| Author |

Message |

Easyrider

| | Posted on Saturday, December 26, 2009 - 04:41 am: |

|

Petebueller,

the solid line is the front cylinder, the dotted line the rear cylinder. |

Justa4banger

| | Posted on Saturday, December 26, 2009 - 07:23 am: |

|

WOW its interesting the difference in A/F ratio between the 2 cylinders.... IMO they are not even close..Well around 8k they get closer... down low they are all over.. |

Highscore

| | Posted on Saturday, December 26, 2009 - 09:32 am: |

|

Hi there!

This is my first post here. I am from Vienna/Austria and earn my money for living since 20 years now by making motorcycles stronger.

Last summer I purchased a 1125 mainly for its strong Austrian heart, the Rotax Helicon engine. The guys at Rotax designed this engine as a competitor for Ducati. So the Helicon-engine, as it is, is according Rotax capable for + 165 HP at the crank or more than 150 at the rear wheel on a chassis dyno.

Unfortunately the 1125 in stock Buell-trim fails this benchmark by far, because there are only around 130 HP available at the rear wheel.

So my project with this bike is to detect the short comings of the stock Buell trim to unleash the full potential of this jewel of an engine.

One of shortcomings is truly evident, it is the 1125īs cooling system. I am not talking about the aesthetics of the arrangement, but about the air duct thru both radiators at left and right: The air, heated by the radiator is blown below the steering neck,in the center of the motorcycle behind the front wheel.

Exactly at this place there is also the inlet of the airbox positioned where the Helicon engine inhales the air for its combustion. At the beginning of the funnel, guiding the air to the engine there is also the ambient temperature sensor located, whose signal is displayed optionally in the dashboard of the 1125. During cruising at low speeds the readings for ambient temperature are rather such, you may aspect in the desert at high noon. The readings stabilizes just, when the vehicle reaches a speed of more than 50 mph, that means an air speed which blows away this curl of hot air, made by the radiators, from the airbox inlet and the sensor here.

This arrangement of the air duct thru the radiators explains the poor engine culture at partial load during cruising, but this is not the only harm of this design, the real disaster start when testing the 1125 on a chassis dyno:

Unless there is installed +50kw blower power for the test cell ventilation the air speed around the motorcycle is low, similar to cruising in town. Therefore the air behind the front wheel, where the engine sucks its breathing are from, is always in some extent polluted by hot air either from the radiators or the hot engine itself. This causes a huge thermal drift for the engine with huge differences in the measured power out put, there is a difference of up to 15 HP within minutes from one run to the other.

But for development purpose you need repeatability of measurement. It should be possible to reproduce power readings of the same set up,the same tune at the dyno. And this is simply not possible with the stock radiator air ducting of the Buell.

For this reason I have modified the radiator housing of 1125 in this manner:

Additionally I Have changed the direction of the ventilators so that both are blowing now the heated air "inside out". This makes sure there is no hot air in front if the airbox inlet. Now is is possible to make several runs at the dyno, one after the other, with negligible differences.

After this experience I am a little bit sceptic about the dyno graphs circulating around.

So I have dyno-tested the K&N replacement filter on my 1125:

Unfortunately there was no difference at all compared to the stock paper element.

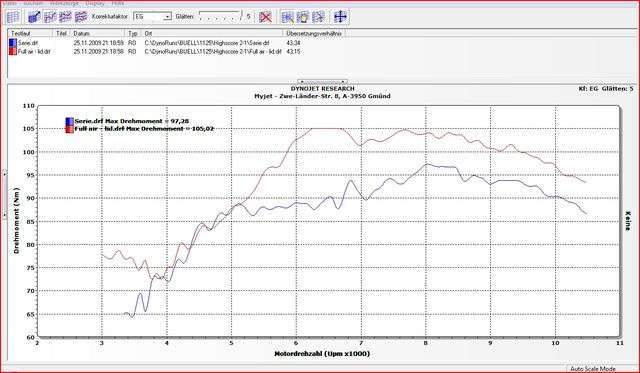

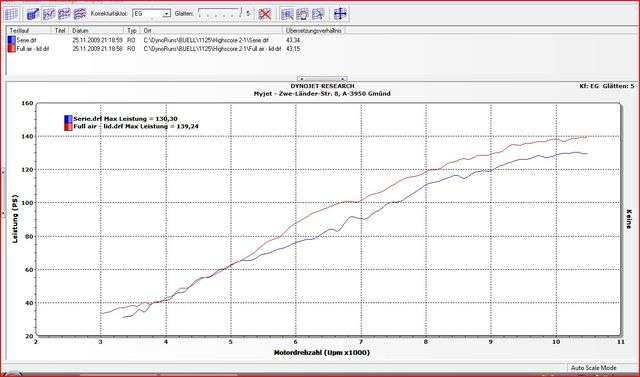

No matter which filter is installed the following graphs show my actual state of r&d for the Helicon engine at the rear wheel:

As I mentioned above the full potential of this engine is + 150 HP at the wheel. I am confident it is possible to reach this goal if we share our experiences here.

