| Author | Message | ||

Spudman1125r |

Just removed the rear wheel on my '08 1125R in preparation for a new tire. The axle came out with no problems whatsoever, but I was somewhat surprised to see absolutely no "wet" (for lack of a better term) lubricant showing anywhere. No grease or anti-sieze or anything like it to even come off on my hands. What I did see was a bunch of dried on and crusty white/silver colored substance that I'm assuming was factory anti-sieze. My question is, what is the best way to clean up the axle before I apply new copper anti-sieze and reinstall the axle? Do I dare use a wire wheel...even if it is very lightly? Emory cloth? Any suggestions are welcome...thanks! | ||

Imonabuss |

Just an FYI, do NOT use antiseize on threads if you are going to torque them to spec. The clamp load will be much higher and you will damage stuff. Sorry if you already know that, but I've seen it happen too often not to comment. | ||

Dannybuell |

Imonabuss - Learn something new everyday. THX! >>Antiseize lubricants can reduce torque required by approximately 20%. << http://mdmetric.com/tech/data1torque.html http://raskcycle.com/techtip/webdoc14.html | ||

Rogue_biker |

I've used anti-seize on the threads of my axles for years. No issues. In nothing else, it makes removing/installing the axles easier. I use WD-40 to wipe clean my axles before fresh anti-seize is applied. | ||

Spudman1125r |

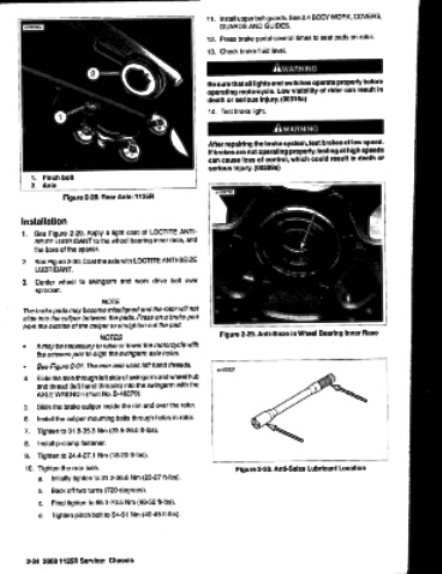

OK guys...I've attached a photo of the actual page in the '08 1125R service manual. Note that it shows in figure 2-30, the "anti-sieze lubricant location". There's no mention of reducing the torque, so can I assume that the Buell torque settings already allow for the anti-sieze? Also, I'm wondering if the anti-sieze is to be put right where the arrows indicate, or on all areas between the two arrows. They do after all use the phrase "coat the axle with Loctite anti-sieze lubricant" in the instructions for reassembly. Nonetheless, the arrow is clearly pointing to an area that contains threads.  | ||

Froggy |

ZOOM! ENHANCE!  | ||

Two_seasons |

Torque is torque. If whatever you are torquing binds before the proper torque is met, then all you are doing is torquing to the binding, not the part. Then, you won't have the correct torque. Anti-sieze is used so the part will not bind prior to finding the proper torque of that part. | ||

Imonabuss |

Anti sieze will dramatically decrease the torque needed for a given clamping load. Standard thread torques are always for clean dry threads. It is absolutely incorrect to assume you can torque to the same level when threads are clean and dry or lightly oiled as to when they are coated with anti-sieze. Torque is a measure of the force needed to turn the bolt. The torque is caused by the friction of the bolt and the female thread as they climb the ramp of the thread and create a clamp load via that ramp. Anti-sieze reduces friction, so you will get a higher axial load on the bolt and threads for a given torque. It is likely the anti-sieze pointed out there is to stop galvanic corrosion between the axle and bearing bores, and not to be used on the threads. You'd need to know for sure or you could strip out the threads in the aluminum, or crush the wheel spacer. Wonder if incorrectly putting anti-seize on threads is side loading the rear whell bearings, leading to bearing failure? Maybe no way to know now that Buell is gone... | ||

Spudman1125r |

Sorry Froggy. My original scan looked exactly like yours. After three consecutive warnings that my file size was too large to upload to this forum, what you see is what you get. LOL How the heck do you get it so clear and yet maintain the 103kb size limit to upload it here? | ||

Jdugger |

The 50lb torque spec for the axle takes into account the use of anti-seize lubricant on the threads. | ||

Zac4mac |

Wet-torque and dry-torque are verrrry different. Manual specs wet-torque. (Message edited by zac4mac on August 14, 2011) | ||

Rogue_biker |

Put Anti-seize on the threads and anywhere it's going to go into contact with the bearings/swingarm. You don't have to apply it like whipped cream! Just put some on your finger and wipe it on the axle. A very thin coat is all you need. If you can see the A.S. coating in raised ripples then there is too much. Spread it around. It won't hurt anything! No need to over-analyze! | ||

Spudman1125r |

Thanks guys. Got the wheel re-mounted just fine last weekend. One other problem that I wasn't expecting though; both of the "click-type" torque wrenches I own do NOT work in reverse! Yup...no clicky for left-hand thread fasteners. So...not wanting to spend hundreds for a digital model, I went old school and borrowed the old style type from a friend. Certainly not as accurate to be sure, but it got the job done. | ||

Poppinsexz |

If I remember correctly you can run a long extension through the axle and torque from the other side. |