| Author |

Message |

Panic

| | Posted on Sunday, May 06, 2007 - 08:01 pm: |

|

"You can make an HD engine a 50 or so degree engine by milling deck planes"

If you remember to also relocate at least 1 pair of tappet blocks, cams, and the ignition if you want to retain the pushrod/rocker geometry, and run as it did before.

With only a 5 degree spread it could be cut by cutting both decks equally, new cams, the pushrods will work at 2.5 degree error. |

Panic

| | Posted on Sunday, May 06, 2007 - 08:08 pm: |

|

Some comments on flywheel inertia (not completely sorted out):

http://victorylibrary.com/tech/inertia.htm |

Diablobrian

| | Posted on Sunday, May 06, 2007 - 09:18 pm: |

|

Panic you aren't paying just for the work on the crank you're paying for the knowledge it took to do it right. |

Panic

| | Posted on Sunday, May 06, 2007 - 11:17 pm: |

|

"you're paying for the knowledge it took to do it right"

What would be the wrong way to take weight off the flywheel?

Sorry, that's a trick question - it's been done the same way for about...

100 years.

I could do it with a file, it would just longer. |

Diablobrian

| | Posted on Sunday, May 06, 2007 - 11:37 pm: |

|

How much do you think the equipment to do it costs? and there is a wrong way.

removing too much is wrong, balance is also not just important but critical.

I have heard the "I'm not paying X$ for the work you did, it only took you 10 minutes!"

more times than I can count. The knowledge of what to do and how to do it quickly and right

the first time is hard won.

Are they supposed to give that away? Do you at your job?

(not counting those that work in tech assist jobs, and even then...)

There is a reason that race shops charge more for work that "anyone can do with a manual"

than the cost of parts + $10 an hour. There are lots of tricks to the trade and small changes

become much bigger than the average person might expect when you start spinning it up to red line.

That "solid" crank is under massive g forces and if the parts are assembled incorrectly....boom.

And yes, I do realize that the crank is pressed together. I was talking about the tendency that a layman has to

consider it a single piece not a series of precision components held together by friction and precision fit.

not by nuts and bolts or anyother type of fastener.

(Message edited by diablobrian on May 06, 2007) |

Panic

| | Posted on Sunday, May 06, 2007 - 11:46 pm: |

|

Perhaps if you understood exactly what removing weight did you would be less... in awe.

I repeat: I can do it with a file, an inmate could do it by scraping the edge on the wall - it just takes longer. |

Diablobrian

| | Posted on Monday, May 07, 2007 - 12:01 am: |

|

I'm a machinist, and have been for 2 decades. I know what's involved, and I've seen first hand

what inexpert metal removal does to high speed parts, and repaired the mess it caused.

Have fun trying though, it falls under the same heading as home porting jobs. Once in a while someone gets

lucky, but without a flow bench it's mostly a wasted effort trying to improve what the engineers did

design on a flow bench, and replicating the same results twice is about a snowballs chance in hell.

I built my own home machine shop too, after becoming disabled, and I know what it costs to "tool up" too.

precision tools are anything but cheap.

Before it comes up, Chinese tools rarely qualify as precision.

Then again, a lot of people own flex shaft dremels or die grinders that means that porting shops

should never charge more than hourly labor at 10-15 an hour right? |

Panic

| | Posted on Monday, May 07, 2007 - 12:12 am: |

|

Really?

2 decades?

A machinist?

I've been doing this since 1964.

Machinists are the people I have to tell "you don't have to understand it, you just have to do it".

I must have done better work for the last 40 years than the people you know. |

Steveshakeshaft

| | Posted on Tuesday, May 08, 2007 - 04:06 am: |

|

Very interested in the shots of XBRR parts. Where's the oil pump drive? Thanks. |

Blake

| | Posted on Tuesday, May 08, 2007 - 06:07 pm: |

|

In a much better place.

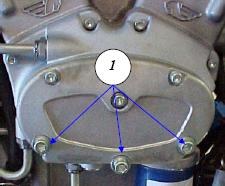

Cam Case & Oil Pump Cover

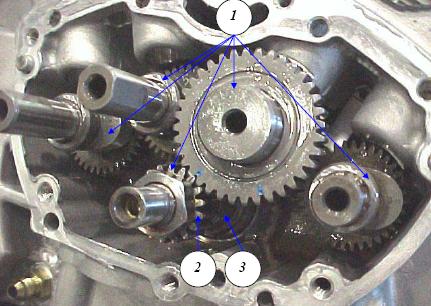

Cam Case

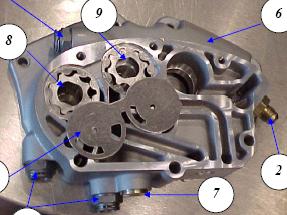

Oil Pump

So much for worrying about that darn oil pump drive gear failure!

(Message edited by Blake on May 08, 2007) |

Steveshakeshaft

| | Posted on Wednesday, May 09, 2007 - 05:29 am: |

|

Thank you Blake. I have been itching to see inside that darn camchest ever since the XBRR was released. I agree, that is a very sensible and very "Buell" progression. I look forward to the day we see XBRR derived motors on the road!

Cheers. |

Rocketman

| | Posted on Wednesday, May 09, 2007 - 06:20 am: |

|

Long since out of print, and much sought after these days, Phil Irving's 'Tuning For Speed' has a wonderfully descriptive section on crank balancing.

Referred to as the 'slide rule of motorcycling', it might well be old school these days, but it's a wealth of information every tuner or potential tuner should have in their possession.

Here's a copy on eBay right now.

http://cgi.ebay.co.uk/Tuning-for-speed-PE-Irving-p 202-22-1952-HB-Clean-inside_W0QQitemZ120116214182Q QihZ002QQcategoryZ90617QQssPageNameZWDVWQQrdZ1QQcm dZViewItem

Rocket |

Reepicheep

| | Posted on Wednesday, May 09, 2007 - 08:16 am: |

|

That is a cool oil pump(s) setup.

Doesn't look like a bolt on bit unless you change the cams at a minimum. |

|