This is the intention behind my contribute here.

Highscore |

Froggy

| | Posted on Saturday, December 26, 2009 - 09:53 am: |

|

Excellent first post, welcome to Badweb. As you are probably aware, the flaws in the stock setup are all due to emission regulations. The warm air blowing into the air intake will raise the engine temperatures a little bit and help it pass various emissions requirements in the US. If you take a look at the race bikes including the 1125RR, they all have the radiators blowing outward. |

Easyrider

| | Posted on Saturday, December 26, 2009 - 10:03 am: |

|

Highscore,

I would like to help where I can., It is a good thing to start your own thread about your own specific issue and leave this one for what it is (-:

Can you post pictures of your Dynoroom Please. I am interested in the part where you blow the air in front of the bike.

Also post pictures about the testing conditions. What are you measuring.

With what software are you measering and what are the engine conditions at that moment.

I can't see your dyno Graph very clear but I try to see the times between 2 runs?. It looks like that the time between 2 runs and swapping the airfilter is 1 minute is that correct?.

Please explain what we are looking at in the graph..

(Message edited by easyrider on December 26, 2009) |

Highscore

| | Posted on Saturday, December 26, 2009 - 01:56 pm: |

|

Thank you for your warm welcome, Froggy.

Sorry regarding emissions I am not with you.For me it is to simply to blame emission-control for every imperfection of engine culture.

I am not familiar with the US test procedure for emission testing, but I guess it is pretty similar to our European Euro-III test cycle simulating cruising in town. The main part of the test simulates riding in first and second gear from traffic light to traffic light with extended periods of idle. The "highlight" of the Euro-III emission test is one minute driving 120 km/h simulating a ride at an urban highway.

So the maximum power the engine delivers during emission testing are just 15 HP, the power sufficient to accelerate a bike up to that speed.

Regarding our 1125 this terms of the Euro-III -cycle demand that only the first - say - 4 mm travel of the throttle grip, corresponding an opening angle of the butterflies sufficient to cranking out said 15 HP, are relevant for the emission test, and this up to an engine speed of 4250 rpm.

Just this small area of the whole working range of the engine is tested, consequently the "closed loop" operation of the ECU, when the A/F-ratio is controlled by feedback of the lambda probes, is limited to this small area of loads and engine speeds. The rest of the engineīs working range is "open loop" -and this literally. Here the ECU controls the engine solely in the Alpha/N-manner by sensing throttle position and engine speed,executing an internal and fix programed correlation table or map.

So the major part of its operation the ECU is not effected at all by limitations due of emission control. The only limitation here is the internal, fix programed map itself inside of the ECU, which does not match the engineīs needs perfectly. This happens for instance when installing an exhaust which really "works" and improves torque. There is simply no sensor at the 1125 which senses (at higher loads)the amount of air pumped by the engine.

If now a better engine helps the engine to charge more air the ECU needs a remapping to supply this new and additional air with sufficient fuel.

And this has nothing to do with emissions and its control.

@ Easyrider

Here are my dyno runs in a better resolution:

The runs show my actual state of my 1125-tune compared to stock. The main part of the improvement is done by an all new REMUS exhaust system with a 2-1-2 header arrangement. The primaries remain stock, after them the gases are joined into a single down pipe which branches out at a second into two parallel tube ending side by side at the expansion chamber of a reflexion-type muffler.

This system is so new that I have no pictures of the final design available until the production starts early January.

When designing a new exhaust system the first step is always an analysis of the stock one and its shortcomings. The stock 1125 muffler is not restrictive. This sounds weird, but measuring the back pressure clearly proofs that is true: 125 mbar is here a pretty "healthy" number. The real deficit of theīstock exhaust system is its simple header layout. That means there are just these two primaries and nothing more, because these stubs end at the expansion chamber at the inlet of the stock 1125 muffler.

So there is just one pipe, one length and thereby one single wave reflection at to header tube end which transfers exhaust energy back to the cylinder to improve the discharge of gases inside the engine.

You can see the effect of this single wave action and reflection by the stock exhaust at the torque graph above. And you feel this shortcoming clearly when riding the 1125: its single-action-header "works" twice within the range: up to to 5000 rpm and from 8000 upwards. Between these two marks the torque and thrust felt is a little bit uninspired.

