| Author | Message | ||

Xbolt12 |

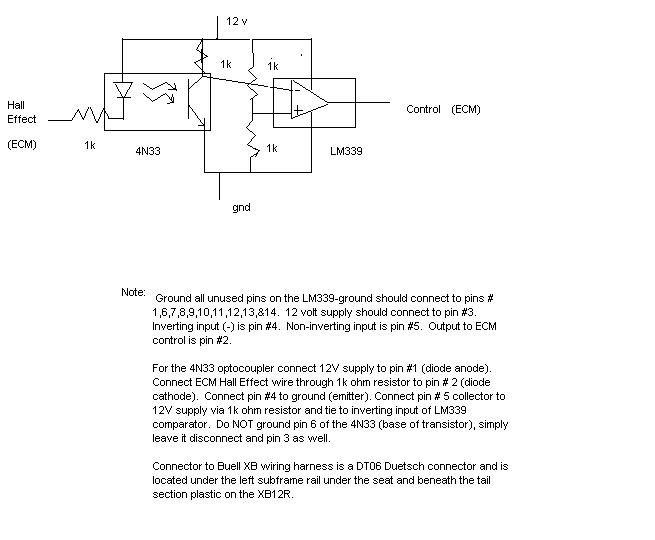

Well I finally came up with a circuit design that works for eliminating the exhaust servo motor on the xb12 when using the stock ECM and after market exhaust. I tried Opto's circuit but when testing it on the bike it did not seem to switch reliably on my bike (maybe the transistor gain was not the same as opto's). Also I had trouble matching impedance with the ECM exhaust control line, I think because it is CMOS logic and under 100 ohms when on or 0 volts. This made it difficult to get an external circuit working. Anyway, I bought a Deutch connector for about $6.00 and removed the motor and harness. Then I built a circuit consisting of an opto coupler feeding a comparator 4N33 and LM339. The opto coupler input internal LED is fed via 12 volts and the return is through a 1K ohm resistor to the exhaust control line from the ECM. The output from the opto coupler ties to the inverting input (pulled up to 12 volts with a 1K ohm resistor) of the LM339 comparator and the non-inverting input is fed with 6 volt reference voltage by a resistor dividing network of two 1K ohm resistors between 12 volts and ground. The output of the comparator is tied directly to the hall effect sensor line from the ECM. Effectively the output of the comparator works as a spst switch to ground (open collector output)and is essentially an open circuit when off. I soldered the components to a piece of circuit board from radio shack and then embedded it in silicone rtv in a small potting box roughly 1.25" x .5" x .5" which I then tie wrapped to the shock reservoir hose under the seat. I rode the bike all day today and the engine check light never even flickered. I'll post a schematic when I get a chance to draw the circuit out with paint or something. xbolt12 | ||

Xbolt12 |

Now the bike is down about 18 lbs from stock and you can really feel the difference (14 lbs Jardine Ti muffler, 3 lbs passenger pegs, 1/2-1 lb exhaust motor and wiring harness). Next stop-airbox mods and then I'll get the original aluminum Jardine chin fairing mounts modified for the extra mounting bolt like the new steel brackets. Should be strong enough and will drop yet another lb from the bike  xbolt12 | ||

Rr_eater  |

Xbolt, Which transistor were you using? I have mad a similar version of OPTO's simulator, and installed it. I have only had the chance to idle check it(wheather stinks), but so far no light after repeated whacks of the throttle. The first one I made did in fact trip the light if you whacked the throttle, but this one does not. AND all the pieces are from Radio Shack! Still would love to see yours, both schematically and a pic installed, as I too want to remove the harness. thanks Bruce | ||

Xbolt12 |

Here is a quick schematic. Sorry about the rough drawing. I'll post the connector part number and source if I can find the receipt.  | ||

Xbolt12 |

BTW: This schematic is for members of this board to use as they like. It represents my best effort and is working so far, but use this at your own risk. I do however consider this my design, so please do not build something to sell based on my design. Thanks, John Stahl AKA xbolt12 | ||

