| Author | Message | ||

Blake |

One thing that seems clear is that whether the stock exhaust is heavy or not integrating a portion of it within the swingarm would save significant weight. How could it not? To wit, the frame for the fuel in frame is heavier than if it were a conventional frame. But the total weight is significantly less than that of a conventional system with separate tank and frame. The same is true for the the ZTL braking system. Separately, some components may outweigh conventional systems, but as a whole on an apples-to-apples basis (cast aluminum wheel versus cast aluminum wheel) it is significantly lighter. Oh, and the Erik Buell Racing ZTL system won a very hotly contested AMA National Championship last year, a German championship this year, and has been well-proven in AMA Superbike in limited outings as well. (Message edited by blake on November 24, 2010) | ||

Hughlysses |

Jeff- good point about the first an likely being the cat. That would make a lot of sense. Who knows, maybe in another couple of years we'll be shipping our swingarms to Drummer (or whoever) to be modified!  | ||

Sifo |

Here's a wild idea: The swingarm must be supported by a spring, well why not ditch the bearings and employ a springy structure to provide for swingarm motion while at the same time acting as the rear suspension spring. The rear shock then would be mainly damper with, if needed, a small spring for preload/sag adjustment. I'm pretty sure Specialized bicycles holds a patent that would cover that swingarm. | ||

Blake |

It likely depends on the specific implementation/form of the spring and whether it includes motorcycles or just bicycles. | ||

Swampy |

Oh! Oh!.....Torsilastic spring for the swing arm piviot! Then all you would have to do is dampen it...... | ||

Blake |

Or just damp it.  | ||

Trojan |

Why you'd single out aftermarket exhausts for the Buell 1125 is odd. That statement surely applies to any serious sport bike and the wide range of aftermarket mufflers available. Are you saying that because some aftermarket exhausts won't meet sound limits that Erik Buell Racing cannot design a moderate weight stock system that would? Huh? I singled out the 1125 for two main reasons: 1. This thread is about the 1125 (or derivitave) exhaust so it is relevant to talk about this motor especially as Erik himself already admits it is a loud motor. 2. We sell exhausts for lots of sports bikes other than Buells, and the 1125 does have more problems meeting noise limits than most other bikes we cater for. It is relatively easy to supply an Akrapovic or other aftermarket exhaust for Ducati/Kawasaki/ANother Jap brand and even KTM (with an underslung exhaust similar to the Buell) that will meet current track regulations whereas the choice for the 1125 is much smaller and not so easy to meet the regs. One thing that seems clear is that whether the stock exhaust is heavy or not integrating a portion of it within the swingarm would save significant weight. How could it not? Why would it be lighter than the current components? Just because you combine two functions doesn't necessarily mean you save weight. What it does mean is that you add considerable complication and manufacturing expense to the equation and you also limit choice for tuners and customers later on. If you want to change exhaust you have to buy a new swingarm? Yeah right  To wit, the frame for the fuel in frame is heavier than if it were a conventional frame. But the total weight is significantly less than that of a conventional system with separate tank and frame. This fuel in frame design saves space, not weight. There is no evidence that I have seen that suggests that the XB/1125 frame is significantly lighter than an equivalent Jap beam frame and tank combined. The advantage of the XB frame is that you can have the airbox larger and with more direct feed to the throttle body, not to save any weight. | ||

Elvis |

Not sure about the comparison to Japanese bikes, but there was an interesting blurb in the (August, September?) Road-Racing world about the weight reduction for twins. Larry Pegram was complaining that the minimum weight didn't mean much because he couldn't lose any more weight easilly. The blurb then anectdotally mentioned that Geoff May just took a few pounds off of the 25 pounds ballast he was using. | ||

