| Author |

Message |

Andersonhdj

| | Posted on Saturday, September 21, 2013 - 05:18 am: |

|

Check for restrictions in your fuel line , ie a kinked pipe , but also don't discount a blockage.

Your system might be seeing pressure at low volume due to a constriction somewhere.

Try to get a line directly off the pump itself and pump into a container.

Slept in this am so have'nt had a further look into more info as yet, howling gales outdoors but will have a look at my XB to see if anything jumps out at me later. |

Andersonhdj

| | Posted on Saturday, September 21, 2013 - 08:25 am: |

|

I know i may be jumping the gun here , but when you replaced the fuel pump, did you replace the pressure regulator as well?? |

Smiles

| | Posted on Saturday, September 21, 2013 - 12:53 pm: |

|

I went to Harbor Freight and purchased their Master Fuel Injection Pressure Test Kit (Pittsburgh Automotive - Item# 97706). For my bike I had to use the number 28 fitting, which fit PERFECTLY between the fuel line and the throttle body.

Whilst having the 2006 XB9SX ECM in, I tested the fuel pressure of the bike with the key switch ON and the kill switch set to RUN in order to have the bike prime. The needle on the gauge didn't move.

I tested the fuel pressure of the bike while trying to crank, and had the same result. The needle on the gauge didn't move.

I repeated these tests with the 2003 XB9S ECM and had the exact same results.

For both ECMs I went through the service manual flowchart meant for NO fuel pressure on page 4-35. For both, I found:

1) Voltage IS present at the GY wire Terminal D on fuel pump connector [86A].

2) Test lamp DOES come on during first two seconds after key ON when test lamp is placed on positive (+) terminal of battery and when BN/Y wire of [86A] is probed.

3) Fuel pump wiring IS good.

Diagnosis: Replace fuel pump assembly.

I didn't replace the fuel pressure regulator when I replaced everything else. I'm thinking I should have just as a precaution. Hindsight is 20/20.

I checked the line from the fuel pump and there are no kinks, cracks, or visible problems. I didn't have a chance to take the line off to see if the pump would deliver gas.

(Message edited by Smiles on September 21, 2013) |

Andersonhdj

| | Posted on Saturday, September 21, 2013 - 01:34 pm: |

|

So we may have resolution soon then!

Somehow ,my gut feel is your pressure regulator may be duff or blocked up.

Perhaps you should check your old fuel pump , just out of interest and see if it is in fact faulty.

It might elucidate matters a bit. |

Smiles

| | Posted on Sunday, September 22, 2013 - 10:36 pm: |

|

*UPDATE*

I pulled off the fuel line from the pump and hooked up the fuel pressure gauge to see if the pump assembly was pushing anything out. To my surprise, it WAS putting out a bit of fuel; however, the amount of fuel that’s being pushed out isn’t even enough to move the needle of the gauge.

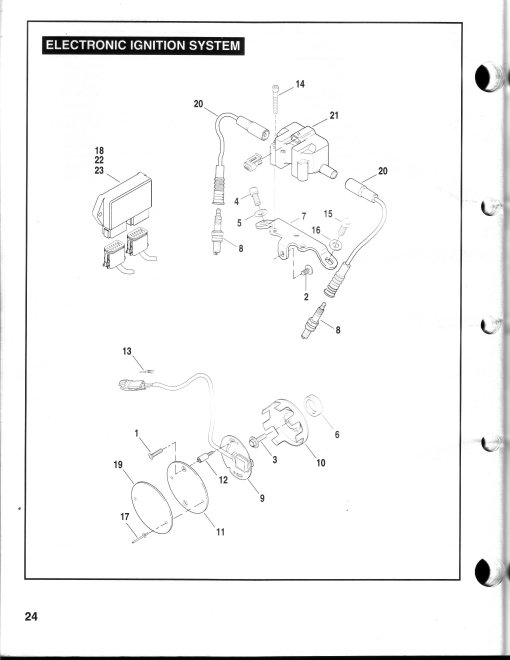

While looking up part numbers for a fuel pressure regulator (62121-99Y) I came across a thread concerning fuel pump cross-references. I noticed some different part numbers being tossed around for the actual fuel pump and decided to look into it.

Some of the part numbers that came up were for the Airtex E2366, which is in my current fuel pump assembly, but then there’s the Airtex E2061.

Airtex E2366

Rockauto Price – $80.79

UPC – 080044011071

Type – Turbine

Volts – 12

Pressure – 100-120

Flow (GPH) – 65-75

Inlet Type – Strainer

Outlet Size – 3/8”

Outlet Type – Hose Barb

Airtex E2061

Rockauto Price – $64.79

UPC – 080044102663

Type – Gerotor

Volts – 12

Pressure – 80-90

Flow (GPH) – 40-50

Inlet Type – Strainer

Outlet Size – 5/16”

Outlet Type – Hose Barb

I have ordered a fuel pump, fuel pressure regulator, fuel pump screen, fuel line, and new o-rings. Currently, the bike is sitting on a stand with the fuel pump removed awaiting the new parts, which should all be here by the end of this week.

Attached are a few pictures to show the differences between the Airtex E2366, E2061, and the original fuel pump of the 2003 XB9S.

Airtex E2366

Airtex E2061

2003 XB9S Fuel Pump (Above)

2003 XB9S Fuel Pump (Side)

|

Smiles

| | Posted on Tuesday, October 01, 2013 - 03:19 pm: |

|

*UPDATE*

The new fuel pump (Airtex E2061) came in and is a PERFECT fit. I paired it with a different fuel strainer (Airtex FS111) than the stock one.

