| Author | Message | ||

Tx05xb12s |

The compensator nut backed off the main shaft causing my primary sprocket to come loose at 3200 miles. Now at 9000 miles it's doing it again. I don't have the tool to lock the sprockets so I can retighten it myself. Anyone else having this issue? Would you guys recommend I take a chance with the dealership that busted my clutch cable housing and scratched the primary cover the last time I brought it to them for the very same problem, and then swore it was like that when I brought it to them and at first refused to make repairs? Or would you recommend I get the tool from Al and do it myself? The bike's still under warranty is why I have a tendency to think HD should make repairs. | ||

Cochise |

Ask them AND TAKE PICTURES, befores and afters. | ||

Tx05xb12s |

Good advice Joseph. I'll be sure and do so if I wind up bringing it to them. I know it's just a loose nut, but it seems to me I shouldn't be having this issue. I can accept a loose fastener and understand that things loosening up is the nature of the technology we're using, but when I have to start disassembling the engine to tighten things, I would call that unacceptable. | ||

Jackbequick |

The locking tool is easy to make. You need a piece of 1" wide x 1/4" thick x 4-1/8" long aluminum flat bar. Round the edges on the ends a little so that it sort of matches the shape of the sprockets and you are in business. The big deal on getting the nut to stay in place is to get the threads on the compensator shaft and the nut meticulously clean, free of old LockTite, and free from oil (use a small wire brush and a good degreaser/solvent). Then put two or three drops of red LocTite on it, tighten it to the new spec (260 ft/lbs?), and you should be good to go. You're probably right about who should do the repairs but it is pretty well borne out here that if you have the talent and tools to do this kind of work for yourself you will be happier in the long run. The first time you do anything for yourself it will pay for the manual and parts book. After that, you are saving money, getting smarter, and expanding your happy riding zone every time you use it. Jack | ||

Tx05xb12s |

Thanks for the specs on the tool Jack. I'll make one since it looks like this will be an issue with my particular bike. You said aluminum here, but I've got a piece of flat bar steel out in the shop I could make one out of. I assume this wouldn't be a problem? Also, I'll bet the nut wasn't put back on with the new torque specs. I think the last time this happened, it was prior to this. Anyhow, thanks again. | ||

Spiderman |

Steel will not be a problem as long as it is soft... | ||

Hogs |

Tx05xb12s, I think what Jack was getting at with the aluminum is, IT has to be SOFT any hard SOFT material wd. work ,but I don`t think I wd. go with STEEL ,BAd MOJO it may work for ya but could cause plms. and we don`t need them Right..! just another .02 cents worth | ||

Reepicheep |

Tangle a towel in there and that can work in a pinch as well. Not sure when they last messed with it, but there is a good chance the factory changed the torque spec *after* they did the work to address exactly the problem you had. It burned me on my Cyclone as well. | ||

Djkaplan |

Don't use a steel flatbar. Off the shelf A36 carbon steel (pretty much the lowest grade available from most material vendors) is probably hard enough to damage the teeth on the clutch housing and rotor. | ||

Hughlysses |

You know, you can just buy the proper tool from Al at American Sport Bike for ~$20 and not worry about hosing up your primary gear teeth or having your little piece of aluminum fold up just as you click 260 ft-lbs on the torque wrench. 260 ft-lbs is a LOT of torque. | ||

Djkaplan |

I've ordered lots of goodies from Al, but spending $20 plus shipping for a piece of aluminum flatbar is way too extravagant for me. I just used a piece of aluminum scrap and made one. I also make my own spicey mustard because I can't believe what the spicey mustard cartels charge for the stuff just because it's 'spicey'... but that's not really important here. | ||

Tx05xb12s |

Yeah, I hate to pay that much for a piece of refuse aluminum flat bar. You're probably right about the steel flat - could break teeth. Dunno, I'll call the dealership after the holidays and see what their attitude is like. If I don't like it, I'll just have to go hunt a piece of aluminum. In the meantime, it's loose enough to keep me off the bike. This really, REALLY sucks since I'm off work for five days and the weather will be good enough for riding. I really wanted to use a couple of those days for a short trip somewhere. I'm sick of just doing little joyrides in the local area. Oh well, want in one hand...  | ||

Davo |

Do you have an impact wrench or know someone that does? | ||

Hogs |

I don`t think you will want to put any IMPACT Wrench on that... Just Torque wrench only... But maybe thats what ya meant. | ||

