| Author | Message | ||

Capndoug |

Good Day Buellers, I havn't been reading and posting much lately. But since I was looking through the classifieds for a new front TS head, I might as well share. Two weeks ago. Floppy da Buell, was having a nice day after stator replacement and when almost back home coughed and clunked, then started to seize. I've got the exhaust off and can feel the front exhaust valve head has disconnected from the stem and then was forced up through the seat into the exhaust port. It still did turn over with the starter but is locked up at the rear wheel while in gear. Its not looking good... So, full forensic teardown starts today. I need to go out and get a head bolt socket, then brace for impact... I'll post pictures of the carnage as it unfolds. Al, sorry couldn't make the bar-b-que. Capndoug | ||

Jkhawaii |

23,000 miles and a broken valve? thats not encouraging | ||

Capndoug |

Well, its a mess. The valve has broken, there is a 3/4" piece I found in the header. The good news is the crankshaft is not seized. The bad news is the front piston is no longer connected.  I'm having trouble getting the intake off. Even with ball end hex sockets I cant get the air cleaner side. I just looked up the trick to cut a piece from an allen and use a wrench to turn it. That will probably work. The itty bitty 3mm screws on the throttle body are not coming out without creating more purchase leverage. Why would anyone put a smaller socket head that is going to get munged up before you can extract it, but it had such a pretty pan head finish.  Once the big piece is out I can cut a slot to get those out. Then I can disconnect the tank from the motorcycle, and start head disassembly. Once the big piece is out I can cut a slot to get those out. Then I can disconnect the tank from the motorcycle, and start head disassembly. Does anyone have an extra heads and jugg from a performance upgrade? BTW, why isn't there a engine purchase or remanufacturing option for Buell or Sportster engines on the website. I need to get it apart to see the rod carnage before planning exact method of resurrection. | ||

Smokinjryan |

Yeah I feel ya!! I will be taking off my front head to see what's going on also. There is no remanufacturing option for Buell or Sportster. Just big twin 1340. Keep us updated. | ||

Capndoug |

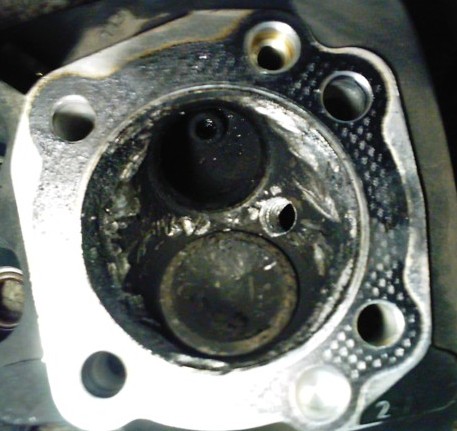

I'll bet pictures of carnage will liven up this thread. The disassembly takes a bit longer than planned the inevitable problems or corrosion and rounding off little 3 mm socket caps, intake sockets unreachable by a standard allen wrench and lots of stuff in the way. So on to the carnage... The first indication of serious damage is the plug head has been munched, something hit it.  The piston does not move in the cylinder, but the crank still turns.  Well the head needs to come off so on to it, first the header. With a flashlight it looks scary in there (exhaust port) little bits of bright metal. The Valve head is not attached...The SO is moving in to get a look and has to move the header pipe. Whats that tinkle, tinkle. In addition to many little shards of metal a very important piece of valve falls out.  This doesn't look good at all. The end of one of the breaks appears to have been partially carbonized over more than half the surface with smaller portion of fresh crystallized breakage.  Well this is going to be expensive, not just because of the replacement parts, but while everything is out it needs to be put back the way it should be... Read on... | ||

