| Author |

Message |

M1combat

| | Posted on Friday, July 15, 2005 - 11:56 am: |

|

No problem  . .

The suspension setup you gave me still kicks •••  . I did remove 1/2 line of preload up front and I think I'm about to remove a little compression damping on the rear plus remove a little rebound on the front . I did remove 1/2 line of preload up front and I think I'm about to remove a little compression damping on the rear plus remove a little rebound on the front  . I've gotten to the point where I'm sliding the front tire around on turn entry (after I bank, but before the apex) so I think I need to take a little weight off of it. . I've gotten to the point where I'm sliding the front tire around on turn entry (after I bank, but before the apex) so I think I need to take a little weight off of it. |

Ingemar

| | Posted on Friday, July 15, 2005 - 12:40 pm: |

|

lol

I removed half a line of preload too but was quick to put it back to were it was. It just felt weird entering turns that way.

I am thinking of trying one step softer on the rear and see what that does. |

M1combat

| | Posted on Friday, July 15, 2005 - 01:19 pm: |

|

I considered that too... but it feels VERY nice coming out of the turns. Quite frankly though, the only time I slide the front is when I run the front across where the cages stick their tires and the "sharpness" of the pavement is worn down a bit. Everywhere else it's perfect. |

Craigster

| | Posted on Saturday, July 16, 2005 - 12:38 am: |

|

We’ll this sounds like fun so let’s try it. Perhaps I did not do a good job of explaining my self earlier, however this could take a while …….

A Stock Zx11 makes about 128 hp to 130 hp on a Dynojet dyno. With a pipe, air filter and some good jetting 132 to 137 hp is fairly reasonable. With Dynojet’s early mass air EFI with huge throttle bodies, they recorded numbers in the 136 to 144 hp range at sea level.

Let’s look at the numbers we know so far. The formula for CF is

X=Hgcf/Bo-RH *(Ta/Tcf)e0.5

Using the old SAE standard Hgcf =29.92, Tcf = 520, Bo = Barometric pressure (in Hg) and RH is the partial pressure of water.

Since we are looking at various tests performed at higher elevations the partial pressure of water is negligible. Also, it should be noted that humidity plays only a small part in the equation. It takes a large change in humidity to make a tiny change in CF.

Lets look at one of the uncorrected Dynojet runs on their EFI ZX11. The run at 3640 ft of elevation shows a best-uncorrected run at 112 hp (The dots on this graph shown at http://www.geocities.com/hellfireperformance/dynosourcepage2.jpg represent 2hp increments).

Since as a rule, Hg drops at 1 inch per 1000 ft elevation we can guestimate that the pressure would be in the 26.28 range (29.92-3.64, with 3.64 derived from the 3640 elevation). I’ll also go out on a limb and give them a nice warm day at altitude to balance out any ill effects of assuming 0-10% RH and 26.28 Hg.

What we get is:

29.92/26.28*(540/520)e0.5 -or- 1.1385 1.0385e0.5 -or- 1.1385*1.019 or a CF of 1.16

Let’s test it: If my numbers are not far off I should be able to bring the uncorrected HP back to where the Correct chart shows the power to be for 3640 ft elevation (130 hp)

112 * 1.16 = 129.92 I think we can say 0.08 hp resolution is pretty good guessing on conditions. Now if everything Blake says is true the next correction factors we develop with our formula will also bring the corrected HP back to 130. After all the goal is repeatable HP numbers and as Blake has put it a 130 hp bike run under conditions that warrant a 1.30 CF will show 100 hp and when the 1.30 is applied we will have out 130 hp back.

For the next Uncorrected Power level let’s look at 7800ft.

He we have a drop in pressure equal to 29.92 – 7.8 in Hg due to elevation. Or a Bo of 22.12 Hg. Also consider that temp drops a little more than 3.6 degrees per 1000 ft elevation. 7800 ft –3640 ft = 4160 ft or a delta of –14.98 deg F. Thus we can solve for our equation with

29.92/22.12 * (525/520)e0.5 –or- 1.3526* 1.009e05 –or- 1.3526 * 1.0047961

Thus we get a CF of 1.36

We see Dynojet got an uncorrected power level of 92 hp. Multiplied by the CF we get 125.03

I know some folks will disagree with me but I don’t believe 125 = 130. Think that there is a ‘Terrible Flaw’ in my assumptions? Look at what Dynojet shows for the corrected value in the lower chart. Surprise! 125 hp!!!!!!

