| Author | Message | ||

Knickers |

So I'm getting my XB9R that I crashed at Grattan back together. Put a new shifter on it today and its giving me trouble. Upshifting there's about 15degrees of rotation of the shift shaft but no shift. Downshifting its a hard stop, won't move or shift. The bike appears to be stuck in 1st based on how hard it is to turn the engine over, but I'm not sure. I pulled the primary cover and saw this  I had a glimmer of hope thinking it was just the shift mechanism spring that had come off. But, I put the spring back on and I get the same results. Anyone have any ideas? Could the spring coming off have screwed up the mechanism somehow? I figure my next step is to pull the clutch so I can see what's going on behind it. Kurt | ||

Reepicheep |

That sounds like the right next step. you can pull the clutch and stator and primary chain as a unit... you just need a few big sockets, and a short aluminum locking bar. | ||

Knickers |

As soon as I get the locking bar from American Sport Bike I'll have it apart. Counting the number of turns at the clutch to the output sprocket it appears to be stuck in 1st gear. | ||

Reepicheep |

Hopefully it's just a detente plate or backed out shift drum pin or something.... | ||

Knickers |

Got my locking bar from asb, giant sockets and torque wrench from Sears. I pulled the primary drive last night and saw this.  What a relief. The pivoting shift shaft pusher doohicky must have gotten spun around backward on impact somehow. I turned it around so it faces the right way and everything is back in order. This is the way its supposed to look.  I'm surprised how easy it is for these little springs to come off. There's just a tiny hook on the end to hold it on. I just know I'm going to be thinking about those springs every time I hit a big bump in the road. | ||

Djkaplan |

Interesting... I've never seen the shift pawl used on XBs. | ||

Bad_karma |

Kurt Thanks for the follow up and pictures. Joe | ||

Knickers |

The saga continues... The afternoon of my last track day at Grattan I start getting some strange symptoms. First the clutch adjustment backs way out and I can't release the clutch. I open 'er up and adjust and head back out. Now I get a different symptom: Upshifting from 3rd gear I get 5th. Uh-oh, bringing it back to the pits and I can hear a nice rattle coming from the bike. I finally open it up and find this..  This isn't looking good - I can't believe I was stupid enough to button up the primary and left some random bolt in there. Looking for further damage I pull the primary drive and find this disaster...  If you look at the photo in my 6/28 post you can see where the bolt and that spacer came from the lower shaft. It must have backed out on its own and gotten thrashed in there. The bad news is it looks like it seriously damaged the case. The material that holds the snap ring on the main shaft is broken away. I'm guessing this means a complete teardown and re-case. At least the transmission turns and shifts freely. Does anyone see a better prognosis? | ||

Blake |

If you can find the required dimensions/geometry info, you might be able to weld and machine a repair. Still requires pulling the case apart. Bummer. | ||

Knickers |

'preciate the sympathy Blake. I guess it'll come down to cost. Does anyone know if cases come as a matched set or can you replace just one of the halves? I may just have to get adventurous and have this thing turned into an 1170cc short stroke monster.  Seeing as how I gotta split the cases and all. Seeing as how I gotta split the cases and all. | ||

Blake |

Now THAT's what I call a kick ass attitude!  | ||

Reepicheep |

I'm sure this is ill conceived, but I kept picturing that image yesterday. The thing that broke was the thing that holds in that retaining ring, which in turn is the thing that holds in that bearing. Two thoughts.... A serious high tech epoxy with some *serious* surface preparation might be worth trying. You have a lot of surface area there, and it looks like the pieces are fairly intact. The JBWeld folks used to have a thing at auto parts counters where they glued two valve heads together, after doing special careful prep. If you could break them apart, you got a prize. The counter was all torn up from people trying, and the valves were still together. Don't glue the bearing though. I'd probably do a little research and try it... you don't have much to loose. | ||

Diablobrian |

The case halves are matched. They have to be for the bores to line up precisely. I hate to be the bearer of bad news, but you need to know. If you were going to go for one of the big bores that requires case boring you might be able to get away with swapping just the one case half, but even then it's more than a little of a dice roll whether or not the bores for the crank and tranny shafts would match close enough to avoid more trouble there. I'm sure that there will be lots of anecdotal evidence of people mixing and matching case halves that will chime in now but I'd carefully consider the source before trying it. | ||

