| Author | Message | ||

Wylie_coyote |

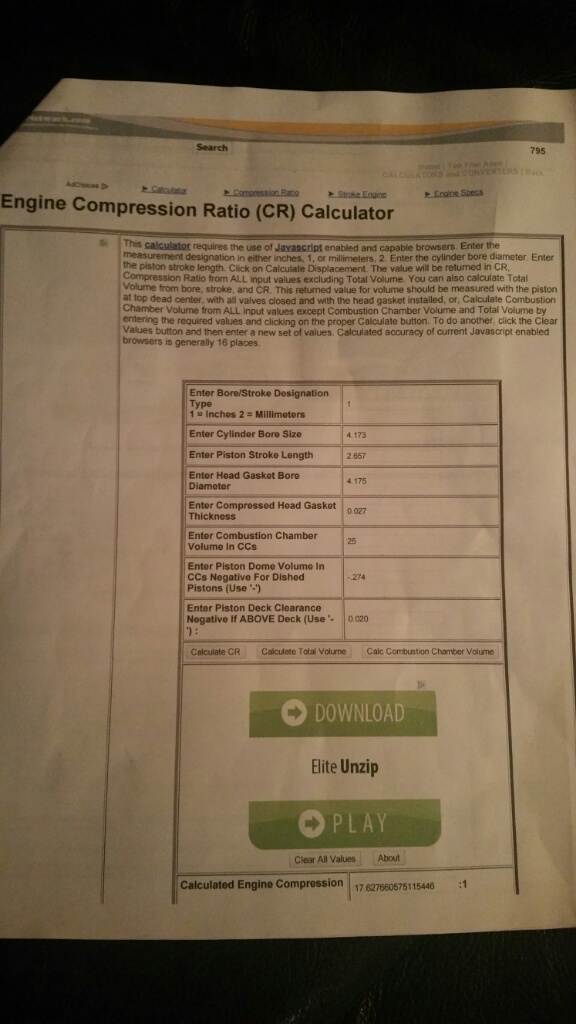

Hi, I really need some guidance. A broken motor mount forced me to drop the engine and I decided to have the ebr 1190 kit installed. New clutch, gaskets also installed. Upon firing it up for the first time everything is going well when suddenly the top of the clutch cover starts spraying milky looking fluid. Turns out it's oil and coolant. Boo The hd mechanic that did the install tells me it's a 17.6 to 1 compression ratio and gives me the worksheet. I call bs, it simply wouldn't run I think, so that's why I tried to fire it. Now before I head back into hd and try my best to not go postal, I want to make sure it isn't something I've done. I replaced the water pump gasket and both clutch cover gaskets along with a Barnett clutch. Pics attached | ||

Wylie_coyote |

Pictures  | ||

Wylie_coyote |

Leak  | ||

Wylie_coyote |

Puddle  | ||

Stevel |

Your thread makes no sense to me. First, I can't read the entered numbers on the worksheet. Second, where did your head and piston volume numbers come from? The formula to calculate CR is total volume divided by swept volume. Total volume is bore area x stroke, plus head volume, plus piston volume, plus compressed gasket volume, plus or minus piston to deck clearance at TDC. Unswept volume is head volume, plus piston volume, plus gasket volume, plus or minus piston to deck volume at TDC. Bore = 106mm Stroke = 67mm Swept volume = 591.258cc Head Vol = 25cc Piston vol = 27cc? Gasket vol (compressed) = 8cc Unswept vol = 60cc (Note, I assumed 0.0 deck height) Total vol = 591.258, +60 or 655.258cc CR = 655.258 / 60 = 10.8543 to 1 I personally do not believe 27cc is correct for piston head volume. I'm thinking 23cc is closer. (Stock 1125 piston is 15cc) So in summary, some gasket is leaking somewhere and it is not a design issue. The CR is not the cause. Only disassembly will reveal the fault. The EBR folks could never sell a bore kit with 17+ to 1 CR. It is unreasonable. Of course you should also realize that the mechanical CR has no bearing on reality. Real compression does not start until the intake valve closes. On the 1125 the intake closes 60 degrees ABDC. This puts the effective CR at just over 8.5 to one. Have you never asked yourself why you can run the lowest octane pump fuel and not experience detonation (pinging)? | ||

