| Author | Message | ||

Xgecko |

Ed factory is now (2002) 170 not 165 if hat helps matters any | ||

Blake |

EZ, Without an A/F reading the only way to tell if your jetting is optimum is if you are expert at reading spark plugs, or if you continue increasing jet size until performance remains unchanged or starts to suffer compared to next lower jet size. Consider that the Buell twins, which use the same basic carburetor, run best with anywhere from a 185 to a 195 main jet. At near sea level, the twins are running 190 or 195 mains. You have a long way to go if the modifications you've implemented come close to matching the carburetion characteristics of the twins. What you REALLY want to avoid at all costs is running your engine lean, ESPECIALLY at high speeds, where the main jet comes into significance. | ||

X1glider |

That top pic of the black fairing looks like something Dark Helmet would use! ![:]](http://www.badweatherbikers.com/buell/clipart/proud.gif) May the Schwartz be with you! May the Schwartz be with you! | ||

Sarodude |

'Why didn't anybody tell me my ass was so big?' | ||

Xgecko |

Things I noticed today after switching to a 175 today. It barks...it pulls a bit better in higher reves...it doesn't decel as quickly when you chop the throttle...I can't hear the valves rattle anymore when I roll on under load (hill etc) I pulled the plug (NGK Irridium) yesterday and noticed brown on the edge threads and on the collector (or what ever you want to call the bent piece over the electrode) it looked nothing like the previous plug that came out which was just about perfect (grey/tan). I interpretted this to mean that this along with the slight knocking in the valves and the less than desirable pull to mean that it was a bit lean. I switch ed it out and went for a test ride. SOTPDyno says it pulls better. I'll need some more mile before I pull the plug for a good look but right now I'm pleased. I started from scratch with the Airmix but I ended up at about 805degrees (just under 2.25 turns) which was where it was before. | ||

Ezblast |

Why do you think I named my bike Blastvader;0) And live in the Dark side(inner sunset -SF,Ca - almost always fogged in) - lol -Ok Blake you got me - here that Xgeko - we both may have a long way to go! Fun-fun-fun! Blasting on the Dark side - ahhaaaaaaaaahaaaaaaaahaa! EZ | ||

Xgecko |

SOTP Dyno | ||

Ltlboybuell |

XGecko, now you got me paranoid, LOL. I'm still running the 165 main and the WB as per Dynojet's instructions but now I want to call them and get the reason(s) they recommend leaning out the main with an aftermarket exhaust contrary to popular opinion. That and I've spent the last half hour pricing A/F ratio gauges and oxygen sensors  . But I did find a really cool digital bar graph meter that I may just have to pick up tomorrow . But I did find a really cool digital bar graph meter that I may just have to pick up tomorrow  . I think I remember reading somewhere that Dynojet's needle has a different taper and their mains flow more than similarly numbered mains from other manufacturers. Atleast I hope that's it since I'm all paranoid now. . I think I remember reading somewhere that Dynojet's needle has a different taper and their mains flow more than similarly numbered mains from other manufacturers. Atleast I hope that's it since I'm all paranoid now. Rich | ||

Xgecko |

REmember I have a different...more open intake and I'm running an irridium plug in additiion to a WB Exhaust | ||

Sarodude |

EZ- I was looking at your dyno sheet and couldn't help but wonder what we might see if you did a dyno test with / without the Direct Hits thingie. Maybe you could post pics of the airbox and filter mods when you have a few. I'm curious how that all looks. BTW, watch out for that Bub pipe. Mine died a fairly early death - around 4k miles I think. The welds were OK. THe base metal AROUND the weld just wouldn't handle it at the rear mount - the one on the megaphone. You may want to think about arranging some clamp around type of thing for that. I had to coat hanger it from San Diego to LA. As it stands, my Bub sits in the garage urging me to turn it into FrankenBub. I was gonna shorten the pipe a bit and try out a generic SuperTrapp or something. Anyway, look me up if you're planning an LA trip. -Saro | ||