Xbolt12 |

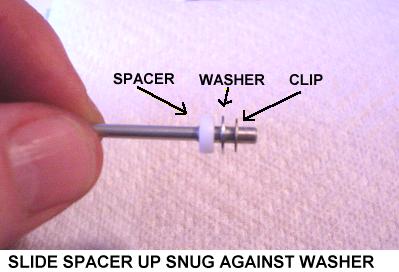

The connector you will need (at least for the firebolt) is a DT06-3S-E004 (3 Socket Black Plug) and (3) Solid Sockets, Nickel, 16-18 AWG. Total price was $6.84 from Batts Racing. Do an online search-I don't have their contact info. Also the connectors are Deutsch DT type (Hemet, CA if I recall correctly. xbolt12 | ||

Xbolt12 |

Oh and the transistor I used was an NTE 123A equivilent for what Opto specified and that may be why it did not work correctly (at least I did not get the voltage levels I expected when measuring on the bike, so I never ran it). xbolt12 | ||

Xbolt12 |

Radio shack will have all the parts but the 4N33 for my circuit. You will have to get that from another source. xbolt12 | ||

Blake |

Very cool. Thanks for sharing.  | ||

Fullpower  |

opto designed his circuit in australia, you would have to invert all values, and use a PNP transistor to make it work in the northern hemi..... owwww my head hurts..... the nurse is coming have to run now... | ||

Xbolt12 |

I'm telling you... I was ready to admit defeat and put the harness and all back in when an LED (I mean a light bulb) went off in my head.  xbolt12 | ||

Xbolt12 |

And for those who just have to know, the stock servo motor is a cheap little DC motor and some nylon gears driving the cable. One gear has a small magnet in two positions, and passes over a hall effect device on a circuit board. So the ECM can only sense an open or closed valve position as some of us suspected. The motor control unfortunately is done by a 36 pin surface mount ASIC (application specific integrated circuit). The chip is obviously a DC motor control circuit. It is manufactured by ELMOS and the part number is a 2500B, for those who might try to get a schematic out of ELMOS. The only other noticeable component is a 47uF 50V Electrolytic capacitor. BTW my motor is fine, but the plastic welds are gone. xbolt12 | ||

Opto |

You're darn right Fullpower, I should have thought about that before posting. Down here I still haven't had a CE light (from the active version) and the old code 21 is no longer in the history memory. Now I got a code 13 but that's another story... | ||

Surveyor  |

My head hurts from reading this incredible thread!! All this brain power and effort could be put into saving the world if Eric would just give us what we want....a progammable ECM. God be with the days when tuning involved fitting larger main jets and raising the float needle a couple of notches........bet most of you guys don't even know what I'm talking about!! I feel old and depressed. | ||

Glitch  |

God be with the days when tuning involved fitting larger main jets and raising the float needle a couple of notches........ Amen! Brother! You may feel old and depressed, but remember one thing, you're not alone. | ||

Peter  |

How do you raise a float needle a couple of notches? | ||

Glitch  |

Place needle in a paper cup. Place paper cup in the tub. Run water in tub about an inch.  I think he's talking about shimming the needle, not a "float needle"...  | ||

Peter  |

Yeah I know... I was just being a smartarse  | ||

Surveyor  |

You guys are right of course.......my head was hurting when I posted... | ||

Smitty  |

} if Eric would just give us what we want....a progammable ECM. That would be an EPA no no!  The Buell team went to great lengths to make a bike that gives power low emissions and ease of use. The bike is great for its intended use and the ECM delivers the goods. Now for racing applications only thats another story. Tim. | ||

Blublak  |

Hmmmm.. So what we're really asking about is a 'Race Only - Fully Programmable ECM' - for use by all us.. Uh.. amateur, club type riders.. Right? So, now that it's phrased right.. do ya think we can get the company to do it? Or do you think it's too much of a headache from a legality (for the Elves) stand point? Later, | ||

Xbolt12 |

Surveyor, I'm 45 and have been riding/racing mostly on dirt since '72. I have also always done my own jetting/porting, etc. so yes I do know what you are talking about (sadly). Opto, I was probably the crappy NTE equivilent transistor that caused me my grief. Still it is possible it would have worked anyway, I just wasn't seeing the control pull down anywhere near zero volts and the hall effect was not reaching 5 volts during the test outlined in the service manual. Then again, I was using a Digital Volt Meter and perhaps either the circuit or the meter just wasn't responding quickly enough in such a brief test. Anyway, thanks for your schematic which got my started on how to solve the problem. xbolt12 | ||

Xbolt12 |

Please be advised that the schematic I posted above is incorrect. The Control line connects to the diode and the Hall Effect line connects to the LM339 comparator output. xbolt12 |