| Author | Message | ||

Keef |

I seem to have run into a snag on my 1125cr, I installed a K&N filter EBR ecm , and a Barker exhaust and it will not start and stay running,I rev it up it dies.Now here is what I found the tps voltage is 1.6 closed and 3.7 wide open...now the specs call for .3-.8 closed and 3.7-4.5 wide open. also on throttle % it shows wide open is 67.5% that can't be right I believe the tps is bad..would someone go into diag mode and post there voltage and throttle percent on here is for a comparission | ||

Lastonetherebuys |

I had a similar issue last summer dont know what the voltage should be but WFO should be 100% or just shy of. Mine turned out to be the vacume tube coming into the air box was not pulled through enough and caused it to bind on the throttle cable stopping me from going WFO try that or it could be something isn't sitting right under the lower part of the air box. if the hose does not work pull your air box and see if you get the same readings with the air box out of there. | ||

Keef |

i pulled the lower airbox off,the throttle plates are indeed 100% open but the sensor is not showing that, i also checked and made sure i had my 5 volts reference voltage and i do.... | ||

Lastonetherebuys |

have you tried a tps reset? I can't remember the exact details on how to do it but a search will probably brig it up or another member might know | ||

Froggy |

You need to do a TPS reset when swapping ECMs. It is in your service manual, but here it is right from the Directlink guide:

Steps #1 and #2 were reversed. Not sure it makes a difference, but what is shown above reflects the Buell service manual instructions. (Message edited by blake on March 15, 2010) | ||

Bigblock |

turn on key and run switch, hold throttle all the way on and all the way off 3 times for one second each, turn off switch and key, turn on and start. On my bike I have sometimes found it necessary to cycle through the process a few times (including turning it off again) before starting if it was acting funny. However, although my TPS percent has been at 1.5% to 3.5% closed, it has never been off at 100% opening as far as I have actually checked, but good luck! | ||

Bigblock |

I type too slow! | ||

Mrrickbo |

This is out of the manual (EDM) that I have: The output signal from the TP sensor varies from: • Approximately 0.3-1.0 Volts at idle (closed throttle). • Approximately 3.5-4.5 Volts at WOT. This is out of the Service manual that I have as well: Manual Calibration 1. Verify throttle cable adjustment. 2. Turn the ignition switch to ON. 3. For three cycles: Pause one second on each throttle stop (fully open, completely closed). ****Note: Verify throttle cable adjustment.**** With engine running, turn handlebars through full range of travel. If engine speed changes during this maneuver, turn engine OFF and adjust throttle cables as follows: 1. Loosen cable adjuster lock (5) on each cable. 2. Turn adjusters (4) in direction which will shorten cable housings to minimum length. 3. Point front wheel straight ahead.Twist throttle control grip to fully open position; hold in position. 4. Turn adjuster on throttle control cable (2) until throttle cam stop touches stop plate. Tighten cable adjuster lock (5) on throttle control cable adjuster; release throttle control grip. 5. Turn handlebars fully to right.Turn adjuster on idle control cable (3) until end of cable housing just touches the cable guide. 6. Twist and release throttle control grip a few times. Throttle plate must return to idle position each time throttle grip is released. If this is not the case, turn adjuster on idle control cable (shortening cable housing) until throttle control functions properly. 7. Tighten cable adjuster lock on idle control cable. Recheck operation of throttle control. Perform at your own risk. If you can't do this properly, take it to a shop.} | ||

Keef |

i have done all the above adjustments to no avail,I was just wanting to verify that most everybody shows 100 at full throttle and mine does not so with all that said looks like the tps sensor for some reason is fubarred...ebr is sending me one to try..... | ||

Keef |

i believe i found the problem,someone and my bike is new i am the first owner screwed up the wiring at the tps connector they swapped terminal 2 and 3 around and then didn't fix the wire correctly and the sensor wire was not even crimped.... | ||

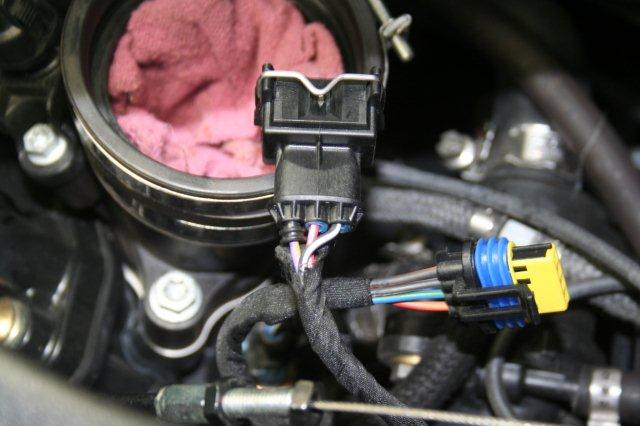

Keef |

this damage to the wiring and improper repair was done at Ukes H-D when they installed the 2010 handlebars before I bought the bike on top of the sloppy work the red/white wire that they put in the center goes in # 3 hole and the violet /yellow wire in # 2 hole as all can see that is not the way it has been done...and oh yea i am pissed ...and for the curious you say how did they cause it, well i assume it happened when the tech pulled the throttle bodies up and off to install the throttle cables,he neglected to disconnect the tps harness and pulled 2 wires out of connector and then screwed up trying to repair the damage he had caused by inattention to detail.....  | ||

D_adams |

Just curious here, but why is that lock nut loose on the throttle cable? | ||

Keef |

dave,if you look closely,the throttle bodys have been removed to access the TPS wiring harness pigtail... | ||

Richieg150 |

You DONT have that kind of trouble with a TUBER LOL.... | ||

Lew360 |

Maybe I did something wrong, but neither my high bar kit or my manual said to remove the throttle bodies. I wonder why the "mechanic" felt the need to do so? (Message edited by Lew360 on March 13, 2010) | ||

Kickstand76 |

not having read any other entry on this topic, i would guesstimate a back-flow of exhaust, or lack thereof. sensors glitching | ||

Keef |

fixed finaaly got the wires out of the cavities repaired (soldered) the terminals and put them back in there PROPER location put 'er all back together now i have 2-100% on throttle after the tps reset and now it starts and runs and souds got with the ebr ecm going to take it for a quick ride between rains and check it out a little as it was set up the ecm never saw more that 67.5% throttle even though the butterflys were wide open so i had to be lean as hell at wot...  | ||

Therealassmikeg |

Excellent diagnosis and repair! | ||

Tbowdre |

nice work | ||

Mountainstorm |

Excellent problem solving Keef. Well done. | ||

Jdugger |

> fixed finaaly got the wires out of the cavities repaired (soldered) That may come back to haunt you. Solder makes the wire brittle at the tinning end point in vibration and movement prone environments. On a bike, mechanical crimps are actually best. | ||

Dirty_john |

well done sorting it out yourself, I trust that you will not be returning to that dealer for any servicing |