Took the bike apart, removed fuel pump assembly, put together E2061 and FS111, and shoved the assembly back up into the tank. I primed the bike and found out the pump works VERY well when gas sprayed from where the fuel hose connects to the fuel pump. I checked the line and found nothing was wrong. I checked the hose connection and felt it was somewhat loose. Naturally, I felt I should tighten the nut on the fuel pump. The nut felt it should break off the fuel pump connection.

After exchanging some “choice” words with the fuel pump I decided to remove the fuel pump assembly….again. Luckily, I still had old fuel pump assembly. I pulled the assembly out of the tank, swapped the parts, double-checked everything, went over the fuel hose and the connections, triple-checked everything, and then put it all back together.

Good News: The bike starts and sounds AMAZING

Bad News: The bike won’t idle

With key set to ON and kill switch set to RUN I can keep it running if I’m pulling back on the throttle. As soon as I let off, it dies.

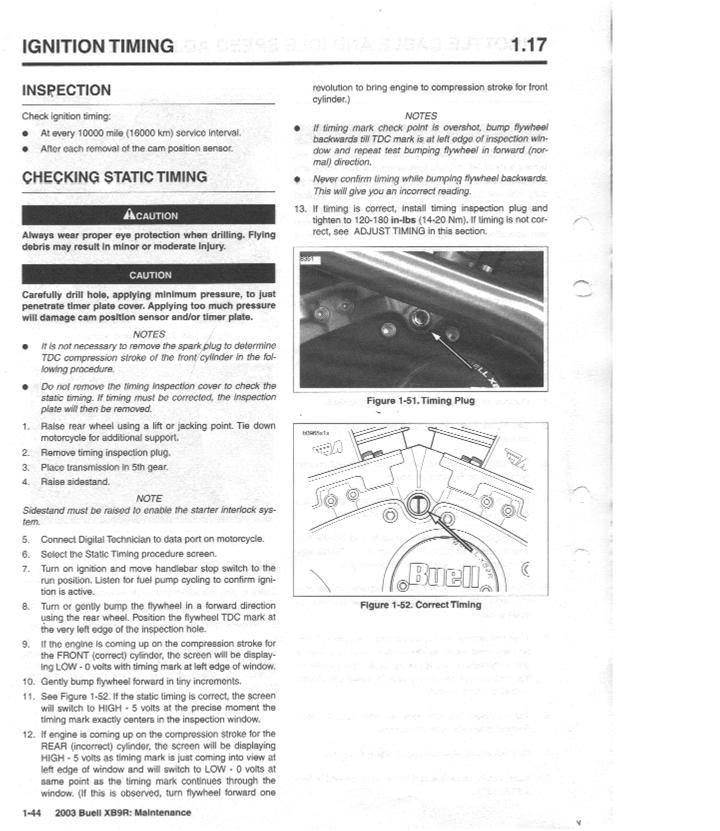

I decided to check ignition timing and found it to be incorrect.

Front Cylinder Compression Stroke

Voltage is at 0 with timing mark on left edge of window

Voltage is at 5 with timing mark beyond (out of view) right edge of window

Rear Cylinder Compression Stroke

Voltage is at 5 with timing mark centered

Voltage is at 0 with timing mark centered/continuing through window

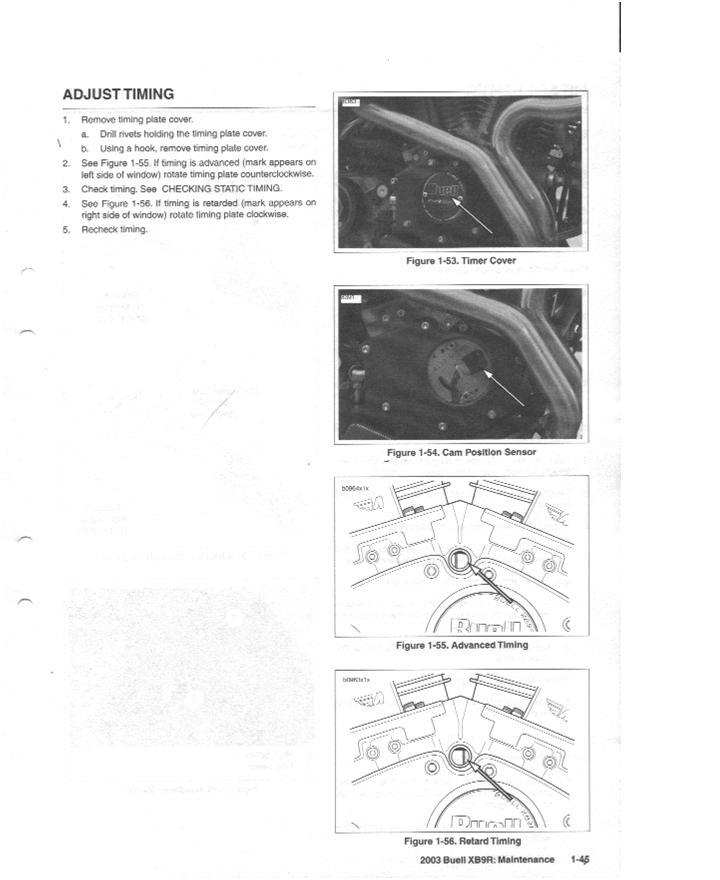

I have attempted to adjust the ignition timing, but I feel I’m doing something wrong. I assumed the timing to be retarded and followed the service manual instructions by turning the timing plate (#9 in the diagram) clockwise. Each time I moved the timing plate I checked the timing, but it didn’t feel like improvements were made.