Ezblast |

I'm thinking of adding a rubber washer to the rear mounting to help soak up some of the stress. Actually when it does crap out I'm thinking of going to a supertrap 3" universal with 14 to 16 disc.s mounted off the bub header pipe;0)Sweeeet! The airbox mod was to drill/cut out the venturi ring leaving only the filter holding ring left for air to pass through, Drilling the filter is an old hot rodding trick - 1/16 bit at high speed at random 1" intervals through out the filter never going all the way through said filter,Engine vent turned away and down from carb,(some ditch the venturi carb ring - some do'nt - I did'nt.),check sealing of box. The new engine echo you'll get for this bit of handy work is well worth it. I love LA - born and raised. Sorry lost the origional stock dyno pull - just wrote down the basic numbers - did'nt know then what I do now or would have kept it.:0( Blasting on the dark side!EZ | ||

Buellzilla |

Hi guys! Just wanted to share some helpful hints, that you may already know or may not or could stand being reminded of. After letting my Blast sit in the driveway for a couple of weeks (unforgiveable I know), I started it up and found that the oil light stayed on. I only ran the engine for less than a minute and shut her down. I then pulled the dipstick and found my oil level to be up near the full mark despite the fact that the engine was cold. I then checked my fuel petcock and, sure enough it was ON. My oil was diluted with gas. I had to drain out all the oil and replace the filter much sooner than anticipated. Moral of the story, get religious about shutting off your fuel petcock whenever you park the bike. One other anecdote. I recently took my Blast to the local Harley/Buell dealer for state inspection and front tire replacement. After they replaced the tire, their test rider started it up and headed out for a road test. I noticed that he reved the engine up to a fairly high rpm and held it for a few seconds before letting it drop back down to idle and engaging 1st gear. This is exactly the same formula that I use to avoid the usual clunking/grinding that occurs when you try to engage 1st gear after idling in neutral for a while. The test rider is a long-time Harley owner/rider and rider training instructor. He knows his stuff. (rev while clutch lever pulled in) Has anyone else noticed that when the Blast is cold and you disengage the clutch and try to push the bike there is a lot of resistance but once the bike is warmed up and you disengage the clutch it will freewheel just like it's in neutral? I've checked ALL my clutch adjustments and they are in spec. Try putting your Blast in first gear, pulling the clutch lever and moving the Bike forward or backward when it's cold and see if yours behaves the same way. | ||

Buellzilla |

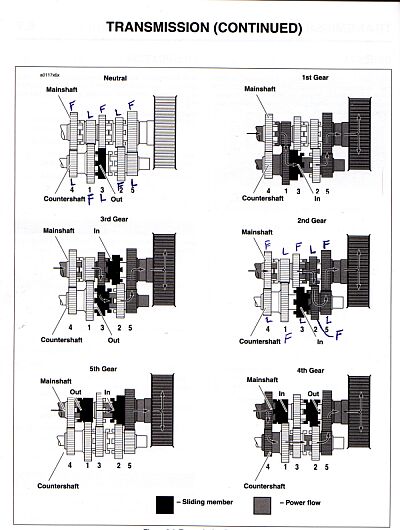

OK. I've been staring at the transmission power flow schematic in the Service manual for about an hour and I think I've got it figured out. The mainshaft is located high in the case and out of the oil whereas the countershaft is quite low and much more immersed in the tranny fluid. The difficulty of engaging 1st gear comes from the fact that the #3 gear on the counter shaft needs to slide sideways and interlock with the #1 gear on the countershaft which is right next to it. If these two gears are spinning at the same speed, you have no problem at all. When you're in neutral with the clutch engaged, the #1 gear on the countershaft is going to spin regardless of how cold and thick your tranny oil is because it's receiving power from the fixed #1 gear on the mainshaft, however when the oil is cold and thick, I think it induces spin of the whole countershaft. The #3 gear on the countershaft is fixed to the countershaft so faster countershaft rotation equals faster #3 gear rotation. When #3 and #1 are spinning at roughly the same speed, they will easily mesh with one another. On the other hand, when the oil is warm and thin the #1 cntrshaft gear can spin freely whilst the #3 gear and countershaft barely turn at all, so when you disengage the clutch, the mainshaft and #1 gears keep spinning quite fast, but since the countershaft/#3 cntrshaft gear is turning more slowly, it doesn't want to lock into the faster spinning #1 cntrshaft gear without protest. The answer is to rev the engine to induce more spin into the countershaft/#3gear so that when you drop back down to idle, the #1 gear will slow down because it is locked to the mainshaft which has to slow down because it is locked to the engine crank by way of the primary drive chain, while the countershaft/#3gear will continue at it's higher spin rate due to the flywheel effect. If all goes according to plan, the countershaft will end up spinning at nearly the same speed as the mainshaft so that the #3 cntrshaft gear can slide sideways and lock into the #1 cntrshaft gear without complaint. When you go for second gear, you've got the same problem all over again. The #3 cntrshaft gear is now trying to lock into the #2 cntrshaft gear but the #2 cntrshaft gear has been spinning much faster than the countershaft all along since it is meshed with the fixed #2 mainshaft gear at a higher ratio. In order to get a smooth shift you have to wait for engine rpms to drop so that the mainshaft and #2 gears are forcibly slowed down to approximately the same speed as the countershaft/#3 cntrshaft gear. Important to understand that the #1 and #2 cntrshaft gears are free spinning (not fixed to the countershaft), whereas the #3 cntrshaft gear is fixed to the countershaft but slides left and right to engage it's two neighbors #1 & #2. I have to do some experiments now. Maybe I'd get better results with leaving the clutch engaged while revving. I seems that the clutch is never so fully disengaged that it doesn't induce a little bit of mainshaft spin when in neutral. I might also get better results by taking my medication regularly. | ||

