| Author | Message | ||

Bluzm2 |

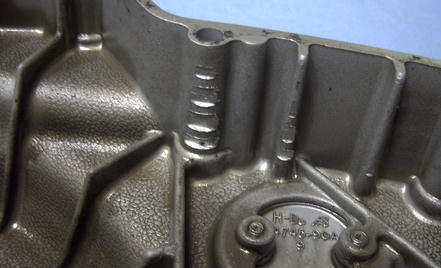

OK Folks, If you haven't checked your primary chain tensioner, you better get to it ASAP!!! THERE ARE BAD ONES OUT THERE WAITING TO GET YOU!!! I pulled my primary and cam covers in prep for powder coating. See below for what I found when I pulled the primary cover. I suspected there may be a problem as I felt I had too much "slop" in the drive train. I checked the primary tension regularly. The last time I checked it, it was really loose. I guess that's where the chain groves came from. I caught it a bit too late. I also checked the serial number on my motor. If I read it correctly, mine may have been one of the last batches with the old tensioner installed. The motor build was early 2000 near as I can figure. This is the "damage done". Fairly deep groves but none through to the bolt hole (the black mark is a small chunk of gasket, didn't see it until after the pic was taken). Not going to worry about it. Just put the new tensioner in when it gets back from the powder coater and slap it back on.  This is the damaged chain tensioner. Notice the cracked metal backing plate at the centerline of the adjusting bolt.  I guess the bummer about the whole deal is that I have the extended warranty. I bought the tensioner just in case as I knew I was taking it apart for powder coating. What if I had let it go? I wonder if I can at least get reimbersed for the tensioner and gasket. I doubt it..... Brad | ||

Ccryder |

Brad: You dodged the bullet, for sure. My 99' S3T on the way home from Home coming did this (@25,000 miles)   It was covered under warranty but it was almost the straw that broke the Camels back. That waited for the primary seal, battery, and starter solenoid. Later Neil S. | ||

Reepicheep |

Ditto those two shots, either could have come from my 2000 M2. Same cracked backplate, same gouged primary cover. I think I am going to call Buell this afternoon and make sure my sprocket nuts are the right parts. They have been retorqued when I replaced my tensioner, and seemed OK, but I want to make sure I don't have the wrong part, pulling the tranny to replace shafts and bearings would be possible, but a hassle. I will post if I can get info on how to tell which bikes had the wrong parts. | ||

Seeeu911 |

Ditto squared ! EXACTLY the same thing I discovered when pulling my primary...scared me bad. | ||

Bluzm2 |

Donn, When you cut your cam cover, did you alter the wire hole on the bottom? I'm about to do mine and thought I may avoid problems with a few questions. I cruised the archives and found both your pic's and BHR's. I haven't quite decided how to do the "tail" section to keep the dowel pin socket. I'm leaning toward the way you did it. I'll probably start cutting and decide as I go. Brad | ||

Seeeu911 |

Hey Brad, I did not modify the wire hole. It was a major pain with the pins. Fairly straight forward to cut and smooth. Just time consuming. The Powder Coat actually looks beter the better the more surface prep, it tends not to mask surface flaws. It was fun though. | ||

Bluzm2 |

Donn, I talked to the folks at Classic Coatings, they said they sandblast all parts first. I assumed that you should start out with a decent surface before the sandblasting, he confirmed that there shouldn't be many flaws. Although the powder "flows out" a bit when heated, it won't hide groves and deep scratches. | ||

Seeeu911 |

Brad, I'm sure it will turn out sweet when youre finished. Any word on your research for SS briaded lines ? I'm looking for swaged lines not the ones with the screw clamps. Please post if you find some. | ||

Bluzm2 |

Haven't got that far yet Donn, I'll keep you posted. | ||

Mrossi |

I've seen the scary pictures of the failed chain tensioner and I'm wondering whether anyone knows if the old or the new one is installed in the X-1 Millenium limited edition ? Thanks M. Rossi | ||

Bluzm2 |

M. I'd bet on it being the old one. I bought my M2 in Aug 2000, the motor was built very early 2000. It had the old one. I wouldn't take the chance. It's not a hard part to change and it's cheap, less than $20.00. The gasket and shift shaft seal sould be less than $10.00. The six pack is $6.00 (good beer). Oh yeah, you'll need a quart of tranny juice also. Brad | ||

Djkaplan |

I know what I'm doing this weekend. I'll be spending it in the shop with my M2 which I bought in August of 2000. Isn't the new tensioner a recall part? | ||

Bluzm2 |

Not that I have heard DJ. Anyone else out there heard different? | ||

Danny |

I know of no recall regarding the chain tensioner. I also know of no service bulletin, but that doesn't mean it's not out there. I will look tomorrow and find any info. Danny | ||

Bluzm2 |

You Da Man Danny! Thanks Mucho! Brad | ||

Pjmule |

I had my primary off last weekend putting a new crank seal in ,and while checking the tensioner I found a small crack it but it was still holding together.I planned to put one in while I had it apart so I allready had the parts.About $25.00 for gasket, seals, and the tensioner,not bad for the peace of mind after seeing all the ones that have broken here.Better check em out guys! Pat Mullaney Dj,had any good wheelies lately? | ||

Djkaplan |

Jeez Pat, You're the Wheelie King! How does that Boss sound? | ||

Blake |

Buell: Please don't go soft on us now. The primary tensioner should be a grattis upgrade. Keep you great reputation for fixing all systemic problems. Same goes for the speedo sensors.  | ||

Reepicheep |

They should at least get the word out about the tensioners... The part is cheap enough that I don't mind putting it in. I guess I would rather see the paperwork and overhead costs that would have been incurred for a recall applied elsewhere. But that speedo sensor... that's for sure. I dropped $100 on two sensors before I armored up the second. That ticks me off... thats the one that hurts. | ||

