| Author | Message | ||

D_adams |

Not sure if this is really worth watching, can't see anything and can barely hear it, but it was 5th to 6th gear WFO. | ||

1324 |

Subscribing to follow this more closely. Nice work so far! | ||

Geforce |

Hehe...yeah I just messed my pants. SWEET! Dean, I'll be back tomorrow around 11-12 if you need me to buy ya a beer! | ||

Ezblast |

Very nice! EZ | ||

D_adams |

Just called Gateway and tentatively scheduled an 11 AM slot for the dyno. They're still waiting on a part for the permenant installed dyno and the mobile one is at another site. If needed, I might travel to wherever it is just to get this done. It's either a little farther south in Festus MO or over in Mt Vernon IL. I gotta track it down just to be sure I can get it done this weekend. | ||

D_adams |

Hah! Tracked it down, I can get a single run in on Saturday for sure, possibly more. | ||

Blackflash |

Sounds exactly like mine sounded when i put the 3 tip in mine and removed the two pipes.Mine started like crap too.The bike was very flat until 7k and it ran horrible.I ended up buying a new pipe off ebay and cutting the stock tips and angling them on a 45 Degree angle.I havent been following this thread to much but the work envolved looks good.But by removing the two tubes totally ruins the flow of the bike.I know I did that mod.God it ran like crap and started like crap to until I added screen inside the tip to give it some backpressure again.WOW | ||

D_adams |

Well, it idles fine, runs fine at 3000 rpm, fine at 4500, 7500 and 10500. Doesn't matter what gear/speed, it just hooks up and rolls. 3rd gear is still sweet for wheelies. Dunno what you did different exactly, but this one hasn't lost anything. Saturday will be Judgement day for this pipe though. I want the numbers on paper to prove one way or the other. My first run doesn't have the torque curve mapped since the pickup sensor was broken. Hopefully that is fixed now. Either way, I can compare HP, so that will show what it's doing, dips, rises, etc. All I can say is, this one runs just fine. | ||

Xb9er |

wow that sounds great. Just let me know when to send my pipe!!!!! | ||

Blackflash |

did you take any of the tubes out? | ||

Kokomochandler |

you cut the s pipes out but did you drill the hole in the wall like in your first outlines ? | ||

Geforce |

No drilling. S pipes removed. Outlets changed. | ||

D_adams |

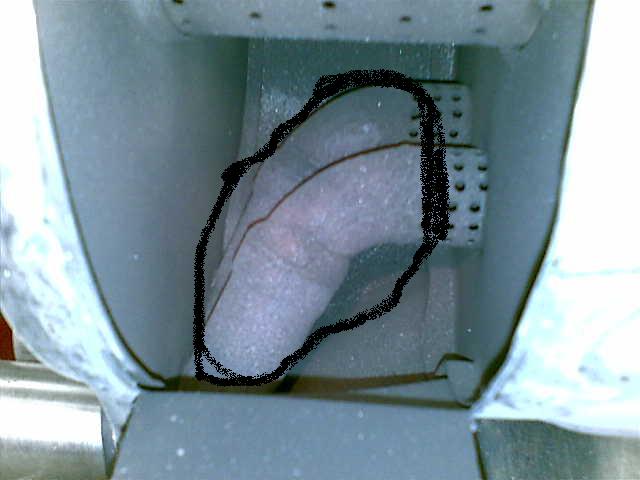

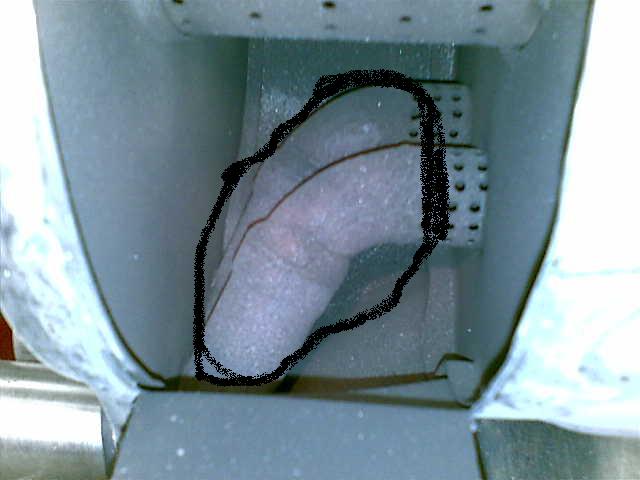

I only removed the 2 small pipes running through the 2nd chamber. No holes drilled at this time, although it would be easy to do if needed. Dyno run comes first to see where it's really at. It will be run on the same dyno as it was originally, although by a different operator. Temperature will be probably 25 degrees cooler. I'm sure that will have a small effect on the results, but not a lot. Here's the part that was removed circled in black.  | ||