By adding an additional length to the stock primaries, by coupling an additional common down pipe via a Y-joint to them, it is possible to install a second reflection point into the system. This second reflection shifts the torque down to the middle of the range,creating a new peak around 6 grand. This is the remarkable effect of the "after"-curve at the graph above.

As far as I know all aftermarket manufacturer go this way. Commonly the end of the system is defined here by a single absorption type muffler.

Nothing to say against this layout regarding performance. But this "īrace can" at the end of the tubing is necessarily small, there is simply no room for a large canister when providing a sufficient ground clearance. And this arrangement works only when it is "straight thru" without any restriction at the outlet.

The goal for developing this new REMUS system was to achieve this "straight thru" performance but with EC-homologation for public road use. So this pipe sounds different, but it is not really load. And - yes - it covers a catalytic converter. The branch out of the single collector tube into two tubes is a consequence of this functional requirement. This arrangement makes it possible to decouple the muffler, responsible for the social compatibility of the system, from the header as the source of engine performance and the improvement documented by the dyno runs.

Well, Easyrider, I know you are also designing exhaust systems for the Helicon engine. So I felt the need to explain this here instead of answering your questions.

Of course I am controlling the engine, ECU and exhaust gas, continuously on the dyno. I use for this purpose the POWERIZER analysis software.

But this is another story. Please let my monologue stop here.

Highscore

(Message edited by Highscore on December 26, 2009) |

Thefleshrocket

| | Posted on Saturday, December 26, 2009 - 02:10 pm: |

|

Highscore, I've learned quite a bit from your first two posts. Your explanation of why the stock exhaust doesn't make as much power as a properly-designed aftermarket exhaust makes a lot of sense. It also explains why people sometimes post power losses with the cheapy slip-ons which seem to be nothing more than a Y-pipe attached to a "regular sportbike" muffler.

I especially like the nice boost in midrange power with your Remus system. Is all of your tuning done using the Powerizer? And if someone was to buy a Powerizer, could they get a copy of the tune from you?

(Message edited by thefleshrocket on December 26, 2009) |

Easyrider

| | Posted on Saturday, December 26, 2009 - 04:41 pm: |

|

Highscore, In Your Dyno Graph there is only 1 minute between 2 runs,

You say in your post above that

The runs show my actual state of my 1125-tune compared to stock

Do you swap a complete exhaust within 1 minute warm up the bike and tune the Bike, I am lost a little here with your graph.

I still wait on my awnsers, What are we looking at in your graph , Where is the picture off the dynoroom, be specif what the differences are that you made between the 2 runs, Where are the AF values of the runs, Are the conditions you show us SAE corrected and why is dat not shown on the graphs.

What is the correction that they use on the Dyno.. We have to know what we are looking at here.. |

Highscore

| | Posted on Sunday, December 27, 2009 - 08:34 am: |

|

Well, Easyrider you are looking for the detail. One minute for a pipe swap is a really fantastic time. May be a network failure is the explanation for that curiosity.

In fact there are days between these two runs I have posted.

When searching for power and testing new stuff it is a good thing to build the bike back at some point of the process, at best to all stock. There is always the possibility, something has happened with the engine from one run to the next. A "perfect cause" for curious power fluctuations is for example a weak ground point, especially of the ECU.

So I have a collection of three test run series for "all stock" available, starting with an average of 128 HP, going up 130 and ending with 132+. The first series was in the Summer with a test cell temperature for the dyno of more than 30° C, the middle one was at 20 in September, the last one in autumn.

During this lest session I made an "all stock" run in early morning with an test cell temperature of 6° C, which inspired the engine to crank out 138 HP at the first run. At the runs following, when the temperature became more comfortable, the power went down to 132-134 HP.

An hour later after I began a new test series with the REMUS pipe. I started with a test cell temp of 10° C and amazing 145 HP - and this without mapping and a rough and chattering graph indicating the leanness of the engine. The procedure following was adding additional fuel. This smoothed the graph as expected. But sun was shining, the temperatures went up ending in the +20° C - region. At the end of the session I gained a smooth graph, but just shy 140-142 HP peak power.

I told this story to show how sensible the 1125 reacts to any changes, not only of the ambient conditions, but of its internal engineīs thermal too. Here there is just a small window from 78° C to 88° C of coolant temperature, where the engine shows its best. When this temperature raises above 90, the power goes down.

All these testings have been performed on a Dynojet roller, So the output measured is "corrected" to standard conditions. The "Korrekturfaktor" - as displayed on my graphs as "EG". So it is not an old fashioned and optimistic correction according "DIN", but to the modern "EC"-standard, which is pretty the same as the actual "SAE"-correction.

