| Author | Message | ||

Blake |

tach might be off 4%, speedo might be off 4% the other direction. That's be 8% total. | ||

Oz666 |

I usually assume (I know, I know, you & me) 3% of full scale on a gauge, but mechanical tachs should have a tighter tolerance... i.e. indicated = 6800, + (.03*8000) = 7040 Hmmmm, maybe Oz alsolearningoldHTMLcodes | ||

Blake |

Your S3 has an electrical tach. | ||

Oz666 |

Yep, should have remembered, I only lubed one cable when I took the fairing off. Regardless, accuracy should be the same, I would hope. Until the pulse when my KZ650 & 305 Dream will be really valuable and still running! Oz | ||

Oz666 |

Well, since my major employer has decided that, currently, there is only enough work for the accredited engineers & given me an indeterminate unpaid vacation, I was going to pull the pulley cover today. BUT - checking the MANUAL (the firstest thing I bought from BMC), I found the following: All quoted from 97-98 S3-S3T Buell Service Manual - P.N. 99489-98Y, purchased 7/01

I am now about 90% sure that it's 29 teeth, but I will count the teeth for Rocket when I do the 10K service. Oz VIN now posted in my profile - maybe Court will tell me about my wonderful bike... please, please, please (time & resources permitting, of course) | ||

Budo |

I am supposing someone has replaced a drive belt. How about posting the procedure with pictures? Supposedly you can remove the right side isolator and slip the belt by. How about it? | ||

Blake |

The "Belt Too Tight" example is in the first Archived page above. | ||

Sportyeric |

Let me pose a different question than my tranny thread question that comes at the matter from a different angle. Supposing a person was to have stripped the splines on the pulley AND stripped the splines on the shaft, which doesn't really happen, I don't think.). Would it be necessary to replace the countershaft 5th also, because of matching wear patterns? And if one should but didn't, what would be the life span of the result? I've searched the archives and read of bearing replacement and pulley replacement. Has anyone had the misfortune to be experienced with mainshaft 5th replacement? | ||

Blake |

How many miles on the tranny? | ||

Sportyeric |

My current tranny has 70,000 miles and a broken off dog, probably from first or second gear. I haven't looked yet. Repairing it would require replacing the broken one and its matched counterpart. I'm contemplating using one from a 94 Sporty with 30,000 miles that I don't have the 5th gear mainshaft for. Since tranny design changed in 94, and mine is a 92, it would require the replacement of my current 5th mainshaft by a 94 design. If I also have to replace the countershaft main, then I will have to disassemble the cassette, and buy another gear, which then requires more money and disassembly than simply fixing my original, lesser mileage notwithstanding. Money's tight this year but the replacement bike will be in the shed next year, so a temporary fix is adequate. Saving a hundred bucks one way or the other is going to be the determining factor as long as this years reliability is not unduly compromised. I'd appreciate your opinion, Blake. I've been wrestling with this all winter. | ||

Blake |

So as I read it the two low dollar choices being considered are: 1. Replace main and countershaft gears in existing 70K mile '92 tranny or... 2. Use 30K mile '94 tranny with a new 5th mainshaft gear without replacing the countershaft 5th gear. If it were me, with only one year of service needed from the tranny, I'd definitely use the '94 tranny and take the chance in leaving the existing countershaft 5th gear. I would carefully check the countershaft 5th gear teeth for noticeably uneven wear, especially looking for instances where one edge has not worn-in at all due to misalignment of the original two mating gears. If not similarly misaligned with the new mating mainshaft 5th gear, the thin section of unworn gearface will be trying to carry the entire drivetrain load. The results should be obvious. Some very careful touch up filing to take off any such raised portions of the countershaft gear should prevent problems. Further, I would run a heavier duty (redline heavy shockproof?) tranny lube to help ease any effects of mismatched wear patterns. I would change the tranny lube after the first 500 miles, and I would ride the first 100 miles VERY gingerly never exceeding 1/4 throttle in  . . Eric, I don't have any real world experience to back this up, but it sounds reasonable in my mind that if a little extra vigilance and caution are exercised, you should easily be able to get a year if not a full remaining lifespan out of such an installation. Good luck, Blake PS: A reverent Haiku in praise of the transmission might not hurt either.  | ||

