| Author |

Message |

Aaron

| | Posted on Sunday, March 02, 2003 - 09:08 am: |

|

It's been my experience that high ratio rockers in a Harley motor without correcting the geometry is a BAD thing. I've literally seen them produce LESS lift at the valve because they jacked up the geometry so bad. |

Pammy

| | Posted on Sunday, March 02, 2003 - 11:08 am: |

|

If the geometry is off, you have a few options. You can put a spacer under the rockerbox(spacers are readily available). Or you can mill the rockerbox side of the head accordingly. We find the spacer scenerio is more common.

It's always beneficial to open the valves more quickly. You have 3 options to make this happen: 1) You can increase the flank angle on the cam lobe.

2) You can increase the diameter of the lifter base.

3) You can increase the rocker arm ratio.

A higher rocker ratio basically makes the engine breathe better. When the ratio is higher, the valve can be opened faster and it can be lifted higher.

This is why it's so important(perfomance wise) to match your head porting to your cam and of course all of the peripheral parts therewith. |

Aaron

| | Posted on Sunday, March 02, 2003 - 12:08 pm: |

|

You can also buy rocker boxes that allow you to move the rocker arm around. |

Pammy

| | Posted on Sunday, March 02, 2003 - 12:53 pm: |

|

Aaron, I think you are thinking of rocker to rocker box top clearance. I could be wrong. I will ask Wes when I see him.

To change the geometry with very little expense, only a spacer is needed. |

Blake

| | Posted on Sunday, March 02, 2003 - 02:53 pm: |

|

Pammy>>> "Wes honey, am I wrong?"

Wes>>> "Never!"

|

Aaron

| | Posted on Sunday, March 02, 2003 - 03:13 pm: |

|

Pammy: a high ratio rocker is longer on the valve side, as opposed to being shorter on the pushrod side. It tries to fall off the edge of the valve.

You are correct, raising the rocker box centers the rocker tip on the valve better because the valve is angled, and it's a simple and easy approach. But it has a drawback: it puts the rocker arm in a more rotated position. You want the rocker arm to be at a 90 degree angle to the pushrod and valve stem when you're at 50% lift. When you raise the rocker boxes, you're now moving in the direction that will put it past 90 degrees at 50% lift. You can compensate for this with a longer valve.

Another approach is to just move the rocker arm over, and there are rocker boxes readily available that let you do this. They also let you move the rocker up if you want to ...

|

Rippin

| | Posted on Sunday, March 02, 2003 - 09:45 pm: |

|

Aaron and Pammy,

I value the advise from the both of you very much. I also appreciate your input and taking the time to help! But maybe I was under the assumption that since it was a roller tip that it would produce less side loading on the valve tip and easier on guides and the stem. Also less friction. I did not realize the 90degree @ 50% lift.

I know that when I changed to 1.7's on my 302 it consistantly ran.12-.15 quicker and about 1mph on the big end in the 1/4. Had no other problems with valve geometery. I also found that between three dif. cams I tried in it the one that had least duration and overlap but equal lift netted quicker times also.

Just hoping to get the roller benefit and added lift since I already have .490 cams with out lots of grief.

Thanks again Ryan |

Pammy

| | Posted on Monday, March 03, 2003 - 06:45 pm: |

|

Oh, so I was wrong. Forgot to ask Wes(he was at the shop working). It was my younger daughter's birthday celebration Sunday.

Blake, believe me, the scenerio NEVER works like that. The floor show around here is quite colorful at times.(no charge, of course)

Ryan, I talked to the great Chuckholio and he says you are better off just changing the cam. Pricewise and stresswise on the valve train. We have never had a problem with using a spacer for the issue you may face.

Aaron, those rocker boxes sound pricey. I can imagine that they would be in excess of $700 or so. Good to have that info. We have never needed something like that so far.

Speaking of dyno charts...the yellow beast was fired off today and made a pitiful 146rwhp. Everything that could go wrong, did go wrong. Still a work in progress, but time is running out. Tomorrow should be a bit more promising. |

Jim_Witt

| | Posted on Monday, March 03, 2003 - 08:21 pm: |

|

Pammy mentioned:

Everything that could go wrong, did go wrong.