Looks like a 130 hp bike run under conditions that warrant a 1.36 CF will not return to 130 hp.

Still need more convincing that there is some wild and crazy agenda here? Let’s check 10800 ft. Remember these are uncorrected numbers from an EFI mass air bike. It is compensating for pumping losses better than a carbureted bike would do.

Applying the same logic as above 10800 ft would have a correct baro pressure of 29.92 – 10.80 Hg or 19.12 Hg Likewise we could reasonably expect another 3.6 deg F drop in temp per 1000 ft of elevation above out 7800 ft mark. We’ll make the numbers easy this time and just use 10 deg for a delta (instaed of 10.8).

Thus we have:

29.92/19.12*(515/520)e0.5 –or- 1.55*0.9951 = a CF or 1.54

80 hp * 1.54 = 123.2 Notice a pattern here? 123.2 is not equal 130 either. As the CF gets larger more and more error is introduced. Perhaps I’m making this up. Hey, don’t take my word for it, check the corrected dyno chart. Alas we see that even Dynojet only corrected back to 122.5 to 123. This is good, as it demonstrates my temp pressure and baro assumptions are pretty close (I have to admit, I’ve done correction factors once or twice before).

Now let’s apply my admittedly crude reversal factor. We know we should expect a hot rodded ZX11 to make 134 to 139 hp. Can we get there? For correction factors larger than what the SAE prefers (5% on the old 1990 standard and 7% on the latest) I’ve found the following trick works well. It is best at 20% to 30% but we’ll see how it works at these values.

Our first example uses a CF 1.16 and gets close to 130 hp. But we don’t have a sea-level power chart to compare with. Let’s see what we get. I say 1.16 should be more like a 16% loss in original power. Thus we solve for the original numbers:

X HP-16% = Uncorrected Hp –or- X HP *0.84 = 112 -or- X HP = 112 / 0.84 or 133.33 hp. 133 and change is close to my 136 to 144 number if slightly on the low side of what I would expect at sea level.

Solving for 7800 ft yields:

X- HP – 36% = Uncorrected Hp –or- X HP *0.64 = 92 -or- X HP = 92 / 0.64 or 143.75

OK, now we are on the upper end of what I would expect at sea level, but not out of the range of the highest number I have read (I heard 150 was expected, but do not think it was achieved).

Solving for 10800 we get:

X- HP – 54% = Uncorrected Hp –or- X HP *0.46 = 80 -or- X HP = 80 / 0.46 or 173.75

Clearly this does not work. However since the SAE does not suggest using numbers beyond 7% to begin with, I’m not too discouraged that a 54% multiplier does not correct back so well.

This can all be repeated with the newer standards of 77 deg F, 29.23 in Hg and 1% Humidity and you will get the same results as shown on

http://www.geocities.com/hellfireperformance/dynosourcepage3.jpg The numbers never correct back to the same peak value. Yes, Mechanical efficiency assumptions are not perfect at peak torque, but what even DJ fails to reveal in their newsletter is that the 85% ME is only meant to be used at peak torque. It can be lower (less efficient at low rpm as the engine struggles to pump fluids, it rise and become more efficient as revs rise towards peak torque and then drop again as the engine struggles against incredible pumping and sealing losses. The other thing they don’t talk about is the slight temperature mistake in one version of software. As the temp rises, the CF should rise and it does, up to a point, however it takes a nosedive and then comes back up again. Oops! I bet they thought nobody found that. Slight code error on their part converting Deg F to Deg C. They also throw in a small inertial factor unrelated to the drum in an effort to, what I believe is, to make the numbers more pleasing to owners of bikes being tested.

Getting back to M1s XB

As I said earlier:

You were really making something like 62.88 hp at the wheel (62.88 *1.32 = 83). We know that this is wrong so if we tinker with the numbers a little and say (X hp * 0.68 = 62.88) you would probably be closer to making 92.5 hp at sea level. Could this be far off? Perhaps but let’s compare it to others that we know: Cycle World recently tested an XB12 at 89 hp and previously dyno tested one at 94 hp.

Based on the above, I cannot see how anyone can view the charts, do the math and walk away convinced that a high CF is either reliable or reasonable.

As Blake stated:

The correct mathematical relation for determining the corrected HP is...

SAE HP = CF * Actual Measured HP

Agreed? I hope so. Thus we can solve for the measure HP as follows...

Actual Measured HP = SAE HP / CF

Therefore the correct values for your example would be...