Road_Thing |

Transmission's five gears Spinning in thick oil and heat Push you down the road. | ||

Sportyeric |

Thanks Blake. I wasn't understanding the concept of matching wear. I do now. I've got two vehicles down at once and its hurting. Ford Aerostar van. Faulty transmission design. Fire the engineers! Sportster aillng too. I blame only the rider. One stupid mistake. | ||

Sportyeric |

Ooops. I meant: Fire the accountants! | ||

Ara |

I'm am ashamed to ask this, however I'm 47 and my youthful pride has long since left me. Question: What lubes the tranny? Am I unknowlingly changing the tranny lube when I change the Sport Trans gear oil in the outer primary? Is there a pass-through hole between the outer primary and the tranny, or is there a third lubricant in my S3 that I've never (I'm shivering in fear, here!) changed??? Russ | ||

Aaron |

Relax, you're doing it right, Sport-trans oil lubes both the primary and gearbox, yes there's a passage connecting them. Not so in Big Twins, though, they use separate gearbox oil. | ||

Ara |

Whew. Thanks very much, Aaron! Russ | ||

Blake |

Eric: Now you asked for it amigo.  There's more to the geartooth wear phenomenon than what I described; the mode I described presents the gravest risk for your scenario. The other modes involve very slightly skewed contact surfaces... There's more to the geartooth wear phenomenon than what I described; the mode I described presents the gravest risk for your scenario. The other modes involve very slightly skewed contact surfaces... The contact surfaces of matching gearteeeth start out when new virtually parallel to the shaft on which they are mounted. As they wear, the imperfect nature of things mechanical will have one gear shifted offcenter relative to the other gear. Most obviously, and as already discussed, this creates a raised step/ridge on the gear edges where they are not making contact with the opposing gear; one gear will have a ridge on the left, the other on the right. Aside from the obvious ridging effect , there is an important secondary effect to this slight misalignment. If the gears are slightly off center relative to each other, the load they carry/transmit in turn acts off center on each gear tooth. More load on one side of a tooth causes it to twist ever so slightly, like a sheet of gypsum board twists when you lift from only one corner as it lies flat on the floor. Over time this miniscule twist causes the contact surfaces to wear askew/slanted, no longer parallel to the gear shafts, but as opposing teath wear they remain parellel to each other, so the effect is inconsequential. However, mate a signifacantly worn/skewed geartooth to a new perfect (well almost) tooth and you can end up with insufficient contact area to endure the intended design loads. The resulting stresses can break a tooth and/or cause excessive wear/pitting in the contact area of each gear tooth. Hence, I would break in the at risk gear VERY carefully so that it can have an adequate chance to wear-in and develop parallel mating contact surfaces. With just 30,000 miles wear and a very careful break-in, I would take the risk that the new gear will, with careful break-in, seat well enough with the old to avoid excessive wear and dangerous stresses. BTW, in my previous post I said I would be very careful in 5th gear. That was completely converse to what I meant; I should have said "1st through 4th" not "5th" gear. I've corrected my post accordingly. Does that make sense?  | ||

Sportyeric |

That is a marvellous explanation of "matching wear patterns". Thanks Blake. I was leaning towards following recommended procedures and replacing the matched pair from whichever tranny I decide to use. Your explanation of the lean or twist, and especially the broken tooth scenario, firms up that decision. I'd studied the power flow diagram in the manual so I noticed about 1st to 4th (but I didn't want to sound cheeky to correct you, since I knew what you meant.) The old tranny needs replacement of a gear (pair) other than 5th, so it will more likely be repaired and returned to use. Given that a pair is needed one way or the other, and the hassle of getting the 5th mainshaft out, plus bearing costs, I'll save the newer one for a future big-budget crank up rebuild. Since fixing my current one doesn't require removing the mainshaft, it then doesn't require removing the belt pulley, which is why I've been trying to make this decision before investigating which gear is broken. Thanks again. Sorry I kind of double posted my question from the transmission thread. Feel free to relocate this there if you like. | ||

