| Author | Message | ||

Manimal |

OK, so i have a couple questions about my 03 Xb9R Firebolt and if there are any Buell Techs out there that can answers these it would be greatly appreciated. 1. After i've been riding my bike and my cooling fan shuts off it will make a single clanking noise periodically. It has done this ever since i've owned it. How normal is this and what is it? 2. At how many rpms should my bike be idling at? Right now it idles at 500 rpms and will occasionally die when my bike is cold. 3. My bike just turned 10,000 miles. What checks and maintenace should be performed at this point? I appreciate your help | ||

Punkid8888 |

Well you asked for a Buell tech but so far you only got me. For the clank noise, I think I have the exact same noise on my bike. I usually shut of the bike and I get the normal clicking and creaking from the exhaust and about 3mins later I get a louder click. I assume it’s just the muffler straps against the muffler cooling at different rates. So I don't think its anything to worry about. The idle is very low, I believe the spec is 1050 to 1150, I am actually very surprised to see it able to idle that low. I would like to see you verify the idle through a digital tach like a timing light or DVO meter with the tach lead. I think you will have a combination of idle screw adjustment and tps reset. Unfortently I am not sure the exact procedure, but some one should chime in with it. 10,000 I am actually about 500 miles from that service too. From the manual I believe the following are up for service Oil change Primary fluid change Primary chain adjustment Spark Plugs Fork oil change And TPS reset (which you def should do) And your classic inspects and checks brakes, tires, fasteners, blah blah blah Personally I did my primary chain adjustment and fluid at 5K and plan to do it again at 10k, oil change obviously, spark plugs, and I never did my steering head bearing check so I will do that to. I plan on skipping the fork oil change till 15K and skipping the TPS reset till it starts running funny. Have fun, and if you don’t have a service manual yet I strongly recommend getting one, It a good investment. | ||

T9r |

May folks that ride Buells on this forum are techs by ownership, not by certification (though we got some of them too). For the technically enclined, I like try to tackle most maintenance myself. Lucky for me the Buell brand makes that pretty simple. The VDSTS is an awesome toy, which allows one to do TPS resets and know how the bike is running via computer or Palm computer. PMCS (Preventive Maintenance Checks and Services) - Leads to the second of all useful tools the service manual. Granted there is great knowledge here but nothing can beat the words with photos of the manual. Oh if your an engineer, the charts are just fun to look over. Timing of the engine is something that should be looked at as well. The bike will not run as well if not timed correctly. Keep asking the questions. | ||

Skully |

How are you guys checking timing? | ||

T9r |

One Mississippi, two Mississippi, and so on... Ah but here is how: http://www.badweatherbikers.com/cgibin/discus/show .cgi?tpc=32777&post=477842#POST477842 "I used Steve-O's (2k4xb12) method for checking/setting the static timing on my 12. Not sure if the process is exactly the same on the 9. Here's his original post with details, worked like a charm! I checked my timing because of a consistent ping I had at ~3800 - 4000 RPM. My timing was set too advanced. --- 2k4xb12 posted --- I did a writeup in the knowledge vault a while back. Here's the link: http://www.badweatherbikers.com/buell/messages/384 2/78049.html?1096725661 About halfway down the page, look for my post. If you don't want to take the time to click and look, here's the text: There's been discussion lately about the ability to adjust static timing without the need to hook the bike up to the Digital Technician. It can be done, and it's really quite a simple process. Here's how to do it on an XB -- not sure how similar the other models are in terms of wire colors, etc. but the process should be the same. 1. Rear up on stand. 2. Remove seat. 3. Remove timing mark inspection plug. 4. Gently pry back the silicon rubber seal to gain access to the terminals of the gray connector on the ECM. You'll need to stab your DMM leads in from the back, and this makes it easier. 5. Set DMM to read DCV, 20V range. Insert black DMM probe into pin 7 (black wire with white tracer) and red DMM probe into pin 3 (if I recall correctly -- anyway, it's the green wire with the white tracer) 6. Sidestand up, key on, ignition switch on, transmission in 5th gear. You should hear fuel pump come on and then time out. 7. Looking through the timing mark inspecion hole, turn the rear wheel in a forward direction until the timing mark is visible at the left edge of the hole. You should see zero (or close to it) volts on the DMM. If you see +5V, then you're at TDC for the rear cylinder -- rotate the wheel until you see the mark again. 8. The meter should change from 0 to +5V just as the timing mark passes the center of the hole. As a bonus, the fuel pump comes on at the same instant, providing audible feedback as well. Turn the wheel slowly, and if you overshoot the mark, back it up until the mark is again at the left edge, and then go forward. Don't try to check/adjust it while turning the wheel backwards. 9. If the timing is advanced (transition occurs before center), nudge timing plate CCW. If the timing is retarded (transition occurs after the mark passes center), nudge the plate CW. If, as the other thread suggested, somebody wanted to connect an LED to monitor this transition, you could easily hook it up as follows: Connect a 330 ohm dropping resistor to the anode side of an LED. Hook the other end of the resistor to the green/white wire of the CMP sensor(pin 3, gray connector at the ECM). Hook the cathode of the LED to the black/white wire of the CMP sensor (pin 7, gray connector at the ECM). Using the above instructions, the LED would be off with the timing mark at the left edge of the hole with the front cylinder before TDC. It should then transition to ON just as the timing mark passes the center of the hole. Additionally, both techniques can be employed by making your connections at the CMP sensor connector. I chose to probe the ECM connector because there you don't need to remove any trim pieces or cut any wire ties to access the proper wires." My personal opinion, it still ain't that easy. | ||