Like what?

-JW:> |

Pammy

| | Posted on Monday, March 03, 2003 - 08:57 pm: |

|

Getting the wrong parts...numerous times. This motor was one of Wes' wild experiments. He IS a mad scientist, you know. So things are re-evaluated as he goes along. More, proper parts will arrive tomorrow. Some will have to wait til after Daytona. Oh, well, the journey is half the fun... |

Jim_Witt

| | Posted on Monday, March 03, 2003 - 09:12 pm: |

|

Pam,

Since I simply don't know, if someone wanted to decrease the size of their ports, like in high velocity intake porting, if you didn't want to use epoxy and weld them instead, HOW would you weld it (like what process)?

Cheers,

-JW:> |

Pammy

| | Posted on Monday, March 03, 2003 - 09:30 pm: |

|

We have a guy that welds aluminum. Then Wes just starts over. We(as always, when I say "we" I mean Wes) do it all the time. But he uses a special epoxy as well. |

Jim_Witt

| | Posted on Monday, March 03, 2003 - 09:57 pm: |

|

Pam,

Do you know the actual welding process. BTW, if you can someday, I'd sure like to see a close up picture of it "before" the shaping process takes place via Wes.

-JW:> |

Pammy

| | Posted on Monday, March 03, 2003 - 10:09 pm: |

|

I don't know what the process is called.It looks like a weld on a weld on a weld. He has to be careful not to leave any air pockets. I will try to remember to snap a photo next one he does.

Are you planning on welding some heads? |

Jim_Witt

| | Posted on Monday, March 03, 2003 - 11:46 pm: |

|

Pam asked:

Are you planning on welding some heads?

Who knows. I don't know a thing about welding heads, but I've done a ton of critical welding for years on pipe and tubing. I just like to know what the process is. Hard for me to believe it's stick rod on aluminum, but I'm not saying it can't be done.

Thanks,

-JW:> |

Redstripe

| | Posted on Wednesday, March 05, 2003 - 06:38 pm: |

|

Allrighty then;

Stock displacement,

Pro-series system,

Race ECM,

K&N and gutted airbox,

Compression raised slightly,

Heads worked over,

Squish sorted, -was wayyy... off-

Screamin' Eagle 536's slotted in,

Red Line tranny and engine oil,

Ignition retarded.

2000 x1 RRS, mileage 13.500. At this point cams reported knackered, as was the shift-drum and forks and more important; oil pinion gear badly worn!

Have bought Bakers' shift-drum as AW seemed to have good experiences with it.

Whole thing modified and dialled in by Charley from Bike Hospital in Waddinxveen, Holland.

Very nice work indeedy! Thanks again.

|

Blake

| | Posted on Wednesday, March 05, 2003 - 11:13 pm: |

|

Very nice!! |

Aaron

| | Posted on Thursday, March 06, 2003 - 08:37 am: |

|

What Blake said! Congrats Jilles! |

Redstripe

| | Posted on Thursday, March 06, 2003 - 11:13 am: |

|

Why thanks, guys.

For relative "moderate" modifications, the bike has changed pretty drastic... No complaints. -biggrin- J. |

Aaron

| | Posted on Saturday, March 08, 2003 - 07:48 pm: |

|

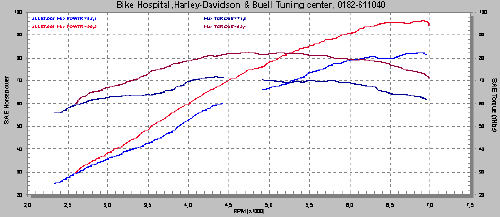

Stock is in blue

Modified is in red

2003 XB9S owned by High Country Harley Davidson/Buell

NRHS 1200 Kit

NRHS Signature Series Big Bore Pipe

Power Commander III

Stock cams

The goal of this project was a streetable, reliable, pump gas friendly hot rod XB12 without breaking the bank. We were hoping to get to the century mark, but as you can see, we're going to have to push things a touch farther to get there. It's pretty clear to us what's holding it back, too, it's just a matter of whether or not to continue. We don't want to price the thing out of the market.

