| Author | Message | ||

Jtskir222 |

when the spring breaks does it make it sem that the clutch is gone? my 97 s3t today felt like it slipped a bit off the line then it would only go about 10 mph. the motor is running fine and the clutch seemed fine it just seems to be slipping. has anyone had this problem? | ||

Blake |

JT: Does your clutch cable/lever have adequate free play? | ||

Road_Thing |

JT: If you're talking about the M6 spring, the answer is "no". The only obvious sign that the spring has broken is a lot of extra slop in the driveline as the primary chain goes slack. Of course, if a piece of the spring were to somehow jam up the transmission, your rear wheel would stop turning--I suspect you'd notice that... Blake is probably on the right track, as usual! r_t | ||

Ccryder |

Have any of you Buelligans replaced the primary crakshaft seal (P/N 35151-74)yourselves? MR is in the process right now and any helpful hints would be appreciated. The way the seal was installed it seems to be installed backwards to the logic that suggests it should be there to hold back the engine crankcase pressure. The open side of the seal was towards the primary side not the crankcase side as would be expected if crankcase pressure was to help the lip seal. Anybody's $0.02 would be appreciated. Side note: There is apparently a "special" double lipped seal that is only available for "special" problem child bikes that won't stand up to the stock seal. But.... this special seal is special order only (or so it is said). Anybody got a spare double lipped primary crakshaft seal laying around?? | ||

Blake |

Neil: Mike Paladino changed his seal a month or so ago. There is a new seal. Nothing special, just new design. Your parts manager should be able to give you the new number. It was posted here somewhere a while back. | ||

Jtskir222 |

THANKS FOR THE INFO GUYS. BUT AFTER READING MORE POSTINGS IT SOUNDS LIKE MY SHIFTING BEARING WE NT. I HAVE HAD A FALSE NEUTRAL BETWEEN 2-3 WHILE ON THE GAS. AND YESTERDAY WHEN IT HAPPEN I WAS TWO UP ON THE BIKE DRIVING ANOTHER GUY ON IT AND THE BIKE I'M SURE WAS OVER LOADED. WE ARE BOTH AROUND 195. WHILE RIDING THE BIKE WITH HIM I HEARD A FEW SQUEAKS FROM THE FRONT PULLY AREA WHEN I WENT OVER A FEW BUMPS?? AFTER READING THE OTHER POSTS ABOUT THE BEARINGS IT SEEMS I MAY HAVE THE SAME THING. IS THIS A COMMON PROBLEM WITH THESE BIKES? I JUST BOUGHT MINE. IT HAS 6000 MILES IT'S A 97 S3T. THE CLUTCH FEELS FINE ON IT. HOW BIG OF A JOB IS THIS? WHAT IS THE APPROX COST OF THE JOB / PART'S? IS THERE ANYTHING I CAN DO TO KEEP THIS FROM HAPPENING ANGAIN?? THANKS FOR ALL YOUR HELP. MARK | ||

Blake |

Please lose the ALL CAPS! | ||

Jmartz |

Cyrider I have done it a couple of times. Ping me off line if you want directions. Jose | ||

Jeffsd |

There is an article on chain tensioners for big twins in the August 2001 issue of Hot Rod Bikes. It mentions the M-6 and the HB 125 chain tensioners. It talks about installation but does not really compare/rate them. I'll continue to check here for more developments. I'm considering on of them for my 00 x1. Jeff | ||

Leeaw |

Jeff, I was advised to stay away from them because they only deal with the chain going in one direction, and are not made to handle it when the bias is shifted towards the rear. | ||

Blake |

I agree with Lee. Upon deceleration the chain can slap the upper cover leading to problems. If you use the stiff spring and are attentive to not let the chain become too loose so that the tensioner is not taking up say more than an extra 1/2" or so (total of ~1" when cold), you might be okay. The tensioner will reduce the amount of noise and vibration from the primary chain, if that's a concern to you (usually only a concern when the chain is getting loose). | ||