Blackflash |

Ya that's exactly what I did. It ran smooth at low end . But the reason why it was smooth was cause there was no grunt . I even locked my afv at 106 106 it still ran worse at the dragstrip my times went from 10.58 134 mph to 10.72 130 mph until I put a stock can on again then she ran great again . Does she even pull a wheelie in second with it like that? Mine wouldn't until I put the stock can back on. Not kidding!! I thought in your plans you were adding holes not gutting the second chamber out. I wouldof told you not to go that route. I did that. And more noise doesn't mean it faster. Noise only distracts what is really happening. | ||

D_adams |

Yep, it still wheelies, 1st, 2nd and 3rd gear. Too wet to try a run tonite, had a different camera, but it was raining.  | ||

Boogman |

can i ask the question .. how deep did the tip s go into the chamber ? and did you weld on th e inside wall to hold in place ? or were the welds on the outside of the can enough ?? Love ya work and you would have an order from me if you get to that .. however Im over the pond in Australia .. any help/advice appreciated .. ive ordered a new can to do this surgery .. | ||

D_adams |

These pipes were only 4" long, so there's about 2 inches sticking into the pipe. The welds on the outside are enough to hold it. I'd do it, just figure out the exchange rate and shipping costs. I'm sure it wouldn't be cheap to ship it here though. It's all pretty well documented with pics. I used a 1/16th inch cutoff wheel to open the top and a sawzall to remove the tips and interior pipes. Shaping the oval holes was done with an agressive cutter in an air grinder. I think it's about 3/8th's of an inch in diameter. Gotta get a new one of those too, I destroyed it on this project. Lots of broken cutting teeth on it now. From there, fit the pipes into the holes and verify the angle I wanted. Cut the angle for the outside. I used about a 45 on the outside, but the pipe angle itself is about 37-40 degrees I think. The outside angle can be cut however you want, or left square. I used a scotchbrite ball to smooth out the inside of the new pipe and a 120 grit scotchbrite and sandpaper wheel for the outside. For a full polish, follow it up with 5 minutes on a cloth buffing wheel and then some simichrome on a rag. Keep in mind that the polishing will get ruined when you weld it on, so I didn't do a lot of it on this one. They're kinda short, so there's really no point. You can't see the back side unless you remove the rear wheel or use a mirror. After all that is done, then weld the flap closed to seal the top of the pipe. It's very thin walled sheetmetal, so either use low heat or move fast, otherwise you'll blow right through both the outer and inner skins. Yep, there's 2 sheets there, about .025" thick each. I tacked it in several places to prevent it from deforming as I went around the cutout. Even so, it still wanted to warp pretty bad. After all that's done, clean the welds with a sanding disc on the air grinder, wash off the entire pipe, tape the new outlet pipes off, then shoot the whole thing with high temp paint. If you have an oven, bake it, if not, mount it on the bike and use the heat from the exhaust to do the baking. Maybe 7 hours start to finish if you take your time and do it right for the first try. I'm figuring I can get one done in 5 hours or so, not counting the paint drying. Unfortunately, I have to split my time between 2 or 3 days on each pipe. I've got a 10 hr a day job and the wife seems to like to go out shopping a lot. Between her, the job and trying to get some riding in, I stay pretty busy most days. I also fix computers on the side and have been doing that for 12 years now. | ||

Cafefun |

So If the dyno turns out all right what are you thinking you will charge to do this? | ||

Blackflash |

make sure you dyno the bike that day with the modded exhaust then onto the stock pipe.I guarentee youll see a loss.Those two pipes are very inportant.Gutting them caused more airflow from all chambers. especially from the rear baffle flow was increased .I bet ya the pipe is pretty loud.Like ive said ive done that.Twice actually.And everytime that i put my stock can back on it made me grin again.That pipe is ruined!!!dave at o s b rode my bike after i did what you did .And he said my bike was horribly flat.We uploaded his tune and it ran even worse.There is a way to louden this pipe but thats not it.Im very close to the right increases for proper chamber flow. | ||

Cafefun |

I would also like to see a run with your exhaust then a run with a stock one same day. just time to switch back and fourth. | ||

Blackflash |

I know what taking that rear set of tubes out does!!small changes need to be done to this pipe not major gutting. | ||

Blackflash |

I also am wondering why this pipe causes it to crank over so much before it starts in the videos. That s exactly what mine did until i put the stock pipe back on.Hell my jardine didnt even cause my bike to do that.No backpressure!!! | ||

