| Author | Message | ||

Unibear12r |

Why do you HAVE to tie the throttle linkage together when you de-noid? Because there's a return spring in the noid that helps the throttle plate spring keep up with the throttle actuator. It's not real strong but it's there. I should have known that as they are always either powered both ways or have a return spring. I got a lot of throttle hesitation test riding today without the linkage tied together. Without the mass of the noid & noid cable to fight with I would have thought that it would be easier for the plates to keep up with the actuator side but now I see why the opposite is true. So it's time to lift the air box again and tie the linkage. But high heat, movement and edges are the last place for a tie-wrap (zip-tie to some). Anybody come up with a better idea yet? Anybody in aftermarket sales coming out with something? I wonder what Buell racers might be doing? Then again as often as they tear into their bikes a ty-wrap could be checked often. I don't want to take the airbox off that often on a street bike and I don't want a broken ty-wrap getting into something where it doesn't belong. | ||

Jmr1283 |

i used small wire from lowes. its the same as safety wire. small gauge but strong enough. | ||

Voodoo |

Anyone in the Raleigh NC area done this to their bike. I would love to possibly get some "hands on" experience with this. Ie test ride. Thanks. | ||

Jmr1283 |

ill have to go into the garage to see the guage but i think its about a 32th thick to a 1/16th. it was very is to wrap around then after a couple times cut it enough to to be able to take both ends the twist them to tighten it up. | ||

Badlionsfan |

We used safety wire when XB9 did mine. | ||

Fresnobuell |

PAIR OF needlenose pliers and thin wire does the the trick. | ||

Zac4mac |

I just used a nylon zip-tie. Working fine for the last 3 months or so. Z | ||

Eaton_corners |

Remember black ty-raps are uv resistant and made for higher heat applications. | ||

Bob_thompson |

I did as Jmr1283 did but used stainless steel .035 wire for a little additional strength. Just stole a piece from my MIG welder. A roll of this is about $10.00 from Home Depot and has many hundreds or thousands of feet on a roll. Good for most safety wiring also. A best buy. Bob | ||

Steeltech |

Dammit, I didn't know that it would be necessary to tie them together. Now I have to go back in. Anyone have a good, clear picture of where you have been installing your cable ties? Update: So I just ripped the airbox apart. I don't see why you need to tie them together. There is a hefty spring that holds constant pressure against that linkage. So unless you remove the spring, why tie? Using the picture below as reference. I'm guessing the red X marks where you want safety wire, but the blue arrow is point to a very sturdy spring that applies constant pressure to that assembly. http://img401.imageshack.us/my.php?image=solenoidlinkage2gr0.jpg Any reason why this spring is not considered strong enough to do its job? I would appreciate a swift response as my bike is now apart and I plan to ride in to work tomorrow. ST P.S. how you do post visible images on here? do the [IMG] tags not work? (Message edited by SteelTech on November 17, 2008) (Message edited by SteelTech on November 17, 2008) | ||

Redscuell |

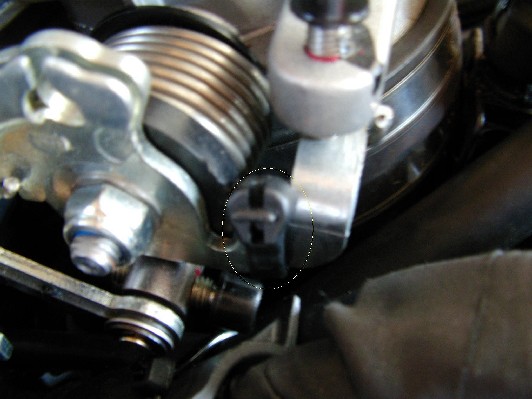

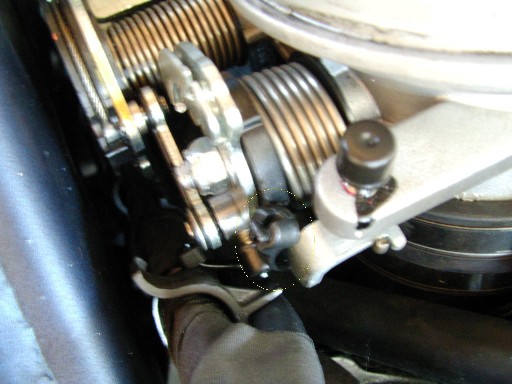

Pics, courtesy Markel.    | ||

Steeltech |

Thanks for the pics, Red. Please see my previous post though as I have edited. | ||