Xl1200r |

I have no idea about the clank, but the muffler strap hypothesis sounds feasible for sure. As far as I know, a 10kmi service is nothing too fancy, but a dealer might charge a pretty penny for it. Your idle is WAY low, and I too am suprised the bike even runs at all that low. A TPS reset is not a bad idea. I'm not knocking on your ignorance (not all folks are mechanically inclined), but I'd almost bet that it's never been done. To adjust the idle - - - There's a small round silver knob on the end of a fat black cable that sits on the top inside corner of the left-side air scoop. Keep looking, it's there (took me a couple times until I saw it). You can try turning it by hand, but there's a fitting for a hex key on it that makes life MUCH easier (it's the same size as the allen wrench in your bike's tool kit. Make sure you don't adjust the idle until the bike is fully warmed up. Best bet is take it out for a short ride first. Spec is 1050 - 1150rpm, but I find this is usually too high for my bike, and 1000rpm is as high as I can go before I get a hanging idle. It might take some playing with (keep in mind your 9 may act differently than my 12). | ||

Fullpower |

3/16" allen wrench for idle adjustment. | ||

Xb12lp |

My 2006 Ulysses makes really bad noises at idle, it sounds like it has rocks in the engine at idle. It goes away after the motor rev's up. Is this normal? | ||

Mdm |

> it sounds like it has rocks in the engine at idle. Ohh, rocks are bad. It should sound like marbles !  VDSTS question, i have a palm t3 kicking around will the software and cable work on the T3 palm ? (sorry to hijack) | ||

Johnnylunchbox |

XB12LP - if it's rocks you hear at idle, I'd say it is almost definitely a loose primary chain. You'll get a distinct clack-clack sound if the chain is loose. It's very easy to adjust. | ||

Tank_bueller |

VDSTS question, i have a palm t3 kicking around will the software and cable work on the T3 palm ? (sorry to hijack) I hope so. I just ordered a Palm Tungsten E2, and a serial adapter. I already have the cable and software for PC. I didn't even think that I might need a different cable???(I'm sorry to continue above hijack) | ||

Odinbueller |

Idle should be at 1000 RPM +/- 50 RPM. Any higher, and you'll get the slow engine deceleration, any lower and you'll starve the top end of your motor of oil. 10K service is involved, but not out of the realm of the shadetree mechanic or proficient do-it-yourselfer. If you're interested in a Factory Service Manual, we have a good selection in stock & offer 10% badWeb discount. PM me if you're interested. That noise I would have to hear to determine if it's bad or not. Since it happens after the bike is shut off, I'd say that it's a component cooling and contracting. Chris | ||

