| Author |

Message |

Radon30

| | Posted on Friday, February 07, 2003 - 11:51 pm: |

|

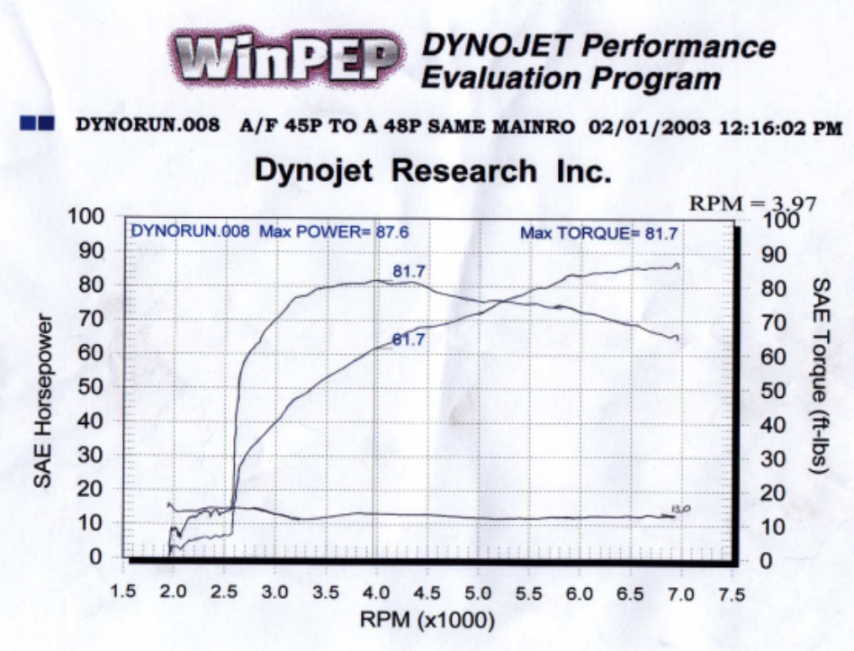

Im looking for a little more torque out of this engine package. That is why i kept the cam lift low. Can some one help me out on getting some more power out of this????

Ported heads Hyperformance

JE pistons 30deg chamber matched .042" squish

Andrews N8 cams(.500" 264 dur.)

Adj. Crane crome moly pushrods

Dyna 2000i ignition 40 deg static curve 3

Force exhaust with baffle

Force winder intake small k&n filter

Stock carb and needle 195 main 48 slow |

Radon30

| | Posted on Saturday, February 08, 2003 - 12:06 am: |

|

|

Kcbill

| | Posted on Sunday, February 09, 2003 - 04:00 pm: |

|

You say you have the Force breather on with a small filter. Alert! Is this the one they supply with it? Also the 90 degree piece on this set up needs to be ported to match the diameter of the carb opening. It is almost 1/8" to small. You can do this your self if you have a air compressor and air drill with a 50 grit sanding wheel. Use a carb gasket to go by and some calipers. It will get you close depending on you talents. I would think with your combo that you should see at least 100hp. Are you sure your timing is set ok? Did they do any adjustments on the dyno? The bike motor oil should be up to temp also to be accurate. Was the dyno guy setting on the bike? He should not be on it. Was the back tied down? I have been told by some really good tuners It should not be. Did they try changing jets. If I am not mistaken thats only one jet size bigger than stock. You could improve on a needle change. I will get back with you on the needle number. I can't remember right now. The carb could use some more tuning. Did they use an air fuel ratio meter when testing your bike? Did they remove the air breather? They should have made one run with it off. If you only asked them to dyno the bike that is all they would have done. If they were to tune it on the dyno some thing is wrong. Your Thunder Storm heads were good heads to start with. Why did you change them? A set of stage two thunder storm heads, good exhaust, mikuni 42 and ignition will take you to 100 hp from my experience. |

Radon30

| | Posted on Sunday, February 09, 2003 - 11:37 pm: |

|

kcbill, Not sure on the Force winder bought the bike used already installed seems to be an older version, seen other force winders with larger filter. When i set up the dyno time i specified i wanted the bike to be dyno tuned, timing, jetting. They did adjust my timing to 40 deg static, went from a 45 pilot to a 48 left my main alone because A\F meter should to be ok 13.0 wot. Tuner was on the bike during the testing. My air cleaner was never removed during the testing. I specificaly asked if they thought my air cleaner was to small, answer was no. I did stick with the thunder storm heads, sent them to hyperformance for a supposedly trick head job, may have back fired. |

Kcbill

| | Posted on Monday, February 10, 2003 - 12:31 am: |

|

Radon one more thing, how many cfm of air do your heads flow? That will be very important to know. The 195 main jet was stock main in 1998. You need some more tuning. |

Reepicheep

| | Posted on Tuesday, February 11, 2003 - 03:15 pm: |

|

I am thinking of trying to do my own pseudo "dyno tuning" by using my GPS connected to a PDA or laptop computer. I know others have done this and was curious how well it works.