Court |

Do you have time to breakaway and take the Analytical Reasoning section of the LSAT for me? Heck.....I'm just as bad. I was totally lost, trying to follow your example. So I go and retreive a handful of neighborhood cats, name them each after a shaft and commence oiling and spinning them in the proper sequence. By the time I got to that lever part about the clutch the effort had pretty much fallen apart. I've now got: A) A house full of oily cats B) Nice wood floors covered in cat vomit C) Disgusted neighbors. D) No clear understanding of what the heck in going on in the BLAST tranny..... Soon as you pop that next med, mail the jar! Court | ||

Buellzilla |

How many rpms you reckon you got the cats up to? I don't blame anyone for not understanding my post. I think it's not possible without a diagram or 12. Basically power goes from the clutch to the mainshaft and onward to the final drive gear on the outside of the engine which your belt connects to but for every gear other than 5th, power is sent through the counter shaft. When the bike is in neutral, the mainshaft and countershaft can spin independant of one another. This creates differences in speed which makes it hard to engage 1st gear. By revving your engine up you can, by means of friction induce the countershaft to spin faster, then when you let off the throttle the mainshaft will drop rpms quickly while the countershaft maintains it's momentum. The result is that, now the countershaft is spinning nearly the same speed as the mainshaft which allows 1st gear to engage with a modicum of dignity. Perhaps this will help:  I wrote "F" & "L" labels to indicate which gears are (F)ree spinning and which ones are (L)ocked to their respective shafts. I'm sorry about the cats and the vomit. Maybe the kitties will need to spend the night soaking in the parts washer eh? | ||

Prof_Stack |

All this stuff about gears spinning got my head spinning! Yikes. rd350 (Philip Mattingsly) sold me his Corbin seat ($200 + $22 UPS) and today I put it on. Not a great fit. I had to put another plate on the front metal tab to thicken it. Here is the digital photo I snapped today after getting it on. Notice the gap:  Here is what Corbin show on their website:  Here is the Corbin next to the stock (high) seat:  Later, I'll post a riding report after a 50 mile ride around Seattle. | ||

Xgecko |

Prof, Bend the metal tab down in the front and adjust the latch Bolt until looks better. It took a while for me to get mine lined up and in the end it didn't look real good until I installed the Buell tank mask (now it looks almost like stock in the back) You should like the feel of it. I know I do and I couldn't even think of going back to the stock a$$killer...err I mean seat. | ||

Jeffb |

S1 wheels on a Blast. I have seen a few people do this. What are the tips and tricks of doing this? I know I have to modify the swing arm. Does the front axle work? How about the front and rear caliper mounts? Jeff | ||

Xgecko |

I don't think anyone here has gone that radical. You might want to call Crossroads Performance I know they were considering marketing a kit for it....they should be able to tell you more of what you need to know. | ||

Prof_Stack |

Thanks Xgecko for the advice on the Corbin seat. To be quick: the 50+ mile ride I took last night on the Blast with Corbin seat went well. At first I could feel more of the road through the seat but after awhile I found myself being very comfortable on it. When I filled up after 50 miles and got back on to head home, it was like I was just getting on the Blast back at the start of the ride. It was a rejuvinating ride after three days of being Prof again at the HS.  So the (SOTP) "Seat Of The Pants" analysis of the Corbin seat is: a slightly-less-than-perfect fit on the Blast but definitely the type of seat to get for the rider who likes to do more than, say, 75 miles per ride. | ||