If anyone has any tips or any information on how to set static timing I’m all ears.

But hey, the pump works!

(Message edited by Smiles on October 01, 2013) |

Andersonhdj

| | Posted on Tuesday, October 01, 2013 - 04:45 pm: |

|

Glad to hear you've got her running again!

I may be off the mark here but perhaps a TPS reset is in order??

Your timing should not affect your idle that drastically , considering that she now starts and runs all be it with some throttle applied.

Again, i may be missing something but i suspect that reference to the rear cylinder is clouding the issue.

Your only interest should be the front cylinder, get her to TDC and rotate backwards till the timing mark lines up exactly, this will only be a few degrees, then rotate your timing plate till you have a high signal , aligned exactly with the timing mark and lock the plate.

There is no logical reason for your timing to have changed without intervention of some kind.

(Message edited by andersonhdj on October 01, 2013)

(Message edited by andersonhdj on October 01, 2013) |

Froggy

| | Posted on Tuesday, October 01, 2013 - 04:54 pm: |

|

I agree with Andersonhdj, try doing a TPS reset and idle adjustment again. If possible get the bike to warm up before doing it, if not then do it cold but try it again after it warms up. The idle is a pain to get right with the motor cold. |

Jdcolcol

| | Posted on Tuesday, October 01, 2013 - 10:32 pm: |

|

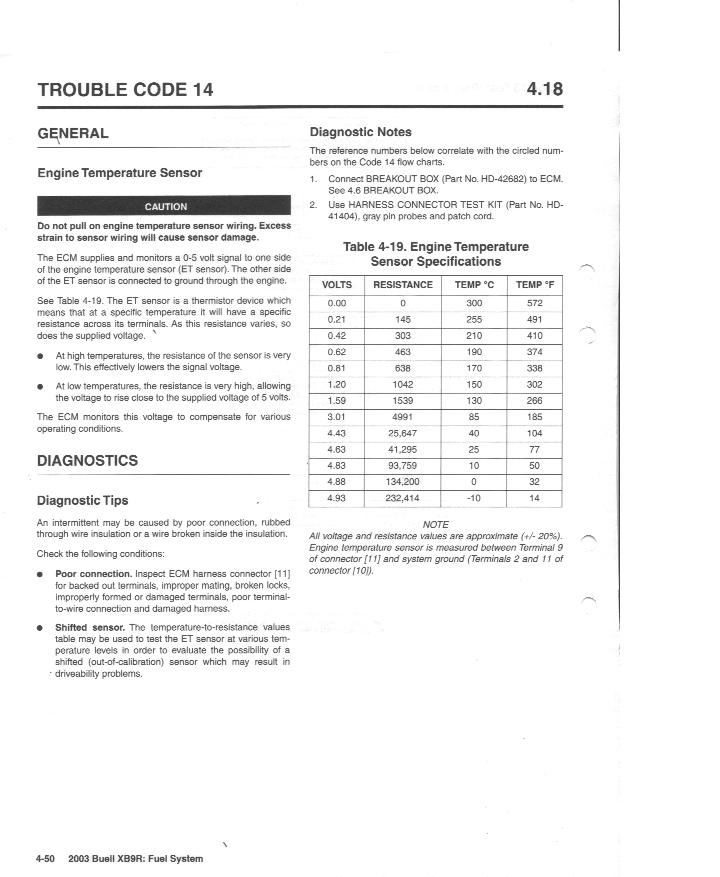

Not sure if the XBs have engine temp sensors but I know on my x1 that when the head temp sensor went bad it made the bike run like crap do other crazy things and didn't throw a code on ECMspy. Just somewhere else to look if you still have problems. But what the others said tps reset!! |

Smiles

| | Posted on Thursday, October 03, 2013 - 02:48 pm: |

|

*UPDATE*

Forgot to mention I picked up a trouble code for the cam position sensor, which is why I felt I needed to set the timing. I'm 99% certain I was looking at the trouble code history and not the current readings.

After "setting" the cam position sensor I tried to start the bike and thought someone shot at me due to the HUGE pops that came from the exhaust. Afterwards, I did a TPS reset.

I figured there was some extra fuel in the system since I had to play with the cam position sensor for quite a while. When I tried to start it (with earmuffs) I noticed puffs of black smoke and 1/2" flames shooting out from either exhaust end.

Froggy - I'm thinking I have to go back in and fix my mistake with the CPS before I can warm the engine.

Jdcolcol - XB's DO have an engine temperature sensor. Previously, Anderson posted about warming the engine up and seeing if it would run, which would be a sure sign of the ETS. I wish I would have done this test BEFORE I played with the CPS.

This is the order of what I'm thinking needs to happen:

Fudged up CPS and should have left it

--Redo CPS job

See if bike will start

--If bike starts and idles, the forces of nature won't be able to keep me off it

--If no start, see if engine can get warm

----If engine can get warm and idle - Maybe Engine Temperature Sensor is bad

----If engine can get warm and won't idle - We'll see |

Andersonhdj

| | Posted on Thursday, October 03, 2013 - 05:17 pm: |

|

quote:--Redo CPS job

See if bike will start

--If bike starts and idles, the forces of nature won't be able to keep me off it

This seems like sound logic , if she does start , you may find she won't idle straight off , you may have to keep her just above idle for a bit , till she's cleared her throat! May even take a few go's but if all is good she'll settle right down!

