| Author | Message | ||

Bad_karma |

I will be installing the motor in my 99 S3 here in the next few weeks. I have been pondering the idea of adding a metal strap of 3/16 steel between the head bolts on the front mount. Pro's? con's? Thanks Joe | ||

Djkaplan |

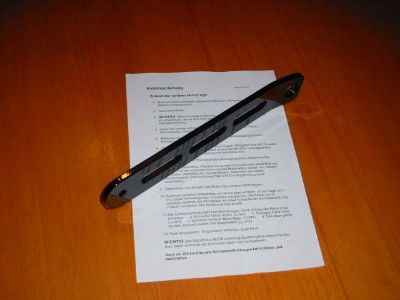

I think these guys have a better idea...    Not sure how to get stuff from them, though. I hate to say it, but it wouldn't be hard to do this yourself... | ||

Buellistic |

If you make the engine too ridged it will vibrate like a old ridged engine sportsters ... In BUELLing LaFayette | ||

Djkaplan |

Look at the strut again... it doesn't restrict the engines range of motion during vibration (at all), it vibrates along with the engine. It just keeps the top of the motor mount secured and keeps leverage off the two bolts that screw into the head. See? I can't see any disadvantages with this idea. A novel, out-of-the-box approach, in my very humble opinion. | ||

Oldog |

it doesn restrict the engines range of motion during vibration all it vibrates along with the engine. It just keeps the top of the motor mount secured and keeps leverage off the two bolts that screw into the head. See? Err? no, it mounts on the top of the front iso and ties back to the Engine between the cylinders on the top center mount, It supposed to reduce stress on the 2 front bolts? I'm sorry I cant make that work Load moments transfer stresses from the head thru the front mount which the bolts clamp to the head in tention, from there up the mount through the center hanger bolt, this transfers the motion to the rubber and its mounts to the frame. IMO the issues with busted heads / hangers and mounts relate to A. loose bolts B. flawed parts C. excessive stresses due to A or B ie left / right bolt gets loose or the arm of the mount cracks and over loads the bolt / head casting etc... I find my self agreeing with Lafayette in that if the engine is to closely constrained Then the Flexible mounting setup that helps to reduce vibes will be circumvented. One other point the D washer appears to be missing this will compromise the integrity of the forward mount IMO. I would like to gets Hughs' ( Huglessys ) take on it as he is an engineer. (Message edited by OlDog on June 18, 2007) | ||

Oldog |

Joe: on the front hanger, I would consider a nice billit piece, with a webb between the arms, several firms sell them and AAOMY did a piece ( in the KV ) and actualy made one. DJ just posted a pic recently of his. IMO the strap installed under or ontop of the mount will likely compromise the setup and result in breakage [ IMO ] | ||

Djkaplan |

"I would like to gets Hughs' ( Huglessys ) take on it as he is an engineer." If engineers always agreed with each other, my job would be sooooo much easier... | ||

Djkaplan |

"Err? no, it mounts on the top of the front iso and ties back to the Engine between the cylinders on the top center mount..." Look again and think about it. The mounting location for the rear of the strut is tied to the engine, not the frame... it vibrates exactly in the same plane and with the same amplitude as the engine and front mount (visualize it). It does not restrict motion in the any of the isolators or tie-bars. For it to do what you think it does, the rear of the strut would have to be fixed to the frame (but it's not). The strut keeps the moment off the two mounting bolts when the engine is vibrating in the front isolator. It does not tie the top of the isolator to anything, it just ties the isolator bolt to the same vibrating mass the mount itself is attached to. I'm sure if you think about it for a minute, you'll agree... look at the system as a whole, not just one part of it. But even if you (and Buellistic) don't agree (but I suspect you eventually will), it doesn't matter to me, I'll respect your opinion anyway. But that doesn't mean I'll agree with it. | ||