Spudman |

I was heading home from work just before the holidays when the tranny suddenly felt funny. It was kind of familiar, like too much lash in the chain, but was far more pronounced than any time before. As soon as I got home I opened the inspection cover to find the primary waaaaay loose. So I adjusted the rub block to take up the chain slack, but this placed the adjustment nut at it's very end. Time to replace the rub block. Went to the dealer for a new rub block and gasket (had to be ordered, come on Harley make these dealers stock consumables!). So I tear into it after the parts arrive and guess what I find.  The right hand side of the plate was laying in the bottom of the primary case, but the left hand side was still attached to the screw and the rub block. The chuncks of plastic sharpnel on the right hand side of the above pic were jammed in between the flywheel and the case. There were fine little plastic shavings all over the entire inside of the primary case and cover. I also pulled the clutch basket and tranny to clean them up. What a mess! The new rub block (part # 39975-90A) does have a beefier plate but is it enough? Hard launches and wheelies are part of my daily commute, afterall it is a holigan bike. I just hope the new piece is up to the abuse. | ||

Reepicheep |

I have the headers and muffler off my bike for polishing right now (easy job and makes things look great, I highly recommend it) and was thinking about modifying the primary drain plug to make primary fluid changes easier... Instead of having to drop the muffler, I would like to be able to just wrap aluminum foil around the normally installed muffler to channel the fluid, and just loosen the drain bolt, without pulling the whole muffler. Any of you more experienced machine shop types have any ideas? I was thinking of just drilling one hole down the center of the bolt opposite the head, then another hole through both sides that intersects it at the bottom of the hole (about 1/2 of the way down the entire bolt). That way, when I loosen the bolt about 1/2 to 3/4 of the way out, it will drain through the bolt. Any ideas if this will work or not? It seems pretty simple. I have a couple extra rubberized washers from my minivan that I can use with the bolt just to play it safe and prevent leaking. I guess I will still have to periodically pull the whole bolt to clean the metal shavings from the magnet, but that could be done whenever I have the exhaust off for some other reason... Any suggestions for size of the hole? That primary fluid is pretty thick... can I get a big enough hole to flow fluid without loosing strength on the bolt? Maybe it would be easier to just scare up a hand pump of some sort and run a tube through the clutch inspection cover for primary fluid changes... Bill | ||

Mrossi |

Has anybody out there got a part number at hand for the primary cover gasket and the shift shaft seal for '00 X1 Thanks | ||

F16hd |

Reepicheep Bill, The very first time (500mi)I had to change my tranny oil, I was appauled at the stupidity of the drain plug/muffer proximity....and I was damned if I was gonna take off the muffler every time. I decided to fit a drain hose setup, similar to the engine oil drain. I looked at several possible approaches, but most put the drain hose a bit too close to the muffler (even if I cheated the muffler down a bit by elongating the mount holes). In the end, I shortened the head of a grade 8 blot, and tapped it for a very short 1/8npt 90 degree fitting. The hose runs rearward then upward along the rear of the primary cover to a tidy little billet plug/holder I made. The setup works great, and allows for an oil change in minutes. I have a nice photo of it, but my aol doesn't let me upload it. If someone can ping me, I can send them the pic to post it. groupklemm@aol.com Harry in AZ | ||

Reepicheep |

Thanks Harry... good idea, avoids all sorts of headaches, and sounds simple enough. But stop wasting time here answering my questions and get back to work fabricating those updated shifters so we can start sending you money! Geesh. Some people  Bill | ||

Reepicheep |

Here are Harry's pics... very cool setup...   | ||

Blake |

Bill: At home, I use a hand pump through clutch cover as you mentioned. It works extremely well. I use the aluminum foil over muffler method when I want to check the plug magnet's accumulation of metal bits. An old kitchen knife (long flat thin) will help you support the plug and get it started. I've not removed the muffler on a Buell since the first time I change the tranny lube on my 1st '97 M2 back in 1998. Thanks for the pics, Harry, Bill  Blake | ||

Ara |

In lieu of aluminum foil over the muffler, I use a half-gallon plastic milk carton cut away so that I have a 1/2 inch deep catch pan on one end and a pouring nozzle (the top of the carton) on the other. It's reusable and works wonderfully. Just a suggestion in case you're like me and like to clean the magnet every time. | ||

Blake |

Ara: How much gook do you find on the magnet. I hardly get anything anymore. | ||

Ara |

Blake: Like you, I got more accumulated on the magnet earlier in the bike's life than later. This was especially true because at the first service the H-D/Buell tech sucked the primary fluid out with a big turkey baster (similar to your method) and didn't check the magnet. (He also used a full quart of Sport Trans, but that's another story...) I didn't even know that there was a magnet on the drain plug until I did it myself at the next service and there was a bunch of stuff on it. Less now, but still worth the doing - about the size of a green pea or so. As you may have guessed from previous posts, I'm something of a fanatic about maintenancem and do everything on my bike and autos as if the world turned on it. So I pull the primry plug every time and give it plenty of time to drain before I seal her up and refill. | ||

Jim_Witt |

Cheers, Since I was TIG welding today on 1/2" O.D. SS sockets welds, I thought I experiment with the dran plug concept on my lunch hour (not that there's anything wrong with Harry's). I still need to work on a few things, but it was a nice experiment. Oh, BTW, the other fittings in the pictures are of a 1/4" O.D. SS micro 90 degree elbow and a 1/4" O.D. SS micro tee. If you put your mouse pointer over each image, I tried explaining what'z going on in each picture, well sort'a.     Hey, I'm board! -JW:>) |