Ambient pressure and temperature affects the dense of the engineīs charge and thereby its power output. So the power of the same engine differs, when tested on a dyno at sea level or in the mountains, in summer or winter. The idea behind a "correction to a standard" is to make runs comparable performed under different ambient conditions. The "standard ambient conditions" are (something close to) 20°C at sea level or 1000 mbar atmospheric pressure. An increase of 100 m in altitude above sea level causes a decrease of 10 mbar in ambient pressure which scarifies - roughly spoken - the engine output for 1%. The same happens when the ambient temperature raises for 10° C.

So the "EC" or "SAE"-correction adds or subtracts, depending on the offset of the actual conditions within the test cell, some % to the power measured at the dyno roller. The Dynojet performs this procedure - as most other dynos too - automatically.

This "standard correction" is the same procedure when testing the 1125 in the cold or in the hot. So when testing an engine in the cold at sea level there is usually a "-" for the corrected power in relation the to dyno roller,

So this correction has nothing to do nor it explains the sudden increase, the power boost which occurs when testing the Buell below 10° C ambient temperature.

Deep temperatures at the engineīs intake together with a high a high ambient pressure not only cause a higher oxygen content in the air inhaled by the engine, a higher air density also effects the physics of wave action and acoustics inside intake runners and airbox by changing the (local) sonic speed of wave travel.

Of course have such differences of wave propagation some effect to the engine, but usually not so dramatically as in the case of the Buell.

That close temperature-benchmark, below which the 1125 engine transforms into a screamer, reminds more to a rotary valve 2-stroke-racer than to a street legal modern 4-stroke.

Indeed this behavior is absolutely unique, no comparable other V2-engine shows it.

Therefore this phenomenon indicates in my opinion a subtle problem within the intake arrangement of the 1125 which needs further investigation.

For these reasons I have chosen two 20° C test runs of my collection to show an realistic and average gain.

Now it is up to me, Easyrider, to go into detail: You are from Netherlands, the country, people live not at but below sea level. So it is hard to find a region with higher ambient pressure. And so probably the Netherlands are the best place in the world for dyno testing the 1125.

Furthermore all dyno tests you present at your website show an ambient temperature of 5-7° C. So are you are just making developments during winter?

So your dyno numbers are impressive, but this is valid even for your "all stock" runs offering close to 110 NM at the wheel. This are 10% more I "find" here in Austria.

Regarding dyno room pics: I am now on vacation so I have just pics at hand stored on my laptop:

Primary these pics are intended to present the air ducting and the filter I am manufacturing for the KTM 690 SMC. But they also should give an idea of my working environment: There are tons of fresh air in my test cell and there are computers.

The time-honored Sun EPA75 is my 2nd choice for exhaust gas analysis. Most time use just its pump to sniff exhaust gases out of the muffler for a Wideband Lambda analysis.

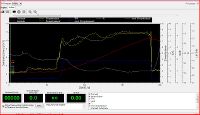

The screen shot following displays a data log performed by my POWERIZER analysis software:

The pic shows the record of a dyno run with REMUS pipe and stock fueling. The "X-axis display the record time. The "red" shows the increase of engine speed during the run,starting aprox. at 2500 rpm and ending at 10300 at the limiter. The "blue line shows TPS-output-tension, here the maximum value for WOT. The "white" and "yellow" curves above show injector timing, the effective pulse width at front respective rear cylinder (note the huge difference between front and rear).

The "light-grey" curve below shows the corresponding Lambda of the exhaust gas.

The average lambda is around 0,85, a shy to lean for an engine with cylinders of that volume. And there is a lean spot around 6000-6500 where lambda raises up to 0,9.

This area of leanness corresponds perfectly with the action of this 2nd exhaust header length, added to the stock primaries by the REMUS, creating new torque exactly within this range.

These data are monitored by this:

Here the printed circuit is covered by a simple plastic box, my customers get it inside of a fashionable anodized alloy containment.

This device not only monitors the injector pulse width according load (TPS-signal), it furthermore allows to make pulses longer or shorter. So it works, like Dynojetīs PC, by the principle of pulse width modulation:

The new "green" curve at this screen shot displays the pulse width which are now operating the injectors by the Powerizer. Now the average lambda is 0,83 fluctuating between 0,82 and 0,84.

My device goes, like Dynojet, the "piggy back way". You, Easyrider, prefer the method of hacking the stored data inside the ECU to remap the fueling. Both techniques have advantages and disadvantages.

And at the very end all these devices and procedures are just tools, whose success, of application depends more on the abilities of the operator.

Therefore I like to focus our intention here, instead of arguing about who has seen the most power on his dyno or created the flattest fuel curve, onto the problem: What are the real shortcomings in the set up of the 1125, hindering the engine to show its full potential.

