| Author | Message | ||

Kruizen |

Ok so I'm getting ready to replace my pads and change the brake fluid, but I'm having a major issue loosening the 2 Caliper Mounting Fastners holding the front caliper. I'm using a 4mm socket bit but am extremely worried about striping the head. Is there a lot of tread lock on those bolts?? ANY suggestions would be helpful edit: realized I spelled fastener wrong in the title. (Message edited by kruizen on January 05, 2012) | ||

Chessm |

youre going lefty loosey, right..er correct? | ||

Kruizen |

yeah - yeah, I figured that was coming. when I was taking off my passenger pegs I actually snapped a allen/socket in half, there was so much loc tite on the bolts, all four of the bolts threads were completly covered in loc tite. (Message edited by kruizen on January 05, 2012) | ||

Timebandit |

heat is your friend. | ||

Kruizen |

What do you think: Hair drier, heat gun or benzomatic??? | ||

Jdugger |

The pin hangers or caliper fasteners? The caliper fasteners are 5/16ths drive Pin hangers are 13-15ft lbs. Loosen w a torque wrench and don't go above 16 or so... | ||

Kruizen |

Was actually using an 8mm but I'll go get a 5/16 and try that, wish they would have stuck with either sae or metric for the entire bike. Thanks | ||

Kruizen |

now i'm f'd, top one came out fine. Bottom one the allen wrench slipped and started to strip out the bolt. HELP | ||

Timebandit |

I hate it when they combine metric and SAE. Some of the small fasteners are so close in size that it becomes hard to be sure that you're always got the right tool in hand. it's pretty common for bolt faces to fail when threads are seized, or if you make the mistake of using the wrong size wrench and round-off the head. if threads are seized then there's no way to free the fastener without exceeding the torque spec. but if you've rounded-off the allen fitting then you may just have a wrench fitment problem. it sounds like you've already got a wasted fastener that's going to have to be replaced. at this point you can't save it and your only concern is how to safely get it out. if you need heat to loosen the threads, i'd try a fine point MAPP gas torch. MAPP burns hotter than propane. you can get it gas at Menards. heat the fastener head with the tip of a fine point flame, then quench the threads with penetrating oil. repeat. if your allen socket's face is rounding then you may have to (kludge) pound a larger size T-handle allen or Torx into the opening, or use a broken bolt extractor. good luck! (Message edited by timebandit on January 06, 2012) | ||

Nuts4mc |

...if you have a gun type weller soldering iron - use "induction heat" by holding the soldering guns tip on the head of the bolt ...at full power for like 5 minutes...it may soften the loctite...some metric/SAE allen head are close in size - you may need an SAE allen wrench to "force fit" into the socket and remove Mr. Bolt....good luck PS - don't have the equipment? - drill the head off... | ||

Kruizen |

Wow haven't heard Menards since I was living in Michigan. Going to try and drill the head tonight. | ||

Zac4mac |

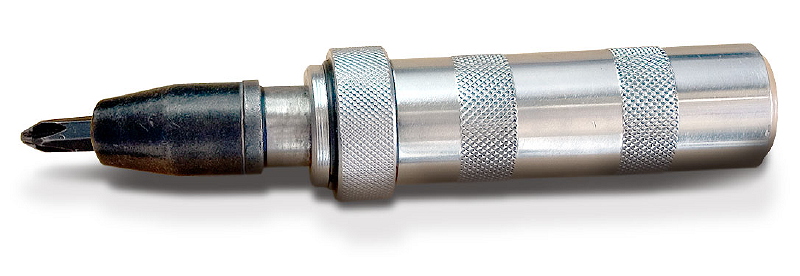

One of the best "old school Harley" tricks I picked up is - Heat it and Beat it. Fine point torch and a pin punch for concussion. An expendable torx driver is your friend. As is a manual impact driver -  Z | ||

Dannybuell |

One of my first motorcycle tools 1970-71? was an impact driver, metal case and a variety of bits. | ||

Kruizen |

drilled it out, seemed like I was drilling way to deep, but its just a very deep head. Nice thing is that the bolt is the same bolt that hold on the passenger peg brackets. | ||

Kenm123t |

take your tig welder and turn it down and start the arc at the bottom of allen head or torx bit and heat up the alum corrossion and the loctite. Most of the time its the only way to get rotor carrier bolts out of Tuber wheels | ||

Timebandit |

what's better than a BFH? a BFH that converts it's whack into rotational energy.  |