| Author | Message | ||

Vospertw |

All, I've had a frustrating couple of weeks. I realize I'm doing something wrong but need some help here. I've managed to crack all of my windscreen holes and one airbox hole in the last few weeks. These weren't the first times I've had either off the bike, and used the same tools, technique, etc. in the past. I have a very small electronic 1/4" drive torque wrench that I set on the min spec for those fasteners. Is there an unwritten rule about only going finger tight or something?? As you know, the plastic isn't cheap and it's pretty frustrating to follow the manual and still have a problem. I'm not a professional mechanic but I've been working on my own bikes (first Buell though) for a number of years. I have a pretty good feel for what's tight/not tight. I regularly run a tap through threads to clear old loctite and debris to avoid false readings - but this is getting old fast! This started happening during some cold (for SoCal) weather - could that have something to do with it? In all cases, there's been no "crack" upon tightening; they've all shown up after a ride or two. Let me know if you guys have some hints. | ||

No_rice |

i dont even want to be the one to say this, but im not sure you can even get the cherry bomb translucent plastics anymore to replace it.(thats what your profile says anyway) because i havent checked that specific color, but if i remember correctly last time i looked the translucent stuff wasnt very available from hd. as far as cracking them, did you remember to have the reinforced rubber/metal inserts in the plastics? atleast i think thats how they updated stuff years ago to fix that cracking problem... ive never had a translucent set myself. | ||

Vospertw |

No_rice - supposedly the flyscreen is available. I just found out about the airbox cover so haven't checked yet. That was really surprising because I had to take the bike to the shop for some warranty work, and the cover was fine - 14 miles later - cracked! I double checked the parts book - they show (and I have) the rubber/metal inserts for the two front fasteners on the airbox only. I wonder if I should just order a couple for the rear anyway? That was something I was kicking around, either finding something that would fit all the fasteners like that or just adding a rubber sealing washer or something like it under the plastic at each fastener. The whole thing really baffles me (and pisses me off!) since I've been working on this bike now for a year and all of a sudden I'm screwing up the plastic. By the way - is the translucent stuff worse than other pieces? I'd be willing to switch over to the solid red or something if it would help. Are there any aftermarket choices? Thanks for the quick reply, amigo. | ||

Greg_e |

General rule: Hand tighten all plastics. | ||

Vospertw |

Thanks Greg_e. Bums me out though - that's a track day that's now invested in parts that shouldn't have needed to be purchased. You SHOULD be able to follow the service manual without breaking anything. | ||

Skinstains |

For what it's worth, I never use power tools on aluminum, and would never use it on plastics. I see guys putting axles in with air & elec. and it just amazes me. Are you sure you're using the correct bolts ? Not trying to be condescending but if you use the bolts without a shoulder I could see a possible problem. What are you going to do with the cracked parts ??? | ||

Greg_e |

I would glue the broken parts if you have all the pieces. If the break is clean you may never see the problem: http://www.usplastic.com/catalog/item.aspx?itemid= 22996&catid=486&clickid=searchresults Should work on the see through air cleaner covers. | ||

Vospertw |

Skinstains - sorry - when I said "electric" I meant that it's not a mechanical "click" type wrench. It gives a light and a "beep" when you get to the target torque - you still have to move it by hand. I agree with you on using any type of powered driver. No worries on being condescending; I'm the one asking the question. Yes, I have the bolts with the shoulder. Greg_e - thanks! We have an industrial supply store not too far away; I'd be surprised if they don't have something like that. However, a piece from the airbox is missing already. Luckily from an aesthetics standpoint, it's one of the fasteners covered by the seat. My bigger worry is keeping the cracks from propagating. Not sure yet what I'll do. I have a ZG sport touring screen that just arrived - I'll put that on for now. I have a flyscreen on order but I thought I might just keep it safely stashed for some future need. I'm hoping the airbox will stay reasonably intact for a while. My thought was to order one (before they disappear) and keep that safely stashed too! Just curious - if I needed to, could I use an airbox from any year? (Message edited by vospertw on January 23, 2011) | ||

Greg_e |

That stuff will cause additional cracks, only good if it is completely broken. To mend cracks find some of the slow set type from Weld-on the fast set stuff evaporates so quickly that it can cause temperature induced cracks. | ||

Delta_one |

the translucent plastics tend to be much more likely to crack than any of the opaque stuff from what I have seen, some have even complained of cracking if gasoline dribbles on it when filling up. my black is a little flexible and the kick ash that I looked at buying was very hard and felt like it could be brittle. | ||

Vospertw |

Thanks Delta. All of the XB airboxes are compatible, correct? | ||

Froggy |

Yea the translucent plastics are a bit more delicate, but to this day I'm yet to crack one, I just hand tighten with a screw driver with the T27/30 or hex key bit. It is funny how some report damage from gas, it makes me wonder if there is another factor like wax or something, as I've spilt gas several times without issue. Once my Hero Blue translucent Uly screen got a face full of the back of a car. Destroyed my short windscreen, but the flyscreen survived unscratched. As for compatibility, any XB airbox with the vent by the gas cap will fit (06+). Any year Lightning flyscreen will work. | ||

2008xb12scg |

Froggy, I think there are 2 sizes fly screens for the lightning aren't there? I have to question myself cuz youre always right about this stuff. But I bought one from an older bike (an xb also)that did not fit my 08, the air box did but the fly scrren didn't. Just a fluke? I still have it I don't remember if it was to big or small. I still need to sell that thing one of these days.. | ||