Davo |

I don't know what it would hurt. I do it all the time on other HD's. Just clean it off, put on some red thread locker and stand on it. I might be off base though. I have a locking tool but I don't have a torque wrench with numbers that high. Some of the bikes I work on have very light weight clutch shells and a locking tool will tear them to pieces. | ||

Xb9 |

Lowes or Home Depot have the Aluminum stock | ||

Dcmortalcoil |

I may be way off base, but I remember reading in a technical article that a way to really tighten a nut to the true torque recommendation is to grease the threads or put anti-seize. It's may be counter-intuitive, but seems to work. I've done that with the front pulley nut, wheel bolts, and the steering nut, with no loosening problem. | ||

Tx05xb12s |

Thanks for the tip on Lowes/Home Depot. I'll go check them out tomorrow. I've got a pretty good selection of tools, but dad's the master mechanic. I think his fabricating is usually steel, but you never know about him and his packrat tendencies. It wouldn't surprise me to nose around his shop and come up with a piece of aluminum suitable for making the tool I need to get this nut tight. I need to get some red lock-tite too. All I've got on hand is blue, which I have been using liberally every time I take something off the bike. I'd imagine a local autoparts store should have it. Anyway, gotta get this little issue solved so I can move on. I'm itching to put the R front fairing bracket/top triple tree and rear subframe on it so I can slap a sharkskins racing kit on it with a custom paintjob. It's all about priorities, right? I live on sandwiches and ramen while I sit in the dark and unplug/turn off everything I'm not using and walk to work so I can maximize my disposable income to be spent on my baby. I don't wanna grow up...I'm a Buelligan Kid! | ||

Spatten1 |

Home Depot in my area only carried 1/8" or so aluminum flat bar, which seemed to thin to take the torque. I cut one piece 4 1/8" long and another about 1/2" shorter. I doubled them up for strength, keeping the smaller piece centered on the larger piece, with self tappers holding them together. There is about 1/4" of the longer piece sticking out beyond the shorter piece on each end to grab the sprocket teeth. Worked fine. Good luck. | ||

Tx05xb12s |

Cool. I'm on the way out the door now to go see what they've got. Dad said he didn't have any aluminum out there. I'll come up with something. Worst case, someone said put a towel in it in this thread. It'd probably get the job done at least good enough to ride if I can't get any aluminum over the holiday weekend (timing sucks). Hey also, I'm thinking I'm probably going to need a new primary cover gasket, right? What's it made out of/can it be reused? I've never had it off myself. I know without even asking the idiots at the local stealership don't have one in stock and probably couldn't get one this year. So I'm going to make do with what I have on hand if I want to take that trip. I'm in a little university town about four hours ride from Galveston if I take the scenic route. Thought it would be cool to blast off down there Monday and spend the night. I'll just find a cheap hotel room with a door wide enough to ride my bike through and I'm all set! I could spend the day walking on the beach and visiting a few of my favorite bars, or maybe the other way around if I can find some company in the bar. LOL! Anyway, motorcycle rides and walks on the beach with drunken strangers- South Texas Christmas bachelor style. | ||

Hogs |

Tx05xb12s, You can reuse the gaskets,just be careful when ya remove the covers,Get a good 3M or other Brand name sealer Not a fan of Silicone myself,and put just a thin wet coat on both sides of the gasket,helps to hold it in place as well on reinstall, and be easy with the torque specs. when tightening the bolts stay on the min. specs, some of them bolts can break easy if ya come on to them so be gentle... | ||

Djkaplan |

"I don`t think you will want to put any IMPACT Wrench on that... Just Torque wrench only... " "I don't know what it would hurt. " It could potentially get the pressed together crank halves out of alignment with each other. It could loosen the rotor magnets. The rotor itself has the warning 'NO IMPACT' stamped right on it. These sound like reasonable reasons not to use an impact wrench on the crank nut to me. | ||

Buell920 |

http://www.badweatherbikers.com/buell/messages/327 77/247447.html?1166888889 scroll to the picture of the pinion/crank notice the side load were on the race. this is what happens to a crank that has been misaligned. | ||

Djkaplan |

"I may be way off base, but I remember reading in a technical article that a way to really tighten a nut to the true torque recommendation is to grease the threads or put anti-seize." Loctite and other thread locking compounds act as lubricants when they are first applied so you can get torque as close as possible to the specified rating. Threads on fasteners and tapped holes also have to be very clean to get an accurate torque reading. It's a mistake not to use Loctite when it's clearly specified. | ||

