| Author | Message | ||

Highscore |

Let me tell you about the latest state of development for my private 1125. I like to begin with some dyno graphs, all taken on the same dyno, with the same bike by the same - hopefully - experienced dyno-operator, by me. Same day, same bike, same dyno:   The base run below shows the power of the stock air box. There is a Remus-pipe installed and the mixture is sorted in pretty nicely. The Remus does not make anything better than other slip on solution here around, which keep that thin stock primary headers, the advantage of the Remus is - therefore I have chosen it - that it offers the performance of a straight thru muffler while keeping the noise in limits. In deed the Remus is in Europe approved for street use. To gather this "label" it even covers catalytic converters. But this is not the place to talk about exhaust, my field here is the intake system of the 1125. The upper graph shows the performance of free breathing stock velocity stacks:  The filter here is a K&N. But even the stock paper filter makes no difference, compared to running with no filter at all above the stacks. This performance is the bench mark for what the 1125 is capable to do. And I guess, +140 WHP is a nice figure to proof this matter. Therefore it looks like, there are 10 Hp hidden and masked by and within the stock air box. To validate this thesis, a put this simple pressure measurement "gauge" onto the stock airbox:   This is a simple tube, attached tightly to the inner air box and routed to a bow in its middle. The bow is filled with water. Since the filter element is due its pretty large surface - no matter of its material - not restrictive at all. this simple arrangement shows precisely the pressure drop, the depression, created by the stock air box: You just have to look, how far the water column inside the tube is lifted up downstream the air box. This test shows, that under full load the 125 pulls up the water inside of the attached tube for 6 cm. Here is has some advantages to live in Europe and to be used to the metric system, because 6 cm of water are nothing else but 6 mbar depression or restriction by the air box. 6 mbar does not sound so dramatic. But when you have done - like me - this testing on real efficient ram air systems, as you find for example on Japanese bikes, you now, that 6 mbar is to much: Power restriction and loss starts above a value of 2-3 mbar, when the reference are absolutely free breathing velocity stacks. Good ram air intake systems show this efficiency For this reason it looks like as the 1125 is lacking air in its stock trim. The easiest thing to bring some more air into the play is to remove the inner air box cover. This opens new surfaces below the outer "cosmetic" cover, where air can enter. So the pressure drop of the intake system - any "shielded" intake has some - should stay within reasonable limits. The outer cover costs here in Austria € 350,--. For this reason i kept it untouched. So I do not know the actual level of restriction. The dyno graph in the middle shows the effect, when running the 1125 without inner cover. The result is not to bad, as I have heard it here in some other threads. Regarding peak torque, the figures come pretty close to the "full open" breathing stacks. This shows that the engine is gathering now sufficient air. But it lacks the nice grunt close to the rev limiter behind 10000 rpm, the range, where not only the stock air box, but also the "open arrangement" makes its best power. This sounds curious. But when you look on the dyno graphs above you may see the explanation: The base run with the stock air box shows a definitely rough pattern up to 6000 rpm. Here up to this range the water column inside of the tube, attached to the air box shows also a strange behavior: It starts fluctuating and rising close to atmospheric level (Sorry I was not able to make a picture of it) This "pressure build up" inside of the air box indicates internal wave action. Unfortunately anything regarding this action, which pushes up the (average) interal air box pressure via "atmosphere", is harmful. The erratic shape of the power graph within this range indicates this trouble, because the A/F-ration here is nit the reason for the phenomenon. On the other hand, this same wave action, which disturbs engine performance up to 6 grand boosts obviously the power production at the very end of the range. Although the numbers with removed inner cover are nit so bad, the engine obviously is shy tho pull strong behind 10000. Air box design is a tricky subject. The volume above the stacks, connected primary to the engine, does not "calm2 anything, it reacts like a resonance volume. This volume may additionally be triggered and tuned by a 2nd resonator like an intake tube into this air box chamber. Now we are at home at a 2-stage-resonator with properties, hard to calculate. Such a resonance chamber acts in some way like a spring, conserving energy by and from the engine´s intake breathing. If thing go "advantageously", this resonance action by the box add to the action inside of the engine`s intake runners to push additionally air into the engine. If this resonance is out of time and order, it sacrifices the charge for the engine. It looks like as in case of the 1125 air box, both phenomenas take place: Up to 6000 the internal wave action inside of the box hurts engine performance, close to the limiter it boosted it. Since I use my 1125 preferably in the mid range, I could live pretty good with that disadvantage behind 10000 by removing the inner air box cover. This mod mobilizes not only substantial grunt in the mid range, it smooths also the power delivery definitely. This mod is a first step to tune the 1125 engine for real torque. For this reason I shall keep this "trick" for my further tuning. | ||

