| Author | Message | ||

Andymnelson |

yeah I did LOTS of wiggle testing before swapping the ecms, including wiggling the ecm connectors- nothing seemed to help :-/ I'll be glad when I get past this! | ||

Brown_e |

Also make sure you have good solid connections at the battery. Mine would shut down and come back on. | ||

Uly_man |

Andymnelson - "2) E.B.R. ecm. I sent my P&A race ecm to them over the winter to have it remapped. They new my setup: stock motor, breather reroute, K&N, Drummer SS. The bike has ran OK with the new ecm, but not really any better. The muffler valve was still on (when I got the bike to the shop, and restarted it next time, the valve was just opening and closing time after time, with the engine light flashing). I have since disabled the valve (as should have been done by E.B.R.), but the combo of the bike not running right, the valve being enabled and not having the high idle on warm up (as others have reported) makes me think that something went wrong with the flash." I am not having a got at Erik Buell Racing but all of that sounds a bit odd. FI does not have a high idle to warm up it is done with fuel. You will see it in the ECM-SPY program. You can re-map a STD ECM with ECM-SPY anyway you like and even use a map from someone else. This is what it was designed for and as long as you know how to use it and store your OEM map you can not go wrong. The 06 OEM map can adjust itself to just about any can/set up and should idle and run fine if the rest of the bike is ok. What the engine needs though, for best results, is re-fueling adjustments for the low to mid rev range and you will notice it instantly on the road. You will gain very little top end on the Uly. I would suggest going back to stock can and ECM. Once the bike runs smooth/right go with other cans and stuff. | ||

Andymnelson |

So, I installed the original ecm today (previously, it was just a quick plug-in and diagnostics, no run time), and the same issue occurred! Ran for a bit, then just shut off, with ecm light flashing steady. This time, it randomly came back on it's own (I was fishing for my phone to take a quick video of the flashing to post here, and it just came back on  ). ). At least my fan is functional now. I flashed my oem ecm with the E.B.R. fuel and timing maps, and having run them back-to-back I will say this: low rpm performance is definitely increased with the E.B.R. unit- not more powerful, but MUCH smoother. I don't even know where to go next... | ||

Etennuly |

I hate to ask, but did you open the harness in the steering neck area yet? | ||

Etennuly |

I hate to ask, but did you open the harness in the steering neck area yet? Have you checked the ground wires on the steering neck? | ||

Andymnelson |

yes to both, even tho I'm pretty sure neither would be the cause- there's no inputs to the ecm up there... But yes, I took a look at the harness up there as well as in the tail, and I have addrrssed all grounds. | ||

Etennuly |

OK then, I will run other ideas around in my squirrel cage to see what comes to mind..... My thoughts there was your issue is similar to one I had where the ignition switch was suspect. The second time I opened up that harness is when I found the broken wire inside the wax filled heat shrink. | ||

Andymnelson |

Yeah I just don't get the check engine light portion of it tho! When it shuts down, the check engine light flashes slowly and constantly until the point at which it wants to start again. The fact that it does it with 2 ecms tells me it's not an ecm problem, but an external input problem of some kind....and as far as I know the light flashing like that is not a normal failure mode! | ||

Jhallgren |

Not sure if the 06 has a crank sensor like my 09 does, but if it does I would check that out. With out that the ecm does not know the crank is. Also maybe email Erik Buell Racing and see what they might say. Couldn't hurt. Weird thing is though I would think the crank sensor would throw a DTC. But experience tells me from when I was an auto mechanic a few years back, just because a sensor goes bad, doesn't mean it will throw a DTC. | ||

Ratbuell |

06 does not have a crank sensor, timing is done by the sensor on the cam cover. Again, 06 does not have an ECM controlled idle-up. And again, Erik Buell Racing does not typically enable/disable muffler valve control, just the DTC/CEL associated with an unplugged motor. Unwrap the wires at your ECM and make sure none are rubbed through or broken. Do the same down by the 77 connector. Also pull your fuel pump and check those wires. And for the exhaust actuator...just unplug the damn thing. That alone could fix it (I've seen stranger things!). | ||

