| Author | Message | ||

Gentleman_jon |

Having broken no less than three T-40 Torx bits today removing my rear wheel sprocket and brake rotor, and finishing the job with a pair of vice grips, ( ugh), I just could not help wondering if there might not be a better fastener for the job? Any suggestions, my brothers? How about regular hex head bolts that one can get a socket on, or Allen Button heads? Grade Eight, goes with out saying. Or, does anyone know a source for "unbreakable" T-40 3/8" drive torx bits, maybe "impact" grade? I can't seem to find any on line. The guy at my hardware store is fresh out of ideas, ( and T-40 torx bits).  By the way, the bolts were installed according to the Shop Manual. I'm thinking a little less Locktite might help. I forget if the manual calls for Blue or Red, but I assume I used what was required. | ||

Chasespeed |

I have a set of Torx that work with a Impact Driver, use them on brake parts, usually, GM.... So they are out there. And, if yo are bent on changing them, either Allen of Hex head(though, I would go with regular bolts)... Good luck Chase | ||

Spiderman |

Get some grade 8 zinc coated button head allens. OR grade 8 zic coated SHCS (socket head cap screws) with washers, if you have the room... | ||

Slaughter |

Grade 8 is neither here nor there. There's not enough load to make the high tensile grade 8 a requirement BUT some imbeciles use TOO MUCH Locktite at the factory. I barely use any. I also use hex heads but check clearance! | ||

Gentleman_jon |

anybody got a lead on Impact grade Torx t-40s? | ||

Slaughter |

My go-to source for fasteners is Fastenal: http://www.fastenal.com But that's because they have one really close to me here. I still think that IF you don't use hardly any Loctite, you're going to be OK. I've used up my annual profanity budget on a couple occasions trying to remove the original fasteners. Never had that problem removing the ones I've installed. | ||

Gentleman_jon |

Thanks Slaughter, I didn't know about them. They look very good. | ||

2_spuds |

If you apply some heat to the head of the bolt to loosen the loctite it will make removal a lot easier. I always use a propane torch with a pencil flame on them first. | ||

New12r |

I broke 3 impact grade torx(snap on, and Matco) trying to get mine off. I will be using ARP fastners on the rebuild. | ||

Jackbequick |

If you saturate the entire threaded shank with red LocTite on bolts in a chamfered recess, the LocTite can squeeze up and fill the recess around the bolt shank and the chamfered or recessed area around the head. LocTite is an anerobic adhesive, it sets up when air is excluded. If it sets up on all the threads and in all the other areas where it is contained, it may be developing enough holding power to exceed the strength of the bolt. A drop is a lot of LocTite. If the threads and bolt hole are clean and free from oil, I'd put a scant drop on the end of the threads and spread it up and down the end of the threads with clean fingers. If you have 5-10 threads moistened, that should be enough. It will be chased up the threads as the bolt is inserted. The small propane pencil flame micro torches are good for breaking LocTite red (262 or 271) loose on smaller fasteners. Put the just barely visible in dim light tip of the flame on the head of the fastener and dissassemble while still hot. The target temp for getting the aqdhesive to release is 250C/482F. http://tds.loctite.com/tds5/docs/262-EN.PDF http://tds.loctite.com/tds5/docs/271-EN.PDF As a guy that has had to remove more than an average number of broken bolts (retired gunsmith/machinist), I'm much more in favor of screwing around with some heat than I am with easy outs and drills and stuff. Jack | ||

Henrik |

McMaster-Carr www.mcmaster.com is a good place to look for out-of-the-ordinary tools. I've had my share of "fun" removing a front rotor a few years ago - still haven't caught up with my swear-word allowance  The story is in the archives somewhere. The story is in the archives somewhere. In the end I had a local welder weld nuts onto the chamfered bolts and all bolts then came out easy. Of course I'm sure the heat from the welding did most of the work - but I wasn't able to get enough heat into the bolts with my small pencil torch. Now I use very little blue locktite and also add some never-seize to the bottom of the bolt head where it'll contact the rotor. Henrik | ||

Kootenay |

Torx drive is designed for speed during production AFAIK, and compromises strength of the fastener/driver connection (specifically the driver). More prone to stripping in my experience than hex (Allen) head screws. Anyone who is familiar with both Phillips and Robertson head wood screws knows that some drive systems are superior than others, even though they may be slightly more difficult to produce--but fasteners are produced in vast quantities, and speed of production is important as it affects unit cost. In GJ's place, I'd be installing hex-head screws... | ||

Mortarmanmike120 |

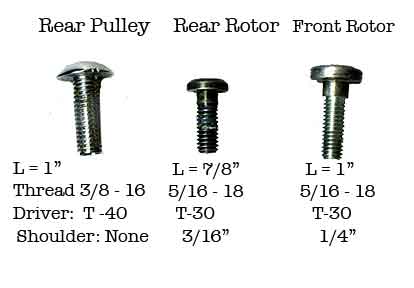

Anybody know the specs on the rotor bolts? ie length, thread, dia, etc... I may be tearing mine down in the near future and would like to look around for alternate replacement bolts. | ||

Gentleman_jon |

Ok, here are the stock parts:  Note that the rotor bolts have shoulders to allow the rotor to " Float" I would be nice to find these in chrome plated allen heads. The shoulder could be a problem. Also note that a T-27 will grip the rotor bolts, but not properly. Any Ideas anyone? | ||

Mortarmanmike120 |

Here's a link to a company called Diamond Engineering that makes tons of fasteners. High grade polished bolts. Probably pricy. http://www.depss.com/ Thanks for the info BTW | ||

Gentleman_jon |

Depss guys have a lot of Harley Fasteners, but the shoulders on the rotor bolts are a problem: here is what they say: "Thanks for your interest. Unfortunately, the only fasteners we could help you with is the rear pulley. The rotor bolts are, as you've indicated, shoulder bolts. Which we don't stock or manufacture." Bummer. I can just see me having these made for lotsa bucks each. Once you know what the right thing is, it's hard to accept the anything else, am I right?  | ||

Mortarmanmike120 |

Yep I agree. I wasn't aware they didn't make the right rotor bolts. I was optimistic and just assumed that since they sell roughly a gajillion different types that they'd have the ones we'd need. Bummer. Sorry.  | ||

Billybob |

try snap on for torx bits | ||

Gentleman_jon |

The Snap Ons look good. Naturally they are not cheap. They have replaceable bits. Only one problem: Snap On has replaced so many of them that they are out of stock.  |