Froggy |

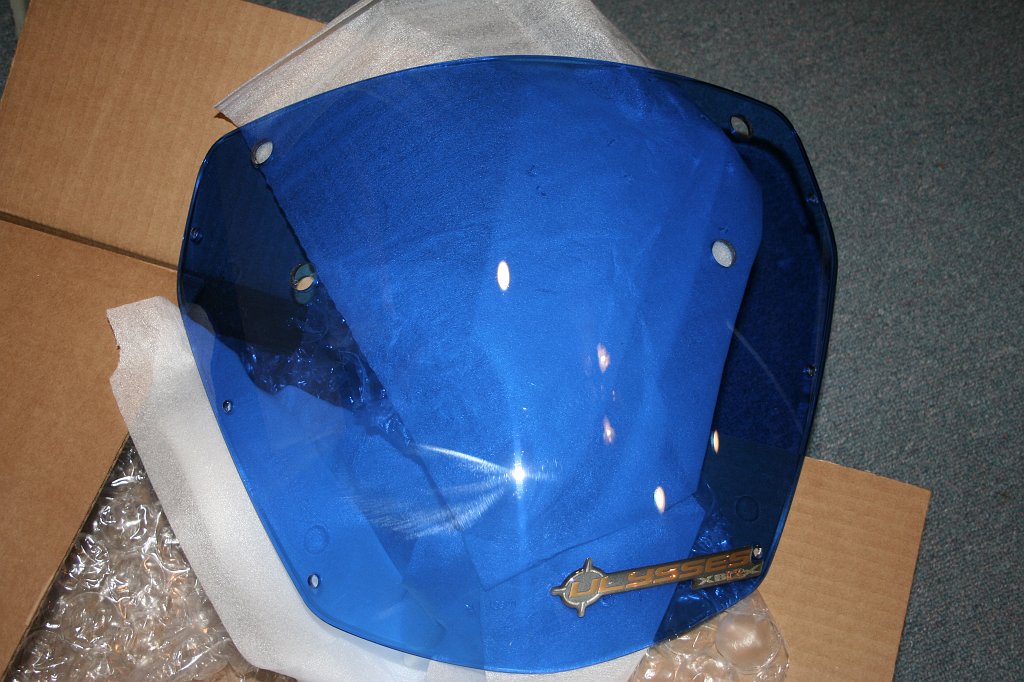

All XB Lightnings use the same flyscreen. The Uly flyscreen is much larger, and has 4 large holes in it on the upper half for mounting the windshield. Uly flyscreen:  Take a pic, I can tell you what it is. My first guess would be that its a flyscreen off a tuber Lightning, but I couldn't say without a picture. | ||

Vospertw |

>Yea the translucent plastics are a bit more delicate, but to this day I'm yet to crack one, I just hand tighten with a screw driver with the T27/30 or hex key bit. Thanks Froggy - but what are you saying... I'm a ham-fist?? You know, the whole reason I bought that little torque wrench was to avoid over-torquing small fasteners like this. Lesson learned, however. I'll be putting my trust in loctite and frequent checks. | ||

Froggy |

I got an electric torque wrench too, but I only use it on the axles. Everything else I do by hand. I am not strong, so it isn't possible for me to do much damage do these bikes. I just do it till they are tight, no loctite, no checks. I am yet to lose a flyscreen fastener while on the road, but I lose them all the time in my garage somehow... | ||

Spdrxb |

My screen cracked slightly at one hole years ago. Its only about 1/8 inch long, stop drilled it continued riding. It wasnt worth the money for a new one,plus Its barely noticeable.You have to look pretty close to even see it. Use the smallest drill possible and it wont progress any further. How bad did you crack it? | ||

Spdrxb |

OK its more like 1/4 inch oh well I have lived with it so far....character I guess  | ||

Delta_one |

I know for cracks in cymbals we drill a little circle (sometimes all the way through if we have to) at the end of the crack to keep it from spreading, not sure if it works on plastic though. | ||

Vospertw |

I've already ordered a screen. On the airbox, I think I'm going to lose some material, so thought I would drill stop any cracks and then use a dremel to smoothly radius around any lost pieces. I'll see if I can still use a fastener after that, but since it's somewhat held in place by the seat, I might try a couple tabs of Velcro is I can't keep the fastener. | ||

Xb12mel |

Yeah... After 25K miles, both holes for the Airbox cover under my seat were gone. I used some reinforced packing tape around the inner edge of the Airbox cover to prevent further loss and to give me something to put the mounting screws through. That was about 5K miles ago... still working like a charm. I also have the cracks from the fly screen you're taking about. I put Crazy glue in the cracks on the fly screen... In retrospect, I should have drilled them... YMMV | ||

Vospertw |

I think I might be able to save it. There are multiple cracks around the hole, but only two that are heading further into the airbox. I think I'll stop drill those cracks, then try to use an acrylic/plastic bonding cement over each of the cracks. I was wondering if plain old airplane model glue would work for that - it basically attacks/fuses the plastic. Might not look pretty but it's under the seat anyway. Also thinking of using a rubber or fiber washer - or even a strip of adhesive backed Velcro (fuzzy side) around that particular hole to give a little cushion. |