| Author | Message | ||

D_adams |

If I had to guess, it's a possible design flaw, but I'm not an engineer, so I do miss stuff on occasion. I fail to see the need/point for the roll pin at the pivot point on it. If the belt breaks, sure it will over-rotate, but it won't hurt anything. It can't swing down any more than the heim joint and spring allows, so it's only path of travel is up. If I understand that piece correctly as it's designed, then the spring pin limits it's movement and will eventually do like it did in that pic. Just simple metal fatigue from being stressed I suppose. Looks like it's just the main bearing that went out on mine and man is it a mess. The needle bearings appear to be ok, as does the main shaft. I'll take some measurements, but it feels pretty smooth and tight with nothing else weird going on. I'll see how the output shaft/gear cleans up, if it does, then I'll only be replacing that one bearing and seal. The crank appears to be in decent shape as well. This has got to be one of the worst ball bearing failures I've ever had happen to me, but at least it wasn't totally catastrophic and exploded. | ||

Reepicheep |

Wow! Now *that's* a bearing failure. | ||

D_adams |

So it was $125 for a complete gasket set, $35 for that bearing and 2 seals and then $37 for cleaners and sealant for the case. Close enough to call it a $200 repair. Bought the gasket set online a few weeks ago, the local dealer had the bearing and seals on hand. I was mildly surprised. (Message edited by d_adams on December 26, 2013) | ||

D_adams |

So without looking at the manual for reference, what's the "easy" way to get the shift drum detent spring mechanism back in place when putting it all together? | ||

Reepicheep |

Sorry it broke, but that is very cool to have "been there done that". I've been down that far into dirt bike cases, and once I get past the initial "why me" whining phase, its actually pretty fun. | ||

Cataract2 |

D, are there any better bearings that might be used in place of the stock one there? | ||

Akbuell |

Ouch! And thanks for the pics. Always helpful to see what is in there, instead of looking at line drawings. Were it me, given what got me there in the first place, I would be replacing the needle bearings. As much for peace of mind in the future. After all, the hard part is done, and getting all of any debris that might be in them would be problematic. Dave | ||

D_adams |

I spun the needle bearing on the shaft, it's smooth like it should be. Changing those would be a pita without a press. I did figure out that removing the neutral light/detent ball gains access to the shift mechanism so that I can push it over and assemble the cases. | ||

Reepicheep |

Based on what I was told by the Harley dealer that rebuilt my 5th gear drive assembly, even with the press it is a PITA. I spent 20 minutes with a vise and washers and pipes and got nowhere, so I paid them $50 to rebuild it for me... based on the mumblings when I got it back rebuilt, I think they lost money. | ||

Woodnbow |

Speaking of engineering... does anyone else miss the trap door style transmission? | ||

Cataract2 |

Yes. | ||

Brakes2late |

My 06 Uly just started making the same noise at 86k miles. Pulled the sprocket and sure enough my bearing looks similar, but not quite this bad. Started dropping the motor yesterday. So how many specialty tools are needed to get everything apart? | ||

D_adams |

Large socket for the clutch side, another for the transmission pulley. I'll get the sizes tonight if it doesn't get posted earlier. I want to say 1 7/8" for one of them, the other was a fair bit smaller, maybe 1 1/8" or so. The clutch does not need to be completely disassembled to remove it, you'll also need about a 4" lock bar to go between the rotor and clutch basket to loosen the nut on each. A 1/2" impact will remove them all, or at least they did on mine. Everything else was just common hand tools. | ||

Brakes2late |

Great, thanks. I should have the motor out Saturday. | ||

Uly_man |

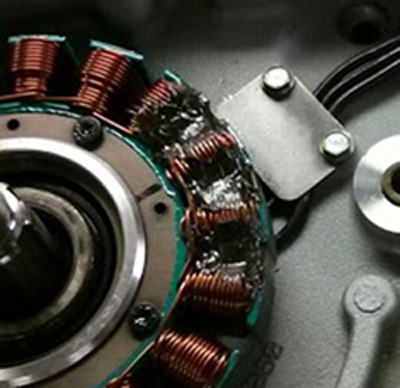

Just a thought but this looks like a burnt out Stator. Did you replace it?  | ||

Reepicheep |

I wonder if loosing the trap door was just a cost savings measure, or if it was necessary in order to achieve greater precision for better shifting. I suspect the former, it was just a cost savings deal, which is really unfortunate. That was probably the one thing that the Tubers did better. I wonder if it was an HD call, or a Buell decision. | ||

Brother_in_buells |

The xbrr bikes still had the trapdoor. | ||

Cataract2 |

If I could get my hands on XBRR cases.... | ||

D_adams |

Stator was still charging fine prior to disassembly, 13.5-14 volts on the display I put on the bike, also checked with a Fluke meter for accuracy. It did look a little dark, but it's just the epoxy and/or lighting in that pic I think. It's still open, so I'll have another look and test the legs to make sure. | ||

Woodnbow |

As far as I know the trap door was lost to cost savings on the 2004-up rubbermounted Sportsters... I imagine Buell just went along for the ride. | ||

Brakes2late |

All I've got left is pulling the clutch, then I'm ready to drop the motor. Figured it would be easier while still in the bike. Looks like 1 1/8" socket? | ||

Ducbsa |

No trap door is a cost savings, but it must be stronger. That would certainly benefit Buell motors more than Sportys. Regarding the XBRR, maybe it has some special details that make it strong enough, but still giving the easier trans work benefit. | ||

Sifo |

No doubt it was about cost savings. My understanding was that they didn't have that many trans failures to begin with, so there wasn't much benefit to having easy access to the trans. If it were a strength issue, I don't think they would have had good reliability in the first place. It would be nice to be able to drop in a 6 speed trans, but honestly, the cost/benefit doesn't look that great to me on an older bike. | ||

Brother_in_buells |

Don't want to high jack this thread but here is the inside of a xbrr engine, http://xlforum.net/vbportal/forums/showthread.php? t=829935 | ||

Brakes2late |

Nice. Thanks for sharing. | ||

Uly_man |

"Stator was still charging fine prior to disassembly, 13.5-14 volts on the display I put on the bike, also checked with a Fluke meter for accuracy. It did look a little dark, but it's just the epoxy and/or lighting in that pic I think. It's still open, so I'll have another look and test the legs to make sure". The Stator should look the same all the way round. That "black" stuff is burnt enamel from the wires of the Stator, which is the insulation, and will short out the Stator at some point even if it is ok at the moment. Have someone else check it over if you are unsure. | ||

Brakes2late |

Any tips on getting the flywheel nut loose? Clutch main shaft came lose right away but the nut on the crank won't budge. | ||

Sifo |

I hear a nice hefty impact wrench is the way to go. Otherwise it's probably going to require a helper pipe on the wrench and the primary will have to be locked up with an appropriate tool. I'm told a standard brass door hinge fit right in there. | ||

Brakes2late |

I'm assuming right hand thread, unlike the clutch main shaft nut. The manual doesn't say. It does say the clutch nut is left | ||

Brakes2late |

Got it. Right hand thread. |