I rode the bike, and I'm here to tell you, it's a THRILL. More exciting than my 115hp M2 by far. It's a wheelie monster for sure, reminds me of that 100" S3 I had when it comes to elevating the front wheel at will. No problem at all lifting it in the first three gears, and that's saying a lot at this elevation where we're typically down 20% on power. I just can't imagine this thing at sea level; experienced riders only need apply! VERY quick, too. The power is instantaneous, yet the bike is docile and well mannered at any rpm. The pipe has the characteristic Force snarl too which I just love. It's quite the ride, I gotta figure out how to get me one of these! |

Blake

| | Posted on Saturday, March 08, 2003 - 11:05 pm: |

|

Yeah baby! Bring that thing down to Kilgore and see if your arm sockets can take the stress. Great power all the way from 3,200 to 7,500 rpm. |

Hootowl

| | Posted on Sunday, March 09, 2003 - 03:54 am: |

|

60% more torque around 4K. Nice! |

Bud

| | Posted on Sunday, March 09, 2003 - 06:07 am: |

|

Aaron,

Correct me if Iím wrong, but looks like the pc111 stops working > 4,5 rpm

Did you have a go with some larger inj. ??

I did some ruff calculating, seems that the stock inj. will never go over 100 hp with out help

Btw, looks very nice indeed

Saving on till next winter

Gr,m |

Court

| | Posted on Sunday, March 09, 2003 - 06:19 am: |

|

Ohhhhhhhhh...Myyyyyyyyyyyyy...Gooooosssssssssshh !

Now, THAT'S the Buell we've been begging for! I can already hear the thing rattling windows on 2nd Avenue at midnight!

Well done !

Court (I'd insert a "Kilgore voids the warranty" condicil in the paperwork...  ) ) |

Aaron

| | Posted on Sunday, March 09, 2003 - 08:58 am: |

|

Bud: The PC3 is working fine, but you're right, the stock injection is what's constraining it. It's fixable, it's just money. Someone else's decision. |

Kcbill

| | Posted on Sunday, March 09, 2003 - 02:12 pm: |

|

Aaron what is needed to bump this motor up to your calculated performance figures? By that can you clarify exactly what parts you are looking at and projected hp. I'm thinking it was about 115, no? I bet you guys were anxious to finally see it run. Congrats! Sam is thinking road trip! Go ahead and say come on down. |

Shazam

| | Posted on Sunday, March 09, 2003 - 04:29 pm: |

|

I'll definitely be interested to see what it's gonna take to get to that 115 number, well, besides cash!

bigger injectors or a remap? Aaron I think I would like to speak privately with you soon. I will try and give you a ring this week.

what you all have done is phenomenal. |

Peter

| | Posted on Sunday, March 09, 2003 - 04:59 pm: |

|

Very cool! |

Aaron

| | Posted on Sunday, March 09, 2003 - 06:01 pm: |

|

Bill, I could tell you, but I'd have to kill you

You can see that it's on the trajectory to get it there, then it noses over. That pretty much tells the story.

I'll say this though ... if you can talk HCHD into letting you ride the thing, even around the block, it's well worth the trip out here. Damn thing is a HOOT to ride. If you've ever ridden a stock one, the constrast is amazing, it just transforms the bike. |

Kcbill

| | Posted on Sunday, March 09, 2003 - 10:09 pm: |

|

Ok Aaron you have my permission to kill me. You my proceed. |

|

»

Buell Dynamometer/Dyno Testing Archives »

Archive through March 09, 2003

»

Buell Dynamometer/Dyno Testing Archives »

Archive through March 09, 2003

»

Buell Dynamometer/Dyno Testing Archives »

Archive through March 09, 2003

»

Buell Dynamometer/Dyno Testing Archives »

Archive through March 09, 2003