Blackflash |

What is the going rate for this type of work your performing? | ||

D_adams |

Tell you what. You do it your way, I'll do it mine. If I'm wrong, then I'm wrong, but SOP says no losses in power. Saturday will tell. I have one run scheduled, I'll see if they can work me in for a 2nd a few hours later. As far as the slow start, I had a Jardine and it did the exact same thing. It does it on the stock one as well. Sometimes it takes a few cranks to start, other times it fires right away. No rhyme or reason to it that I can tell, but I know it's not this mod. Doesn't matter if it's hot or cold, it's just temperamental sometimes. My normal labor rate is $70/hr for just about everything I do on the side, whether it's bike repair, welding, computer repair or whatever. My time is worth something, what's yours worth and do you need your pipe done also? | ||

Geforce |

This was the plan. The numbers also dictate priority. 1. Add more sound without going overboard. 2. Change outlets and redirect exhaust flow away from wheel. 3. Avoid significant powerloss. If we get some extra power then great. The intent behind Operation "Muffled Thunder" wasn't at all aimed at trying to squeeze more power from the pipe. We'll find out more on Saturday. After hearing the pipe myself today and taking a good look at everything I am very happy with the outcome. The sound isn't ANYWHERE near as loud as my D&D. It sounds great! Just loud enough to really sound nice. | ||

Redscuell |

I guess I didn't understand the earliest posts about this mod -- but NOW I'm understanding that what's been done is to REMOVE the S pipes, but not replace them with larger ones? (Yes, 1.75" i.d. would be right for the new S bends.) Sorry, but what made you think simply removing the S bends, and increasing the size of the outlet pipes, would work? Just cutting off the S bends doesn't remove the restriction of the openings through the final chamber wall, into which the S bends were welded. I don't think suitable design criteria should be "louder but no loss of power". The criteria I had were "natural sound (the v-twin thump) and an increase in power". Otherwise I'd have removed my triple outlet toot sweet. | ||

D_adams |

Ok Red, I wasn't going to respond to this, but in a nutshell, if you look at the pair of 2.5" pipes that are in the same chamber as the ones I cut out, you might notice that they are both drilled in an entertaining pattern of small holes, roughly .050" in diameter. Here's the pic again in case you missed it.  Now, look at how many there are in this pic on just one pipe, I'm counting 8 of them. That's in a 3" long section about 1/2" wide. Are we in agreement there? K, good. Glad you can count with me. So anyway, 8 holes every 1/2" of the circumference, comes out to something like 7.85 around the outside if you wrap a tape measure around it. Yes? No? Yeah, go ahead, multiply 2.5*3.14 and see what you get. Then grab the seamstress tape measure and check again to be sure. K, we'll go with 7.5" to be generous and make it easy. Now, multiply that by .5 and you get 15 and then add that last .5 in there for a total of 15.5 (fifteen and one half) 1/2" sections. Now, provided I haven't lost you in this so far, multiply that number by 8. What didya come up with? 124 holes? How much flow will I get out of this seemingly insignificant set of holes that previously went nowhere? Hmmmm. How much of a hole is that? Mind boggling, isnt' it? 0.00196349541 * 124 = 0.243473431 per pipe, ie; .25" per pipe, soooooo, just a rough guess, there's a 1/2" hole in the 2.5" pipes when the surface area of all the pinholes are added up. Just in case I lost you on that calculation, it's the hole size * PI R squared. Got that? Good, glad you followed along so far. Now on to the fun stuff. If we measure the ID of the stock pipes, we would find that they are 1.125" and the ones I installed measure 1.625" so, there's just a straight .5" difference in ID. The surface area is considerably greater and I'm running out of time to do the math on all of this. However, suffice it to say, there was additional flow available from the 2nd chamber to increase flow and also allow for additional sound, just by removing the 2 S-pipes. It's not the maximum amount that I could have done, but in all likelyhood, it will make a difference in power. It DEFINITELY made it louder than stock, but it's not overbearing like a straight through exhaust. It also looks essentially stock and not hanging out there like a third leg. Have a good day boys. Enough math for me at the present. Edit, sorry, that last part sounded condescending to engineers in general and I shouldn't have slandered them as a whole, so I'm retracting the phd/engineer part. I don't want to get a flame war going on here. I'm just posting what I've done and the results I've seen and heard so far. I've got another video or 2 to post, just haven't uploaded them yet. (Message edited by d_adams on November 05, 2009) | ||

Reducati |

D, keep up the good work; alot of us are following this thread, and looking for exactly what you are doing. thanks! | ||

D_adams |

Thanks, if anyone's interested, pm me. I have a list going for when it's ready to go. | ||

Xbswede |

Looks good and sounds good. Good job. |