Elvis |

October:  | ||

Stirz007 |

"The Harley-Davidson Softail has one major deficiency: its tail isn't soft." "Harley owners have tried many fixes, such as increasing spring rates, but the fixes usually just make the ride stiffer. Enter the KT Components Sofspension. Noted race-car builder and Pro Stock driver Ken Thurm has gotten away from the straight, fast and narrow and swapped to two wheels, and one of the results of that change in interests is the Sofspension torsion-bar kit for Softails. The Sofspension replaces the stock dual shocks with a torsion bar and single-shock setup. The torsion bar mounts where the stock swing-arm pivot shaft used to be, and the shock mounts in place of one of the coil-overs. Why a torsion bar? In theory, a torsion bar can react much quicker than a spring, allowing it to rapidly control the swing arm over closely spaced bumps. Another advantage to the KT suspension is adjustability, allowing the bike to be raised or lowered throughout the entire range of suspension movement, using only a 5/8-inch open-end wrench for adjustment. Three different torsion bars are available, depending on the application. The light version is for riding solo or occasionally double; the medium bar is for two riders with full saddlebags, and the heaviest bar is for extreme loads. The base price is $699.95; add another $99.95 for chrome parts. Thurm claims it can be bolted on by the average biker in about an hour." http://www.hotrod.com/techarticles/chassis/harley_ davidson_kt_omponents_sofspension_install/index.ht ml I checked the KT Components site ( http://kt.kendonusa.com/ ) and couldn't tell whether they still make them. They do work as advertised, at least for that application. | ||

Court |

The Softail was the opposite of everything known to mankind about good engineering. It's saving grace was consistency. It handled, stopped and accelerated poorly. They had nice paints jobs and sold well to those willing to accept a plethora of shortcomings and compromises to that paint job. | ||

Rohorn |

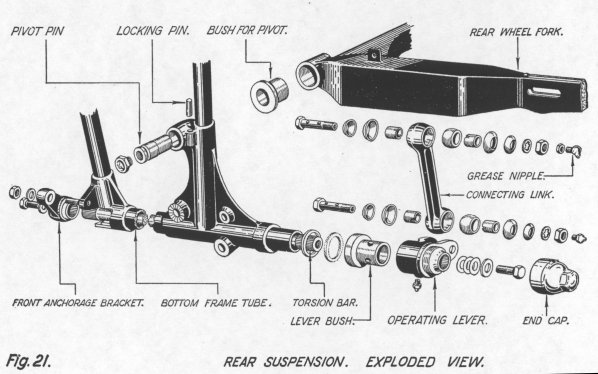

Douglas had a torsion bar rear suspension after WWII for a few years.  | ||

Stirz007 |

"The Softail was the opposite of everything known to mankind about good engineering." = I'm thinking this is probably in the realm of personal opinion than an "accurate statement", but that wasn't the intended point of the post. Just showing a specific example of torsion bar rear suspension for those who might be interested in expanding their knowledge base related to MC suspension systems that have been developed (sorry). | ||

Trojan |

Many cars have used torsion bar suspension for many years, including the VW beetle and some race cars too. That doesn't mean the system is any better than a decent coil over or one of the other setups available. Torsion bar suspension on a sports bike would be evry difficult to tune and the few examples I have seen tend to lack sufficient damping for high speed motorcycles (But fine for a Softail H-D). Suspension and motorcycle manufacturers have spent years perfecting what we have now so it would be hard to beat I think. However if sufficient time, money and effort were put into it I'm sure that someone could produce a system that would be almost as good as traditional motorcycle suspension....but why bother unless the point is purely to be different? (Message edited by trojan on November 26, 2010) | ||

Mr_grumpy |

The major problems for installing torsion bar suspension on a bike are the length & the huge variations of load. On a car you have plenty of room to put in long torsion bars which enable you to have a much more constant spring rate. On a bike it has to be much shorter, therefore the turning moment/length ratio has to be much higher. On a car, the weight difference between loaded & empty is much less, proportionally, than a bike. Especially when you add in the variations of fat/skinny rider, solo/2up, luggage etc. Much easier & cheaper to have bolt on adjustable coilovers. Personally I don't see that the gains from integrating the exhaust into the swingarm will be worth the cost, in this case. As if you're going to do that, you've then got to put the oil somewhere else. But it's an interesting intellectual/engineering exercise nonetheless. | ||

Crackhead |

Thee 1125 don't have the oil in the swing arms. The motors have a built in sump. | ||

