| Author | Message | ||

Mark_weiss |

As promised a few weeks ago, here are a few views of my home made fork service tools. If you are doing an oil change, it is not necessary to remove the cartridge from the fork. 1. These are the tools needed. The wooden piece is used to compress the fork spring. I cut the face hole and did the side drilling before cutting the board in half. The hole saw was 1-1/2". The aluminum clip is just cut from a piece of stock from Home Depot. I drilled a hole a little bit larger than the damping rod and then made the side cuts to form the slot.  This is the compressor installed. The two side screws fit loosely into holes in the spring spacer.  A bit of muscle later, and at least one extra hand, and the clip is installed. It is a two-handed job to compress the fork spring. Once the spring is held down, the clip slides onto the damping rod, under the locknut for the fork cap, and above the spring spacer.  Before loosening the locknut and removing the cap, make sure that you have backed out the rebound damping adjustment. | ||

Mark_weiss |

Here's another view of the compressed spring with the clip installed. At this stage, the compressor can be removed until it is time to get the clip out.  | ||

Etennuly |

That is awesome. I believe I will copy that compressor idea, best and simplest I have seen yet. Thanks. What did you do for a seal driver? | ||

Thesmaz |

very cool, thanks for sharing!! | ||

Electraglider_1997 |

http://www.badweatherbikers.com/buell/messages/142 838/631411.html?1305252910 | ||

Mark_weiss |

I tried the split PVC approach but found that the seal fit too tightly in the fork for good results(at least on an '08). I thought abut leaving the wiper off so that I could use the slider to drive the PVC (that would have worked) but really wanted the protective cover. I spent $40 on a splittable seal driver. I found it at Cycle Gear. It has inserts which allow it to drive several different size seals. | ||

Electraglider_1997 |

Mine was for an 06' and worked like a charm. Don't know about using on an 08. | ||

Tootal |

Yep, more than one way to skin a cat! | ||

Electraglider_1997 |

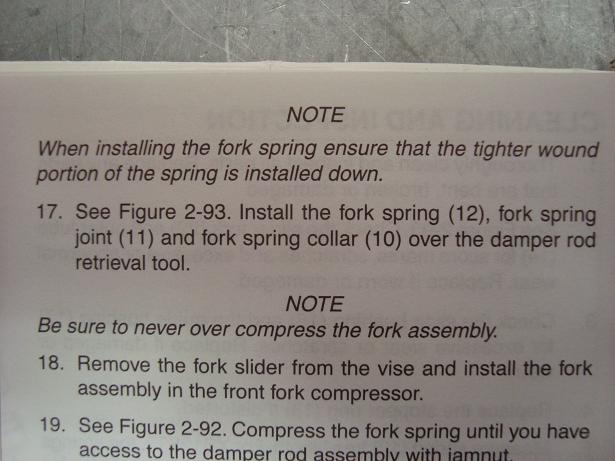

I see that the more tightly winding of your fork spring is at the bottom. I've always wondered if it makes a difference how the spring is installed. I still have the original 06 springs but my son's 07 has the newer progressive wound springs. | ||

Zac4mac |

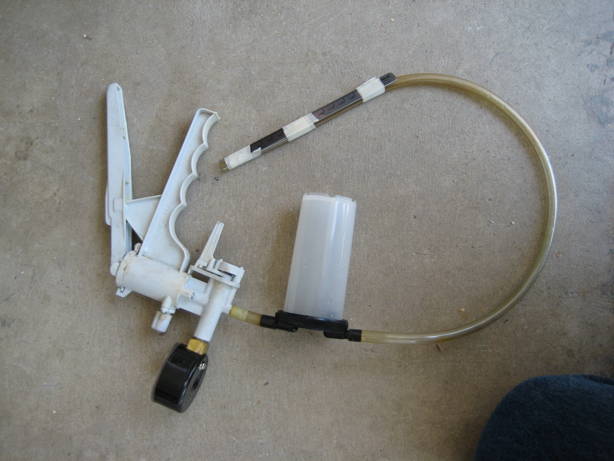

I made my own set when I did the Uly's forks. Damper tool - basketball needle soldered to some brass tubing, so it breathes, ending in a 1/8" NPT union.  tube clamp, put in vise and hold tube vertical.  35cc syringe - get at a farm supply store for livestock - and some vinyl/brass/carbon fiber tubing.  Modified(cut ends off a little) a ratchet strap, add a piece of bicycle tube and run thru axle hole for a spring compressor.   Zack | ||

Mark_weiss |

I don't think that it makes any difference to the spring itself, might make a difference to the fork. If a progressively wound spring is installed upside down compared to spec, a different amount of steel will be submerged in the oil. This, in turn, will affect the fork's oil level which could make a difference, depending on how much change occurs. | ||

Merc16 |

Wow, you guys are creative !! | ||

Brucen |

This is the tool I use to set my oil level   | ||

Whisperstealth |

And if you only changing the oil, why don't you have to remove the cartridge? | ||

Motorbike |

I've always wondered if it makes a difference how the spring is installed. The service manual makes reference to this in the section for the XB12STT/XB12X and XB12XT forks. Thanks. XB12STT/XB12X and XB12XT Fork Special Note:  (Message edited by motorbike on December 18, 2011) | ||

Electraglider_1997 |

Motorbike, Thanks. Haven't had a need to reference the fork part of our 07 service manual only the 06 manual. | ||

Motorbike |

You are welcome. I failed to mention that I got this info from my 2008 XB Service Manual. Thanks. | ||

Mark_weiss |

\quote {And if you only changing the oil, why don't you have to remove the cartridge?} The cartridge need only be removed if there is a need to service an internal part, such as a (flow metering) shim stack. Oil changes do not require access, the cartridge is pumped out and purged of air while in place. If I were to pick up a used Uly, and found that the fork oil was REALLY dirty when drained, I would probably remove the cartridge for a quick visual check and easy access to make certain that it was really clean. |