Stevel |

Going back to your first post, why would you go postal? Why would you assume the fault ownership belongs to HD? My point is simple, there can be no argument who pays for the repair cost until all facts are known. To eliminate finger pointing, make sure both the original mechanic and you are present at the disassembly. | ||

Wylie_coyote |

Good point Stevel. I've had some problems already with the local dealer. When the mechanic told me it was a 17.6 to 1 I already knew there were going to be issues. I only brought them the engine already out of the bike. Since I've gotten it back I discovered the throttle bodies were on backwards, my rear valve cover has two stripped bolts and it's mixing coolant with oil. They promised my engine back in 3 days and ended up having it over 2 weeks. Now I'm going to probably end up missing the dragon event and have a fubar 1190 install on a bike I have completely rebuilt from the ground up. The only thing I didn't do myself was install the ebr kit. Now I have a lawn ornament. Going postal is never a good idea, however turning my bike into a paper weight.....well its kinda ruffling my feathers, you know! | ||

Rodrob |

There is a specific head bolt/nut tightening sequence that could lead to head gasket failure if not followed. The only other place I can think of where the coolant would mix with the oil, short of something cracked, is the main case gasket up by the engine mount between the cylinders. Throttle bodies on backwards? How is that even possible? If it were me, I would take it apart with a third party witness present and photo document everything. Sorry for your loss. | ||

Wylie_coyote |

The main case gasket near the left side motor mount that I just had welded back together? The heat from the welder perhaps has fried the gasket? | ||

Wylie_coyote |

And this is why these forums absolutely rock. It never even crossed my mind that having the left middle motor mount Crack welded could have fried the gasket. I guess I'll have to wait and see..... thank you all for your help! I truly appreciate it | ||

Stevel |

The main case gasket near the left side motor mount that I just had welded back together? The heat from the welder perhaps has fried the gasket? Aha We don't know the whole story! You welded on the motor when it was assembled? I think gaskets are the least of your problems. Welding causes severe heat distortion on aluminum. Normally this can only be done when disassembled where the heat distortion might be somewhat controlled. It is entirely possible that re-machining or item replacement may be in order. | ||

Rodrob |

There is a coolant channel that runs right underneath the engine mount between the cylinders. Two long M6 bolts hold the case together at that point. A Triangle shaped metal gasket (part of the main crankcase gasket) seals it. If that is where you had the crack, welding might cause enough distortion that it might never seal, or a hairline crack into that chanel might not show up until it was under stress. Sorry. It sucks. What year is the motor? oops - just say Stevel's post after posting this. So I confirm his opinion on the weld. (Message edited by rodrob on April 05, 2015) | ||

Wylie_coyote |

It's an 09. The mount is what caused all of this, it's why I dropped the engine. I talked to the welder and mechanic about this and that's why we did the BBK install after in case too much heat got to the cylinder. I know he took precautions to minimize the heat risk. It's still possible it's the head gasket which at this point I'm actually hoping for! The dragon trip at the end of April sure isn't looking very promising | ||

Rodrob |

Well, at least it should be obvious if that is where it's coming from. Pull the airbox. | ||

Wylie_coyote |

As I'm sure you already figured out, I'm not the brightest bulb.... How do I tell? It's mixing inside the engine. Everything looks fine around the mount. I'll post a pic shortly | ||

Rodrob |

Oh sorry, I misunderstood. If it's mixing in the engine, that's more difficult to see. Unfortunately, your going to have to tear it down, unless when you pull the head, it's obviously the head gasket. But I am betting it's not. Sorry. | ||