Mr_grumpy |

Learn something new every day.  | ||

Trojan |

Found a secret pre-production test photo of the patent pending forks that are matched to the new torsion bar rear suspension system.......  The good news is they have managed to hide the ugly side pods at least  Check out the new ZBF front brake system too...... ZBF (Zero Braking Force) | ||

Tiltcylinder |

You know, that trailing link, leaf spring setup is not as bad a ride as you might believe... I've ridden one! Not much damping but enjoyable in it's primitive glory. | ||

Blake |

>>> This fuel in frame design saves space, not weight. There is no evidence that I have seen that suggests that the XB/1125 frame is significantly lighter than an equivalent Jap beam frame and tank combined. The advantage of the XB frame is that you can have the airbox larger and with more direct feed to the throttle body, not to save any weight. Your statement of the design goal is accurate, if not complete. One design goal does not preclude the other. It is ALWAYS a design goal for all components on a sport bike to minimize weight, is it not? All you need do is look at the amount of additional aluminum needed for fuel containment in the Buell XBike and 1125 frames and you can see that no conventional sport bike tank system is going to come close to such a meager weight. The Buell frames are designed to support Buell powerplants, not inline fours from Japan, so to compare the weights of the two frame/fuel reservoir systems is less than pertinent. If the Japanese frames needed to support the Buell engines and especially the Buell XBike rubber isolation system, they would be much more robust. How much does just the fuel tank and mounting hardware/bracketry on a Ducati 1198 weigh? Another design goal is cost, and another is reliability. When one part performs multiple functions, cost can often be reduced, so too complexity; reliability and durability conversely may be improved. | ||

Blake |

A torsion bar suspension would not eliminate the need for swingarm pivot bearings. Not at all what I was thinking. I was envisioning what amounts to an elastic hinge and would eliminate the need for the bearings. I agree with Matt on this one, the torsion bar configuration would seem to offer little to no benefit, likely the opposite. | ||

Reepicheep |

*forehead slap*. Now I get it! Cool idea, but you would have to figure out how to make it rotationally elastic, but not elastic in other dimensions, otherwise it would just feel like a loose swingarm. I don't know what that feels like, but it can't be good. On the other hand, just like you engineer flex into the sidewall of a tire so you have a suspension when cranked over, perhaps an elastic swingarm pivot could be built that could flex along multiple axis's in controlled ways, and add to that. So the swingarm can continue to work when the bike is cranked way over. | ||

Firebolt020283 |

wasn't the point of the fuel in frame on these bikes to move the weight of the gas lower because he said that having a full tank of gas on a GP bike was hard to steer. At least this is my understanding of the Buell old buell videos that used to be on the buell website back in the 04 time frame. | ||

Froggy |

There are many benefits to the fuel in frame design Erik used, including the reduced sloshing effect, and the forward filler neck makes it easier for a race team to refill the bike while a rider is still sitting on it. | ||

Blake |

>>> Cool idea, but The cool idea part is easy. The "but..." not so much.  Metal fatigue would seem to be one of the biggest hurdles. Interestingly, CF/Epoxy has virtually zero fatigue (crack growth) issues. Metal fatigue would seem to be one of the biggest hurdles. Interestingly, CF/Epoxy has virtually zero fatigue (crack growth) issues. (Message edited by Blake on November 30, 2010) | ||

Blake |

| ||

Stirz007 |

Already thunk of, maybe different or non-specific application, though.... http://oiwa.eng.shizuoka.ac.jp/field/hinge/hinge_e .htm | ||

Blake |

Gee Jeff, I've known about flexure hinges for a long, long time. I'm not claiming to have invented material elasticity. I've just not seen one applied to a production motorcycle swingarm suspension. | ||

Stirz007 |

That is probably an accurate statement - Old as mouse traps, anyway..... JM | ||

Hootowl |

How would you keep the swingarm from twisting the hinge? Left side of hinge goes down, right side of hinge goes up, swing arm tips side to side. What keeps gravity from turning the hinge into a Z? Not pooh-poohing the idea, just wondering out loud. |