| Author | Message | ||

Nwrider |

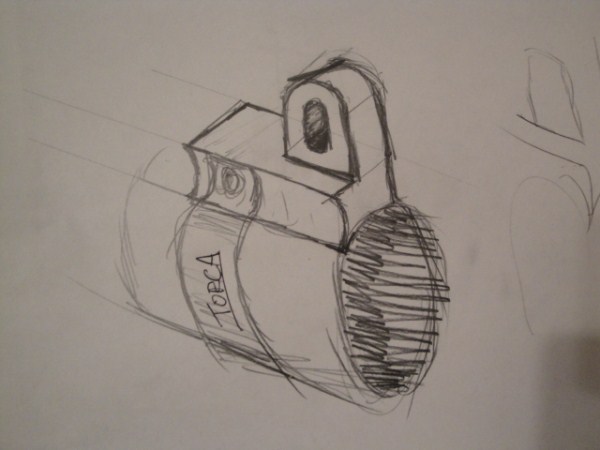

So after putting together a complete race exhaust.. I do not have a shoe. After kicking ideas around with another member who loaned me his shoe to copy, this is what I came up with. I have no CAD skills so I made a rough sculpture that I will be taking to a machine shop with the specs. I am waiting on a few different size Torca clamps to finalize the design. The shoe will replace the spacer on this style clamp. It will be wider than the spacer which is why I have to figure out which diameter clamp will work best.  The base will likely be shorter but this will give you an idea. One solid chunk of aluminum with one bolt hole for the clamp, grooves to seat the clamp band and one bolt hole for the Y-hanger.     I have only contacted one machine shop regarding production and was told there would be 20 piece minimum. Help me make this happen guys! I don't know the cost yet and plan on shopping around but please let me know if anyone is interested. Michael (Message edited by nwrider on November 13, 2011) | ||

Ratbuell |

Any idea how much $? If it works with all stock hardware, I could go for one or two as spares... | ||

Brinnutz |

I think there were a few iterations of the race header mounting shoe. The best one had small tabs on the rear of the shoe to help prevent the clamps from backing off of it, as was a typical problem. Al solved this with the double clamp setup, but I'd like to see something similar implemented and I'd buy a couple then. Edited because I just noticed you want to use aluminum...Why aluminum? Why not stainless like the exhaust and current piece already is? That's the only way I'd be in for some. (Message edited by brinnutz on November 14, 2011) | ||

Nwrider |

When I find out a cost I will post it. I could make it out of stainless. I had aluminum in my head because it will be so thick. No need for tabs, the clamp will bolt to the shoe. When I get the clamps I will take some more pictures. I am open to suggestions as well. | ||

Blake |

I don't follow your chunk of clay concept. Needs slots for the clamp, yes? There is a way better type of clamp. See the "Easy to Install" type at... http://www.mcmaster.com/#bolt-hose-clamps/ The band has flared edges that preclude prevent cracking and subsequent failure. I won't use anything else on the Cyclone. Went through too many of the conventional types. The "High Torque Bolt" types look like they may offer significantly improved durability too. I've not tried any of them. | ||

Nwrider |

Blake, You are correct sir. There is a slot for the clamp on my "chunk of clay concept". It just isn't that visible in the photos. It will make more sense when I get the clamps. The plan is to use the strap only from a smaller diameter Torca clamp (2 1/4 or 2"). The difference in diameter will be made up by the width of the part being machined. A longer bolt will be required to squeeze the strap tight into the slots. Wow.. that "easy to install" clamp looks beefy! Looks like it would work with the race shoe but not what I am attempting to do. Could someone post a side view photo of a mounted race shoe? I am curious how far it hangs off the leading edge of the muffler inlet. Thanks! Oh.. and my apologies for another thread on this subject. I couldn't find the last one. (Message edited by nwrider on November 15, 2011) | ||

Blake |

I think I understand. When you say "a complete race exhaust", you are talking about a custom, home-made exhaust system, not the factory race exhaust? Yes? I was thinking you were talking about the OEM race exhaust. Structurally, the bracket configuration you are showing give me pause. The excessive height of your bracket is likely going to see a massive amount of bad vibration, the kind that eats Buell exhaust systems for lunch. The best approach I've found is to clamp the header and muffler as rigidly and tightly as possible to the engine, as close to the XB type mounting scheme as you can manage. The OEM rubber bushing was a really bad design. The fix was the "Y" bracket, but still with rubber bushing. Better, but still a problem. I use the original "L" bracket but with a tightly fixed solid bushing, and then clamp the heck out of the shoe too, at both ends. Even with that, the header can crack and fail where the rear cylinder's single head tube is welded to the collector. It's neat when it does so while you are going WOT and the header tube pops up in your face, the only thing stopping it from viciously attacking you is your right leg. LOL. Probably the freakiest thing I've ever had happen on a motorcycle. The hot rod Cyclone does not tolerate average exhaust parts. | ||