Sportyeric |

To share some knowledge in return: if you're ever running out of gas on a deserted highway and want to coast for ten miles but can't because the clutch drag is slowing you down, don't try to find neutral at 50mph or you will find gremlins like these in the primary on your next transmission oil service. Let's see if my new ISP lets me upload pics to you.  | ||

Blake |

A very good decision I think, now that I recall your agressive riding style. A very good decision I think, now that I recall your agressive riding style.  I'd hate to see you have to baby your tranny so much that you'd be relegated to riding trail behind a bunch of chrome flaunting cruisers. Or to have to go so fast to keep it in 5th gear all the time and end up running off the road. That'd probably be me, but dammit, that gear would NOT be overstressed!  Blake | ||

Henrik |

Nut size question: A search revealed the following socket sizes: Clutch hub nut: 1 3/16" socket Engine sprocket nut: 1 1/8" deep socket but I'm missing the size for: Final drive transmission sprocket nut: I'm thinking 1 1/2" but am not sure. Cluth plate question: I've heard about the spring plate disintegrating. Would it be worthwhile to replace the spring plate with another set of steel and friction plates? TIA Henrik | ||

Aaron |

1-7/8" | ||

Road_Thing |

"Nut Size Question" -- not with a ten foot pole!! | ||

Steveb |

Henrick, I don't see any reason for a deep socket on the 1 1/8" engine sprocket nut as the reg'lar fits fine on my S2. Steve | ||

Rocketman |

Henrik : I assume you're refering to the plate in the middle of the pack ? As you know, my clutch is a story of legend but here's my experience so far. Use a Barnett or similar heavy duty pressure (spring) plate. It will beef up your left wrist a tad but not enough to bother a big strapping Dane like you. Then if you do decide to get rid of that expansion plate, replace it with Stock Buell plates. Stock have given me the most reliable results to date. Rocket in England | ||

Henrik |

Thanks for the info guys. Road Thing: I knew something like that was coming  Steve: no other reason for "deep" than that I found it recommeded in a search in the Knowledge Vault. If a regular socket fits - so much the better. Rocket: thanks - yeah, you do seem to have spent more clutches than most  Henrik | ||

Al_Lighton |

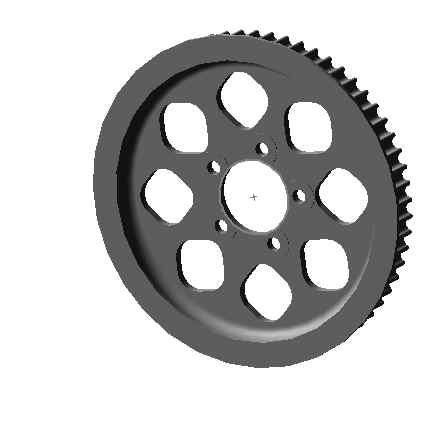

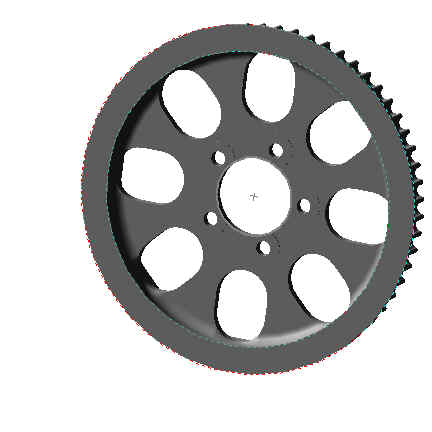

I'm playing with a solid modeler to come up with some patterns to NC mill the stock pulley. Here are a couple ideas. If anyone wants to post a couple other hand drawn ideas, I'll try to work 'em into the pulley model. I'll provide the Solidworks file to anyone that wants it, you could take it to your local neighborhood NC machinist and they can enter the CAM profiles pretty quick from the Solidworks file.    | ||

Al_Lighton |

another  | ||

Jmartz |

Al: Did you see the one I had milled similar to the last one you posted but with a thhinned edge and smaller slotted holes between the large ones? |