Unibear12r |

I've used black tie-wraps in my occupation for about 30 years. IMHO the heat (mainly) at this spot makes them unsuitable for this application without a great deal of supervision. Thanks for the ideas everyone! | ||

Steeltech |

Well...its 7 o'clock and no one can provide suitable evidence that the zip-tie or safety-wire is even necessary. Again, the spring that is already there to apply resistance to the solenoid keeps the throttle plates closed. I am going to reassemble minus the tie down. I also don't see why a plastic tie wouldn't work in that area of the intake. You will be back in there every 12k miles to do a valve lash. That would be roughly every year if you ride often enough. I doubt the plastic would degrade that fast. So if you are that concerned about it you can replace the plastic zip tie every 12k or just look at it every 12k, besides the fact that it isn't really necessary. If anyone wants to dispute me...go ahead. I've been waiting for someone to do that ever since I took the airbox apart. ST | ||

Slypiranna |

Ok, when you put it that way... The reason for locking the real throttle body 1:1 is to prevent the possibility of the butterfly fluttering and/or delaying actuation during rapid transients. This was found a concern way back in February of 08. This also has been documented a concern on a few models that had weird tps readings. Throttle response and known WOT throttle are two of the side benefits. The noid must be disconnected, the throttle cables adjusted to minimum play and a tps reset performed. Safety wire is the best method for this mod but tie wraps have already proven fine in excess of 12k miles on over 10 examples. If your in doubt of anything, use true safety wire to lock the rear linkage. While your in there, lube all throttle linkage points. Please be aware that while many have done all the above, no one recommends it for the non tech to attempt. You can do damage! Nor is this recommended period...as it goes against EPA noise limits. This is a race only mod that WORKS. You will get a check engine light(s) with two difference codes, a P open code and the Active intake system code but it doesn't affect the ecu/engine at all and will self clear after approx 50 run cycles from the ecu. I hope this helps answer your questions. (Message edited by slypiranna on November 17, 2008) | ||

Unibear12r |

Reread my first post Steel. When I figured out what was going on I could make it happen. It did fine rolling on the throttle slow but get it up to mid range and rapidly close and open the throttle and I could get the plates to stick closed almost 1/2 to 3/4 of a second before they would bang open. It was a little uncomfortable in the twisties bogging & banging through the corners. You should tie the linkages together. | ||

Steeltech |

man....i just took the f*cking thing apart twice....once to do it....and once to tie it to see what the f*ck you were talking about. I've got enough practice doing that sh*t for one week. Here's my problem...I had it apart and a message pending for 3 hours and no one said anything. I say "whatever" and put it back together and then get a response. Alright. Here is my beef with the "needing" a zip tie. What you are saying is that Buell has a faulty system in place. Because at WO on certain gears and RPM, the solenoid doesn't even operate. The spring does its job and holds the throttle plates WO. But now you are saying the spring is insufficient even though removing the solenoid doesn't change the operation under many circumstances. Well, now its to late. I won't have the free time to do the damn thing again for a little while. I am going to keep riding as the absence of the zip tie would seems to pose no more threat then the early map use to when going WOT (pause...launch suddenly to WO...yeah that was fun finding that out). My only concern is if the hinges on all the throttle body linkages began to seize up...from corrosion or something. But that would be an issue shared by the good folks that still have the solenoid. For now...I'm just gonna run it. ST P.S. If I'm not mistaken, the TPS is zeroed on 08 and later Buells every time you turn on the ignition. XB and 1125 models. (Message edited by SteelTech on November 17, 2008) | ||