Aaron |

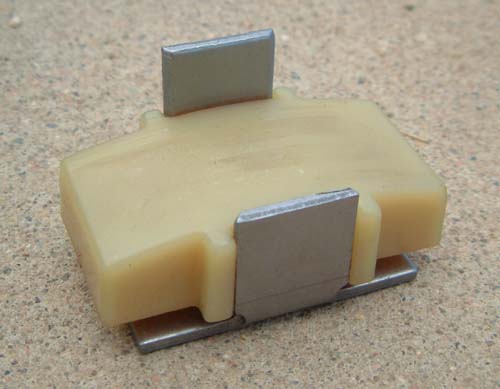

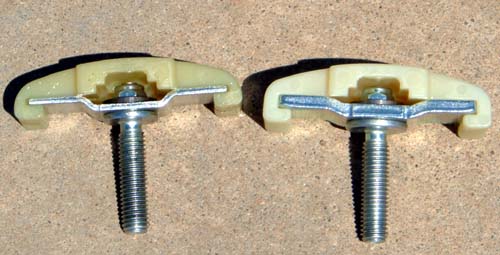

What you see here is an M6 tensioner that I pulled out of my S2 with about 1000 miles on it. I pulled open the primary because it was noisy and vibrating and this is exactly how I found the tensioner. Yes, the spring is in place.  Here is why it was stuck down. The chain has ground a burr into the M6 steel frame, which the shoe was hanging up on. I personally won't use one again, and I've been removing them from my bikes as I get a chance.  Yesterday, I went back into the S2's primary again and swapped out the tensioner on the left (which had replaced the M6 about a year ago) with the tensioner on the right. I'm putting these into all 3 of my late model bikes. Cheap insurance for $15. Part number 39975-90A AW | ||

Sportyeric |

Jtskir222. What progress on your problem? Everybody's been ignoring you for lack of clarity, I think. (Although they're all being MEAN to me so count your blessings. Anyway, your first post said it wouldn't go over 10mph. Now you say things are fine but you suspect the "shifting bearing". WTF is that? Do you mean the detent plate? I don't know anything about false neutrals (or anything else according to some) but I have had the tranny out by myself with just hand tools so I could help there if no-one more competent will. | ||

Jeffsd |

I went to San Diego Harley today and talked to a salesman named Fred. He races Buells. I asked him about the tensioner and he said that it did not need one(other than stock). I asked about noise and he said that it was normal for that engine. Aaron, are you replacing your M6 tensioners with stock parts? What is the difference between the old and new tensioners that are side by side in the lower picture? I have less than 3000 miles on my 00 x1 but I can not get used to all that noise.It worries me. (I bought the bike used and have only had it for two weeks) I may pull the primary cover when I can just to take a look. Is there anything specific I should look for? Thanks, Jeff | ||

Blake |

Jeff: The new one on the right has a beefed up steel support plate/shoe about twice as thick as the old one. | ||

Leeaw |

Now I am annoyed. I asked the dealership while my primary was off, to change to the "newer" chain tensioner. I said I was told something was beefier on the new part, but he said not to worry about it. I would have gladly paid $15, but I probably would have to wait longer to get the bike back anyway. Getting her back today, and she should be better than new. New shock, 10K service, fixed tranny. | ||

Aaron |

Jeff: What Blake said. Look at the difference in those puppies! All 3 bikes used to have M6's. The S2's got removed last year after it failed, in favor of the stock piece, which got swapped for the heavy duty piece on Saturday. The S1 lost it's M6 in favor of the heavy duty factory piece the other day, too. The M2 will get the same treatment as soon as I get a spare hour. Anyone want a slightly used M6? Nah, I like you guys. AW | ||

Court |

Uh....Calling Brad Galbraith....how soon can you get me one of these babies? Part number 39975-90A Court | ||

Reepicheep |

(moved to transmission... getting more depressed) | ||

Aaron |

Finally got around to removing my last M6 and replacing it with the updated tensioner today, here's how it looked:  Much like the S2's failure, the chain had been grinding pretty significantly onto the M6 frame. Only worse. This unit had 5000 miles or so on it. Looks like it would not have made it much longer before the chain ground it completely off. Lots and lots of metal filings on the drain plug. Don't use them things! AW | ||

Buelliedan |

Aaron, Whats the part number for the new tensioner? That number you posted would lead me to believe it's an older part, Shouldn't a newer design have a -00 number or did they just continue to use the old number with the newer part? And do you know what year they started putting them in our Buells? Dan | ||

