| Author | Message | ||

Steeleagle |

I posted this in the KV section, but noticed after the fact that KV doesn't seem to have the traffic as Old School, so I'm double-posting it here. I've got my engine (1992 RS1200) torn apart to replace a crank and am performing due diligence in checking all the other stuff while I have it gutted. Among other things, I want to verify the wear status of the cylinders, not knowing mileage, etc. on them. HD says you need to use a torque plate to get accuracy for any bore checks. While I understand the concept, for the purposes of strictly trying to see if I might need an overbore (and therefore new pistons...which would impact my crank decision (thinking S&S)) how far off will my assessment be if I measure WITHOUT a torque plate? If a plate is the only way, a quick check tells me I'll either need to farm it out or spend $400 to buy a plate, unless there's an agricultural engineering solution for getting reasonable accuracy. I'm mechanically fearless and fiscally irresponsible, but don't REALLY want to spend money I don't need to. I know HD assumes that if you're torn down that far, you MUST be a full-tilt shop and have all their goodies, but...not so much! Anybody with experience that can guide my efforts? | ||

Rick_a |

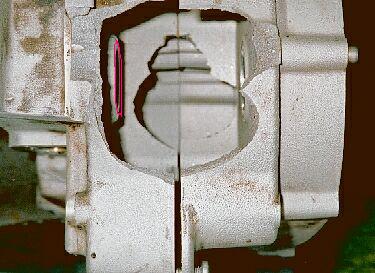

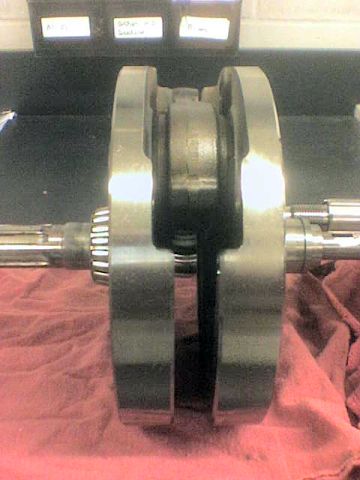

You can still get accurate measurements for bore size, just not warpage. If you do get it oversized, make sure the shop doing it will use torque plates when boring the cylinders. Any shop that does H-D's should be equipped to do so. When I needed to replace my crank, S&S couldn't even give me a rough idea for what it would cost me. I was considering one of their knife-edged cranks, but nobody was willing or able (apparently) to give me a quote. They are pressed on one end and bolted/welded together in the other which is a bit odd. I ended up getting one of the new tuber pressed pin cranks and installing a crank scraper instead. 0.085" needs to be machined out of the right crankcase half as shown below.  Hoser's picture of the area requiring machining Old vs new flywheel       | ||

Buellbozo |

Most times, single cylinders are bored on a machine that has the cylinder's top surface bolted to the underside of a heavy toolsteel platten. This serves the function of a torque plate for machining purposes. A bore that is machined round shouldn't need a torque plate for honing, just proper technique with the hone. You can't hone an out of round cylinder to round, torque plate or not. you can put taper in or take it out with a hone properly used or misused. The two important measurements are taper, top to bottom, and out of round, top and bottom. The bore will invariably be larger fore and aft due to thrust forces. While dial reading bore gauges are nice (and expensive), a simple telescope gauge and appropriate micrometer, properly used, give perfectly good results. This is just my experience, your mileage may vary. | ||

Steeleagle |

Thanks, guys. I'll be checking with a bore gauge and will do a quick check w/o a plate to see if I'm in the park on tolerances. The walls still have the hone cross-hatching, and there's some light scuff marks, but not scoring. I might post pix if someone is interested. Otherwise if the bores seem OK I'll have them cleaned up with a re-hone. Stay tuned. Re; Crank: I got pricing from my local HD dealer for an S&S and the only issue is they need piston weights...thus my inquiry into bore measurements, etc. I'd have one on order already but need to determine if I need a revised upper end or not. I'm still waffling on whether to get their knife-edged unit or not (No price on that one.). The price on the S&S standard unit was less than HD's replacement cost. Additional comments/suggestions welcomed. | ||

Buellbozo |

Just a thought if you don't already know... If your cylinders are in spec enough to allow just honing to restore the crosshatch, be sure to use a "ridge reamer" at the top of the bore before honing. Simply honing the ridge out is a sure way to induce an unwanted taper. | ||

Fast1075 |

My experience has been that if there is a measurable ridge, the top of the bore is tapered. | ||

Steeleagle |

Re; Ridge reamer: Yep. Good tip. Got it covered. Thanks. Per the HD manual, they suggest allowing 0.003" for final honing to reach desired bore diameter in the case of an overbore. Just out of curiosity from those that have experience, how much does a standard clean-up hone remove? | ||

Buellbozo |

Can't put a number on "standard cleanup hone(ing)". I'd answer that question with "As little as needed, and no more". The rule of thumb I've always gone by in an overbore-hone operation is to bore to the major dia. of the piston in hand, then hone to specified cleasrance. A lot depends on the honing method; whether a "powerstroke" honing machine, or a manually operated, drill motor powered hone. The more material you leave to hone out with a manual hone, the more chance you have of screwing up your nice new round bore. Technique is everything here. |