| Author | Message | ||

Silverbuell |

Buellistic, Left the receipt at home on the workbench. I will post it tomorrow morning. Tim | ||

Silverbuell |

Buellistic, The new gasket part number is 34955-89B. I installed it dry last night, no leaks as of this morning. More excitement as one of the derby screws is stripped requiring me to install a helicoil. At least I can do it with removing the primary cover. Looking forward to finishing this starter clutch replacment and riding soon. Tight Lines Tim Burns 98 S3T | ||

Buellistic |

Silverbuell: "THANK YOU", $ have up-dated my PARTS BOOK... In buelling LaFayette | ||

Lake_bueller |

Another question for the throbbing brain that is BWB..... My 1998 S3/1 is giving me some fits in first gear. There seems to be a hesitation then jerking after releasing the clutch. It's got me completely baffled. Is it the chain tensoner (upgraded by previous owner)? Or maybe the clutch is going (the bike has 38K miles)? Or could it be that first gear is giving up the ghost? Has anyone experience anything that sounds similar? Doing the first gear herky-jerky in WI: Dennis | ||

Blastin |

Detent Plate? | ||

Jmartz |

LB: The condition you describe is caused by wear in the gear engaging dogs and to some degree lateral resistance of the fork's movement over the shifting drum. | ||

Lake_bueller |

So what's the cure...a new trany? | ||

Stubby |

5/8 inch? I'm at work and don't have one at hand, but I seem to remember the manual calling for 1/4 to 3/8 inch total deflection when cold? Egads! The clatter from the primary must be deafening at that setting. BTW, what do you guys use to gage your deflection settings? I have a vernier caliper which I use for metallic cartridge reloading, but it is only an "eyeball" sort of arrangement at best.  edited by stubby on August 15, 2003 | ||

Reepicheep |

Nah. A couple new gears, some time with a fine file, and a pile of misc bearings, thrust washers, and clips. The tranny is easy to pull, straightforward (but a little time consuming) to rebuild, and parts ain't bad. Figure $50 to $60 for each gear, and they probably will be replaced in pairs. Worst case, you need four gears. You should not need to press any bearings out unless you discover mainshaft damage, or 5th gear drive assembly problems. It would frankly not be that bad a job. Just to make sure we are on the same page, what you are experiencing feels like the bike jumped a tooth on the belt, right? And it only happens once when you go into gear, until you shift again, right? And it probably is worse when you try to shift with the RPM's higher? Aaron first described it and posted pictures, I posted some as well (with more to come soon). | ||

Reepicheep |

Stubby.. I think the hot setting is 1/2 to 5/8, but I am going from memory as well. As far as the clatter, it only does that for a while. Once the high parts get these nice little grooves in 'em, it gets nice and quiet  I just eyeball it based on a set of vernier calipers as well. It varies quite a bit in different positions anyway, so I just get it close to the high side. My primary case does have some pretty nice internal grooves (from time with a broken primary chain tensioner), so that probably gives me a little more room for slack without making a racket. In my book, if I don't hear it slapping around in there, it's not too loose. | ||

Buellistic |

BUELLers: Adjust the primary cold on the tight spot 5/8" to 3/4"... As long as it is no looser than 3/4" and no tighter than 5/8" it will be fine... In buelling LaFayette | ||

Roadrunr |

HENRIK HELP,how did you get your old crankshaft oil seal out? I have your pics on the installation but I am having trouble getting mine out. | ||

Roadrunr |

nevermind, my home made mini dent puller worked. | ||

Stubby |

thinking a fella could find a spanner of proper distance between the tines and use that as a gage. Just gotta figger out the proper distance... Stubby. | ||

Hootowl |

RR, Still free this weekend... | ||

Lake_bueller |

Bill, Correct...only happens after the initial shift. It also only happens in first gear. I think I'll try to make it until this winter. I don't ride that bike too often anyways. Thanks for the help!! | ||

Stubby |

Where to get good quality primary cover gasket? Mine is leaking again. Stubb | ||

Doncasto |

Greg: The stealerships should now be providing a new upgraded coated metal(?) version of the waskewy ol' paper gasket. I was told that HD/Buell has finally decided that all their whiney customers may have been right and will be replacing all/most/some of their old gaskets with the new configuration. The new "improved" gaskets were about three times the price of the old paper ones - with no option to buy the paper gaskets (now discontinued). The new gasket material is much stiffer and about twice as thick. It fit right up to my primary yesterday, and did not attempt to slip off or out of position as much as the paper version. It has not leaked so far, but all I have done is warm it up and back it off the work stand. I have not had any remarkable leaking problems with my primary gaskets once I learned to tilt the bike toward its right side when reassembling. Are your sure that your primary cover is not warped or damaged? I seem to recall someone here having run across that somewhere back in the distant past. Did you get the information on the CycleFest at Copper Mountain? Are you planning to head up there next weekend? Don edited by doncasto on August 18, 2003 | ||