Knickers |

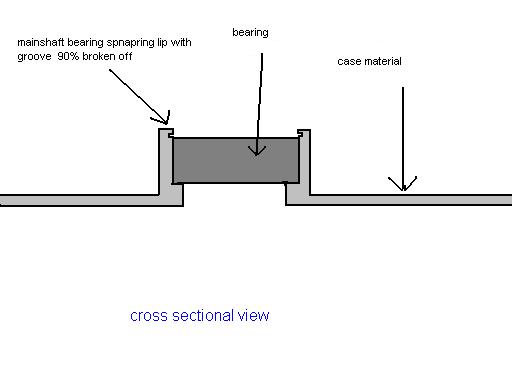

Thanks for the replies. This may be whacked but I like Reepicheep's idea - mostly because it seems I have nothing to lose. The material that broke away is 90% intact so if I can line it up and bond it back in place I may be able to get the snap ring back in there. If that doesn't work I guess I'm faced with all new cases. There's too much in this engine to let it go.  | ||

Reepicheep |

I wonder if some sort of super low temperature silver solder like brazing approach could work as well... That would be worth researching as well. Heck, if it was "undoable", you might be able to just fasten that bearing race in there directly. Or figure that if you can get that bearing attached without ruining it... it can stay there for the life of the engine anyway. A one way ticket, but it might be a nice long ride... Again, I would not go into it with high confidence, but perhaps high hopes, and nothing to loose. The other thought I had was trying to build up some sort of metal plate that would use some of the existing bolt holes to create a new bearing retainer. Doubt there is much room to work in there though... | ||

Knickers |

I'm having 2nd thoughts about trying to repair this. I've been looking at closeups of these photos and it looks to me that the small portion of the casting that didn't break off was the portion in front of the gap in the snap ring in the 6/28 photo. That tells me there was probably a huge axial impact on the shaft that broke the case, not the bolt rattling around in there as I previously thought. What could cause such an impact? Clutchless upshifts? One time that day I accidentally bumped the shifter and did a clutchless downshift. Or did the bolt back out of the lower shaft causing the main shaft to load up hard against the snap ring. I don't know enough about transmissions to say, I'll have to study the manual. Anyway, if axial impact loading is something that can happen again I don't want to put in a weaker joint. | ||

Knickers |

These are the closeups: You can see the only portion of the casting left is right where the snapring gap was.   | ||

Reepicheep |

Is the shaft bent or that bearing damaged? That bolt looks... "squished"... like it went through a press of some sort. Cant think of what that could have been besides the primary chain and sprockets. Unless it somehow got back in the tranny. So if that was the case, maybe it "cocked" the shaft, and thats what caused the axial loads. Meaning that if you repair it, and put get the bolts out this time, it's a non repeating event. I don't think its supposed have an axial load. I am *way* over my head in this, but I don't think that type of bearing can take an axial load in the first place. It sure is an impressive "chunk" though. Almost like it was cut with a punch press... | ||

Reepicheep |

Or maybe that screw became a wedge. Near as I can tell, you have a new "mark" at the 1 o-clock position in the case around that bearing. Though I would have expected the mark to be deeper for that kind of damage. | ||