Swampy |

Just do it yourself! The hard part is finding a 260 ft lb torque wrench! If you use an impact gun how will you know when you get to 260 ft lbs? Stuffing a wrag in the chain is pretty tough on things, I have tried that method before and I was afraid of bending the crankshaft or breaking the clutch basket before reaching torque. It just was too spongy feeling. The locking tool is the only way to go, you get a good solid hold on things without damaging the goods. | ||

Americanmadexb |

well im alittle late, but i also had this problem with the compensation nut at, i dont remember 700 miles or so on my 06 Ss. I now have 4,500 and i hope i dont have to go threw that shit again! | ||

Tx05xb12s |

Just got back from dad's place. I didn't bring the bike out there today since we were supposed to be celebrating the holiday together. I didn't want to tie him up in the shop away from the family. So, I'm trailering it out there first thing in the morning. We're thinking instead of wedging a flat bar in between the sprockets and taking a chance on bending/breaking a tooth, we're going to build a long handled tool that will have two bolts welded through it matching the holes in the sprocket. This will be used to hold the sprocket stationary while the bolt is tightened. This way we don't put any stress on the shaft or sprocket teeth. Dad was a machinist once upon a time so he can fab up most anything we come up with. I'll take pics of the tool for you guys. May give us all a better solution! So, it looks like I'll get my beach trip after all. I've got the coolest dad. Speaking of which, he loaded me up with some choice new tools for Christmas this evening. But the best presents of all were used...a 50 year old set of dial calipers and thread gauges that belonged to his father. What a guy. I probably won't use them for much more than measuring bolts and bolt holes when I need to go buy a new one or tap out some threads, but I guarantee you I'll cherish them always. Thanks for all the help guys. I'll keep you posted on my progress when I get back tomorrow. | ||

Jackbequick |

I mentioned aluminum for the flat bar because it eliminates all danger of damaging the sprocket teeth. But my regular one is made from a piece of 1/4" +/- laminated fibreglas, like from a boat hull. If I made one out of mild steel I would try to fit the sprocket teeth more closely to spread the load out more but those sprockets are going to be a lot harder than mild steel. If you look at the forces on that, there is very little radial or turning load on the teeth of the sprocket. You are basically trying to push that piece of flat bar in towards the sprocket centers with the primary chain restraining it all. Actually a pretty clever design. The load on the locking bar is a compression load and it would basically have to deflect or bend to fail. Impact wrenches are not recommended because of the danger of loosening the magnets that are glued to the inside of the stator. And if one of those comes loose it would probably really raise hell in there until you get it stopped. I'm thinking major damage would occur. You guys all have a good Holiday, I'm out of town for Xmas. Jack | ||

Djkaplan |

"We're thinking instead of wedging a flat bar in between the sprockets and taking a chance on bending/breaking a tooth, we're going to build a long handled tool that will have two bolts welded through it matching the holes in the sprocket." The handle is going to have to really long to counteract 260ft*lbs of torque and you'll have to make another one to take the clutch basket out. The locking bar is simple and works for both the rotor and clutch. It's easy to use, only takes one person, and it's how the procedure is outlined in the service manual. I think it would actually be harder doing it the way you're proposing. Just get your dad to make a locking bar! | ||