Buellistic |

ATTENTION BUELL TECHNICANS: There are 13 fastners that hold the primary cover on, 12 allen screws and one bolt(shifter)... Get yourself 13 bolts 2 inches longer than the fastners, cut the heads off and cut a screw driver slot where the heads were... Then use what you just made as dowles to hold the gasket in place and guide the primary cover on... In a cross pattern remove the dowel guides one at a time tighting the fastners finger tight... Properly torque the cover on in a cross pattern... The Gasket,primary cover P/N 34955-89A will not leak if installed properly!!! In buelling LaFayette,MECHANIC Harley-Davidson University, Class of 1959 | ||

Reepicheep |

LaFayette... Thanks, I used a variation on that method way back when you posted it earlier. Instead of bolts with their heads cut off, a small dowel rod (that fits through the primary cover holes) cut into 4" long sections, fed into a pencil sharpener to "sharpen" them at both ends. They thread in finger tight easily, thread out easily. Heck, if you have some laying around, pencils are probably about the right size, and would likely work well also. The big advantage is that it holds the gasket in place while you line everything up and position the cover. | ||

Roadrunr |

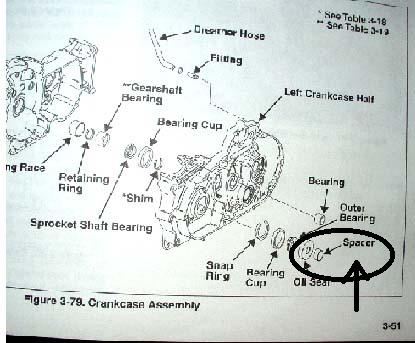

Help please,  Any one know the part number for this spacer? "2000 X1" My dealership didn't even show it in their book. Any reason why I couldn't use the old one besides the owners manual saying not to? Any one know the part number for this spacer? "2000 X1" My dealership didn't even show it in their book. Any reason why I couldn't use the old one besides the owners manual saying not to? edited by roadrunr on August 20, 2003 | ||

Reepicheep |

My 2000 M2 manual does not say not to re-use it. You can't reuse the oil seal, but I can't imagine that the spacer can't be reused. They do say that if you pull the spacer, you will have to throw away the oil seal and put in another, maybe thats what you are reading. That being said, that statement is not exactly true either, if you are patient and careful. You can get the spacer back in without pulling the seal. Aaron suggested the thin end of a cable tie. | ||

Henrik |

Roadrunr; sorry I didn't get back to you - I've been swamped lately. Glad it worked out. henrik | ||

Rick_a |

Isn't the 5/8" to 3/4" primary adj. for big twins? Sportys/Buells are 3/8" to 1/2" cold. | ||

Buellistic |

Rick_a: All the BUELL MOTOR MANUALS are wrong and should reflect 5/8" to 3/4" cold on tight spot, primary chain... In buelling LaFayette | ||

Stubby |

Installed a new primary gasket last night. It was of a different, stiffer, material, and it held its form perfectly. The dowels might be helpful, but I didn't need them for the new gasket material. Think I will return to SportTrans oil though. The Mobil 1 75w90 leaked out pretty badly, and that smell... ugh!? It bugs me to have to change the tranny oil every 5k, but I guess I'd best get used to it. The Buell tech at the local dealership hammered that little screw that adjusts the ball/ramp gizmo for the gizmo inside the primary which adjusts clutch engagement. That pisses me off... take your machine to a "professional" and it comes back looking like an amateur with the wrong tools hacked on it. Oh well, if you want it done right you do it yourself. Stubby. | ||

Mikej |

"The Buell tech at the local dealership hammered that little screw that adjusts the ball/ramp gizmo for the gizmo inside the primary which adjusts clutch engagement. That pisses me off... take your machine to a "professional" and it comes back looking like an amateur with the wrong tools hacked on it. " Take the bike back to the dealership and park outside their service bay. Go in and find the owner and the service manager. Go out in the parking lot and remove the cover and show them what the tech did and strongly request that the screw be replaced right there where the bike is sitting. If you don't then that tech will just keep hammering away at other people's Buells. | ||

Reepicheep |

Why on earth would someone hammer on that screw? I can't think of any reason, except maybe they failed to put the circlip back in correctly, and that whole assembly popped off and was beating on the inside of the derby cover with the engine running. Did they replace the derby cover? Any marks on the inside of that? Or are you just saying they just hacked it all up. Even then, that thing is easy to remove and easy to adjust. Can't imagine why anyone ever would have to apply enough force to it to distort it, unless they did not know you have to lift off that locking nut before it will thread out... Oh. Yeah. That would do it. | ||

Bud |

from a mechanic point off view; sometimes it's better that the customer don't look at you fingers if your fixing there ......( fill in ) out off the workshop; customer; you hear the windnoise around the doors off my car when i'm doing over 80 mechanic; sir, will fix that for you, have a cup off thee while waiting. customer leaves his car, fore a cup off thee, mechanic gets a grip on the door and bends the window frame just a bit (the door already good lined out ) customer, comes back. happy and surprised that it was fixed so quick. problem solved..... i don't wanna know, what would have happened if the customer had stand and watch't the procedure gr,b | ||

Mbryan67 |

I need to replace the primary cover gasket. The problem is that I cannot get the cover off. I know I'm supposed to turn the clutch adjustment screw a quarter of a turn but it doesn't move much. Should I have to apply a lot of tension to move it? I have a 96 S1. edited by mbryan67 on September 04, 2003 |