Highscore

(Message edited by Highscore on December 27, 2009)

(Message edited by Highscore on December 27, 2009)

(Message edited by Highscore on December 27, 2009)

(Message edited by Highscore on December 27, 2009) |

Pash

| | Posted on Sunday, December 27, 2009 - 12:42 pm: |

|

Interesting stuff Highscore, always nice to see another slant on things and I like the fact that you marry theoretical knowledge with practical application rather than a simple trial and error approach.

I prefer the hacking of the ECM to gain results, and prefer a combination of logging and dyno, but you are right on the button when you say that the shortcomings need to be known before the solution can be identified.

The design of the solution may be different for each tuner, but they must always focus on the customer's needs.

Keep up the good work and don't be put off by others when posting your thoughts, they are all valid... |

Xelerator

| | Posted on Sunday, December 27, 2009 - 06:37 pm: |

|

I'd like to see dyno runs with IAT-graph (Intake Air Temperature), showing the influence of the radiator fans blowing towards the intake funnel.

Cold air is the key to further gains.

Thanks

Chris |

Dynosaur

| | Posted on Monday, December 28, 2009 - 04:33 am: |

|

In all cases, You need a dyno first. When you have a dyno you can correct the fuel tables and the timing tables (when you know what you do). When you do this correct, You DON'T need a O2 sensor.

You only need a 02 sensor, if you are NOT able to make a good fuelmap. Or you dont want to do it without (-:

Hey Easyrider, do you know what you are doing?

Just been doing a walkabout around the site and I see you lost 20% of gas mileage for Ccryder with your maps compared to the Buell maps... Bet you would have lost nothing if you kept the O2 sensor...  |

Colintornado

| | Posted on Monday, December 28, 2009 - 05:26 am: |

|

HIGHSCORE,good to read your posts,I take from what you say that the data/map for the input of the MAP sensor(manifold air pressure)is only used within the closed loop area.? |

Easyrider

| | Posted on Monday, December 28, 2009 - 08:16 am: |

|

Highscore,

This topic is specially for you:

http://www.badweatherbikers.com/buell/messages/290 431/524991.html?1262006078

You can keep all your data there and talk to all the people about what you do. |

Easyrider

| | Posted on Monday, December 28, 2009 - 08:24 am: |

|

Highscore,

first of all, I am not a fan of REMUS exhaust. Second, I am not a fan of Piggy Bags. like the remus Powerizer.

Third, I use a Huge air-conditioning to keep my tuning environment constant, Otherwise it is not possible to tune a Buell for different environments.

I am just a simple guy who is every day in the dyno room for the past 2 years on Buell motorcycles and make products to let a Buell run Good.

When I read your post, I also see that you are still in a learning curve.

When you like to know some secrets just ask them, otherwise stay in your own topic.. |

Easyrider

| | Posted on Monday, December 28, 2009 - 08:31 am: |

|

Dynosaur,

Yes I hope I know what I am

doing?

The 20% of gas mileage for Ccryder is one of the reasons I am working with him to solve this. When I tune the fuelmap I make the bike run between 13.6 and 14.2 AF

In cold environments the cold start enrichment is still on, How colder it gets how more fuel the bike will use.

ask ccryder how cold it was when he was testing if the readings in his instrument panel was below 78-80 degrees, the shoke (cold start enrichment) is still one and the bike will use more fuel.

The other reason is that when I adjust the bike, it is running very lean in the 2500-3500 RPM range, The only thing I do is I adjust it back to 13.6-14.2, what you get then is a lower MPG.

Still ccryder, helped me with feedback to get the best from 2 worlds, Good running engine, and a good MPG. I never tuned for MPG before, more for reliability and performance. We have to see if we can achieve the ultimate mapping.

(Message edited by easyrider on December 28, 2009) |

Blackflash

| | Posted on Monday, December 28, 2009 - 12:48 pm: |

|

Since were talking dynos/alpha n tuning/lambada here let me throw this in here to loosin some more screws. http://www.factorypro.com/dyno/true1.html http://www.factorypro.com/dyno/true1.html |