Djkaplan |

"I have been pondering the idea of adding a metal strap of 3/16 steel between the head bolts on the front mount." Aluminum mounts with the legs tied together have had the same failure mode as those that don't. Seeing as how steel expands (ever so slightly at the distance involved) than aluminum, I'm not sure you'd be getting anything out of this modification. It may make the situation worse (heck if I know, though). It would be 'different'...use something harder than A36 steel if you try it. | ||

Bad_karma |

Thanks all Jim and Daniel, I think this project will get shelved for now. Joe | ||

Limitedx1 |

it looks to me like that strut would only stop stress in the frame between mounts, it does not connect to the motor on either side. if the two tube spars from the back mount to the front cant stop that flex, then there would be alot--alot more breaks. my 2 cents | ||

Djkaplan |

"...it does not connect to the motor on either side." I hate to keep saying it, but look again. It's tied to the engine at the rear, and it's tied to the engine at the front (through the isolator bolt). The mount the isolator bolt is attached to (squarely, I might add) is directly mounted to the cylinder head. Please look again. Am I the only one who can see the merits of supporting the top of the isolator bolt? The bolt is is trapped in a tube that keeps it square once it's torqued down. Supporting the top of the bolt helps keep movement of the engine from creating a moment on the front engine mount. What's causing the failure of these mounts is conjecture at this point, but the advantages of the strut aren't. It doesn't created anymore stress in the frame, it doesn't restrict movement of the engine (that was intended), and it doesn't keep the locating rods from their range of motion. It supports and ties in a part of the engine that needs supporting. Whether it's a solution to this problem is yet to be determined, but every argument against it (so far) is not based on what the strut is actually doing. I implore everyone to look again. If you still think leverage on the front mount is a good thing and doesn't need to be addressed, we don't need to discuss it anymore, but all replies will be read. | ||

Bad_karma |

Daniel I see exactly what you are saying. It insures that both end of the mounting bolt are in phase. Eliminating a rocking stress on the bolts to the head. I would be interested in trying this setup. | ||

Oldog |

I caught that, What I seem to be missing is the intent, to reduce loads on the 2 bolts facing forward? or the Front Iso, As I formulated my responce I missed that it was attached to the bracket between the heads and Initialy thought that it was tied to the frame, I may be missing some thing I see the IDEA all moving together next time I have the tank off or the manual out I will look at it again ? the idea is that the top end of the front hanger bolt is forced to move with the bottom this saves the bolts / hanger? what is the part made of? If engineers always agreed with each other, my job would be sooooo much easier... ROFLMAO!  | ||

Phatkidwit1eye |

I dunno... I had a flash back to installing my motor and the first thought that came to me was "#$%* That! I'm not taking that apart again unless it breaks" However, I'm not an engineer and when working on my bike I have to remind myself "righty tighty lefty loosey". But I think getting rid of the D washer isn't a good idea. Hmmm...I tried to type out what I was thinking, but it all got jumbled up. Lemme try it this way.... Take the isolator and put the D washer on it. Wouldn't that spread the weight/vibes out more evenly over the rubber part? Then say putting that straight bar over just the center of the rubber? So, wouldn't machining the end of that new piece into a D shape help it spread the weight/vibes out? Or is it that the Vibes and such have been reduced to such an extent that the D washer is no longer needed? I think I understand what it's trying to accomplish. Is it trying to minimize the up and down movement of the front Isolator? Or am I incorrectly picturing how the front isolator works? Well crap...I think I'll go back to lurking now. | ||

Djkaplan |

"Well crap...I think I'll go back to lurking now." Don't do that, Phat. I thought you brought up some interesting points that certainly deserve pondering and chin rubbing time. The Deutschlanders that make the strut also make another interesting part, worthy of BadWeb argument and debate as well... Check out their rubber mounted hanger for the race header.  Would this part succesfully eliminate the notoriously failure prone hanger, or would it create a resonance that would shake the whole system apart, breaking exhaust studs, cracking welds, and shearing tubes... like the factory system has been known to do? Heck if I know, but I had a much different solution to the problem. |