Actual Measured HP = 130 HP / 1.3 = 100 HP (not 91 HP)

Well Let’s see, rather than just using text, let’s use numbers:

SAE HP = CF * Actual Measured HP

We saw 130 as our best measured HP on the ZX so then 130 = 1.54 * 80, but 130 does not equal 123.

Sure we can say NO, No, No it’s the 122.5 that is the SAE HP….Sure any one with a 6th grade education could look at the numbers and say 123 (SAE HP) = 1.54 (CF)* (80 AHP)

The problem is to be convinced that Actual Measured HP = SAE HP / CF is always going to yield the same number is to ignore the results from actual testing.

One CANNOT say actual measured power is equal to SAE Corrected Power/CF. That is a dangerous assumption. If the corrected power one is speaking of, is measured at sea level, you cannot ever assume simply dividing the value by the CF used at elevation will yield the elevation’s uncorrected power. Likewise you cannot expect to multiply an uncorrected number at elevation by a CF and expect that will translate back to the same value as sea level.

I’ve shown you with the math. As someone said,' Math don't lie'. |

Blake

| | Posted on Monday, July 18, 2005 - 02:12 am: |

|

Craig, the erroneous assumption/math with which I took issue was your contention that a 30% gain via CF to uncorrected power should then be equal to a 30% loss to corrected HP. Which of course is absurd, yes even to someone with a 6th grade education. 30% of 100 will never equal 30% of 130. But that is what you were contending. At least that is how I read it.

You were contending that 100 HP + 30% should equal 130HP - 30% and that since it did not that the dynojet CF scheme was inaccurate. Wrong.

It was your assumption and your math that were inaccurate.

As to your post above, you broach an entirely new issue, that correction factors applied based solely on a change in atmospherics will lead to errors in reported uncorrected HP, errors attributable to the fact that power lost to parasitic factors is left unaccounted for by a rear wheel dynomometer's raw results. But Craig, please read the article again. Dynojet and SAE do indeed account for that very issue. The Dynojet man even did the testing and provided the very results in the report that show how well they do address that issue. Since 1990 the SAE correction factor has assumed a 15% parasitic loss for rear wheel dynomometers. The variance in the dynojet test results is well within the normal spread of data for dyno testing and is easily attributable to other factors such as the effect of cooler temperatures on engine oil parasitic losses, cooler lubricant in the dyno bearings themselves, etc.

Dynojet results do indeed include a correction for the error you are now talking about.

To be clear, your original math error and bad assumption had nothing to do with the issue you are now addressing. At least not the way I read it.

And to be clear, one can ALWAYS say that actual measured power is equal to corrected power/CF at a particular site for a particular dyno pull, always. That is the governing equation. Period.

The dyno measures the power and applies a correction factor. It is that simple. For any particular dyno pull, uncorrected HP is always equal to corrected/CF. Always.

You say you've shown me the math. A variance illustrated by unreasonably extreme circumstances, testing a motorcycle on a trailer dyno at 10,000 ft above sea lever. But the variance in the result was NEGLIGIBLE!!! Around a mere +/- 2%!!!

Why only a +/- 2% variance even when testing at 10,000 FT above sea level? Answer... The dynojet SAE CF includes provisions to account for the effect of imperfect engine and drivetrain mechanical efficiency (parasitic losses), so the issue you are worried about is in fact negligible. Read the article.

As stated in the article to which you provided a hyperlink and which I commended, since 1990 Dynojet's SAE CF includes provisions to account for the variance introduced by different CFs due to parasitic HP losses. Apparently they assume a 15% parasitic power loss (85% mechanical efficiency) and only apply the CF to the remaining HP that makes it to the rear wheel thus eliminating most of the error you are now claiming prevents valid dyno testing results for Cf's of 1.3 or more. What Dynojet does to account for the effect of CF and parasitic losses (engine and drivetrain mechanical efficiency); that is the exact appropriate thing to do.

Did you read that article???? Suggest you read it again.

(Message edited by blake on July 18, 2005) |

Blake

| | Posted on Monday, July 18, 2005 - 02:27 am: |

|

Is the following "just text" to you?

130/1.3 = 100 (not 91 which was the erroneous result of your erroneous math instigated by a bad assumption)

Try repeating it... 130/1.3=100 (not 91)

Please do not continue trying to convince BadweBrs that Dynojet corrected results are inaccurate for high correction factors. If you insist on trying to tell people here that Dynojet tests with a Dynojet SAE CF of 1.3 or more are not accurate, I'll be forced to delete your posts, on account of they would be egregiously inaccurate and misleading.