Usanigel |

Have you taken into account the ram air effect from the air intake when riding at speed? | ||

Dannybuell |

Highscore - Your assertions are always interesting and enlightening. I am going to my garage now! THX | ||

Blk09r |

I tried running my bike with out the inner air box cover for a few days and ended up putting it back on. I'm not doubting your dyno results but I don't think it works that well on the road. The one thing I noticed was a large fluctuation in intake air temp that I don't see with the cover on. It would range from 80f to 115f depending on road speed. The higher the speed, the lower the temp. Ambient air temp was around 72f. The bike ran poorly when the system thought the temp was above 100f. I have the race ecm and the bike ran rough below 3500 rpm and had a slight surge from 3500 to 4500. It seemed to be running lean. It will be interesting to see if others have the same experience I had. | ||

Dktechguy112 |

I have run mine without the airbox for a few days, and the main difference i have noticed is the increase in noise, it is louder. Which i like. I don't take the bike up to the top end all the time, and when i'm their i don't mind giving up a little bit for the sound and low end grunt. What some one needs to do is to design a collapsible cover, that pops up @ 6k rpms, and is down below 6k rpms. And we could use the solenoid to actuate the cover! (Message edited by dktechguy112 on June 05, 2010) | ||

Aeholton |

Very interesting post. Does anyone know at what speed the ram air starts having any effect on the bike? I'm currently running the long velocity stacks like Blower1. I'm wondering if it would be helpful for around town commuting running without the inner airbox cover.  | ||

Daniii |

The V-Rod benefits from removing the airbox cover, by a well documented 2-3 hp. The ECM flash was at one time supposed to iunclude that possibility. It has a "snout" on the airbox, but doesn't really act as a ram at speed, so removing it doesn't seem to be a negative. Besides, a lot of us stash electrical stuff in that area. If the CR snout is really in a high pressure area, then it may be unwise to remove it. | ||

Ridenusa4l |

ram-air starts at 80mph Jake | ||

Rdmwc |

dktech, im with you, for about a year now i have been tossing this idea around trying to figure out how to make variable velocity stacks, as well as a way to vary the intake dimensions. i was thinking of a vacuum actuator so at high vacuum( low throttle) it would be open(as if there were no inner airbox) and when there is little to no vacuum it would seal up and allow the ram air to work. but i wonder if the vacuum actuator would react to throttle opening to quickly. still havent figured out the variable v-stacks yet. large diameter, short for low end and narrower, taller for higher rpm.  good post man!! | ||