Then it'll be all  !! !! |

Smiles

| | Posted on Monday, October 07, 2013 - 05:01 pm: |

|

*UPDATE*

I managed to set the CPS and checked the timing a few times before I closed everything back up. Afterwards, I did a TPS reset with ECMSpy, pulled the bike of the battery tender, and put the ignition to on.

The gauges swept normally and the fuel pump primed. I hit the starter and instead of hearing it come to life, it clicked over and over as if the battery was dead. I attempted start it three more times, but each time it sounded like the battery had less and less power in it. I noticed the clock read "1:00," too.

I put the bike back on the tender and let it sit until it had a full charge. I swapped out the 2006 ECM for the 2003 ECM, but had the same results. With the 2006 ECM back in place, I hooked up some jumper cables from my truck and got the bike to start for a short amount of time.

It wouldn't idle, but would stay running for a bit if I cranked back on the throttle. Even when I had the throttle pulled back the RPMs would drop, but come back up after one second to where they were.

While pulling back on the throttle, I saw a small amount of gray smoke coming from where the headers connect to the engine. I couldn't tell if it was coming from under the airbox cover or around the throttle body, just that it was coming from the area by the headers.

I haven't attempted to start it again, and am thinking I need to look over a few things. |

Andersonhdj

| | Posted on Monday, October 07, 2013 - 06:01 pm: |

|

Check out your CHT unit. It might be that it's messing around your cold start mixture which would affect your idle.

Also might help to pull your headlight fuse while your trying to get her running.

Less drain on the battery. |

Froggy

| | Posted on Monday, October 07, 2013 - 06:28 pm: |

|

The machinegun click and clock resetting to 1:00 means the battery was dead, it is possible the battery is failing due to the abuse it has taken thus far. Thats why you were able to get it start when jumping off the truck, but these bikes require a good healthy battery to run right. Low voltage makes the sensors read wrong and the system won't inject properly.

I agree on pulling the lights fuse if you haven't yet. |

Smiles

| | Posted on Wednesday, October 09, 2013 - 08:50 pm: |

|

Alright, I pulled the headlight fuse, turned the key over, and the headlight still came on. I tested the high beam and turn signals, and they wouldn't come on. I pulled the two spares along with the headlight fuse, and the headlight still came on.

I attempted to crank it over, but the same thing happened (little attempt to crank, clock went to "1:00," machine gun clicking).

I hooked it up to my truck with the fuses out and it sounded a little better, but still wasn't up to par.

From buellxb (link at the bottom) I read about adding ground cables to the negative terminal in order to help voltage return back to the battery and create a more complete/fluid circuit.

I added 4 gauge wire from the rear bolt that holds down the ignition coil and from the left side of the engine ground. The two wires were routed alongside the fuel line and hooked up directly to the negative terminal of the battery.

Here's the order of wires (closest/touching the negative terminal to furthest/touching the battery bolt head) going to the negative terminal.

1) Rear ignition coil bolt

2) Engine ground

3) Frame ground (wire every bike has)

At this point I did a TPS reset (easier to move the wires around without the ECM plugged in).

After hooking up all the wires and plugging everything back in the start attempt appeared to be, again, a little bit better. I hooked the bike up to my truck, let it sit for 1-2 minutes, and got it to start while cranking back on the throttle.

Last time, when I had the bike hooked up to my truck's battery I noticed the rpms would dip down and then jump back up even if I didn't move the throttle from where I held it (at 3000 rpm). While being hooked up to my truck and having the two ground cables in place the bike stayed at any rpm I chose (2500, 3000, 3500, 4000, 4500) and was STEADY. There were no dips, stalls, or sputters, but there were a few pops and bangs from the exhaust. It even idled for a few seconds! It was a sluggish idle and died shortly after, but it was there.

Some more gray/white smoke came out from under the airbox. It smelled pretty bad and I still couldn't tell where it came from, but there wasn't as much spewing out this time in comparison to last time.

http://www.buellxb.com/Buell-XB-Forum/Do-It-Yourself-Buell-Mods/To-those-with-an-incurable-sputter-in-the-mid-range./3/

(Message edited by Smiles on October 09, 2013) |

Andersonhdj

| | Posted on Friday, October 11, 2013 - 11:56 am: |

|

Have you checked the state of your spark plugs?

Mine had the tendency to foul very quickly if she was'nt taken out on a run and it would be a serious battle to start her.

They tend to burn to a shiny black carbonised state and the only way to clean them is to sandblast or otherwise replace.

Some of the oldskool autoshops may still have plug blasters.

This gray smoke thing bugs me, i know you replaced the harness but are you sure your electrics are ok? |

Smiles

| | Posted on Friday, October 11, 2013 - 01:44 pm: |

|

I checked my plugs about a week ago and they had some grime on them. A dark/black fluid. I figured they were fouling because of the fuel pump being primed constantly and the bike sitting for an extended period of time. I haven't replaced the plugs since then. I did my best to clean them off and checked the gap before putting them back in.

The smoke bugs me, too. I'm planning on starting it up today without the airbox cover or base to get a better idea of where the smoke is coming from. As far as I know the electrics are fine, but after how things have been with this bike I'm not ruling out anything. |

Andersonhdj

| | Posted on Friday, October 11, 2013 - 04:24 pm: |

|

When you tried to clean them did they come clean - as in to a vaguely off white porcelain?