The truth is that a Dynojet reported corrected HP result is EXTREMELY accurate and should under similar testing regimes (tire pressure, engine temperature, weight on rear axle, etc) very closely replicate dynojet testing results anywhere in the country for any other correction factor. Period.

What you have failed to grasp is that the error factor you are now preaching about has been very well considered by the folks at Dynojet who have indeed accounted for it well in their correction factors.

I'm done. |

Craigster

| | Posted on Monday, July 18, 2005 - 12:50 pm: |

|

Please do not continue trying to convince BadweBrs that Dynojet corrected results are inaccurate for high correction factors. If you insist on trying to tell people here that Dynojet tests with a Dynojet SAE CF of 1.3 or more are not accurate, I'll be forced to delete your posts, on account of they would be egregiously inaccurate and misleading.

The truth is that a Dynojet reported corrected HP result is EXTREMELY accurate and should under similar testing regimes (tire pressure, engine temperature, weight on rear axle, etc) very closely replicate dynojet testing results anywhere in the country for any other correction factor. Period.

I'm not saying Dynojet's results using 1.30 or greater would be inaccurate. I'm saying everyone’s' results beyond 1.07 (0r 0.93) would be inaccurate. You do not believe this to be true. Please let the SAE know. I'm sure they would like to be able to open their accepted window beyond 7%. Once they hear BLAKE said so, I'm sure they will bow to your superior wisdom.

If you feel the need to delete my posts based on what you feel are inaccuracies, please do so. I hope you also delete your own inaccuracies, such as suggesting that testing in higher gear on Buell, results in higher power readings because it is easier to accelerate a mass once it is moving (I challenge you to find any physics text that shows moment of inertia for an object changing based on angular velocity of that object....that one was too funny). Clearly you have not designed such a unit or you would know that is not true. You would think to look at transmission gear interface counts and how many gear interchanges are increased or reduced. But alas, I bow to your superior knowledge. I guess M1's XB is defective, since even with mods his bike is down 10hp compared to others that are stock when using the SAE CF at (1.30+).

Or you could read the article and understand that the greater the CF the greater the error there is. I have observed this and tried to come up with a 'fix' for it. You believe there can be no problem with the CF even when faced with proof in testing from a third party. It is unfortunate that you see this as an attack on you (funny that you can post in any tone you wish and you are being 'blunt'....if I reply in similar fashion I'm 'fighting' or 'getting my feelings hurt'.) Why can’t you just keep your feelings in check and have a discussion instead of viewing opposition as a personal attack?

Your talents for creating and operating a website far exceed mine, but your talent for arguing against known facts with out data to support your view is simply unbelievable.

Don't worry Blake I won't post technical thoughts or results here anymore. Clearly you cannot see beyond your own need to be correct even when documents clearly displaying the inaccuracies of correction factors abound. I will not 'try to convince BadweBrs' with my thoughts as insight into engine testing, as it appears this should only be done if it agrees with Blake's thoughts. And that's too bad;I was begining to believe the technical talent on the web (as far as Buell is concerned) had shifted over to this site. |

Opto

| | Posted on Tuesday, July 19, 2005 - 07:37 am: |

|

Craig,

You just got to leave him alone for awhile and he'll come good. Nice presence you have. I drift away and then drift back again, the Buell and the engine draws me back...

Keep up your good work, both of you,

Ian. |

Craigster

| | Posted on Tuesday, July 19, 2005 - 08:11 am: |

|

As always, the man of reason.

Why is it you are always so level headed? |

Blake

| | Posted on Tuesday, July 19, 2005 - 10:13 am: |

|

Craig,

Sorry to see you become combative. You were wrong, you are wrong, and now you are wrong about the reduced drivetrain inertial power losses in a 5th gear dyno run compared to a lower gear dyno run. It is simply physics. If you take longer to deliver the same amount of energy you use less power. If you take longer to spin up the engine and especially its flywheel, the engine expends less power doing so. Simple physics.

Read your geocities link article again. Since 1990, SAE and thus Dynojet have accounted for the very error you are going on about. Read the article. You are wrong now on three counts.

1. 130/1.31=100 not 91

2. Current Dynojet/SAR correction factors account well for the effects of engine/drivetrain mechanical efficiencies versus varying CF's. That geocities linked article explains it well, if you bother to read it all, not just the first page.