Blower1 |

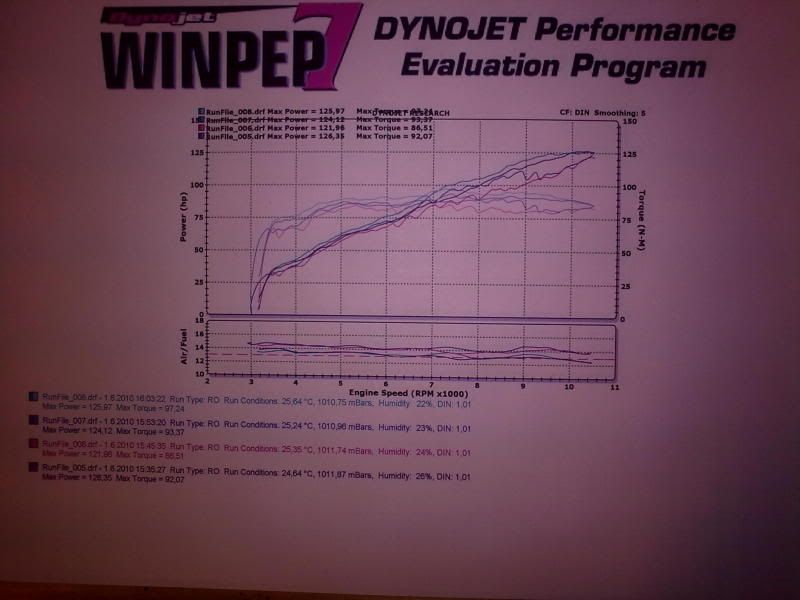

Thanks Highscore, you tests are interesting. I was dyno testing my bike last week. I wanted to know how much a longer velocity stacks effects to torque/hp in the 1125R with stock flash and the 1125R with tuned ecm. The results was good, but the top end was like there was something to "choke" the power. My bike was with oem muffler, so it could be it or the lack of the ram air effect. I should test it once more without the inner air box. Dyno results:  Run 006 stock flash and stock stacks. Run 007 stock flash and longer stacks. Run 005 tuned ecm and stock stacks. Run 008 tuned ecm and longer stacks. | ||

Highscore |

Of course you get the real benefits by removing the inner cover only when you dial in the fuel properly according the new engine breathing. The main difference here is the first part of the range, especially between 3500 up to 4500, where the "bad harmonics" inside of the stock air box do its worst harm. : In deed you get the real benefits by removing the inner cover only when you dial in the fuel properly according the new engine breathing. Probably the Erik Buell Racing ECM is not tuned for this job. Its tune is only valid for the combination of modifications, tested at the Erik Buell Racing-dyno. This is also an argument against a pre programmed Erik Buell Racing ECM. $ 250,-- is a great offer and value. But at least I would like full adjustability. I know Erik Buell Racing offers this opportunity too. But $ 500 more to buy some works is a little bit ..... Back to the air box. With to real fuel inside, the 1125 shows better mid range torque in the middle and better rideability with better response and throttle control. And control is that, what an engine like this with little inertia, but a huge momentum needs. My personal intention, to make this brilliant engine even better, was to improve its mid range and its response at partial load, because I preferably ride my bike in the Alps and need acceleration out of hair pins. For this reason I have also performed some testings with different velocity stacks on my dyno:  This pic shows my test set up with adjustable stacks to check the effect changing the length. The longest stacks, I have tested, were 2 1/2 inch longer than stock. This stacks make torque, but in deed "choke" top end performance massively Making the stacks shorter minimizes this negative effect. The best compromise is the length, shown at the pic above. Here the stacks are 1 inch longer as stock. The following dyno graphs demonstrate the effect of the new stacks:   Reference at this graphs the same dyno run, I have posted above, without inner cover, but stock stacks. The additional length of 25mm at the intake runners is sufficient to push peak torque noticeable. It also pushes the whole torque and power production characteristic of the engine down for 1000 rpm within: peak torque is not only higher, it is now located at 7500 instead of 8500 stock. The loss in peak power is acceptable with such slightly prolonged stacks. The stock engine tune and set up is made for peak power past 10000, shortly before the rev limiter. Here in this range, the power does not climb anymore, as it does it with stock stacks, but it also does not go down. This happens, when stacks are longer. For this reason that " + 1 inch" - velocity stacks seem for me to be the best compromise. In deed the engine suffers 3-4 HP past 10000 even with this stacks. I am sure, I would not really miss this horses during my rides thru the Alps. But for me this fact is unacceptable, by principle. For this reason a tried to minimize this loss by improving the air flow to the engine. This was my first approach:  This brings more air into play, but does not look so nice. Furthermore it is difficult install the seat behind the outer cover lifted this way. For this reason, I am running now this mod:  The shield of the "cosmetic" outer lid, located behind the fuel cap, is removed. Does not look to bad on the bike. And it works. I guess 80 ft-lbs torque are no bad figure. And now the peak power is at the same level as before. Yesterday I have tested this combination at my preferred "play ground". Perfect throttle control, clear and crisp response, immediate acceleration, no surge. And this with a mileage of 40 mpg. One thing is absolutely new: past 7000 it is impossible to keep the front wheel at the ground at WOT. (Message edited by Highscore on June 06, 2010) | ||