If you have a shiny black insulator it's not going to run well at all , basically , the carbon effectively shorts the spark to ground.

You could scrub them in some sand but you have to be certain to get any sand out afterwards.

I sandblast mine and then blow the heck out of them with compressed air coupled with the use of a straight pin to remove / loosen anything that may be stuck between the plug body and the insulator.

So i would do the plugs before you try and start her again , but , have to agree with your plan of removing the airbox and base , just be careful when removing the O2 sensor.

quote:Some more gray/white smoke came out from under the airbox. It smelled pretty bad

Actually it's the smell that bugs me. |

Smiles

| | Posted on Friday, October 11, 2013 - 05:37 pm: |

|

They turned out as white as they were in the package. The stuff that was on them came right off.

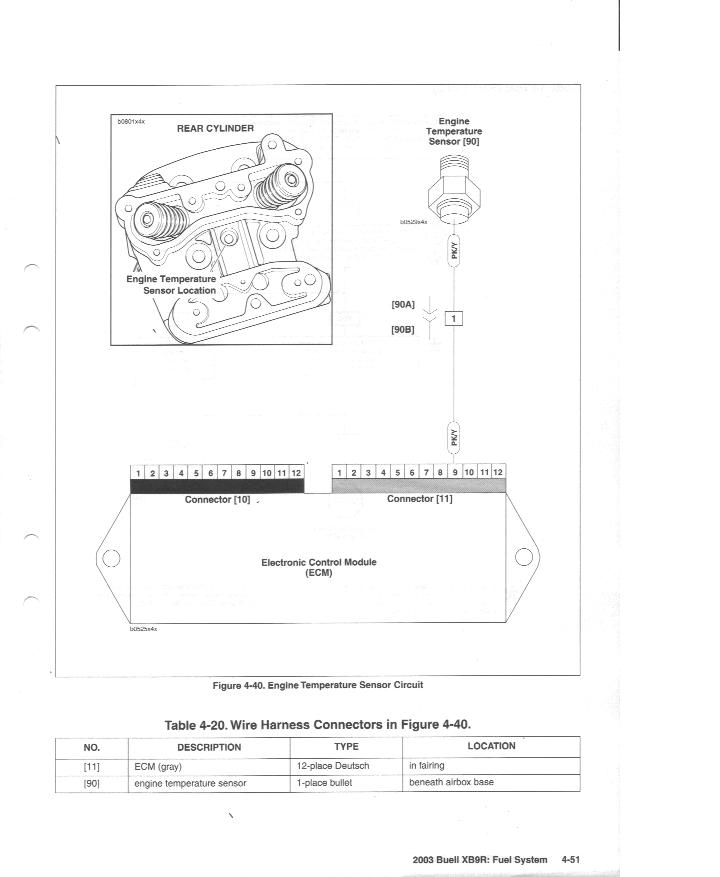

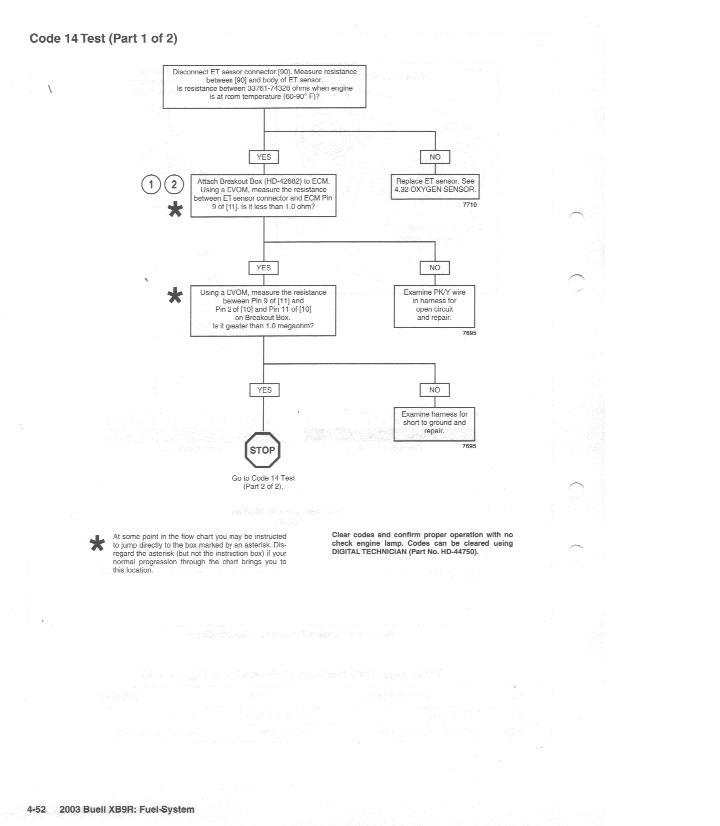

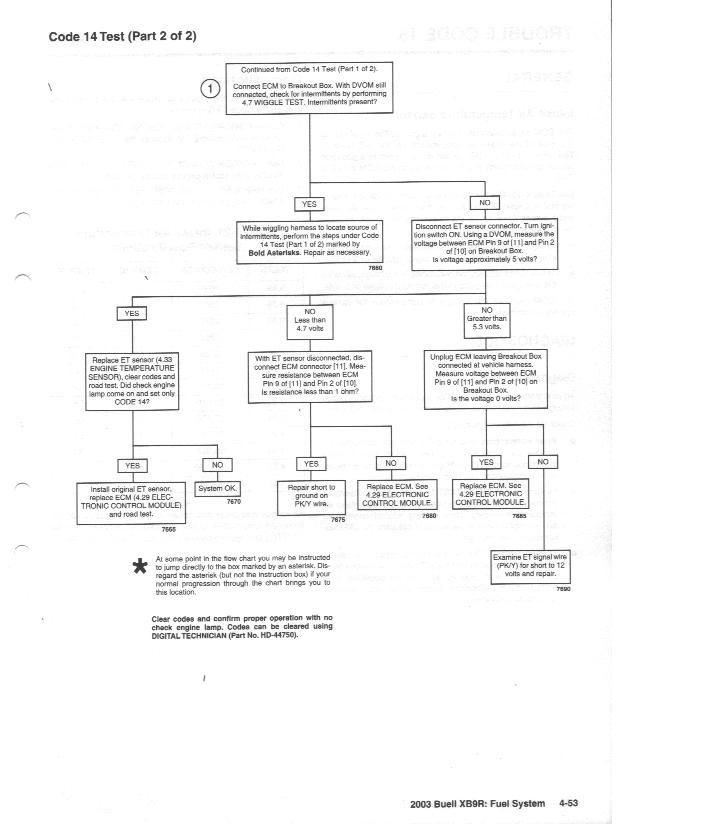

I wouldn’t remove the oxygen sensor if I were to remove the airbox cover and base. I didn’t get around to seeing where the smoke was coming from; instead I went through the flowcharts for the engine temperature sensor.

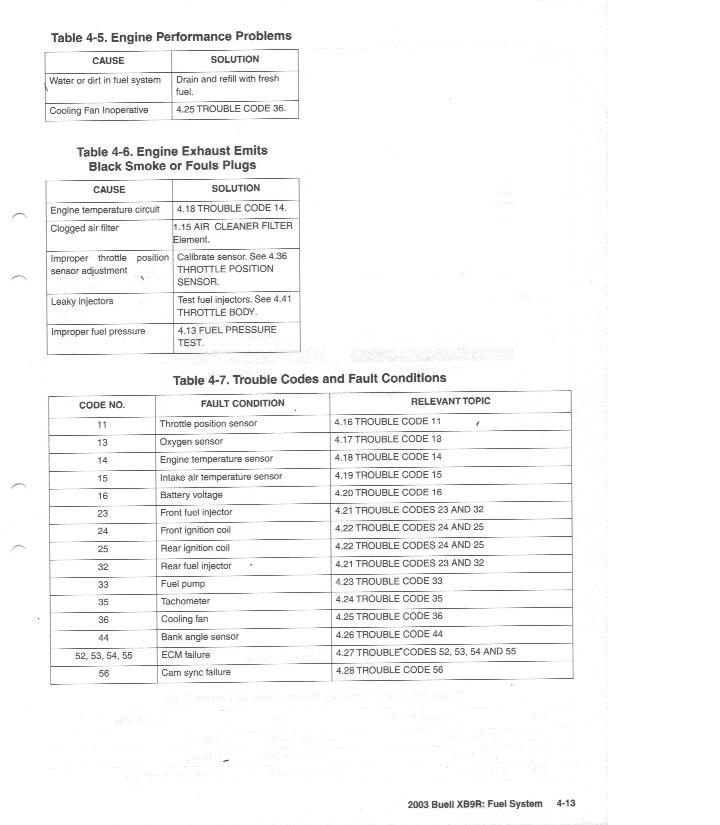

If you look at Table 4-6 entitled, “Engine Exhaust Emits Black Smoke or Fouls Plugs” there are a few different possibilities given:

Engine Temperature Circuit

Clogged Air Filter

Improper Throttle Position Sensor Adjustment

Leaky Injectors

Improper Fuel Pressure

I eliminated Clogged Air Filter-isn’t clogged and Improper Throttle Position Sensor Adjustment-checked it and it’s sitting at 5.5 degrees. I didn’t have time to break out the fuel pressure tester or take apart the throttle body, so I didn’t test for fuel pressure or leaky injectors. This leaves the Engine Temperature Circuit.

I went through the flowcharts for testing the sensor, but couldn’t test the resistance between the connector [90] and the body of the ETS since I couldn’t get the ETS out, nor could I remove the rubber boot over the ETS. I jumped over the first step and here’s what I found:

Resistance between connector [90] and ECM Pin 9 of [11] is less than 1 ohm

Resistance between Pin 9 of [11] and Pin 2 of [10] and Pin 11 of [10] is less than one megaohm

Solution: Examine harness for short to ground and repair

Voltage between ECM Pin 9 of [11] and Pin 2 of [10] was almost nonexistent

Resistance between ECM Pin 9 of [11] and Pin 2 of [20] is less than one ohm

Solution: Examine harness for short to ground on PK/Y wire

Yes, I understand I jumped around the flowchart, but I felt I should test where I could in the moment since I had it open.