3. On an inertial dyno an engine requires a longer time interval to reach its rev limit during a 5th gear pull than during a pull in a lower gear. Whenever an engine spins to its rev limit it is storing a significant amount of energy in its flywheel and other rotating componentry. No matter how long it takes to get there, once an engine has reached its rev limit it has stored an exact repeatable amount of energy in it rotating components, mainly the flywheel and crankshaft.

It should be clear that it take more power to spin up the engine's flywheel more quickly, exactly like it takes more power to spin up an inertial dynomometer's drum more quickly. An engine thus expends less power (power=energy/time interval) spinning up its own flywheel when in a higher gear dyno pull. Thus more power makes its way to the rear wheel instead of being used to more quickly store energy to the engine's flywheel. Thus with all else being equal, a higher gear dyno pull on an inertial dyno will indeed show more power at the rear wheel for higher gear pulls. Simple physics.

On our Buells the fact that 5th gear avoids power transfer via the transmission countershaft also improves rear wheel power output.

However, a 4th gear pull on an inertial dyno will show more power reaching the rear wheel than any pull for a lower gear. This physical truth is evident in any dyno plot that shows a run through all the gears to near redline.

Believe me Craig, it's not that I have to be right all the time. God knows that is not the case. I've been wrong plenty. My concern here is simply advising anyone who reads your posts that they are not accurate and in fact highly misleading. I've tried to take the time to thoughtfully show you your mistakes. I probably could have been more thoughtful. But right out of the box you took a combative stance. Sorry to see that. I'm a fairly blunt spoken man. Fragile egos don't always do well in a technical discussion with me.

The search for the truth should not be a battle but a cooperative/collaberative effort. Sorry for offending you.

Maybe you don't know my personal background. I don't like to hold it up as any kind of justification for my points in a technical discussion, but maybe it will help convince you that I am not full of crap. My professional life for the last twenty years has been comprised largely by intense engineering analysis, both mechanical and structural, lots and lots of rigorous painstaking analysis teh results and determinations of which are relied upon to verify the integrity of aircraft and satellite communications systems. I have a bachelor's degree in Mechanical Engineering along with 18 hours of graduate school and am intimately familiar with all the principles in play in our discussion.

So there it is. I'm not interested in personal attacks or anything of the kind. I'm interested in the honest truth.

Opto,

Please clarify. Are you suggesting that Craigs assertions are accurate and mine are not? |

Craigster

| | Posted on Tuesday, July 19, 2005 - 12:53 pm: |

|

Blake,

Your credentials are very impressive. However I would suggest you design and test a few dynamometers under controlled conditions before believing all your own statements above.

I used to work here.

http://www.land-and-sea.com

I learned a lot more about errors in CF than one could care to imagine. I also learned what errors exist in compettitors software (false compensations)!

I now design much lower tech things:

http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO2&Sect2=HITOFF&u=/netahtml/se arch-adv.htm&r=1&p=1&f=G&l=50&d=ptxt&S1=walker-craig.INZZ.&OS=in/walker-craig&RS =IN/walker-craig

Fun none the less. I was woo'ed back to Ion Implantation mostly for the money, but some days are fun here too. Although I don't get paid to wring engine's within in inch of their life anymore. |

Craigster

| | Posted on Tuesday, July 19, 2005 - 12:59 pm: |

|

This shouldn't be contest of the size of one's member.

You read the data one way. I read it another. You do not believe my point of view. You have threatened to remove my postings. So be it.

If you believe that would promote the truth that is your prerogative. My feelings are not hurt, after all this is just an internet bulletin board, right? There are far more important things in life..... |

Blake

| | Posted on Tuesday, July 19, 2005 - 01:34 pm: |

|

The fact that 130/1.3=100 not 91 is not a point of view. It is exceedingly simple raw irrefutable fact.

That you missed the fact that the current dynojet SAE correction factors do indeed account for effects of mechanical efficiency of the engine and drivetrain is not a point of view, it is fact.

That higher gear runs on an inertial dynomometer do not suffer as much parasitic HP loss to the spinning up of the engine is not a point of view, it is fact.

I'm not at all interested in being right all the time or engaging in a big dick contest.

I'm interested in the truth and the avoidance of spreading false or inaccurate information.

I suggest you read the very article you referenced. Read it past page one this time.

Nope, dyno testing and correction factors are not perfect, they have limited accuracies. But they are proven reliable (see your referenced article) and in no way suffer anywhere near the problematic inaccuracies that you have alleged.