Aaron |

It's listed above in both mine and Court's posts ... 33975-90A. Hey Blake, howsabout putting that number at the top of the page permanently? I think it started with the 2001 models, but I'm not certain. Seems like an old part number, perhaps they cost-reduced the piece some years back and found themselves with failures? | ||

Buelliedan |

Aaron, You are faster than I can edit my posts!! Dan | ||

Buelliedan |

Blake, I see you added the part number. You are the man! But why aren't you asleep. Or better yet after all this time away from your wife why aren't you in bed doing other things?? | ||

Court |

Aaron: I know you are busy now (you'd better be....) but can you post a short summary of the procedure to replace the primary chain tensioner? Are there any deviations from the factory service manual or hints we need to know? Thanks bud.. Court | ||

Reepicheep |

The only deviation I used from the shop manual was to not remove the drain plug for the primary, which saves you from pulling the muffler. Just wrap the muffler in aluminum foil and aim it all down towards the center, and pull the primary cover. It's no more of a mess then normal. You can get the drain plug in and out without removing the muffler, but its painfull and annoying for fat fingered fellows such as myself. The other tricky part is keeping the gasket in place while you replace the primary cover. I used hardwood dowel rod that was small enough to go through the primary cover, and threw them in a pencil sharpener so they would thread in to the crankcase and stay in place while I was working. Don't skip any holes, I skipped two the first time and sure enough the gasket walked and I had a leak. Others have suggested using grease to hold it in place, which would no doubt work well, but I wonder if it would lead to leaks. I try to follow clean room practices as much as possible when putting on gaskets. You will need the new tensioner (naturally) and a new primary gasket. You probably want some gasket remover as well, and a few good razorblades. I also polished my surface with 1200 grit sandpaper, it seemed to serve me well for the rocker box and it was laying right there on the bench. I reused the rubber gaskets for the chain inspection cover, shifter oil seal, and the clutch cover with no ill effects. For the '99 cyclone, primary cover bolts are 80-110 inch pounds. For 2000 models, 100-120 inch pounds. When you are sliding the cover with the new shoe back in place, remember to sneak your finger up and push the primary chain up to be able to go over the chain (and have the shoe adjusted to give as much room as possible). I know this sounds obvious, but you will have a lot going on trying to keep the gasket and all from walking while holding all the parts in place and lining everthing up. Task loading you know  Pinch screw on the old shifter arm is 100-120 inch pounds. It is 59 to 66 inch pounds on the updated shifter. Shift lever bolt (updated shifter) is 27-29 foot pounds. I put loktite blue on everything. I seem to remember it was all pretty obvious. Keeping the gasket in place is the biggest problem you will hit, and be sure to post your broken tensioner picture in the hall of fame with the rest of ours  You will have to adjust the clutch as well, so you need to know that procedure (which is simple enough from the shop manual). An easy (if a little messy) job. Bill | ||

Hogluvr |

Buelliedan, Reepicheep & others requested that I post what I found last night after pulling my primary off to work on my starter problem...  I was told by Bill & Mikej to look out for this when taking the primary off, and I'm starting to feel that my starter going out the other day was a blessing in disguise, even if it meant pushing the bike 2 1/2 miles!! (Fortunately) nothing looks damaged, and I will be armed with the p/n for the new tensioner when I visit my dealer tomorrow to get the new starter drive/clutch assembly to fix my other problem. AW, BTW I think you hit the starter problem on the head, the service manual agreed with your diagnosis, & when I pulled the primary off and hit the start button, the starter gear engaged, but wasn't able to turn anything, just a spinning sound from within... Thanks to all who contribute to this board!! I have saved myself many hours of grief and potential problems, & think I'll go broke buying rounds if I ever meet any of you in person  Mike | ||