Andymnelson |

Understood on all points (and I've not argued since you initially posted them. The first time you stated them was adequate to get the points across to me). I am not looking for a high idle any more, and I have disables the exhaust valve myself....but none of that addresses the issues at hand anyway. I gave a cursory look at the 77 connector and it looked fine. I don't have charging issues either. But I will ad it to my lift of things to dive deeper into. I did unwrap the wires for about 12" from the ecm...and all looked fine there. I'd hate to have to KEEP unwrapping more wires! | ||

Garrcano |

Swap relays, maybe one of them has contact problems. Check relay/fuse box, also from down maybe a bad connection. Open and check right hand controls, specially the kill switch. | ||

Skifastbadly |

When I find myself in the situation you're in, where you've exhausted most of the obvious issues, I generally sacrifice a cat. It hasn't yet had any impact on the technical issues, but it could. | ||

Stevem123 |

I was told by one of the guys at Erik Buell Racing that using an aftermarket mapping program such as ECMSPY can cause problems. He stated that they have moved things around with memory locations between different versions of ECMs and the aftermarket mapping programs can put stuff in the wrong memory locations. He stated he can tell if you send in the ECM. | ||

Ratbuell |

Sorry, I wasn't trying to beat it into you...but there were posts throughout the thread asking those questions so I was clarifying for The Class, that's all  | ||

Uly_man |

Andy - Yeah I just don't get the check engine light portion of it tho! When it shuts down, the check engine light flashes slowly and constantly until the point at which it wants to start again. I agree with you on this and I have never heard of this type of problem before. It sounds like a capacitor discharging but it could be any number of things. I hate to say it Andy but you have a serious problem with this one. So what to do? Well to me it sounds like an electronics problem, not a wire/break thing, and can be caused via a bad resistance at some point but who knows. I wish I could help more but at this stage I would need to be "hands on" the bike. | ||

Zac4mac |

What failure modes cause a no-spark? I know most cars do a no-spark if oil pressure is low.. I don't have any Uly manuals yet... Check those conditions, but more likely, check the sensors for that circuit. I still think you have a bad input to the ECM, either from wiring or a flaky sensor. Zack | ||