Variances in operator technique and the physical state of the motorcycle account for a LOT more variance/error in dyno testing results than anything related to CF. |

Kds1

| | Posted on Tuesday, July 19, 2005 - 02:20 pm: |

|

Well I guess that was a good way to hi-jack another Drummer thread.....gotta call Mike and tell him to send out some e-mails to some guys on the bad web....just kidding....

Kevin

www.kdfab.com |

Blake

| | Posted on Tuesday, July 19, 2005 - 02:29 pm: |

|

What is this "Drummer" of which you speak? Please tell us more. |

M1combat

| | Posted on Tuesday, July 19, 2005 - 02:34 pm: |

|

It's that exhaust pipe that helps to pay the Badweb bills and makes EXCELLENT power all the way across the range  . .

I think someone did a bit of a review on it a while back... Lemme see if I can find it... |

M1combat

| | Posted on Tuesday, July 19, 2005 - 02:37 pm: |

|

Here it is...

Alrighty then... Here are the results...

Driving the pipes...

When I'm leaving a light at a fairly standard pace with the Force pipe I really feel that there's a large hole in the power below 3K RPM. About the time I fully release the clutch I'm at about 2200-2500. Just as I fully release the lever I get a hole in the power. The best way I can explain it is to people who have fired semi-automatic weapons (especially when they are new to it)... You get a dud or have had someone else place a snap cap somewhere in your magazine and sometimes you anticipate the shot and push the pistol forward just as you expect it to go off... This is the way the Force feels when leaving a light. I've literally leaned forward in anticipation of the acceleration and it surprised me that it didn't "go off"...

With the Drummer this just plain doesn't happen (keep in mind I'm still just talking about launch...). I can keep the RPM's at 1500 until I fully let out the clutch and there's no feeling of a lack of power at all (the opposite quite frankly). I can launch and by the time the lever is released it's just plain moving.

After launch, once the Force gets to 3K it really comes on... IT's VERY noticeable how the power builds from 2800-3400. From there it's hard to quantify a difference... We're talking a couple/few HP between the two pipes for the rest of the range (more on that later). With the Drummer, it just makes power from Idle all the way up and doesn't have any "peaks" at all. Smooth and VERY driveable at low RPM's at an apex and coming out. Coming out with a Force you can tell that it doesn't deliver power as smoothly. There is a little more once you get past 3K, but it's the delivery around 3K that catches me out with the Force. If I keep it above 3K... More on that later : ).

Once I'm out with the Drummer and I'm really back to WOT and just looking for the proper entry into the next turn everything just "seems" easier (probably because I haven't just gone through that 3K RPM hit and it's not on my mind or in my suspension). With the Force (after the bottom end), it makes good power until about 4500 or so compared to the Drummer, but then it seems like it starts to wheeze a bit (which for the life of me I can't explain seems how it's basically a damn drag pipe...). There's really no wheezing involved with the Drummer. Once you've used the greater power coming out and you're going through the midrange it feels just like the Force for all intents and purposes but it never starts to wheeze... It just keeps building more power the more you twist it up... very linear (it reminds me of the stock setup, but just a level or two above...).

On the freeway... The Force will pull away from the Drummer if you start about 60, but the Drummer will pull away if you start from about 80... IMO it's kind of a wash there... If you're dragging from 60 you should be dropping a gear anyway.

Roll-on's aside... The drummer makes it to 130 from about 60 in fifth gear a good deal quicker than the Force (which baffles me because, again, the Force pipe is essentially a drag pipe...). Both certainly get there with authority, but you can feel that the Drummer certainly pulls harder once you hit 100 and beyond. Of note... I was doing the high speed testing on I40 at about 6-7000' elevation (just west of Flagstaff for those of you in AZ).

Where DO they work?

Well, the launching from a light thing is done pretty regularly on a street bike. This "pretty much" kills the Force for street use. The saving grace of the Force is that I've become addicted to the EXCEEDINGLY INSANE AND WAY TOO LOUD SOUNDS that it makes. I've heard the Drummer, Loud Drummer, D&D, Jardine and the Force. The Force is a LOT louder than any of those. A LOT louder. I can't stress that enough. It's a LOT louder. A LOT. {There... Was that enough stress? It's a LOT louder} That's the only saving grace really... I do indeed like the loudness. My neighbors on the other hand, do not like it. They haven't said anything to me so far, but I'm sure that's only because I putt home and coast everywhere I can in my neighborhood... I know it pisses off dogs from 1/2 mile away.