I am assuming you just fire up logging as fast as the GPS will do it, and start recording. Then, in second gear from a slowly rolling start, just pin the throttle until redline (somewhere repeatable with a long enough straight and good surface). Repeating 6 or so times in a couple directions and averaging would probably give enough data to get a reasonably accurate picture.

Obviously, you would be looking at the shape of the curve of speed versus time or distance versus time, and thats how you would compare various configurations. I suppose in theory you could make some rough calculations and come up with an approximate rear wheel horsepower, based upon the mass of yourself and the bike, and with a rough fudge factor for wind resistance.

I guess doing it in first gear would make wind resistance much less of an issue, but zero to redline happens so fast you won't get much data to look at. Third gear would give lots of data, but would make wind resistance a huge factor and would require a really long straight and some super-legal speeds. That's why I choose 2nd...

Anybody tried this? Any luck? Any idea what the fudge factor would be for wind resistance versus speed? If I get this going, I will be happy to throw together and publish a web based calculator that would allow you to upload GPS logs, and some basic data about the bike (weight of bike, weight of rider, and rough drag coeficient) and would then generate the "fake" dyno charts.

With OK gps units now going for $100 or less, and dyno runs going for like $50 or something, it would make a lot of $ense to do it this way.

If the GPS accuracy sucks, or the data rate is too low, I could throw together a little piece of hardware that would connect to the speedo sensor and get data that way as well, but the GPS approach would be a lot better and a lot less hassle if it is possible.

Thanks for anything anyone can suggest...

Bill |

Forevernow

| | Posted on Sunday, February 16, 2003 - 12:55 am: |

|

does any one have or know of a posted dyno chart that compares a force pipe to a force pipe with street baffle? |

Kcbill

| | Posted on Sunday, February 16, 2003 - 01:35 am: |

|

Brian Nallin does. Ping him for the info. |

Rippin

| | Posted on Monday, February 17, 2003 - 10:02 pm: |

|

Aaron or anyone,

I've been looking for a chart with a 1250 kitted? bike that has stock T-storm heads. I would like to get close idea where mine would be at. The other problem is I have n-6 cams already in w/Pro-series pipe and old style IDS muf. Have race ing. and 42Hsr. Any help greatly apreciated. Main reason for not having heads done is out of $$. Need for my newest Buell rider in the family.

Btw its an 01 M2

Thanks again

Ryan |

Blake

| | Posted on Monday, February 17, 2003 - 10:53 pm: |

|

Ryan,

The extra 50cc will give you an extra 3% to 4% torque/RWHP, at lease until the heads begin to choke the engine at high revs. |

Rippin

| | Posted on Monday, February 17, 2003 - 11:14 pm: |

|

Blake, Thanks for the input. I thought I saw an article in an early edition B2W mag that just changing to the plated AAC 883 cylinders was worth something like 6hp just because of better ring seal and better cooling over iron/steel liners? I wish I still had those old B2W's. I loned them to a so called friend about year a go and he can't seem to find them. Now of course we have nothing. For paper I mean. This site not with standing you see. Fuell just don't cut the rag for me. |

Rick_A

| | Posted on Monday, February 17, 2003 - 11:53 pm: |

|

The best power per $$ seems to be just good headwork. A 3-4% power increase from 4% more displacement...considering the expense of cylinders and pistons...doesn't seem like a great investment to me.

Dyno runs I've seen here and elsewhere show dramatic power increases can be had with headwork and tuning alone.

If I could go back I'd of done that in the first place...and now I'm penniless and wishing I had!

Do a search of this section...most guys with 1250's seem to have headwork too, though. |

M2cyclone00

| | Posted on Tuesday, February 18, 2003 - 10:12 am: |

|

Forevernow,

I posted dyno charts on May 10, 2002, showing the difference between a baffle and no baffle on a Force Streetfighter. Main difference is below 3000 rpm. Don't use the baffle unless you putt around like I do a lot. The baffle does not make a noticeable difference regarding decibels. It apparently reduces it just enough to get past AMA rules. If you do put the baffle in your Force, rivet it with a number of rivets like I've done. Or weld it in place.

Dave |

Aaron

| | Posted on Tuesday, February 18, 2003 - 12:10 pm: |

|

Honestly, I don't have any sheets showing just the effect of the 1250 kit, but yeah, y'all are on the right track, assuming the motor can breathe it oughta track displacement.

BUT ... it's real advantage is down the road. What we're seeing is that they still seal well and maintain low leak down long after the stockers are degrading. So at 10k, 15k, 20k miles the difference is becoming greater. |

Jmartz

| | Posted on Tuesday, February 18, 2003 - 01:09 pm: |

|

AAron:

After 18,000 or so miles my AAC's have a few vertical deep scratches near the lower end of the stroke. The front one (which reportedly gets less oil) is a bit worse than the back one. They do look a lot better than any sleeved cylinder with the same use (abuse in my case) I ever owned. Since the damage was low I figured I could get some more use before chucking them, perhaps another 10K with new rings and the pistons reversed (back side to front) and exchanged (between cylinders). I must admit power is down from when all the parts were new but I suspect it has more to do with valves and seats than anything else.