Littlebutquick

| | Posted on Monday, December 28, 2009 - 02:04 pm: |

|

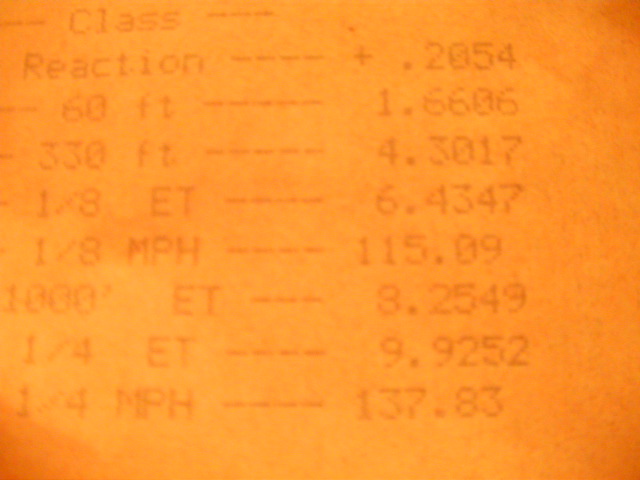

mr easyrider must know what hes doing i use all his products ,i listen to all his advice . i could not of run a nine with out him  the proof is in black and white well pink the proof is in black and white well pink

|

Highscore

| | Posted on Monday, December 28, 2009 - 03:32 pm: |

|

@ Easyrider:

I am a newbie on this board, but not in the the forum world. So it is new for me that the starter of a thread in a public message board is at the same time the principal, governing which themes to be discussed there.

You started this thread here under the headline "tuning". And it is out of doubt, that my posts here are a contribute to this subject.

So why start an inflation of threads all handling the same subject? If I had felt the need to open a new thread, I had done it.

An engine, as mechanism and piece of technique, is "condensed" physics, by applying and reflecting those laws within its operation. Since the laws of physics are the same for all of us here at this planet, there are no miracles or secrets, making one engine perform better than an another. If this is the case, this indicates solely, that the better performing engine covers or suits better to the related physics.

The Helicon engine in the Buell trim is the result of the work of dozens of engineers involved for years in this project. So at first there should be respect for this piece of technique and engineering, because this mechanism matches to the physics all but badly.

But here we are talking about motorcycle "tuning". In my sense "tuning" means making a good thing (we live in the 21.century, any new bike is simply rather perfect compared the standard 20 years ago) even better. Matching this goal is therefore a process of "re-engineering" as detecting the areas, in which tthe factory failed when applying the underlying physics properly.

So when I talk here about "tuning", the "final cure", an exhaust or airbox for example, is just the last chapter. My presentations always start with reflections about the fundamentals of such "tuning" mods.

I have no problem to share these fundamentals with this auditory here, and I have further no problem, if someone applies these fundamentals different. There is more than just a single solution for a technical problem. And I am not shy to recognize that someone else applies fundamentals to a new piece of techniques better and more efficiently than me.

I guess here is the point, why you, Easyrider, are in trouble with me: You have spent 2 years on your dyno and made there thousands of runs. This painful procedure - I am personally too old to hook up for two years an a single bike for r&d - gives you obviously the confidence to know anything about the Buell and the "secrets" of its tuning.

You obviously really believe, you are the "best" Buell tuner. But as I mentioned above "tuning" is a part of technique and engineering. Among engineers there is the same competition as in sports. Everybody tries to make his stuff better than the other. This competition is the at the very end so source of all technological advance.

This is the last if my 1125-"secrets":

This is my proposal for mapping. "y"-axis is throttle position in Volts of sensor output, "x"-axis is engine speed. The values in the table show the percentage of modification of the genuine ECU pulse width. All the values are in the case of the Buell positive. The pulses are prolonged for that percentage.

The "secret" I want do know: cam timing, ignition advance. Has anybody the figures?

Highscore

P.S. (to whom it may concern)

If you feel the need to shift my posts into a new thread, do it.

(Message edited by Highscore on December 28, 2009) |

Therealassmikeg

| | Posted on Monday, December 28, 2009 - 03:41 pm: |

|

Wow, I used that Sun 2 gas analyzer to tune Porsches and Audis back in the early 80s. Other than that comment, I'll keep my mouth shut...

(Message edited by therealassmikeg on December 28, 2009) |

Marinus

| | Posted on Monday, December 28, 2009 - 04:31 pm: |

|

On the one hand, I see Easyrider's point: Highscore could be accused of "hijacking" this thread.

On the other hand, I find Highscore's reporting technique very good. He is giving reasons for the things that he is saying.

Because Easyrider also uses good scientific approaches -- he is known for this -- it is a pleasure to read reports from both of them.

It seems that both of them are pursuing distinct avenues to tuning the Helicon. It should not surprise us if they do not see some things the same. That is healthy. It is like a competition, a competition of ideas. It is a competition where all us 1125 owners will be winners.

Having both efforts make reports in a single thread will collect the information in one place, but it might also become confusing. If I have a vote, I would vote for one thread.

If it stays in one thread, I hope that Easyrider and Highscore will be patient with each other's postings and questions. Because they each have their own starting point, things the other one says may not seem to make sense at first. Just know that you both have the respect and thanks of this community. (hmm, or at least my respect and thanks, I can not speak for the whole community). |

Highscore

| | Posted on Monday, December 28, 2009 - 04:37 pm: |

|

Back to topic:

The dyno graphs following display the effect of hot air by the radiator blowers running compared to not running:

This is my private 1125R from 2008 with 7500 km. It is the first performance test after I have purchased the bike. The result was so frustrating, that I immediately looked for another 1125 for a check.