Slypiranna |

Steeltech, Do it a couple of hundred times and then whine. None of us are here to answer questions within a three hour period. Search archives...this and a whole lot more is as easy as google. Nothing personal, dude but you asked for an answer.  Now search the rest. Now search the rest. | ||

Unibear12r |

Sorry Steel but I'm a bit busy myself back and forth from the computer. Just got done doing some minor wrenching on the Uly and now got to get up and do the single dad thing and cook for the kids. I've yet to reopen my 1125 and tie the linkage together myself btw. I don't see anything "faulty" with what BMC has done here. In fact I'd say that BMC did a nice job of balancing the noid and throttle plate spring against the return spring to give such a good throttle feel and still work against the intake vacuum. I bet some time was invested in that. While I prefer the muffler valve on the XB's for quieting during the EPA requirements I suppose that won't work as well for the 1125. I can't get mad at BMC for using what appears to be a legal loop hole in the law (as to the spirit of the law anyway) to give us more of what we want. Nor can I get mad at them because we choose to mod the bike against the rules that they HAVE to obey. | ||

Two_buells |

Manual TPS Calibration (08 and up) 1. Verify throttle cable adjustment. 2. Turn the ignition switch to ON. 3. For three cycles: Pause one second on each throttle stop (fully open, completely closed). You should tie the linkages together. next time you have it apart hold the throttle about 1/2 open and with your other hand move the butterflies and you will see why it needs to be done. | ||

Steeltech |

I actually did do that this last time I had it apart, Two. I just thought "my finger isn't going to be intake when I'm riding, and the spring seems to be doing a good job". I was also checking to see if it stuck going to wide open and such, keeping an eye on the linkage for the solenoid to see if it separated at any time. I'm not writing off the tie-down...I just didn't see why at the time before I reassembled. Now I won't have time to do it for a week or more. In the mean time I'm gonna run it without and see if I do have any problems. I ran it for about 5 miles tonight just to make sure I had it all back together and such, but hardly a good chance to really play with it. Sly...i'm not saying you are my personal customer service station. I'm saying that I had nothing to go on because no one said anything so I made a judgment call. I tried searching briefly and turned up the same pictures and text that just said "just do it"...but not why.... O, and yes Two...I saw that as well. I bought my service manual before the shop got one  . That of course being to calibrate it manually once your replace it. But am I wrong in believing that it also resets every time you turn the ignition on? I have not purchased the electric one yet as I still have access to one. . That of course being to calibrate it manually once your replace it. But am I wrong in believing that it also resets every time you turn the ignition on? I have not purchased the electric one yet as I still have access to one. | ||

Zac4mac |

Nobody here is telling anybody else "what to do". We do try to pass on ideas that work tho. (Message edited by zac4mac on November 17, 2008) | ||

Carbonbigfoot |

But with that said, here's what you need to do... <grin> Rob | ||

No_rice |

ugh, people try to help. take the advice or leave it. it will effect no one but the individual with the bike. the reason some people(me included) have tied the linkage together is because there have been instances where the vacuum from the throttle bodies sucking air seem to have over powered the springs that are trying to hold the butterflies open making them close or partially close. then they would suddenly spring open causing the bike to jump forward like it was given a handfull of throttle. i dont know that anyone has visually proven that to have happened??? but it is a possiability. therefore i figure why not eliminate the possiability of a problem before it happens. i mean hell, it took me all of 30 seconds to do it when i was taking the noid cable off of the throttle bodies. like i said, its free advice. take it or leave it. just dont get pissy when you ask and get people trying to help you with an answer | ||

Slypiranna |

No_rice, PM sent. mm | ||

Usmoto |

I did this mod back in the summer. I disconn'd my noid but didn't tie the linkages together. I twisted the throttle a number of times and didn't see where the linkages could move on their own so didn't think it was necessary. I've never had any probs since doing this and no code of any type but I shouldn't because I left the noid electrical conn's plugged in, just removed the cable and tied it back. Without the noid, it runs much smoother. |