The Drummer sounds nice and deep (you should have heard it in the Dyno room). It's a very nice sound and it's certainly loud, but not earsplittingly loud like the Force. It'll still prompt cagers to roll up their windows if I pass them with the throttle on, but with the Force, I just have to be somewhere near them and they roll their windows up... Even at idle.

So basically, the Force doesn't work extremely well on the street unless you're willing to work your clutch to keep a launch above 3K AND you really like it LOUD.

The Drummer works off idle, more than respectably enough through the middle, and it's got more on top. If I sit there and imagine myself right next to myself while leaving a light, I'll bet that I could put 6' between me and the Force in that time just after I've fully released the clutch and I'm waiting for the power to come on. The Force then makes a little more power in the middle but I don't think it would catch up by the time I got to the upper end there the Drummer makes more.

This is where it get's sticky...

I generally switch gears around 5K-5300 when I'm having fun... I don't see any reason to rev the balls off my bike when I have all that power down low anyway (you'll see this in the fact that my Dyno's only go to 6K... I didn't see any reason to bounce it because I don't do that to it anyway...). This drops the revs down to where the Force is making a little more power. It's noticeable while letting out the clutch, but about that time the Drummer takes over again...

If I'm just meandering through the twisties, having some fun but not really hauling •••, the Force does offer a few more HP (basically through about 1500 RPM's of the mid-range), but IMO, it's not worth the loss of power below 3K.

Anyway... Here's the sheet : )...

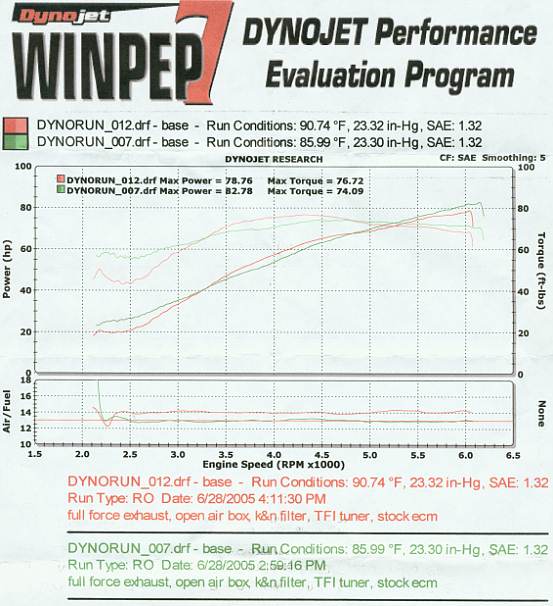

The red is the Force, The green is the Drummer. These lines were made on the same day about an hour apart. As you can see, the ambient temp was about five degrees warmer for the Force runs because it was a little later in the day. Both pipes spent an hour on the dyno. I think their dyno is a bit "sad" so pay no attention to the overall number (I didn't run it to the limiter anyway...). A race kitted 12 was run the same day (just after my bike) and it didn't do quite as well, so I think the dyno is just a little (or a lot) sad. You can see that the Drummer hit 86 at 6150, and the kitted 12 hit 86 at the limiter. I think I'm doin' pretty good with the Drummer ; ).

Don't mind the list of mods... The Dyno tech used my list of mods for the last time I had my bike on his Dyno (which was a few months ago).

The mod list is...

Chopped up airbox (I only left the filter cover)

K&N Filter (not de-oiled or anything stupid like that...)

Yanked Snorkel

Power Commander

Norris Performance Catch Can (Breather tubes re-routed so they don't spew into the filter)

Metzeler Sportec M1's.

EBC HH pads on the front

ZG Double bubble (I'm sure that's worth a couple HP...)

CRG "Shorty" gold clutch lever

Mobil-1 20W-50 in the cases

Mobil-1 75W-90 in the primary

Force header for BOTH runs

/EDIT - RACE ECM

Green = Drummer Muffler

Red = Force "Muffler" (It doesn't muffle a DAMN thing...)

|

Hogs

| | Posted on Tuesday, July 19, 2005 - 03:12 pm: |

|

Hmmm, Wonder if ya can answer this for me Blake , or anyone for that matter was at a dyno ( metric ) bike shop and they were doing runs all day and only going to third gear whats with that?? The highest I seen that day was 192 horse power out of a zx12 done up??