The following graphs are from a 2009 1125CR with 3000 km on, a journalist bike ,I got from the local Viennese dealer:

During the "high-power-runs" the coolant temperature was so low, that the blowers did not run. The intake temperature, displayed at the Buell dashboard was the ambient test cell temperature of approx.27° C. The "low-power-runs" show, what happens, when the temperature at the dashboard goes up to 50° C with the blowers running.

Both engines are stock.

Highscore |

Marcodesade

| | Posted on Monday, December 28, 2009 - 05:37 pm: |

|

If I have a vote, I would vote for separate threads (I get confused easily), with perhaps a 3rd thread where they could debate, argue, and cast aspersions on each other's lineage.  |

Easyrider

| | Posted on Tuesday, December 29, 2009 - 02:00 am: |

|

Blackflash, Interesting link, thanks |

Easyrider

| | Posted on Tuesday, December 29, 2009 - 02:02 am: |

|

Highscore, I will start a new topic, for my work on testing and making the 1125CR run good with our Kit, to keep it clear for the outside world. |

Xelerator

| | Posted on Tuesday, December 29, 2009 - 11:09 am: |

|

OK, I created a new thread for the IAT discussion.

Thanks "Highscore", impressive dyno results.

http://www.badweatherbikers.com/buell/messages/290 431/525266.html?1262102540 |

Highscore

| | Posted on Tuesday, December 29, 2009 - 04:00 pm: |

|

Hope it is o.k. when I use this thread to discuss general topics related to Helicon tuning.

Talking about tunings means for me talking "dyno". Of course the subjective feel of an engine after a modification and how much this makes someone faster, is the stuff really matters.

I for myself understand my work as "torque design", and a dyno graph shows, where an engine suffers in torque and where it is fine. I have done an extensive search in this 1125-message board regarding dyno, but did not find very much. This is a pity.

So it looks like as you, Easyrider, have been the only "dyno-man" here until my appearance. I affirm, that I am not driven - although I have designed an exhaust for Remus as contract work - by commercial intentions when posting here:

Buell is definetely a sports bike. But here in Europe its is distributed via the Harley network. But racers here donīt go to a Harley dealer to buy a sports bike and vice versa no Harley customer is a fan of sporting.

Accordingly low are the sales of Buell. But this is just my experience here in Austria.

Therefore Buell and especially the 1125 is a absolutely exotic here, just around 30 on the street in whole Austria last summer. So there is no danger that I look for new business areas in Buell tuning. My cash cow is KTM.

My intentions regarding this engine are solely personal: The KTM facilities and the Rotax facilities in Austria are rather side by side. The distance is just 60 km. Both factories fight for the crown: "Who makes the best Austrian V2-engine".

Donīt ask me please at this place, in which way I am involved in this battle, but my part is to proof, that the Rotax Helicon engine is superior. I am sure this is the case.

For this reason I am here at this board to collect all information about this engine and its tuning available.

Easyrider, I really appreciate your work and passion. So it is for me evident, that the design of your exhaust makes it to one of the best performing systems available.

Furthermore I am convinced you take great care to sort the fueling of your bikes in. So I am confident your packages are working.

O.k. -you donīt like piggy back and Remus. I make piggy back and work for Remus. So our preferences are different. But does this hinder us to discuss Helicon tuning. I hope not.

My postings should give the proof, that I am not ventilating third party stories but trying my best to explain here my own and personal experiences related to this engine. And like you I try my best understand an engine.

And like you, Easyrider, dyno graphs are for me the key for this understanding.An exactly here, you and me have a discrepancy, robbing my sleep:

Your peak HP# at the rear wheel is 144 , I am seeing strong 140 in my tuning trim: This difference is a bagatelle.

But regarding torque you show astonishing 125 NM while I am struggling around with shy + 105 NM.

I hope we could lead a discussion on eye level. Because if you would say: "This torque shows how much I make things better than you", I would ask you: "and why didn't you conserve this 20% increase up to the red line to transform the 1125 into a 175 rear wheel HP screamer?"

We are talking here about box stock engines and bolt on tuning without any dismantling of the engine. The stock engine has a large and short intake path. So its intake ram is tuned for high rpm. The stock headers a short, so they are tuned for high rpm.

This both explains why the stock engine show peak power close to the rev limiter. And these two stock "tuning devices" keep on working, even when there is an new and additional length added to the stock headers by an exhaust system like yours, Easyrider.