|

Smiles

| | Posted on Friday, October 11, 2013 - 05:38 pm: |

|

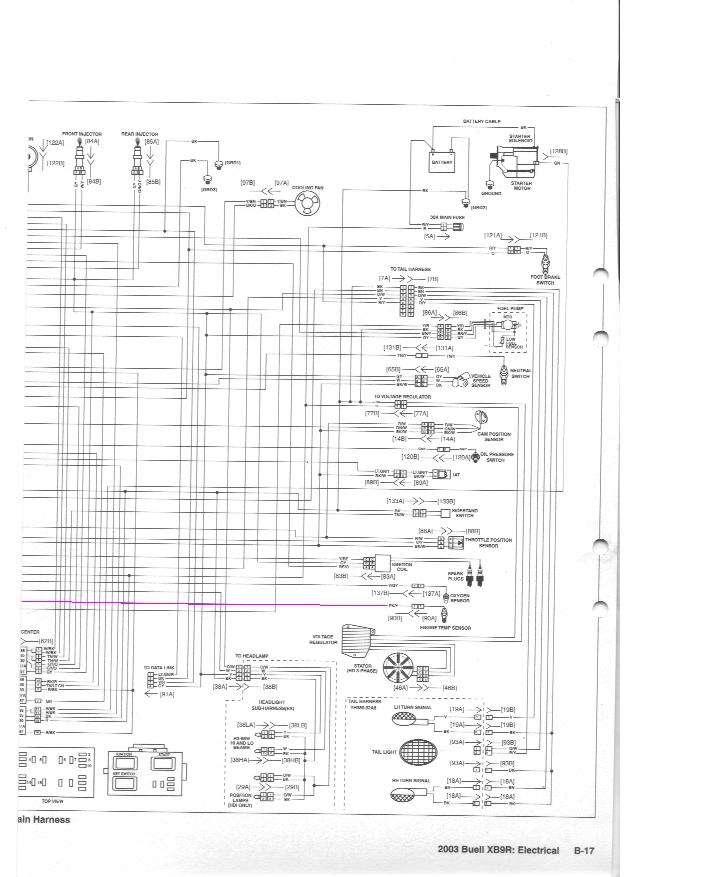

Not all the pictures were attaching. Here are the two flowcharts I was working with:

|

Andersonhdj

| | Posted on Friday, October 11, 2013 - 06:15 pm: |

|

Unfortunately my eyes are failing at this time due to pain meds and the lateness of the hour , Just past midnite! So i can't really follow the flow chart at this time.

Have you then concluded that you either have a short to ground or / and a duff CHT sensor?

Almost white plugs means that there's no enrichment happening at startup and would explain the reluctance to both start and idle but not the gray smoke. |

Andersonhdj

| | Posted on Friday, October 11, 2013 - 07:01 pm: |

|

Ok, so i opened the flowchart on my laptop at 125%.

If you measure between the cyl head and connector 90 you should get a cold reading of between 33k and 74k.

Following what you've indicated / discovered , if you dis term 90 and crank her she should start and idle under cold start condition.(Fuel enrichment active) |

Smiles

| | Posted on Saturday, October 12, 2013 - 04:33 pm: |

|

Don't ruin your eyes on my account!

I have not come to the conclusion of the issue being a short to ground or a bad sensor - I went through the flowcharts and posted the solution provided at the end of them.

The spark plugs returned to their porcelain white appearance after I cleaned them. The black gunk on them came right off.

Now, when you say the cylinder head, do you mean the body of the sensor (under the rubber boot) or the actual head of the cylinder? |

Smiles

| | Posted on Saturday, October 12, 2013 - 05:11 pm: |

|

Just tried to start it with the airbox cover and base off while having the IAT connected. It wouldn't turn over AT ALL. I heard nothing but that (as Froggy put it) "machine gun click".

Before I attempted to turn it over in the upcoming methods, the battery was on a tender and showed a full charge.

Disconnected CHT - clicking

Pulled light fuse - clicking

Hooked up truck battery with CHT disconnected and light fuse out - clicking

Hooked up truck battery with CHT connected and light fuse out - clicking

Hooked up truck battery with CHT connected and light fuse in - clicking

I allowed the battery to be hooked up to my truck battery awhile before attempting to start it again - clicking

I didn't get a chance to see where the smoke was coming from since I couldn't get the engine to turn over |

Andersonhdj

| | Posted on Saturday, October 12, 2013 - 05:27 pm: |

|

Not to worry! It's just age and the valium. I have spinal degeneration.

The CHT screws into the head so the body is common to the head , so in effect anywhere on the head or motor would work.

The clicking / solenoid clatter indicates that something is draining power from the start circuit , assuming you have a fully charged battery.

It sounds like you have a short to ground somewhere in your start cct or perhaps a relay problem.

When you say machine gun click i assume you mean a sustained clattering while the start button is depressed? |

Smiles

| | Posted on Saturday, October 12, 2013 - 07:47 pm: |

|

Thanks for letting me know the sensor screws into the head! I went through the flowcharts again. Here's what I found:

Pin 2 of [10] is system ground A (module)

Pin 11 of [10] is system ground B (coil)

Pin 9 of [11] is a direct connection to engine temperature sensor connector [90]

Resistance between connector [90] and the area surrounding the sensor is 63.6k ohms at room temperature. Good here

Resistance between connector [90] and ECM Pin 9 of [11] is less than 1 ohm. Good here

Resistance between Pin 9 of [11] and Pin 2 of [10] and Pin 11 of [10] is 64.5k ohms (or .0645 megaohms) for Pin 9 to Pin 2, Pin 9 to Pin 11, Pin 2 to Pin 11. ...not good here

Solution: Examine harness for short to ground and repair.

Yes, the clicking noise is from me holding down the start button. The lights dim while the button is being held down and flicker/flash with each click.

Just a thought:

I attached 4 gauge wires from the rear ignition coil mounting bolt and from the left side of the engine ground to the negative terminal of the battery.