Tx05xb12s |

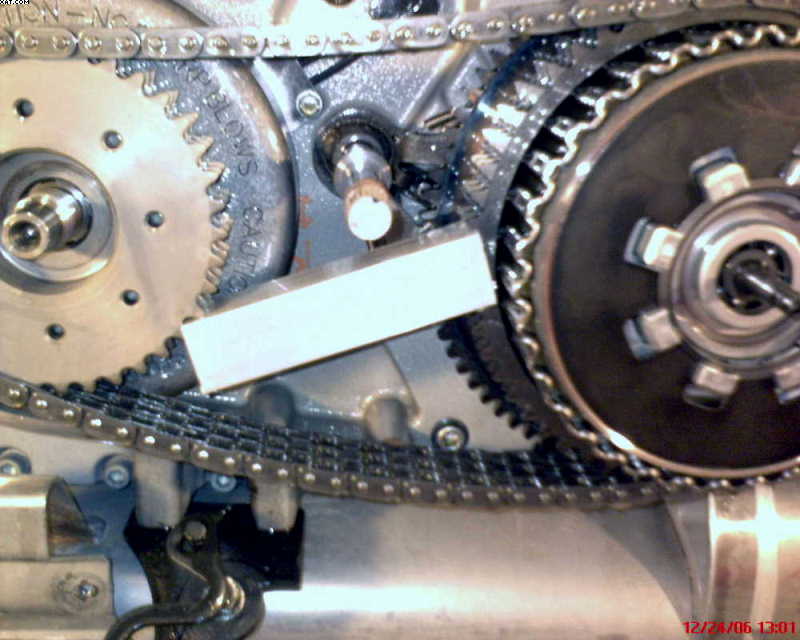

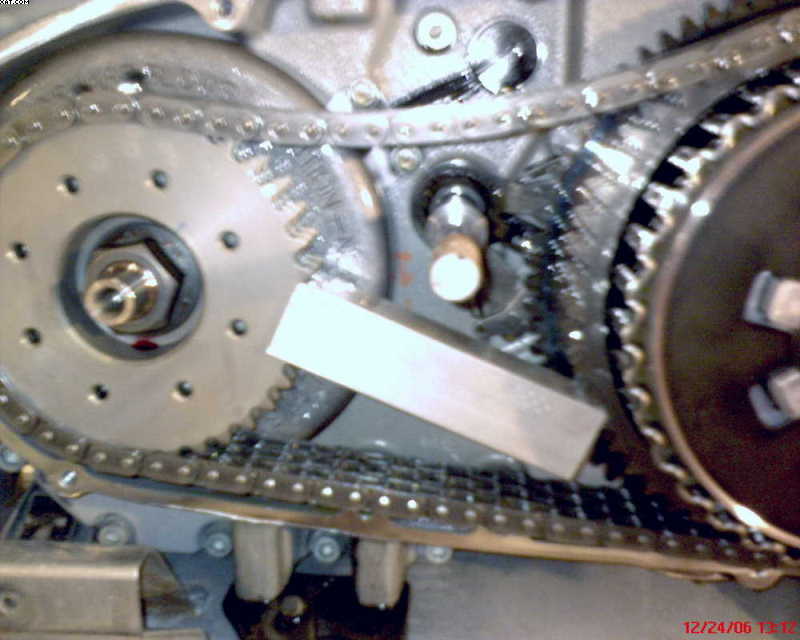

Hey guys. Ended up getting to go on my trip after all. Had a blast, drank lots of beer, met a little hottie on the beach Monday night I ended up spending the past three days with and have plans to go back and visit sometime, and came home with sand in my crack. Just got back yesterday. The bike ran flawlessly and I'd estimate 90% of the noise I was hearing is gone. What remains sounds like something in the drivetrain has some runout or a worn bearing. The noise kicks in about 70 MPH and is modulated with torque. Anotherwords, I can give it gas and it gets louder. I can hold the throttle neutral and just maintain speed and it quiets down almost completely. I think I have the chain adjusted within tolerance (3/8 to 1/2 cold), but I suspect that's what I'm hearing. I'll experiment with the slack the next time I ride and see what it does. Otherwise, there's the front belt sprocket and the idler pulley...I've read where some of you guys are replacing idler sprockets. Is it because of bearing loss/noise I may be hearing? I'm at 9,400 miles. Anyhow, dad called around on Christmas Eve and found a piece of 1/8" x 1" aluminum angle bar. We cut off a 4 1/8 piece and it did the trick. Man 260 ft. lbs. is a crap load of torque! I used a 6 ft. cheater bar on the wrench to get it tight. Here's a shot of the primary with the nut off. \image {sprocket bar} Also, when we examined the compensator nut, we noticed that there were only wear/contact marks on about 40% of the perimeter where it mates up to the shaft and nothing else was touching. So, a little time on a sheet of 80 grit sandpaper gave us a uniform contact patch all the way around. We are assuming this was definitely contributing to it not staying snug. Here's a shot of the finished nut prep work: \image {prepped nut} And finally, it didn't appear that there was hardly any thread locker used when it was re-tightened at the dealership. Here's a shot of my generous slathering of red thread locker including the freshly flattened out back of the nut. \image {finished nut} And here's a shot of the finished job. It's a hell of a lot tighter than it was and the nut was improved. Hope this holds a while. \image {finished job} Being a former machinist, dad didn't have much nice to say about the design relying on some glue to hold the nut on. He recommended several alternatives that would have been a heck of a lot more trustworthy. Now all I have to do is figure out what else is making racket. | ||

Tx05xb12s |

| ||

Tx05xb12s |

Oh and one more thing. I'm happy to report I was able to re-use the primary cover gasket with no leaks. Too bad I didn't remember to tighten the drain plug when I rode it on the test drive after we finished.  |