You understand the reason of my confusion?

Highscore

(Message edited by Highscore on December 29, 2009)

(Message edited by Highscore on December 29, 2009)

(Message edited by Highscore on December 29, 2009)

(Message edited by Highscore on December 29, 2009) |

Easyrider

| | Posted on Wednesday, December 30, 2009 - 01:20 am: |

|

Highscore,

I understand the reason of your confusion?

That is why I said before I see you are in the learning Curve. do you expect that my first tuned 1125 ( My own bike) made that amount.

This is all about the difference in you and me. I made the hours on the Dyno to understand why it is not making the power i Like. and after days and days and days. every time i learned more. The power went up. |

Highscore

| | Posted on Wednesday, December 30, 2009 - 10:08 am: |

|

Easyrider, you are just polemic but do not answer my question.

Regarding "learning curve": I my early days in dyno work, I also made hundreds of runs to detect and solve a problem. But this is over for me now. Meanwhile I have done thousands of bikes, 20 years is a long time, inline 4, two-stroke, rotary engines, the whole stuff.

Instead of try and error with countless runs on the dyno, I prefer now a different approach: I detect problems in the engine set up more by "thinking", that means by making a model of the engine, to comprehend, what an engine does.

Meanwhile - we live in the 21. century - such engine modeling is pretty advanced. All manufacturers and many engine tuner use such a tool as first step in the design process, before building a prototype.

Of course such a "model" is just blank theory, even the best of these analysis tools have a failure of aprox. 10% for their predictions.

So modeling never replaces real world testing, but nevertheless it saves a lot of time and reduces the number of dyno runs considerably without sacrificing quality of the job.

So I have to agree, Easyrider, that my personal "learning curve" became rather flat meanwhile. But it looks like as not me but you are the one, who is still in the first and steep part of this curve where try and error rules.

In the case of exhaust design such "modeling" works pretty accurately regarding the effects of header length and diameter on engine performance. It is for sure that rather all aftermarket exhaust companies use this technique. This explains why, although the look, the appearance may differ, the lay out nevertheless share the same essentials.

Your exhaust design, Easyrider, is also well with this paradigm or "model" of Helicon exhaust operation.

The Torquehammer, the German HPE, Italian Termignoni, US V&H, so name just a few, share the same general layout. Even the full exhaust system by Buell Racing, although looking completely different at the first view, fits nicely into the exhaust model.

Of course there are difference in the individual lay out of each of these exhaust systems. Therefore performance figures will differ accordingly, but the similarities should overwhelm.

Therefore, as long as the rest of the engine is stock, no change in cam timing and/or tune of "intake-ram", any of these exhaust systems, should modify the operation of the Helicon engine pretty in the same way: I makes a rather flat torque curve over the range, showing its maximum between 6000 and 8000. "Flat" means here that should be just a difference of 10-15% between the peak torque in the middle and the torque around 10 grand close to the limiter at end of the engineīs operation range. With this type of engine tune the Helicon is a "screamer", cranking out its peak power just close to red line.

I donīt want to post here always the same graphs, I have done on my own dyno, to illustrate my thesis. Therefore this link to the Saron-website

http://www.saron.biz/en/products/

These graphs match pretty nicely to said the "exhaust model" for the Helicon, as all other systems do this quite well.

There is just one exception, Easyrider: your Thunderhammmer-design, not regarding its peak power and torque at high revs, but regarding to maximum torque in the middle. Your pipe shows an offset for these two torque-numbers of impressive 30%.

Have you ever checked your results on another dyno?

Highscore

(Message edited by Highscore on December 30, 2009)

(Message edited by Highscore on December 30, 2009) |

Blower1

| | Posted on Wednesday, December 30, 2009 - 10:53 am: |

|

Highscore. What you modeling program tells if making the front header as long as the rear header?

Should both velocity stacks/intake runners are equal length? |

Easyrider

| | Posted on Wednesday, December 30, 2009 - 12:41 pm: |

|

Highscore,

I am glad I am in a learning curve, otherwise, I was going to do something else..

The Torque Hammer exhaust (we call it that) is made with more then 1100 dynoruns, The main reason for the development was the poor Torque on low RPM\ with the stock exhaust. My Exhaust was not developed to win a HP Shootout, Keep that in Mind. And there are some secrets inside the exhaust to let the engine do What I like yes.

If somebody makes a dyno run with My exhaust I hope they show the difference in stock versus the Torque Hammer, Like I did on our website, Then you see what I mean.

My learning curve in my live was always trail and error, with everything I do. That is because of my enthusiasm about what I like. Sometimes that is not the best way to go, but i also then like the non complicated approach, and all the fun that it brings. And it keeps me from the street (-: |

|