Saintly |

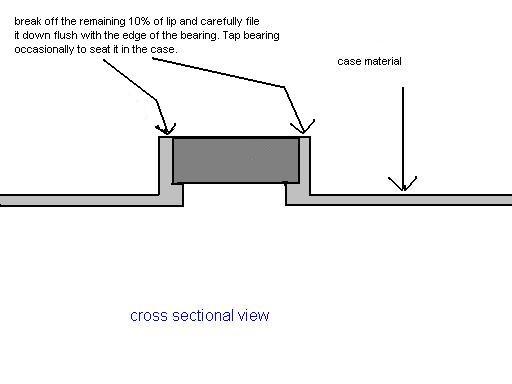

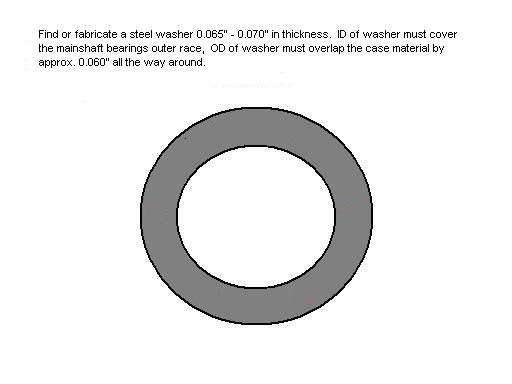

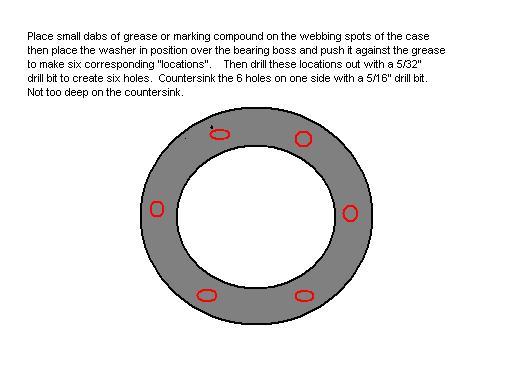

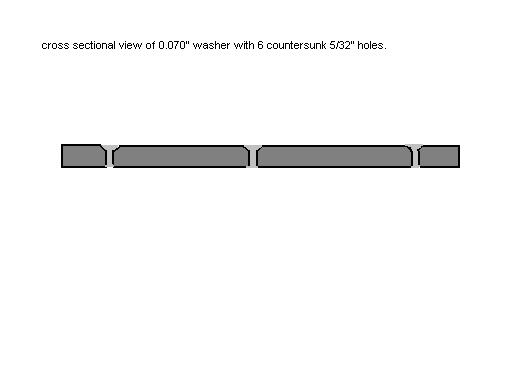

I had a very similar situation once on a ironhead sportster. The snapring and lip/groove broke off of the case where it retained the crank's sprocket shaft bearing. I fixed it without dismantling the engine and it lasted for 7000 miles, at which point I sold the bike and as far as I know it's still working. Here's what I did: You now have this:  You need to create a new stronger bearing retainer. This will be a bolted on plate rather than a sprung ring and weak aluminum lip. So remove the lip:  Now make a plate from steel:  Once you have the plate made and the lip filed all the way down, notice the position of the case re-enforcing webs around the perimeter of the bearing boss. They are your desired point of attachment as they offer the most material.  Now transfer the position of the "webs" to the backside of the washer/plate:  Then drill out and countersink the plate:  When drilling the plate, try to keep the holes "centered" in your target material location. That is: not too close to the outer edge of the bearing, and not too far out into the webbing:  Then use the steel plate as a guide template to drill into the aluminum case material. You want to drill the holes to 7/64" diameter and only approx 1/4" deep. Next you tap the holes for 6-32 thread. and bolt the new retainer down using 6-32 tapered head screws. Try to get the screws with the allen wrench drive rather than the phillips, and use blue locktite.  Good luck. | ||

Diablobrian |

nice plan saintly! It certainly looks like it would be worth a try. | ||

Reepicheep |

Very cool Saintly! Nice! | ||

Knickers |

Wow, I love the idea. This will take some building up of my fabrication skills. Looks like I get to buy a drill press, tap and die set and other assorted new tools. Reepicheep - here's my latest theory on the failure. The bolt backed out of the shaft until it made contact with the back side of the whole clutch assembly. The clutch assembly being bolted to the main shaft got forced away from the case which provided the axial impact on the main shaft that broke the snap ring out. I don't have the parts with me, but I should be able to find witness marks on the hub. The bolt got chewed up but I don't think it went though the primary chain. It did get wedged between the primary cover and the clutch though because there's a whole lot of wear around the outside edge of the clutch pressure plate and spring.  | ||

Saintly |

BTW, Reepicheep I did get that PM from you a few weeks back concerning your Kawi. I tried to reply twice, but my DSL modem let out a puff of smoke. By the time I was back online a week had passed & I figured it was no longer relevant to reply, especially since you had already scored what you needed and at a pretty good price. | ||

Reepicheep |

Yup, thanks! |