Mountainstorm |

Another great topic by Highscore. Thanks! I ran without the inner airbox cover with the Race ECM and an HMF and I found the noise and vibration through the outer cover distracting. Since the ECM was not ready for the extra air I don't think there was any improvement at least not one I could note without a dyno. I considered opening outer cover as you did by removing the fill trim piece but it rains here and I am often in the rain riding. In your opinion, would making holes in the inner cover be sufficient? I think the inner cover stiffens the whole airbox assembly and deadens some noise and vibration. Would a well placed hole behind the fill-neck trim piece do the job? Or a series of holes on each side of the front part of the inner cover work? Thanks in advance. | ||

Gemini |

if you look at the stock eeprom in tuner-pro, the fueling increase doesn't start until 220 kph(about 130 mph) and that is only a 2% increase. the increase tops out at 4% increase at 255 kph( about 158). just saying. it's nice to know at speeds the stock eeprom is programed to make changes. | ||

Highscore |

It is true, that the intake roar becomes tremendously loud without inner cover. I ride now with ear plugs to stand the noise. A surprising fact is, that the noise, its frequency, gets better, when that shield behind the fill-neck is removed. This shows, that the field, we are struggling here, is not insufficient air flow and restriction, but harmonics, harmful wave action inside of the air box volume. Opening the air box chamber as much as possible avoids build up of said waves and resonances within. The rule of thumb for this job is: Make this holes as large as possible. Therefore the question is, if a perforation of the fill-neck shield is sufficient, to calm down the harmful harmonics. I have to agree, I am not happy with this actual solution, not only regarding sound and aesthetics, but regarding performance: In the "full open mode" without any cover above the stacks, the engine cranks out constantly more than 140 WHP. So 5-7 horses are still missing. Nevertheless I am really satisfied with this result now:   This graphs show my actual state of tune compared to "all stock" When I rode my 1125 in its all stock condition, I was very disappointed. Especially its performance at low rpm and partial load was terrific. The engine wanted at least 4000 to come into life. No good habits for someone like me who lives in a capital and unavoidable stop & go traffic. From 4000 upwards to shortly past 5000 the stock engine pulled strong. Behind this margin the engine accelerated further on, but in a rather uninspired manner. Just from 8000 upwards it revved free and and happy, but without real thrust. In deed I was disappointed after after my very first ride with this bike. A + 1000 ccm - sports bike should be frightening at WOT. The stock 1125 felt nice, but its thrust was nothing which opens the mind. When you look at the "all stock" - curves above, you will find a graphic expression, what I tried to say in words. And the "after" -curves indicate that, what I was missing in stock trim, has become much, much better now. Now the engine has healthy power in the "buttom" of its range. It is possible to ride it in 4th gear with 30 mph without any sign of stall or surge. And from 5000-6000 upwards its starts pulling, strongly and linear, with an acceleration, which becomes harder and harder, when engine speed raises. Now the fear and respect of a bike which is always more capable as its rider, is back again. | ||

Jrfarrow1987 |

so explain in as few a words as possible, what is the best option or is it still unknown | ||

Pyrogen |

Ok, let me see if I am following this correctly. The final graphs show hp & torque for A vs. B? Where A= completely stock & B= inner air box cover removed, 25mm longer velocity stacks, the cover around the filler cap removed, and the ECM re-programmed These graphs are results from experiments concerning your original theory that there is excessive turbulence in the air box and consequently performance suffers due to this turbulence in front of the throttle valves. Is this correct? This is very interesting information. I hope I am not missing anything. | ||