Andymnelson |

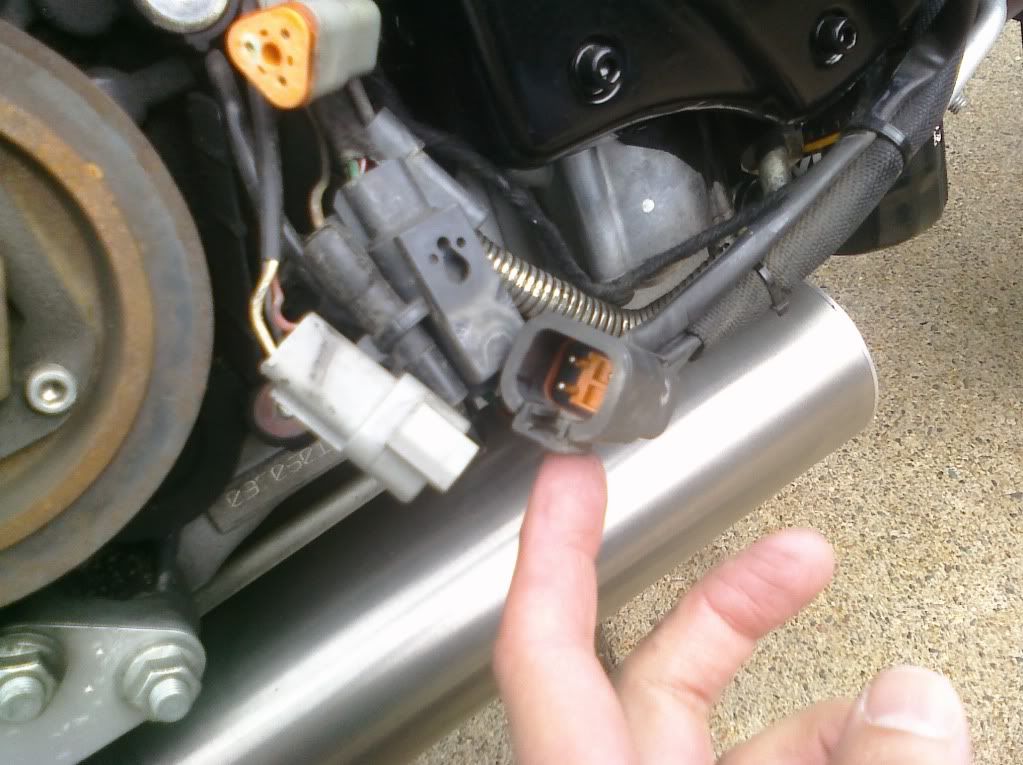

Well I pulled apart the 77 connector, and it looks great. Clean and no signs of overheating/arcing etc.   When inspecting that, I noticed this gray connector had it's wires rubbing on the plastic cover, and rubbed through the insulation. I have limited time right now, does anyone know what this connector is? Hard to tell by the pics, but it's a triangle shaped 3 wire connector.  | ||

Etennuly |

The "77" connector is a two wire connector with much larger wide pins. I have a picture somewhere. I had about ten different wire "rub through spots" like that throughout my wiring harness. | ||

Rays |

Andy your are showing the input to the regulator there - that is the '46' connector. I have seen people report this having issues but very few in comparison to the '77'. This document I put together outlines checking the '77' connector. Trust me on this - just looking for obvious signs of damage without dismantling the connector will not catch all problems. Some folk replace it but a regular check is really all that is needed - mine played up at around 16,000km and I have cleaned it regularly and with 100,000km (tad over 60,000miles) it is still the original plug. Very much a personal choice. https://docs.google.com/Doc?docid=0AflAL-QRJACkZDR yYnh3cl8yMGRxNWtoZg&hl=en The other connector looks like the connection for the cam position sensor (Connector 14). You probably need to check the wiring to the cam position sensor carefully as a faulty one can certainly prevent starting without error codes being latched - I don't know about the steady flashing symptom though. There are a lot of wires crammed into that space on the early XBs and they need careful placement to minimise that sort of rub-through. I would seal up the bare wires to prevent moisture getting into the wires at that point. Actually I just went and had a look at that connector you have shown with the wear spots in the manual and the wire colours match the speedo sensor, The other 3-wire connector with Rd/W, Gn/W & Blk/W wires is the cam position sensor.  (Message edited by Rays on May 13, 2011) | ||

Ratbuell |

...and THAT is what I was getting at when I suggested checking the 77 connector area. Lotsa wires, not a lot of space. | ||

Andymnelson |

duuhhhrrrr...I actually knew that, I simply checked it while I was in a hurry!  I'll pull it apart again tomorrow and check it out. | ||

Uly_man |

"I would seal up the bare wires to prevent moisture getting into the wires at that point". This is a good one to note. Even air on an exposed bare wire or terminal end will cause corrosion in the end. If you can it is best to cut, solder and seal with shrink tubing. Most bike electrical problems are caused by bad earths and/or wire/terminal corrosion. It is also best to avoid mechanical wire connections and sticky tape. Do it right and it will last. | ||

Uly_man |

Andy. It is hard to see but the male part of the 3 pin plug has a white ring around one of the female pin holes. This could be the white powder you get with copper corrosion. Just a thought. | ||

Cpeg |

You don't need to cut and solder the wire to heat shrink it, just pop the pin out of the connector and slide the HS over the wire. | ||

Uly_man |

"You don't need to cut and solder the wire to heat shrink it, just pop the pin out of the connector and slide the HS over the wire." Yes you can/could in that case. But think on this? You can not expect an answer that covers all things and all ways. It does not work that way with this sort of thing. Have bit of respect for those, on BW and other sites that offer for free, that could save you large amounts of money and use your brain a bit. A little effort is required in life. (Message edited by uly_man on May 15, 2011) | ||

Cpeg |

Well excuse me for being brain dead, but I don't agree, those Deutsch plugs are a piece of cake to pull the pins on, that and when you solder a wire you set up a place that can cause the wire to stress break. I did not mean to offend your delicate ego. | ||

Ratbuell |

Actually, deutsch plugs come apart VERY easily...if you have a set of dental picks in the garage like I do. Got 'em for $5 at the hobby shop and they're INDISPENSIBLE. I need to get a couple more sets, and put them in the Buell tool rolls that live in the saddlebags of the Uly and S2.... | ||

Stevem123 |

If I carried most of my tools and spares I'd have 150 pounds of stuff and no room for BEER!  |