| Author | Message | ||

Dktechguy112 |

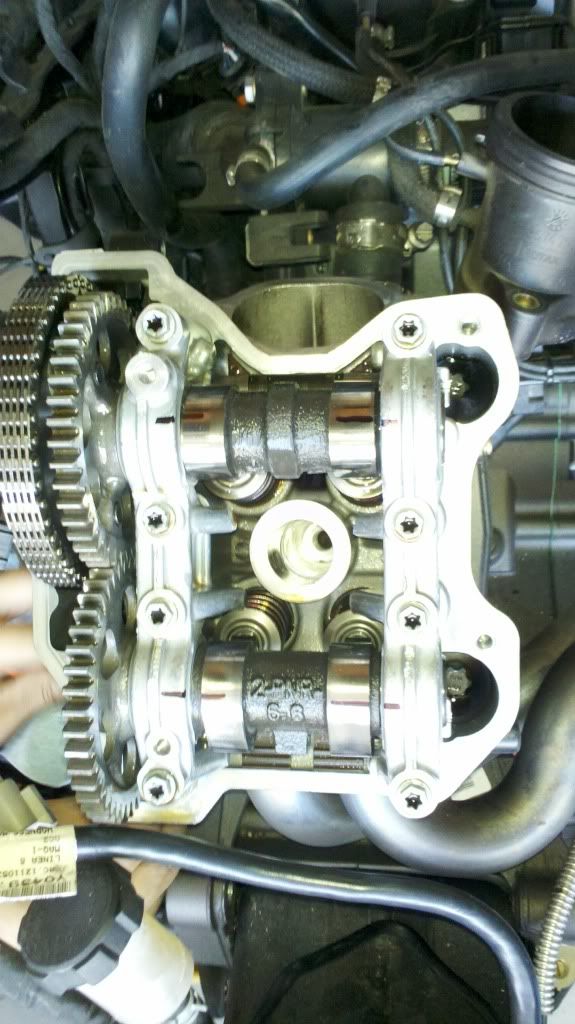

I want to thank William a fellow badweber for helping me out on this rebuild. I would not have been able to work on this without him. We are in progress of rebuilding the motor on my CR. We have the top end off the bike and are thinking about splitting the cases. Does anyone have any experience/tips splitting the cases? For those of that don't remember I found what appeared to be a wrist pin clip on the drain plug when I did the last oil change. here are the pics of the drain plug:   Everything looked great on the top end as you can see by the pictures below. We pulled both cylinders and all 4 of the wrist pin clips were fine. We pulled the pistons and looked in the bottom end, everything looks great. When emailing EBR they said that clip is also used in the transmission (spring detent for the shift drum), the question we are asking is should we split the cases and look through the bottom end to be safe? Here the pics of our progress:                http://s1161.photobucket.com/albums/q503/dwkaufman / | ||

Battyone |

Big job,to be avoided if possible,I'd just remove the right side case and check everything over,that allows access to a great deal of your internals. Maybe pull the altenator cover too and check the starter gears and balance shaft.Then you can retorque the rotor while you're in there. Seeing as you had no issues with the motor until you found the bit in your oil,there's no point in making too much work for yourself. If you must go further then the best thing to do might be to replace allbearings etc so you end up with a fresh motor.There's nothing particularly difficult about splitting the crankcases,but keeping them oiltight on reassembly might be a different matter. | ||

D_adams |

Personally, I'd split them and inspect. I'd HATE to find out that there was something in the transmission broken that I could have gotten fixed in another couple of hours rather than have to do it ALL over again. EBR does it in less than 4 minutes to do a complete build, so you could have it done within a day. | ||

Battyone |

4 mins rofl...I've watched that so many times,makes it look so easy. Took me half a day to get the gearbox seperated,just couldn't get selector forks away from the drum enough to get it out. I agree it would be a bitch to put it all together and find a problem,but the only prob was a "clip" in the oil. There is a wire clip on the shift shaft,that looks abit like a wrist pin clip but smaller. And it would be a shame to go all the way in and not replace everything that can be. I split cases to get new rods made and fitted. Having split a set of cases I would avoid doing it unless absolutely necessary. | ||

Dktechguy112 |

We were planning to re-torque the rotor nut anyways, so we can pull the stator cover and check out that side. Battyone, Would the bike still shift the same if it was missing the wire clip on the shift shaft? The shifting has been great on the bike. Does anyone have a p/n of that wire clip on the shift shaft? | ||

Battyone |

Pull the right side off too,then you'll get access to everything bar the gear box itself.I take it you've had the filter screen out? anything in there? The other bits on your sump plug look more worrying than the clip. there's a parts manual download on UKBEG. | ||

Duphuckincati |

You said in your first post that all the piston clips were good, so this must be the gearbox clip, so in ya go...otherwise you'll always have this in the back of your mind while riding, and I'm guessing there's a chance this could cause a gearbox lock-up resulting in a crash. And we all know crashing sucks. Always. Just different levels of suckiness. Here's an old proverb.. For want of a nail the shoe was lost. For want of a shoe the horse was lost. For want of a horse the rider was lost. For want of a rider the message was lost. For want of a message the battle was lost. For want of a battle the kingdom was lost. And all for the want of a nail. (Message edited by duphuckincati on September 17, 2012) | ||

Rodrob |

Pull it apart! That crap on the drain plug looks horrible. Something went south. I just did my 1190rs motor. If you have an engine stand, make a cradle. I did not and it was a pain. Your gonna need a way of locking the final drive in order to get the detent wheel off the shift drum. I used a big set of channel locks to grab the sprocket. Put the motor back in the bike before you torque all the big nuts - crank, rotor, clutch. Makes it much easier. Make sure you use a drill bit or similar to position the water pump gear correctly. It serves as a balancer. | ||

Figorvonbuellingham |

Wasn't there a recall on the timing chain guide or tensioner? Maybe that's what all that stuff is from. | ||

Battyone |

Wasn't there a recall on the timing chain guide or tensioner? Maybe that's what all that stuff is from. ----------------------------------------- They're plastic. Get the right side off and the altenator case. If there's no damaged parts in there or there's massive damage then you'll have to split the crankcases. I've just found two badly damaged gears with no sign of anything in the oil or on the sump plugs,so you won't know what's goin on til you have a look. | ||

Nillaice |

i replaced a 5th gear bushing. you can split the cases, too. an extra set of hands will be helpful to get and keep the shift drum & fork alignment when putting it all back together. USE THE MANUAL (for it is the word of gawd) and have good FME controls. i laid down some white towels on the workbench, and i should have used garbage bags to cover and keep everything clean. oh yeah; and you need to USE THE MANUAL (Message edited by nillaice on September 18, 2012) | ||

Nillaice |

and since nobody else has said it: an 8mm socket on a drill for the 27 case fastners. rapping and tapping on the cases with a soft mallet helps to work them apart. do not pry with a screwdriver |