| Author | Message | ||

Dsergison  |

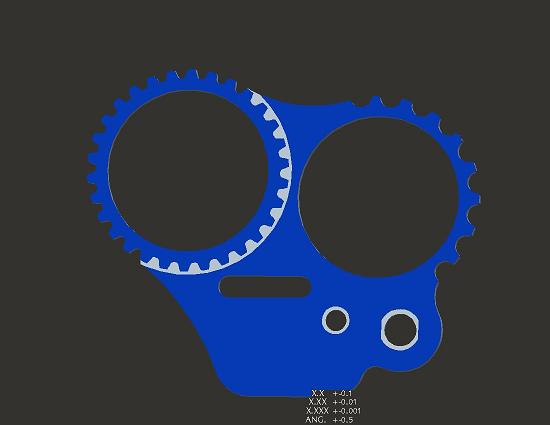

I'm not satisfied with my billet dash. So.... I either want to have gear teeth milled into it, of belt sprocket teeth. belt sprocket = realatively easy manual mill work. gear teeth = justification for major CNC expenditure.  here's a pic representing both ideas.  | ||

Spiderman  |

I think it would be cool just like that! | ||

Road_thing  |

Gettin' a little cabin fever, there, Serg? I think your dash looks great just the way you made it. But, hey, if that's the justification you need for new gear, justify away! I've got a cute little rotary table for my mill coming, so I can empathize! rt | ||

Steve_mackay  |

What did you design that in? The GUI doesn't look familiar. Anyways, ya want that cut on a CNC? Come on up here on any evening except Thursday, or come up on a weekend and I'll cut it for ya. or just send me an iges, parasolid, or step file of it, and I can show ya it completely cut  good work, certainly original  | ||

Dsergison  |

ProE WF2. -- quicky screen snap, left the stupid tolerance stuff on. thanks for the offer. I'm trying to get a Tree journeyman knee CNC for home. I think I need to get more power to the house  currently using a static phase converter for a 2 horse mill. I don't think the 5 horse Tree's VF spindle drive electronics will run on single phase at all? currently using a static phase converter for a 2 horse mill. I don't think the 5 horse Tree's VF spindle drive electronics will run on single phase at all? So far it's just a quick hack model, for visualization purposes. yeah, it's about 12 degrees here and I'd rather be riding. fun fun fun. P.S. what controll does your machining center use? I use Pro/E's machining package. can post process to most types. have output Fadal-6M previously. | ||

Steve_mackay  |

You can get the journeymans in single phase. It was an option. We've got 7 Haas machining centers ranging from 16x30 to 64 x 32" travels. The control is Fanuc compatible. |