Hogluvr |

Someday I'll figure out this image-postin'thing... | ||

Aaron |

Court ... other than the part numbers, this is all from memory, so don't bitch if I forget something. But I just did it yesterday so I shouldn't be too far off. Be sure to look in the book, too. Like everyone, there are a few things I kinda do my own way that won't be in the book, decide for yourself what to do. Here goes: 1) Buy the parts: 1 quart of Sport-trans oil or preferred equivalent 1 can aerosol brake parts cleaner 1 39975-90A tensioner 1 37101-84 seal 1 34955-89A gasket 1 11105 drain plug o-ring (advisable) 2 41191-74 chain inspection cover screws (advisable) 4 943 clutch inspection cover screws (advisable) 1 25463-94 clutch cover o-ring (optional) 2 11171 chain inspection cover screw o-rings (optional) 1 11188 chain inspection cover o-ring (optional) 1 7804 sealing nut (optional) General note: whenever possible, remove fasteners by striking, not pushing. Especially important on the clutch & primary chain inspection cover screws, but it's good practice in general. 2) Drain the primary (which may necessitate removing the muffler, depending on the muffler, the stock muffler on my '99 M2 is not a problem). Hold it upright to get it as completely drained as possible. I realize it can be done without draining the primary, but I think it's important to clean the plug anyway. 3) Lean the bike right, against the wall. 4) Remove the shifter ... use a battery terminal puller if needed ... if you wedge it open with a screwdriver, you WILL break it. 5) Remove the clutch inspection cover. 6) Remove the clutch linkage ... turn the adjusting screw clockwise until the nut comes out ... remove the ramp assembly and disconnect it from the cable by manuevering it into just the right position. 7) Loosen the locknut on the chain adjuster and back the screw all the way out, until it stops. If the muffler is in the way, you'll need a ball end allen wrench. 8) Remove all the cover screws and slide the cover off. Lay it on a rag, open side up, clutch cable still attached. 9) Swap the tensioners, putting the new one all the down, open side showing/closed side toward the cover. 10) Remove the old gasket and clean the surfaces. 11) Hang the new gasket on the motor, on the alignment dowels. If it doesn't want to stay in place and flat, use a little Permatex Aviation Gasket sealer to glue it in place. It's going to be hard to see or verify it's position as you put the cover on and if it gets out of place you'll have a massive leak. 12) Remove the old shifter seal from the cover and clean it's recess. 13) Slide the cover on. You'll have to reach in from underneath and push the chain up so the tensioner shoe can slide under it. 14) Put the screws back in. Torque to 95 inch/lbs. 15) Put a dab of grease into the center of the new shifter shaft seal. VERY CAREFULLY slide it over the shifter shaft. This is tricky to do without damaging the seal. When it's past all the splines, I then smear a light coat of Aviation sealer on the o.d. of the seal. Use a 1/2" drive 9/16 deep socket to push it the rest of the way in. A hammer is not necessary, use your palm. 16) Put the shifter back on. 17) Clean the drain plug and put it back in. 18) Stand the bike upright and add oil, until it just touches the bottom of the clutch spring. Too much is bad. 19) Loosen the clutch cable adjuster all the way. 20) Put the clutch ramp assembly back in. Be very careful not to drop that little cable end piece down into the primary. Slide the nut on and turn the screw counter clockwise, pulling the nut in, until it *starts* to seat. Now turn it clockwise 1/4 turn. 21) Put the little locknut with the spring on it over the screw and into it's pocket. If you have to turn the screw slightly to make the nut go on, make sure you're turning it clockwise. 22) Put the clutch inspection cover back on. Make sure that spring protruding from the lock nut is centered in the cover. 23) Adjust the clutch cable for 1/16" to 1/8" free play, measured where the cable housing meets the lever assembly. Tighten the lock nut and pull the booty back down over the assembly. 24) Remove the chain inspection cover. Adjust the chain for 3/8" to 1/2" of up and down movement cold. Tighten the lock nut. The book says 20 ft/lbs. Put the cover back on. 25) Clean up the mess, using your brake parts cleaner. Did I forget anything? This is not a hard thing to do at all. | ||

Blake |

5b) Loosen the four screws gradually, a quarter to half turn at a time until fully loose. This will help prevent binding/stripping problems. 14b) Torque screws gradually in stages using a pseudo star type sequence. 24b) Locate the chain's tightest position (blip the starter multiple time or try bumping the engine from the rear wheel with the bike in 5th gear). Adjust chain to within spec at it's tightest postion. 25') I like to use contact cleaner. I had a brand of brake cleaner damage the painted finish once. It wasn't supposed to, but it definitely did. |