-Could the two cables be causing this lowered resistance since Pin 11 of [10] is system ground B (coil)?

-Could the short to ground causing the aforementioned lowered resistance also be the reason for the battery to be drained so quickly?

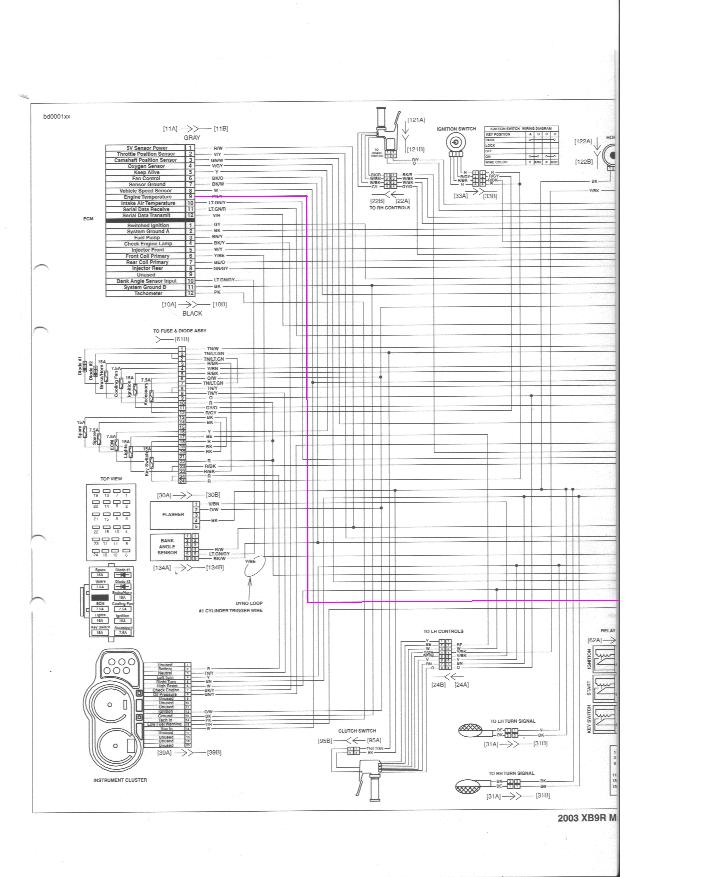

I attached the main wire harness layout and color coded the wire so it stands out more.

|

Andersonhdj

| | Posted on Sunday, October 13, 2013 - 03:53 am: |

|

Ok, i'm going to have to open the diagram on my side and look, i can't get a good look at this one.

2 things ,

(1) Remove the 4 gauge straps. They don't belong.

(2)The bike started and ran , albeit for a short burst on previous attempts - what has changed??

The way i see it , there are a couple of possibilities and i don't want to compound one problem with another,

quote:Yes, the clicking noise is from me holding down the start button. The lights dim while the button is being held down and flicker/flash with each click.

This tells us that either there is a monstrous current sink / drain / short or -

your new battery is fried suddenly due to buckled plates or some other factor.

I would as in (1) above remove the straps then attempt to charge the battery and once that has been done , get a current drain reading while trying to crank the motor. i think the procedure is in section 5 , open to correction

If the current drain is more than the indicated maximum 180

ampere instantaneous reading , this gives us indication that

(a) your battery can deliver the reqd current and

(b)there is the possibility than your starter motor or heavy gauge cable is failing or has developed a problem.

I have seen starters and or wiring fried before today due to excessive cranking leading to thermal failure.

Given that under cranking conditions, there is huge current draw, a short circuit on any light gauge wire would almost certainly lead to fire or at least a smell of electrical burning, which is why i expressed concern about

quote:" bad smell and gray smoke"

It's a pity you're 10k+ miles away! |

Andersonhdj

| | Posted on Sunday, October 13, 2013 - 01:32 pm: |

|

Can you post a pic of the 4gauge wire attached so i can see exactly where you conn'd?

The engine temp line you highlighted does'nt look as though there is anything that could be of issue.

Still looking through your connection description, will get back to you on that one.

Generally though, one would not mix ground within a closed processor system with the rest of unstable electrics , though at some point they would come together as a common ground. |

Ezblast

| | Posted on Sunday, October 13, 2013 - 08:16 pm: |

|

stop using the truck battery, use motorcycle batteries, check the VR - yes, replaced, but since then jumping with the truck battery may have flawed it, also suspect grounds for part of issue.

EZ |

Andersonhdj

| | Posted on Monday, October 14, 2013 - 02:34 am: |

|

I concur with Ez.

Another simple test to do, fuses in, everything hooked up as normal, ign off, disconnect the Battery Pos terminal and hook up a meter in series to check for current draw.

Should be zero.

Also bench test your VR,it's not impossible for it to have failed |

|

Troubleshooting (Poor Starting/Running/Handling/Ride Issues) »

Archive through June 11, 2014 »

2003 XB9S Multiple Problems »

Archive through October 14, 2013

Troubleshooting (Poor Starting/Running/Handling/Ride Issues) »

Archive through June 11, 2014 »

2003 XB9S Multiple Problems »

Archive through October 14, 2013

Troubleshooting (Poor Starting/Running/Handling/Ride Issues) »

Archive through June 11, 2014 »

2003 XB9S Multiple Problems »

Archive through October 14, 2013

Troubleshooting (Poor Starting/Running/Handling/Ride Issues) »

Archive through June 11, 2014 »

2003 XB9S Multiple Problems »

Archive through October 14, 2013