Also All what you say about the force don`t seem to be like that in my case M1, I have no hesitation whatsoever with my Force it hauls as soon as I get on it... I am running the force can on the stock 12 header though , I have the force Header but with all I heard about it on here, I thought i wd. try it with the stock 12 header Lazy me and Wow its been on there I guess a month or so now and it Just well couldn`t work better in my books,roll ups in first and when I hit 2nd Up she comes as well No hole here..!MAybe the force header is POISON ??? |

M1combat

| | Posted on Tuesday, July 19, 2005 - 03:24 pm: |

|

What RPM hogs?

There's no problem at all after about 3K... It's just that the Force combo makes no power at 2500. It's not really a "hesitation" exactly either... It's just a plain old lack of power. The throttle response itself is fine, there's just no power down low.

Of note though, I am going to pick up a stock header and swap it out. I'll probably only tune it with the Drummer though. I've had enough with futzing with the under-engineered piece of crap they call the Force muffler, and I don't like the color of the header at all...

It runs VERY well with the Drummer and the Force header though... |

Hogs

| | Posted on Tuesday, July 19, 2005 - 09:11 pm: |

|

M1, It hauls from any rpm, no hole as you speak of, But like I said It may be due to the force header that you and others are having plms. with , all I can say on the stock 12 header when I hit it from a light it just takes off hard to keep the wheel down.. |

Blake

| | Posted on Tuesday, July 19, 2005 - 09:36 pm: |

|

Hogs,

Some dyno operators are shy about exceeding even 120 mph at the rear wheel. A shredding tire at that speed on a dyno, or even a failed chain can cause some serious damage. It is a valid concern. Higher gear pulls also take more time... gotta work through the gears and the WOT run takes longer too.

Higher gear runs also put a lot more wear and tear on the dyno itself and its brake.

For tuning a bike there is absolutely no need to pull in a high gear. However, if you are trying to demonstrate the absolute peak RWHP on an inertial dyno, you'll get better results in top gear.

Did that answer your question? |

Hogs

| | Posted on Tuesday, July 19, 2005 - 09:54 pm: |

|

Hey Blake ,

Thanks pal , yes it did :-) |

Hogs

| | Posted on Wednesday, July 20, 2005 - 08:40 am: |

|

M1,

I wonder IF that force header is No GooD for the 12, being smaller diameter, step etc.etc. All I can say is that With the Stock 12 header on my 12r The force rocks, hit it and away ya go power is Strong, I do think that the Race can seems to haul better than anything I have tried yet, over say 5000 rpms or so.. ( Drummer, Latus,Force...And as far as sound Goes I don`t think you stressed the Loudest of the Force when ya get on it, Its LOUDDDDDDdddddddddddddd And I`m a happy camper there..Nothing comes close to the Force in Sound PERIOD LoL |

Kds1

| | Posted on Wednesday, July 20, 2005 - 08:53 am: |

|

Hogs,

The Drummer you used, and I'm sure it was not the new design that I just finished recently, and i'm sure if you tried the new one you would definitely know the difference without a doubt, not asking you to get one (just to clear that up) but if there was no difference I wouldn't and others that are using it would not speak highly of it to start with....I personally would love to see the curve that your bike has on paper with that stock header, I know you don't care what a dyno says, but it's the only thing we have to demonstrate a power curve that we can see with our eyes....please don't take this post as being harsh, I mean none of that at all, but I personally love to see other people's dyno runs cause it tells me what I need to do....

Kevin

www.kdfab.com |

Hogs

| | Posted on Wednesday, July 20, 2005 - 09:15 am: |

|

Hey Kevin,

Whats up pal... You are right it was your first series of drummers I wd. say as Ted, an old Bad member here that had put his xb9 down from North Cariolina, Which I bought from him for my son smashed abit, LoL you are right to say to me about the Dynos ,Winos LoL Too many things to effect their readings,I`m sure there are ppl. out there that know there stuff when it comes to them but I`m sure there are MORE that don`t just my pennies worth, And I`m SURE you are not doing the research , and MArketing of a product here that does not do WHAT you are saying :-)I just think that this Force header can NOT be Made to work on a xb9 and xb12 the same,My Force hauls from the time I hit it and on...with the stock 12 header No plms. at all..Never had your new unit and I`m sure If I did it would as well .... all the best! |

Jerseyguy

| | Posted on Wednesday, July 20, 2005 - 09:53 am: |

|

Hogs - Wait 'till you see the new Drummer SS.... You will want one for your collection! |

|