| Author | Message | ||

Henrik |

Can anyone divulge the apparently secret torque specs for the front isolator? Central mounting bolt as well as the 2 isolator alignment bolts. I've dug through my service manual and all I found (in the engine installation section) was tighten finger tight  I couldn't find any mention of the front isolator anywhere in the chassis section. The front isolator is not even mentioned in the index. Have any of you come across this info? Page number? Henrik | ||

Road_thing |

What difference does it make? I defy you to put a torque wrench on the m*****-f*****! rt | ||

Bomber |

crow-foot socket | ||

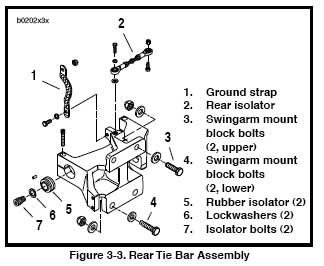

Mikej |

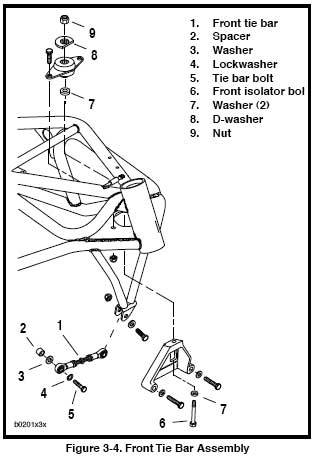

This thread has the potential to get very interesting. I'll look in my manual when I get home later today, then will post what I find. In the mean time I'm waiting to hear what R-T says about Bomber calling him a crow-foot socket.  | ||

Henrik |

With a long extension and a U-joint I can get a torque wrench on the main bolt and the left side "support bolt." I didn't try, but the crow foot might work for the right side support bolt, but I'd have to start calcumalatin' the change in torgue  Any numbers would be appreciated. Also, the support bolts use ny-lock nuts. The main bolt uses a lock nut that's "crimped" at one end. I cleaned everything up nice with my new thread chasing tools and brake cleaner. I know you usually don't combine locking nuts and thread locker, but was wondering if lock tite would be in order for those used nuts/bolts? Belt and suspenders ya' know. Henrik | ||

Road_thing |

Who're you callin' crow-foot, there, Q-Tip?  rt | ||

Bomber |

H -- if you have the crow foot 90 degrees from the long axis of the torque wrench, no adjustment is needed in torque figuring i've never used loc-tite with a locking nut, but there's no harm in making certain that one's trousers don't fall down at an inopportune time, is there? | ||

Road_thing |

H -- if you have the crow foot... . . . . . . ...see a podiatrist!! rt | ||

Bomber |

groan Boo, creepy foot doctor man! | ||

Mikej |

Henrik, sorry, didn't get a chance to look in the book last night, had a root canal done, the way I feel I think the dentist must have been drilling for oil. I'll try to check tonight. | ||

Henrik |

Ouch Mike - understandable. What a way to spend an evening ... Henrik | ||

Blake |

Henrik, If you have the size and grade of the bolt, I can give you the general torque spec for it. | ||

Blake |

Doc, I think you already are aware of this, but just in case... any angle induced in the wrenching shaft via a universal joint or otherwise in relation to the axis of the nut/bolt will affect torque applied to the nut. (That is NOT a personal attack, really!  ) ) Actual torque at the nut would be a simple cosine factor of that indicated by the wrench using the angle of deviation from straight. For instance, for a 30 degree deviation from straight (180-30=150 degree angle at universal joint) the actual torque applied to the nut would be cos(30o)=0.866 or 86.6% of that indicated by the wrench, so you'd want to divide the specified target torque by that same 0.866 to find the indicated torque that will be required to achieve the desired torque at the nut/bolt. If desired, I might be able to reword the above to make it even more confusing.  | ||

Mikej |

I think we'll need a diagram and mathematical formula.  Word format questions are always ocnfusing. Word format questions are always ocnfusing.  | ||

Henrik |

It's sounding more and more like the good old germanic torque spec would be appropriate: Gutentite  Both main and supporting bolts have markings. Not 100% sure, but I think the main bolt is a 1/2" grade 8. Supporting bolts I believe are 1/4" or maybe 3/8". Henrik | ||

Blake |

This may be helpful. Use the "Lubricated" values if using loktite as it acts as a lubricant. Each bolt diameter includes values for standard and fine thread forms, with the first/upper values being for the standard thread form.  Note the cross reference table showing wrench sizes and nominal bolt diameters. You can use that to help identify nominal bolt diameter. If your bolt markings are not exactly matching those shown in the above document, you should be able to identify them via the following... http://www.zerofast.com/markings.htm or... http://www.zerofast.com/markings3.htm  (Message edited by Blake on August 10, 2006) | ||

Firemanjim |

Henrik,the 2 side bolts are 3/8", cannot remember the center bolt size offhand but it takes a 3/4" wrench--though I see a torque spec for it at 100-110 ft/lbs.And as the spec for the other isolator bolts of the same size is 30-33 ft/lbs I would go with that. (Message edited by firemanjim on August 11, 2006) (Message edited by firemanjim on August 11, 2006) | ||

Henrik |

Awesome links Blake - thank you. I printed them out for the garage binder. Fireman: where did you find the torque specs? Service Manual? Page: Btw. I ordered your locator pins. Will keep you posted on possible arrival. Henrik | ||

Firemanjim |

Henrik,I am stuck at work here so I looked in the KV under the S-1 manual and found it in the engine install section. Thanks for the pins,BTW. http://www.badweatherbikers.com/buell/Manuals/S1_1996-1997_Service/BU3a.pdf under installing the engine,section 3-10,look at #8,it gives the torque for the isolator bolts that are the same size as the ones you are concerned with and #11 gives the torque for the center bolt. | ||

Henrik |

Thanks Jim, I see it.    Odd that they don't mention or even number those 2 bolts. Henrik | ||

Xldevil |

Hey. I have no problem to use a torque wrench on the isolator bolt,when fork legs are removed. Ralph |