Daniii |

Looks like some mid range hp can be realized with shortish velocity stacks. I never hit redline. But I'm always pulling from 4K up. Any idea where one could buy velocity stacks, about 1.5" high (3 cm?), that wouldn't require a machine shop? | ||

Mountainstorm |

Highscore what do you think about using sound deadening material like 5mm neoprene on the interior of the outer cover with no inner cover? This should disrupt the reflective nature of the shell and might improve the harmonics by absorbing some of that sound energy that is likely an expression of the wave harmonics you are investigating. I had considered doing this since I have often added sound deadening material to yacht engine rooms and the removable cabinsole panels that often cover them. | ||

Daniii |

I'd have a hard time believing that acoustics could affect 4,000 rpm aerodynamic resonance, but I've been surprised before. It will reduce the sound (which I like, actually. I've been running the V-Rod 'topless" for 60,000 miles (or so). If the 'snout only becomes effective at 80 mph and above, there may be some gains removing the cover for in-town riding. | ||

Drawkward |

If the inner airbox cover is removed it would be wise to move the AT sensor to the airbox itself...the loss of vacuum through the snorkel causes temps to run about 8 to 13 degress higher at the AT sensor. | ||

Ratsmc |

Highscore, you came up with the velocity stack length through trial and error? I ask because in calculating different lengths, I could not come up with anything of any real value up until about 3.5 inches with a boost at about 7k. Everything else would have choked the engine at most other speeds. | ||

Ohsoslow |

i think that some velocity stacks that move/respond to engine rpm/load are in order here...anyone else? | ||

Andros |

Highscore how do you tune your ecm? And what software?! | ||

Blower1 |

Highscore, have you tested the longer stacks with oem muffler? The Remus exhaust you have in your bike has a longer primary pipes than oem exhaust. One inch longer stacks works fine with the combo you have, but with some other exhaust the stacks maybe have to be shorter or longer to make any torque. I saw somewhere in the internet a pics of the 1190 racing buell and there was longer velocity stack only in the front cylinder. The rear cylinder have a original length velocity stack. | ||

Daniii |

As I recall, there are NO velocity stacks inside my aircleaner. What's up with the "original length" stuff? | ||

Blk09r |

Daniii, the tops of the throttle bodies are flared out like a velocity stack. | ||

Aeholton |

Highscore - how about using an airbox cover like this one from Adrenalin-Moto?  Link: http://www.trojan-horse.co.uk/prods/18.html | ||

Freight_dog |

The Trojan Horse cover looks interesting. Highscore, showing an 11 ft/lb torque gain? That is impressive! I bet the thing pulls like a freight train. I think this is a mod definitely worth considering. | ||

