if you want to save a buck, get the less expensive Craftsman beam scale type. If you are only using it at home it will do the job and do it accurately. The "clickers" are nice though, especially when you are tightening drain plugs, though I just marked the back of the scale on my beam type so that I can read it upside-down.... | ||

Ratbuell |

I've used a craftsman lb-ft one for years, plain ol' clicker style with the rotating adjustment handle. Always unwind it for storage, I only have pressure on the set spring while using it. I just got its baby brother, a clicker in-lb, for the small stuff. | ||

Fahren |

good article on torque wrenches: http://www.webbikeworld.com/r3/torque-wrench/ | ||

Natexlh1000 |

"Always unwind it for storage, I only have pressure on the set spring while using it. " This is how I failed. I have not had much luck with my craftsman clicker. Whenever I use it, there seems to be a broken bolt in my future. I will have to get a new one since the old one is from when I rode Japs and that was a lifetime ago. | ||

Tpoppa |

I have a NIB Husky Professional clicker torque wrench. It has a lifetime guarantee. MSRP is $75, I'll sell for $50 +shipping. I am also in OH. http://www.homedepot.com/h_d1/N-5yc1vZ1xjv/R-10005 0843/h_d2/ProductDisplay?langId=-1&storeId=10051&c atalogId=10053 | ||

Gentleman_jon |

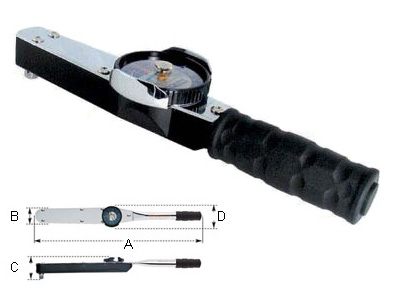

Call me old fashioned, (everyone else does), but I am not a big fan of "clickers". As Natexlh1000 says above, they seem to be involved in too many sad tales. The reason is, one loses feel just a the critical moment, when maximum torque is being applied. In addition, one never develops much "feel" for torque using them. I like the cheap old beam units, which are accurate enough for working on most parts of a motorcycle, or dial wrenches for more critical applications. With these tools, one can feel how much torque is being applied, and stop if something seems wrong before it breaks. Lots of guys have stripped their swing arm drain plugs because the published spec is wrong, and the didn't rely on a sense of feel that they might have learned if they were not using a clicker.  | ||

Froggy |

I picked up this a few weeks ago, I love it! http://cgi.ebay.com/ebaymotors/ws/eBayISAPI.dll?Vi ewItem&item=370288135251&viewitem= Does foot lbs, inch lbs, newtons, works both clockwise and counterclockwise which is important for Buell axles. Oh and its easier to use than that weird wrench that Gentleman_jon uses. | ||

Mr_grumpy |

That's a handsome tool, what make is it? | ||

Radioelasais |

I have a NIB Husky Professional clicker torque wrench. It has a lifetime guarantee. MSRP is $75, I'll sell for $50 +shipping. I am also in OH. http://www.homedepot.com/h_d1/N-5yc1vZ1xjv/R-10005 0843/h_d2/ProductDisplay?langId=-1&storeId=10051&c atalogId=10053 let me have a look at homedepot... thanks for the input guys. | ||

Reepicheep |

I got a harbor freight 3/8 inch drive clicker and used it for a while. It works fine. I since upgraded to a craftsman and a husky, both much nicer, but I'm not sure they work better. I'm all for precision and accuracy, but truth be told, the torque spec ranges for the bolts are typically really wide. And even then, given dirty versus clean threads, temperature differences, locktite, anti-sieze, etc... Im not sure an inaccurate wrench would be the main problem in getting accurate torques on bolts. The better (snap-on, craftsman, husky, cobalt) are no doubt better, and I have never regretted buying a good tool, but (preparing for incoming fire) the Harbor Freight ones are probably adequate for the home user. | ||