Wylie_coyote |

Update. Motor is back out of the bike and the rear cylinder base gasket is completely different from front to back and also might be leaking, it could be residual from clutch cover. Which I still can't figure out how it failed. Brand new gasket torqued to spec. Also the stator gasket right next to weld repair is perfectly fine. Starting to lean towards base gasket not tightened to spec....hardly abelson will get to see me Tuesday bright and early!    | ||

Wylie_coyote |

One more less blurry pic. It's hard to see in pics, but very noticeable in person  | ||

Wylie_coyote |

Here is the welded motor mount  | ||

Wylie_coyote |

I'm really not buying the motor mount being the problem. I spoke with my welder who said it's very unlikely that anything internally would have reached even normal operating temperatures in addition being aluminum it disappates heat rapidly so even if it did reach the higher end of the operating temperature it's highly unlikely it heated enough to corrupt anything. I paid good money to have a certified buell mechanic screw up my bike. | ||

Rodrob |

Looking at your weld, I would tend to agree the it is not the source of your problem. So it must be a head or base gasket. Sucks. | ||

Wylie_coyote |

A head gasket or base gasket failure is way better than the block. A certified buell mechanic at the local hd dealer did that work and charged me 6 hours with the motor already removed, took a week longer than promised and botched the installation on a brand new ebr kit. They had best step up to the plate and make this right. Considering the compression ratio mistake, the oil and coolent having a party and now the possibility of additional repairs, they should feel pretty obligated to do something, imho. Hopefully ebr will answer some questions and we'll see what happens when they open Tuesday morning. I'm super nervous at this point to even let them touch the engine again.....any good recommendations for a good mechanic near charleston, sc? | ||

Rodrob |

I have to say that putting cylinders and pistons on a 1125R is a really simple job if your not splitting the cases. Making sure the cam timing is right is the part where you have to be careful. The rest is just nuts and bolts and a snap ring for the piston pin. I'll be interested to see what it ends up being. BTW If I were doing an 1190 kit, I would want to put in APR head studs to replace the stock bolts. But that's just me. | ||

Stevel |

BTW If I were doing an 1190 kit, I would want to put in APR head studs to replace the stock bolts. But that's just me. Me too, but it's ARP.........jus saying. | ||

Wylie_coyote |

Good advice, I was hoping everything stayed intact and had planned on rebuilding the bottom end. Ebr said compression should have been around 13:1 I'm taking it back to hd in the morning, I really don't know about letting them touch it again though......total pita! | ||

Mustang0 |

I'm a fully certified welder by trade and IMHO that weld looks good and doesn't appear that it would have caused a temperature issue with the rest of the engine case, the heat should have been localized in this case. that being said with out knowing the temper of the original alloy it's possible that some strength was removed with the heating that was done from the welding process. I agree that there appears to be a problem with how that base gasket was tightened. Definitly looks crooked. I will be interested in the out come. Hope everything works out and you can enjoy that trip. By the way are you planning on dynoing the new engine to see what it puts out? | ||

Rodrob |

APR - dyslexia strike again!  | ||

Wylie_coyote |

Tomorrow morning we shall see. I've already devised plan b and ordered new head and base gaskets from ebr and if hd punks I'll do it my damn self, flush the bejeuses out of the cases and fire it off. It only ran for a minute or so and actually sounded pretty damn good. Everyone has really been super cool and I really appreciate the help and guidance. As to the dyno, yes please.... | ||

Zac4mac |

Stevel, Rob.. tell me more about ARP's headbolts. | ||

Wylie_coyote |

Well after having the pleasure of spending the day at the hd dealer I do have some good advice for anyone else having problems with a dealer. Call up hd corporate, attitudes change quick and stuff gets done! EBR has been awesome and have gone way above and beyond. A big thank you also goes out to Dean Adams, he's been a lifesaver. As to the head studs, ebr says don't bother. The oem ones held up to 15.0:1 compression and don't need to be switched out. Hopefully the new gaskets get here quick so we can give it another go..... |