Blake |

"one bolt hole for the clamp" I don't follow that either. Why do you need a bolt hole in the bracket for the clamp? "The base will likely be shorter" Ahhhh! Missed that until now. Yes, MUCH shorter! | ||

Nwrider |

The shoe will not be clamped to the pipe but will be a part of the clamp. The little hour glass shaped piece that the bolt passes through on a Torca clamp will be replaced by the piece I propose to have machined. This is why a smaller diameter clamp would be required. At the clamping surface the part will only be as tall as the grooves that the strap seats in. Excuse my artistic ability, but here is a doodle hopefully illustrating it better. I even labeled the strap "Torca" so it didn't look like random lines. In my mind this seems like a simple and viable solution. But I am no expert or structural engineer.  Edit: I had even kicked around the idea of a second strap that would attach directly under the tab that attaches to the Y hanger. From what I understand the shoe hangs over the leading edge of the muffler inlet(this is why I asked if someone could post a photo of a mounted shoe). If there is clearance enough to clamp around the collector, the only problem would be the difference in diameter due to the wall thickness of the inlet. Maybe a chunk of pipe could be used as a spacer between the strap and pipe? Maybe a second clamp would be too ridged and stress the welds on the collector? I could be over thinking this like I do everything! (Message edited by nwrider on November 17, 2011) | ||

Nwrider |

Blake... Wow... I bet that freaked you out. I would have never thought a header tube could come around on you like that. And yes I am talking about a factory race exhaust. Altho now all I have is the can. Probably be looking into header alternatives if I cant locate one. | ||

Db4570 |

I'm probably being unrealistically optimistic here, but.. My father-in-law has a full machine shop in his garage. He wouldn't be interested in a job like this, but he is a good guy and might be interested in teaching me how to do it. I already have some very basic machine shop skills, and have been thinking about trying to expand my skills a bit. I will see him Thanksgiving and can chat with him about it then. Do you have an idea what this would be worth to you? It's not going to be cheap, but at least you wouldn't have to buy 20 of them. I imagine it taking me a lot of time to do it right. I am leaning toward aluminum, just for easier machining. But my FIL may feel otherwise. Your drawing is actually pretty decent. Could you produce an actual drafting type drawing with exact dimensions, if we got to that point? Also, I don't understand why you need a shoe and not just a sturdy hanger. But I don't know how your exhaust is configured. Let me know if I can try to help. David | ||

Jayvee |

I'm not an engineer, just a "know-it-all" but seems like the weak point here is the little 'backward bend' in the strap as it reaches up to be bolted to the shoe. Why not take advantage of the "roundness" (less concentration of forces at any one point) of clamps, and just go all the way around the shoe with the clamp(s)? Have you seen the way Twin Motorcycles is building their rear mount? Might take a gander at that, they're working on a similar solution to the other end of the can. Very intriguing idea. Seems like some of the real engineers on this forum could help to come up with with technical advice on solutions to this problem that comes up over and over. I would love to have access to machine shop stuff, my dad has it all in his garage 1,500 miles away; sadly he also has no interest in doing this kind of work any more. | ||

Dave_02_1200 |

Michael, I like your design. It looks strong and simple and I think it would look great polished. (You know how I like polished aluminum) Keep us posted. | ||

Nwrider |

Thanks for the input guys.. I may just try and get one or two made and try em out. Jayvee.. Torca makes a beefier version with the same type mount but I see your viewpoint. Dave.. I like shiny stuff too.. kinda like a Ferret in that respect. | ||

Dave_02_1200 |

Any news on the Race Header Shoe? I like the idea and I think the machined part will be an improvement over the welded factory design. Also, I do like the one Aaomy made up that bolts together. Keep us posted. | ||

Ebutch |

| ||

Ebutch |

Here,s Aoomys  (Message edited by ebutch on December 14, 2011) | ||

Nwrider |

There is a member who may be able to help out Dave. I am going to discuss it more with him. Thanks for that pic Ebutch. That appears to mount to the pipe and is not held on by the muffler clamp. Hmmmmm. Can some one post up a photo of a race shoe mounted? | ||

Leonard |

Hey Nwrider..Did you figure this one out? |