Aesquire |

Mr. Grumpy, My bad. I forgot. You are right, It's the Cheese scale. Don't forget the crumbly levels of the scale where chunks of the castings fall out right after you think you've got it assembled right.  | ||

Sifo |

I've had my Craftsman clicker for about 30 years now. Still works just fine. As was said earlier always back it down to zero when putting it away. A clicker may not be the best torque wrench, but it is great for when you can't see the scale on other types. | ||

Drfudd |

we use craftsman clickers at work and those are rarely out of spec when it comes time to calibrate. we also use pneumatic limiters and those are constantly out of calibration, it makes it a problem when you gotta try and figure out if past shipped goods may have an issue. its especially troublesome in my area, which is because I'm the engineer for the Valves we make for the nuclear industry. at home I don't use a torque wrench i'm so used to using one at work my elbow has been calibrated.  | ||

Speedfreaks101 |

I love my digital that I picked up from Cornwell. I have had it for about three years and it is been great. It reads in Nm, in-lb, ft-lb & Kg-cm. If you bought you one I will promise you will NOT regret it. http://www.cornwelltools.com/webcat/products.php?p roduct=CTG3000-%252d-3{47}8%22-Digital-Torque-Wrench (Message edited by speedfreaks101 on June 07, 2010) | ||

Jandj_davis |

I have two Harbor-Freight torque wrenches, one 1/4" drive, one 3/8" drive. For as long as I have had them and used them, I've never stripped a bolt, and I've never had anything come loose. That's good enough for me. | ||

Xl1200r |

at home I don't use a torque wrench i'm so used to using one at work my elbow has been calibrated. I'm with you there - they were required at the garage I worked at when putting wheels back on - I bet I can torque a bolt to 100 lbs/ft within 5 lbs/ft. I agree with what others have said - skip used and buy the best you can get. I don't follow my own advice and got some cheap thing from Walmart - it's accurate enough considering the wide ranges that Reep mentioned. I also don't torque everything like some guys do - there's nothing wrong with doing that, but all you really need to do is know what the bolt is made out of, know what the threads you're going into are made out of, and know what the part is doing. Brake calipers bolts? No torque - a little thread lock and get 'em good and snug. Axles or ANYTHING with a gasket? Definately torque. | ||

99buellx1 |

Just picked up a Craftsman last night. Seems to work? | ||

Bluzm2 |

Concerned about the accuracy of your wrench? Easy to check, really! Clamp the drive end (1/4, 3/8 or 1/2) in a sturdy vice. Measure from the centerline of the drive to the mid point of the grip. Let's say it's 1 foot. Set the wrench to mid scale. Say 50 ft lbs. Set the wrench so it's parallel with the floor. Use a nylon strap to attach the weight to the mid point of the grip. When you slowly release the weight, the wrench should just click as you get the full weight on the grip. If the wrench is calibrated correctly, the wrench won't click with the 50lbs hanging. Very slight pressure with your finger tip should trip it. If your center to center is 18", divide the scale wight by 1.5 for the correct weight to hang from the grip. In this case, at 50ft lbs and 18" center to center you should use 33.3 lbs. Most wrenches can be adjusted. Craftsman included. A bit putzy to do but after you do it once, it's pretty quick. If the extreme ends of the scale are way off, the wrench is in need of replacment. Either that or calibrate it toward the most used end of the scale and only use it for that range. | ||

Sifo |

For those claiming to be able to accurately torque something without a TW because you have used a TW so much, well I have my doubts. First doubt comes from the fact that ratchet handles are usually much shorter than TW handles. That right there will throw you off from your experience. Having said that I agree that experience is good enough for MANY things. Engine internals and cases along with anything safety related I would recommend the TW though. | ||

46champ |

Brad thanks for the check procedure for a torque wrench. Remember people the only torque wrenches the FAA does not require recertification certificates are beam type all others need to be certificated every year. |