Skully |

Thanks Mr. T! | ||

Toona |

I haven't tried to set my timing with the VDSTS software, but on the "gauge page" it shows ignition timing. I'm guessing/assuming that you could set your timing using the software as well. The VDSTS software is relatively simply to use. Maybe a little pricey if you don't have another Buell around, but I service mine, XB9er's, and a few TPS resets when I hosted the Res Ride Memorial Day weekend. Plus the closest dealer is 100 miles to the north, south and west. So I figure I save the travel time/gas by not having to go to the dealer as well. | ||

Dentfixer |

OdinBueller?? "any lower and you'll starve the top end of your motor of oil." Is this opinion or do you have info\fact to back it up? I've been setting my idle on my 06 XB12 low and now you have me worried? Can anybody else justify this point? Thanks. Ron | ||

Starter |

There are other options available to VDSTS. ECMSpy is a DIY cable & program that has been developed by some very smart enthusiasts in Germany from memory. Much easier than going to the dealer and only costs involved currently are for the cable which is a little tricky to make. | ||

Fmaxwell |

Nothing tricky about the cable at all: Bought a USB to TTL cable from Mouser electronics and a 4-pin plug off of ebay. Soldered three wires and had everything working. ECMSpy rocks! | ||

Manimal |

Ok, so i appreciate your guys feedback. Helped a lot. I set my idle at just under 1000 and it is running much better. All fluids were changed less than 1500 miles ago. And spark plugs will be done during the winter. After i rode the other day i sat next to my bike waiting for the pinging noise. After hearing it a couple of times it seems to be (from what i can tell) the muffler straps cooling. My timing seems to be fine. As far as using a VDSTS or ECMspy, I'd have to say that is a little over my pay grade. I have dealership that i would probably get that done at. thanks again Buellers!!!!! | ||

Buellrcr |

IF THE IDLE IS LOW IT DOSE NOT MAKE ENOUGHT OIL PRESSURE TO LUBE THE TOP END. AL SO THE FORK OIL IS CHANGE AT 10,000 MILES | ||

Mr_gto |

From working on evolution vtwins, i have a 87 fxrp, if your idle goes below 800rpm it is bad for the motor because of the oil pressure is too low. i dont know if it the same on the buell motor. | ||

Odinbueller |

Hey Dentfixer, Sorry for the delay. Your oil pump is directly driven by the motor. At idle, you should be at around 950 to 1050 to allow the oil pump to get oil up the galleyways of the pushrods so that the rocker boxes get oil, and then down through the rest of the oiling galleyways. The lower the idle, the less pumping action you have. I've seen it happen on older Sportsters, and with the nature of an XB motor, I'd keep your idle no lower than 950. Not to mention cold starting & idling issues. Chris | ||

Dentfixer |

Thanks for the info guys. I'm waiting for my VDSTS Vista version then I can accurately set my idle. My tach needle is just a hair below 1K so I'm pretty sure it's not too low. Hmmm... does VDSTS or DL or any other software have a setting to read oil pressure? | ||

Odinbueller |

To get an actual reading of oil pressure, you need a gauge that threads into the pressure switch that illuminates the oil light on the dash. | ||

Dentfixer |

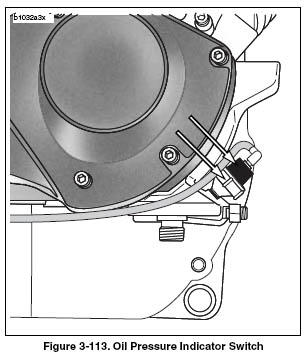

So any HD dealer should have a gauge, right? Where abouts is the oil pressure sensor at anyway? Would need a sensor that would permit the oil light to work too, right? | ||

Odinbueller |

Sorry for the delay in responding, but here ya go...  This should point you in the right direction. And yes, any H-D or Buell dealer should have an oil pressure gauge set. The switch itself is a simple, here's what the FSM states: "The oil pressure indicator switch is a pressure-actuated diaphragm-type switch. When oil is not circulating through the system or when oil pressure is too low, spring tension holds the switch contacts closed, thereby completing the signal light circuit and causing the indicator lamp to illuminate." Hope this helps, Chris |