Highscore |

So many questions to answer. There is one item missing in he list of my modifications: The Remus-pipe. This is no full system with new headers, it is "just" a slip on. Before I start a project I do a lot of theoretical consideration and calculations. But such modelling does not replace real world testing., for example at a dyno. In deed I always start with a dyno run, to analyze a new motorcycle. The important graph here is the torque-curve, its progression. Theory comes then into play to understand its ups and downs. I would appreciate to get a better grasp of the 1125-engine, but one essential information is lacking: cam timing figures. I have not found the time to measure the cam timing yet on my bike. Sorry - I am involved into so many other things. It looks like, Ratsmc. as you know these numbers, when you are able the to calculate the effect of 3 ´´ more at 7000. I guess it would not only helpful for me but also other people here, when you could release his "magic" numbers. Without this information about cam timing, I am only able to calculate the 1125 engine according timing figures, known for similar engine as there are Ducati or KTM. But at the very end development always boils down to a "trial & error" procedure. Regarding velocity stacks, such testing is done easily, just add some length to it and look, what happens. This is done quickly and it gives you a lot information about the engine. I have performed my initial "stack-tests" with the stock muffler in the "free-breathing-mode" to exclude any air box effects. The effect was, that as longer the stacks were, as more power has been choked at the end of the rev range in the peak. The best performing stack was the "short one", which prolonged the intake tract for 1´´. This stack produced clear gain around 7000, but not very remarkable. In deed the result of these tests is, that it is not worthwhile to play around with stacks, when the stock muffler is installed. Here the stock stacks offer the best compromise. This resume is only valid for he stock exhaust. There is a good chance, that things change, when combining the 25mm-stacks with a different exhaust. This exhaust should be preferable one, which "works" and "supports" especially within said 7000 rpm - area. For this reason I build this header:   This header merges - as so many others too - the two stock primary header into a common down pipe. What is new on this design? It is the 2nd branch downstream of that new collector pipe, where directeds into two parallel end tubes, which end in the muffler as end of the system. This 2nd Y-joint defines that desired " reflexion or working point" inside of the arrangement at 7000. The muffler itself is a pure "resonance pot", no wool, just chambers inside, to break up and dissipate the noise internally. In my opinion a "chambered" resonance muffler is the only device, which fits into the limited space down/behind the engine, when you look for efficient noise suppression. The sound of the Remus-muffler is within acceptable limits. Otherwise it would not have passed successfully the EC-homologation. But we are taking here not about silencers. A silencer calms down the noise. That is its job. But is is not the source for engine performance. The best thing, a muffler can do, is not to hinder engine performance. But the real place, this performance is born, is the header. The 1125 is modern. Modern means, that its valves, its holes for gas exchange, are real large. With that large holes at intake and exhaust, the effects, when combining intake and exhaust tune for a common rpm-range, are very often not only additive, but synergistic. "Synergistic" means, that the engine suddenly shows a complete new behavior, an unexpected performance level, which seem to be a surprise, when you like at the effects of intake and exhaust mod isolatedly. This sounds like I praying a new "tuning voodoo". But this is not the case. What I am trying to explain is only, that modern engines with valves of a size, nobody would have believed, it is possible to install such dishes inside of a combustion chamber, act different. "Different" means here, that a single tuning-mod like just an pipe swap or better breath onf air box or a new velocity stack isolated and alone does not set a remarkable effect. Modern engines therefore always need a combination of several mods, which works together in harmony. The "fuel management" is within this combo of mods the last thing. It is the cap stone which makes the project complete. But for itself, it does not make the power. When turning back the fuel on my bike to stock at 100% AFV, power goes down for just 4-5 HP. The engine runs there with an A/F-ratio 0f 13,5;1. This is far to lean for a large bore high compression twin. Not only best power, but the smoothness of the engine run is at home in the case of he 1125 at 12,5:1. So fuel adjustment is not so far a subject for performance, but for engine habits, for things like response and culture. In that way this capstone is as the last item within a working tuning combo, but an essential one. There are many ways to set up the mixture. I go the "piggy back"-way by modifying the pulses at the injector by a separate device, a box, like the Dynojet Powercommander. But my tool is the Remus Powerizer.  It gives me all the freedom I want to have for the adjustment. And I am familiar with this thing. For this reason, I have chosen that device, but I am sure, any other working tool around could do the same job. The stock 1125 air box is no bad piece of engineering. It calms down the intake roar substantially by a volume, much smaller than the "rules of thumb" ask for such a device. This explains from my point of view, why this air box is not designed for performance. My mod now is even no masterpiece of engineering. I just cut a large hole into the stock assemble. May be, there are other ways around, which cut this hole in a different manner, but this should make a difference. My bike now is really, really loud at WOT. Adding some foam to the inside of the cover above the filter and stacks may help to some extent, but just a little. (Message edited by Highscore on June 08, 2010) (Message edited by Highscore on June 08, 2010) (Message edited by Highscore on June 08, 2010) (Message edited by Highscore on June 08, 2010) | ||

Xb1200rick |

My bike now is really, really loud at WOT. LOUD is a understatement. I tried the open airbox with no trim piece mod today. It might make more power but WOT is so loud it hurts.  |