I'll look into the 3 9/16's when the time comes. Fin damage to mine preclude their reuse. |

Jmartz

| | Posted on Tuesday, February 18, 2003 - 01:18 pm: |

|

I think that the scratches are caused by the rings at the gap. When I opened the motor I noticed that the friction surface the ring presents to the cylinder wall was a bit wider near the gap. A closer inspection revealed that the ring twisted in that area with a resulting angle of a couple of degrees. Needless to say I made sure the new ring's gap went elsewhere in both the pistons and the cylinders. |

Rick_A

| | Posted on Tuesday, February 18, 2003 - 02:16 pm: |

|

One good thing about the stockers is you can re-bore and hone them a few times before they're useless. I'm holding onto mine until they are beyond their useful life.

Does Millenium or others offer a lined cylinder replating service? |

Jmartz

| | Posted on Tuesday, February 18, 2003 - 04:00 pm: |

|

I believe so. Unfortunately for one of my jugs the fins are damaged so there is no point in relining it except for racing purposes. |

Blake

| | Posted on Tuesday, February 18, 2003 - 05:20 pm: |

|

JM,

That is strange about the ring twisting. What might have caused that?

Yes, the Milleniums can be replated indefinately. Not that they normally need it. That's the beauty of all aluminum nicasil plated cylinders. Wish the factory would/could go that route. |

Jmartz

| | Posted on Tuesday, February 18, 2003 - 08:06 pm: |

|

The only thing only thing I can think of is that near the gap the ring only has one side, so to speak, holding it up. Not that big a big deal. I still prefer to use this type of cylinder over the alternatives. It is trick (big on my book), weighs less and dissipates heat better. Its ok to have a little more aggravation when reconditioning the surface if it yields an edge in performance (even if short lived). |

Blake

| | Posted on Wednesday, February 19, 2003 - 04:27 pm: |

|

You are probably right, but I think may be more of a symptom of the root cause. It probably manifested right from the start during break-in when ring to cylinder wall friction is highest. Maybe the fit was a little too loose in the ring groove, pistons slightly too small, rings were not sized exactly right, ring gap too large... lots of possible causes. |

Jmartz

| | Posted on Thursday, February 20, 2003 - 08:51 am: |

|

Your friction theory could be tested the next repair as the cylinder surfaces were quite smooth this time. The ring groove width in the piston might actually be thing. Brian would have a fit. |

Pammy

| | Posted on Thursday, February 20, 2003 - 07:09 pm: |

|

Jmartz, was it the oil(3 piece) ring? We have seen them(usually from improper installation)get dragged out into the bore. The ring lands are sized for the rings so it would be a bizarre event for one of the compression or the scraper rings to twist unless they were the wrong rings for your particular pistons. The rail rings are much thinner and consequently more flexible. |

Jmartz

| | Posted on Thursday, February 20, 2003 - 09:42 pm: |

|

no pammy it was upper rings |

Aaron

| | Posted on Monday, February 24, 2003 - 06:33 pm: |

|

1999 M2

NRHS Stage 3 heads

NRHS 1250 kit

SE .536 lift cams

CV44

stock header w/V&H muffler

Work performed by Mike Frieberg of HCHD.

I think it'd pull a little more with a higher rev limit, it hasn't run out of breath yet. |

Hootowl

| | Posted on Monday, February 24, 2003 - 09:56 pm: |

|

Holy backpressure Batman! That was with a stock header and a slipon! |

Aaron

| | Posted on Monday, February 24, 2003 - 10:56 pm: |

|

Yup, and if it's like the others I've seen, just the addition of a Force pipe or an NRHS pipe would put it in the 110 range. But he's not up for the noise (I think they sound mean as hell!). It's a sweet package. |

Peter

| | Posted on Tuesday, February 25, 2003 - 01:33 am: |

|

Aaron,

Did you do any runs with a CV40?

Pete |

Aaron

| | Posted on Tuesday, February 25, 2003 - 08:55 am: |

|

No, we sure didn't. |

Rippin

| | Posted on Saturday, March 01, 2003 - 10:05 pm: |

|

Aaron,

In you expert opinion have you heard of or ever done this? Currently have n6 cam w/.490 lift, if I add Cranes 1.75 roller rockers since I was going to get them anyway how should that compare to SE.536's? Get close to the same lift as SE's but with out the extra duration and not as much ramp/rise? on the lifters plus the added ben of roller? Any help greatly appreciated!

Thanks Ryan |

|

»

Buell Dynamometer/Dyno Testing Archives »

Archive through March 01, 2003

»

Buell Dynamometer/Dyno Testing Archives »

Archive through March 01, 2003

»

Buell Dynamometer/Dyno Testing Archives »

Archive through March 01, 2003

»

Buell Dynamometer/Dyno Testing Archives »

Archive through March 01, 2003