Capndoug |

Well the head has to come I had to read up on how to get it done. One thread said follow the Buell guide for stripping the motorcycle then disassemble all remaining parts around the intake manifold. Thats pretty close. I got the isolator off, supporting the lower engine/shock mount with a floor jack. its nice to move it up and down a little. My little trick(2nd time for isolator), put a thick tape (I use duct, with little pieces of paper towel strategically placed)on the frame piece that have some metal contact with tools and pieces during removal, to keep it pretty. So now the tank is off but sitting on the seat area with blocks keeping the pump outlet from kinking. Those darn 3mm socket head screws on the intake just strip out.  so much is in the way. the 1/4 socket heads on the intake don't fit normal allen wrenches. how about cutting one down a bit to fit, still cannot get good purchase to the right angle. Its off to dinner, and a quick stop for craftsman ball end allen wrenches... so much is in the way. the 1/4 socket heads on the intake don't fit normal allen wrenches. how about cutting one down a bit to fit, still cannot get good purchase to the right angle. Its off to dinner, and a quick stop for craftsman ball end allen wrenches... Well they still don't come off...read a few more tech articles.  Oh yeah, use a cutoff piece of hex wench and a 1/4" wench to turn it. Off to the bench with the dremel. It is really difficult to get anything in an out to those intake sockets but finally, now the wrench is on it, wow that open end is flexing so much it it springs off the hex key. I finally found a position to get the box end on the intake socket hex key. Its stiff but I cant move it with 4" of wrench and finger pressure, must get more pressure, both hands, add a knee against the motor mount for leverage. Arhhhh, It broke free, darn that hurts, well its just a thumbnail and a red badge of courage. Floppy has claimed the first blood of this experience. Oh yeah, use a cutoff piece of hex wench and a 1/4" wench to turn it. Off to the bench with the dremel. It is really difficult to get anything in an out to those intake sockets but finally, now the wrench is on it, wow that open end is flexing so much it it springs off the hex key. I finally found a position to get the box end on the intake socket hex key. Its stiff but I cant move it with 4" of wrench and finger pressure, must get more pressure, both hands, add a knee against the motor mount for leverage. Arhhhh, It broke free, darn that hurts, well its just a thumbnail and a red badge of courage. Floppy has claimed the first blood of this experience. So the front intake bolts are off, I just disassemble the front head and the intake pulls out after removing the front head. Set the tank and intake aside to remove the darn 3mm caps on the bench later. So back to the carnage... Off comes the head. The valve head is sitting there on top of a mangled piston.  The valve seat actually looks OK, the plug threads need to be repaired, some gouges in the chamber. It may be salvageable with some good machine work.  Back to that Piston and cylinder. It slides out really easy, there is not a connecting rod attached. Upon pushing the piston out it becomes more clear.  The height dimension doesn't seem to match anything I have seen in pictures. What's underneath...  Oooo...Thats ugly, where did the lower half of the piston go? Just a few little pieces here, I guess she ate the rest. I'm sure the oil sump/pump is full of undigested shrapnel.  Look again, the cases need a full split. The 10 degree cant in the little end doesn't look like a factory option. Lets look around that block again, there some breakage right around the area between the cylinders, it doesn't look major but important to look at when everything is apart.  Lastly, the Cylinder looks serviceable, boreable.  | ||

Reepicheep |

Thanks for taking the time to post those... Very neat stuff. Sorry about your engine, but thanks for the learning opportunity. | ||

Rocketman |

If you've got it that far apart you are more than capable of repairing it at a very reasonable cost. So much so that it might surprise you. Believe me, I was once where you are now. All is not lost. It's late (early AM} in the UK so will talk later if you want my advice. Rocket | ||

Smokinjryan |

Are the big end bearings of the crank bad? Which would make the piston hit valve and break it off? Very interested as I'm in for my similar surprise any day now. Just got married. I just need some down time to get started. | ||

Road_thing |

Cap: Sorry about that motor! Is that partially carbonized area on the broken portion of the valve stem? If so, it sounds like maybe the valve stem broke part way through, then broke the rest of the way after some time had passed, allowing the broken surface to get that carbonized stuff on it. Maybe the piston had kissed the valve at some point, fracturing the stem and setting the stage for the big bang? Hope your cases and wheels are ok. Please keep us posted--there's a lot of education to be gained by the rest of us here. rt | ||

Capndoug |

Thanks all for the words of support, its all a can do situation, and she will recover. I'm just smarting from impending massive impact to the left cheek. The big end bearings feel good. My analysis of the crystallization and carbonization of the little piece of valve looks like there was a crack in the valve stem for some time, and the fresh break area is only about 40% of the cross section of the valve stem. On another note, while it did not fail, the intake valve keepers have 2 cracks in them. I thought a connecting rod and bearings would be a reasonable fix. Bore and new pistons, or new bigger bore cylinders. Send the heads for stage 2 work, and build a new valve train, front and rear. The hitch is the the '00 crank/rod flywheel assembly is only a one piece buy at the local Harley dealer, almost $800. They also don't do any discounting on any parts that I have seen. Probably standard for HD dealers but other shops for my other Yammie and the SO's normally do 10-15% off retail. So I'll be back to mail order or other recommendations. Does a company like NRHS or Revperf have the capability to disassemble the pressed together crank for rebuilding? I'll call tomorrow. Is the pressed together really superior to the earlier 3 piece, can it even be considered for swap into the 2000 case. I've got a few topics to research. If anyone has tips on building a higher RPM setup I'd like to hear them. New cam, roller tappets & rockers are on the list. While I have the heads off I'll measure all the dimensions for a head design I have always wanted to try. I wonder how the thermal dissipation will be affected If I can build a non-interference induction system capable of 9-10K. I'm looking to buy a bridgeport style mill next year to play with some designs. | ||

Xldevil |

Does a company like NRHS or Revperf have the capability to disassemble the pressed together crank for rebuilding? I'll call tomorrow. Hey. I'm pretty sure Revperf can do it,as well as Hobanbrothers. www.hobanbrothers.com Ralph} | ||

Blake |

Revolution Performance or Cycle Rama can help you for sure. | ||

Smokinjryan |

I took my 99 cyclone apart and found the same with mine.Piston looks the same, no broken valves but my crank bearing were toast. My heads looked good. But my cylinder walls are nicked up. I'm not sure what action to take next. |