Xgecko |

Norm, looking at your photo I can tell that your lock bolt is screwed in too far and the metal tongue is too high. Modifying those two things should bring the rear down you will still have the gap at the very rear until you do something to push the entire seat to the rear (like add a tank mask) but it won't cock up like it does now. Yes that is the most annoying thing about the Corbin seat...however it can be lived with for the comfort it provides no??? | ||

Prof_Stack |

115 mile ride today (75 mpg at the fillup). Mobil-1 15W/50 Tri-synthetic is staying between the marks on the oil dipstick. Good stuff. Mobil-1 gear oil is next. Another SOTP Corbin seat update: The Corbin seat, despite not fitting like one would expect for the marquee, was VERY comfortable for the long haul. There is more room to move one's rear on the seat. Some of the lower rpm vibrations don't come through the seat as much as they did on the stock seat. It has a gel pad as well as foam and is MUCH firmer than the stock seat. But the rider will not forget he is on a thumper. My suggestion: if you don't like the original seat, check out Corbin or Sargents or perhaps a local m/c upholstery shop (we have 2 in Seattle). Thanks Xgecko for your comments. I'll try it. | ||

Jeromius |

I've got to get one of those . . . I've been pulling 175 - 200 mile trips on the Blast every weekend, and it pretty much puts me out of commission for the rest of the week. I've definitely got to get one before I do Deal's Gap in September. Thanks for the review! | ||

Jeromius |

Tricked out the Blast with some cool decals this past week - think they turned out pretty well! | ||

Prof_Stack |

Corbin says their seat is one inch lower than the standard Blast seat. The truth is, you don't sink down as much and you're really sitting higher, about an inch I'd reckon. I noticed that yesterday on my ride, more wind was getting to my shoulders than before. No big deal. But I put on the stock seat again and immediately noticed two things on a quick ride: (1) your weight is more towards the tailbone and right down the middle. The Corbin definitely spreads out the weight, and (2) the foam better insulates your rear from some of the road shock than the Corbin.  | ||

Buelliedan |

Okay I'm stumped. How the heck do you adjust the primary chain on a Blast? I thought it would be just like a big Buell but it isn't. What does that bolt in the center of the cover do? Why is the adjuster appear to be a non adjustable bolt? HELP!! | ||

Xgecko |

There are two bolts on the bottom of the Primary case one the rear is the drain don't turn it or messes will ensue. the forward one should have a spacer and a nut (or just a nut depending on the year. This is the Primary adjuster | ||

Circlip |

OK, I admit that I'm jealous of Prof Stack's Corbin seat. After accumulating a lofty 330 miles on my Blast, I've got to say that the seat is the weak link (front and rear suspension could use a bit of a tweak also, but they do not cause me physical pain like the seat). I'm not really excited about paying Corbin $300 for a new seat. I had some discussions with Sargent about rebuilding the stock high seat (after the snows fly). Anyone else gone this route? Any success stories (or failures)? I do actually really like the Blast. It's just a real hoot to ride. The other day I saw an M2 in the parking lot of my local hardware store. I did develop a strong case of twin envy, but I've ridden the Blast since then and I'm happy (except for that seat). | ||

Prof_Stack |

Circlip, The Corbin is great, and the poor fit on the back end is not a problem when I'm riding. Just pains me to have such a "big name" manufacturer have sloppy attention to detail. I just saw that Corbin raised the price to $349. Yikes! Suggestion: some people get a gel pad for the stock seat. They remove the staples and cover and carefully carve away the foam to get the gel pad where they want it and then affix it to the foam (tape? glue? I don't know), and then restaple the cover back on. Cost is less than $100. JC Whitney has good prices. Anybody else had experience here? Prof (I put the Corbin stuff on my website.) http://www.connectexpress.com/~nhardy/buellblast_home_page/blast_home_page.htm | ||

Buelliedan |

Xgecko, Okay, I kinda figured the front one was the nut but how do you adjust it? How do you access the chain since the footpeg mount is in the way of the cover? |